ECU OPEL CROSSLAND X 2019.75 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2019.75, Model line: CROSSLAND X, Model: OPEL CROSSLAND X 2019.75Pages: 253, PDF Size: 7.76 MB

Page 82 of 253

80Instruments and controlsService displayThe service system informs when to

change the engine oil and filter or a

vehicle service is required. Based on

driving conditions, the interval at

which an engine oil and filter change

is required can vary considerably.

Service information 3 215.

A required service due is displayed in the Driver Information Centre for7 seconds after switching on the

ignition.

If no service is required for the next

3000 km or more no service

information appears in the display.

If service is required within the next

3000 km, the remaining distance or

time duration is indicated for several

seconds. Simultaneously symbol

C lights up permanently as

reminder.

If service is required in less than

1000 km, C flashes and then lights

up permanently. Remaining distance

or time duration is indicated for

several seconds.Overdued service is indicated by a

message in the Driver Information

Centre which indicates the overdued

distance. C flashes and then lights

up permanently until service is

executed.

Reset of service interval

After each service, the service

indicator must be reset to ensure

proper functionality. It is

recommended to seek the assistance of a workshop.

Operate as following: ● switch off ignition

● press and hold button M or

CHECK

● switch on ignition, the distance indication begins a countdown

● when the display indicates =0,

release the button

The C disappears.Retrieving service information

To retrieve the status of the service

information at any time press left

button underneath the Driver

Information Centre.

Or

Page 100 of 253

98Instruments and controlsTelematics servicesOpel Connect

Opel Connect is a new way to stay

connected and secure on the road.

Features available with

Opel Connect are:

● emergency call function

● breakdown call function

When the vehicle is equipped with

Opel Connect, these features are

automatically activated. Terms and

Conditions apply.

Opel Connect is operated by the buttons in the overhead console.

Note

Opel Connect is not available for all

markets. For further information,

contact your workshop.

Emergency call function

Vehicles featuring the emergency call

function are equipped with a red

SOS button in the overhead console.

The emergency call function will

establish a connection to the nearest

public safety answering point (PSAP).A minimum set of data including

vehicle and location information will

be sent to the PSAP.

Note

Establishing an emergency call may

not be possible in areas without

sufficient network availability or due

to hardware damage during an

accident.

Automatic crash notification

In case of an accident with airbag

deployment, an automatic

emergency call is established and an

automatic crash notification will be

transmitted to the next public safety answering point.

Emergency assistance

In case of an emergency you can also manually place an emergency call by

pressing the red SOS button for more

than two seconds. The LED flashes to confirm that a connection to the

nearest PSAP is being established.

The LED illuminates steadily as long

as the call is active.

Pressing the SOS button immediately

a second time will terminate the call.

The LED switches off.Status LED

Illuminates green and red and

extinguishes after a short time, when

the ignition is switched on: the system

works properly.

Illuminates red: fault in the system.

Contact a workshop.

Flashes red: backup battery needs

replacement.

Breakdown call function Pressing . for more than two

seconds connects you to a roadside

assistance service provider.

For information about coverage and

scope of services of the roadside

assistance, please refer to the

Service and warranty booklet.

Vauxhall Connect Vauxhall Connect is a new way to

stay connected and secure on the

road.

Features available with

Vauxhall Connect are:

● emergency call function

● breakdown call function

Page 137 of 253

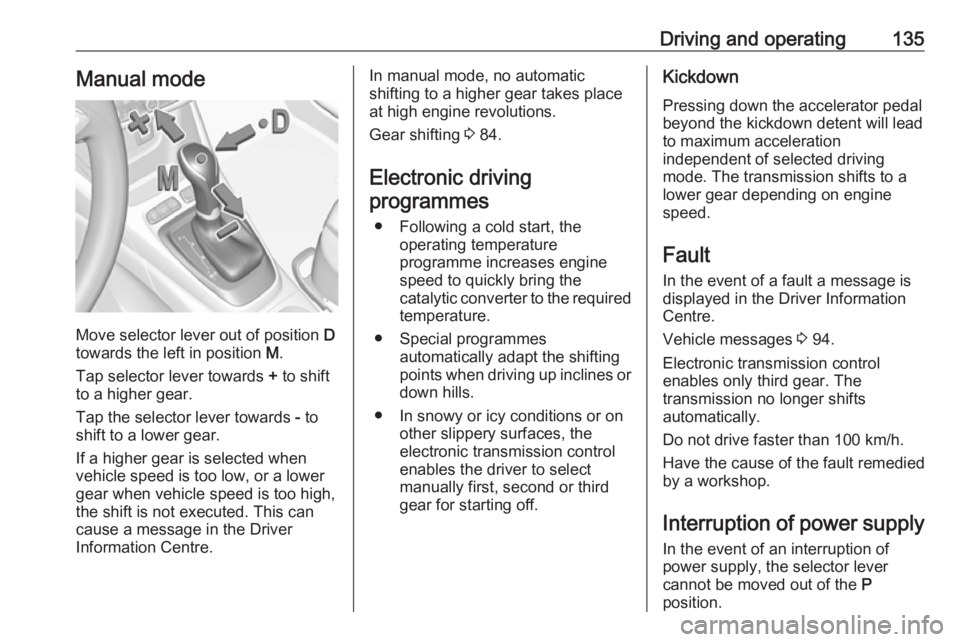

Driving and operating135Manual mode

Move selector lever out of position D

towards the left in position M.

Tap selector lever towards + to shift

to a higher gear.

Tap the selector lever towards - to

shift to a lower gear.

If a higher gear is selected when

vehicle speed is too low, or a lower

gear when vehicle speed is too high,

the shift is not executed. This can

cause a message in the Driver

Information Centre.

In manual mode, no automatic

shifting to a higher gear takes place

at high engine revolutions.

Gear shifting 3 84.

Electronic driving programmes

● Following a cold start, the operating temperature

programme increases engine

speed to quickly bring the

catalytic converter to the required

temperature.

● Special programmes automatically adapt the shifting

points when driving up inclines or

down hills.

● In snowy or icy conditions or on other slippery surfaces, the

electronic transmission control

enables the driver to select

manually first, second or third gear for starting off.Kickdown

Pressing down the accelerator pedal

beyond the kickdown detent will lead to maximum acceleration

independent of selected driving

mode. The transmission shifts to a

lower gear depending on engine speed.

Fault

In the event of a fault a message is

displayed in the Driver Information

Centre.

Vehicle messages 3 94.

Electronic transmission control

enables only third gear. The

transmission no longer shifts

automatically.

Do not drive faster than 100 km/h.

Have the cause of the fault remedied by a workshop.

Interruption of power supply In the event of an interruption of

power supply, the selector lever

cannot be moved out of the P

position.

Page 173 of 253

Driving and operating171

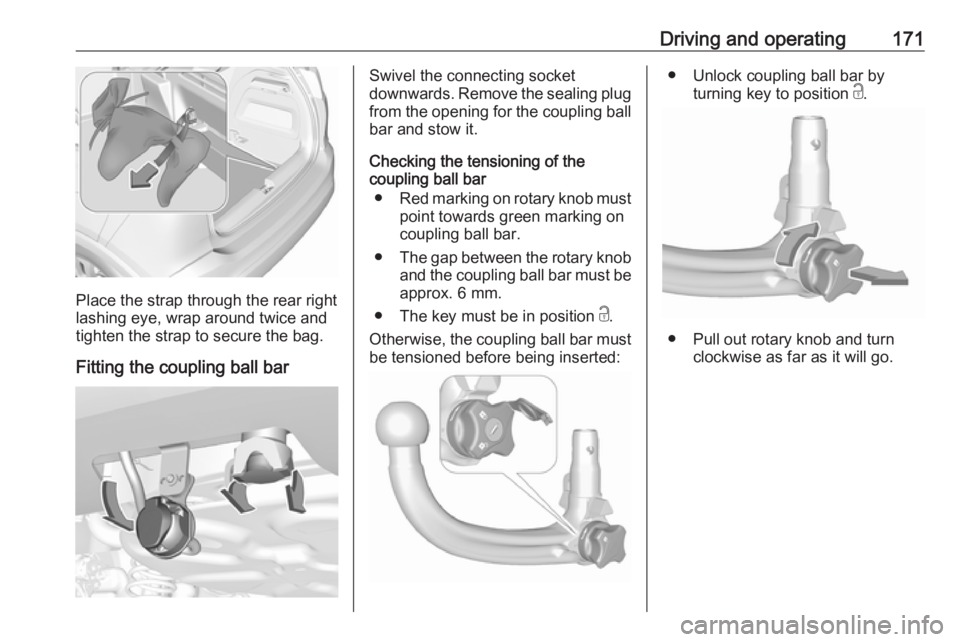

Place the strap through the rear right

lashing eye, wrap around twice and

tighten the strap to secure the bag.

Fitting the coupling ball bar

Swivel the connecting socket

downwards. Remove the sealing plug from the opening for the coupling ball

bar and stow it.

Checking the tensioning of the

coupling ball bar

● Red marking on rotary knob must

point towards green marking on

coupling ball bar.

● The gap between the rotary knob

and the coupling ball bar must be approx. 6 mm.

● The key must be in position c.

Otherwise, the coupling ball bar must

be tensioned before being inserted:● Unlock coupling ball bar by

turning key to position c.

● Pull out rotary knob and turn

clockwise as far as it will go.

Page 175 of 253

Driving and operating173Swivel the connecting socket

upwards.

Stow the coupling ball bar in the bag and secure by fixing the strap through

the rear right lashing eye. Wrap

around twice and tighten the strap to

secure the bag.

Page 187 of 253

Vehicle care185Sidelight / daytime running light

In case of defective LEDs, have them replaced by a workshop.

LED headlights Headlights for low and high beam,

sidelights, daytime running lights and turn lights are designed as LEDs and

cannot be changed.

Have lights repaired by a workshop in

case of failure.

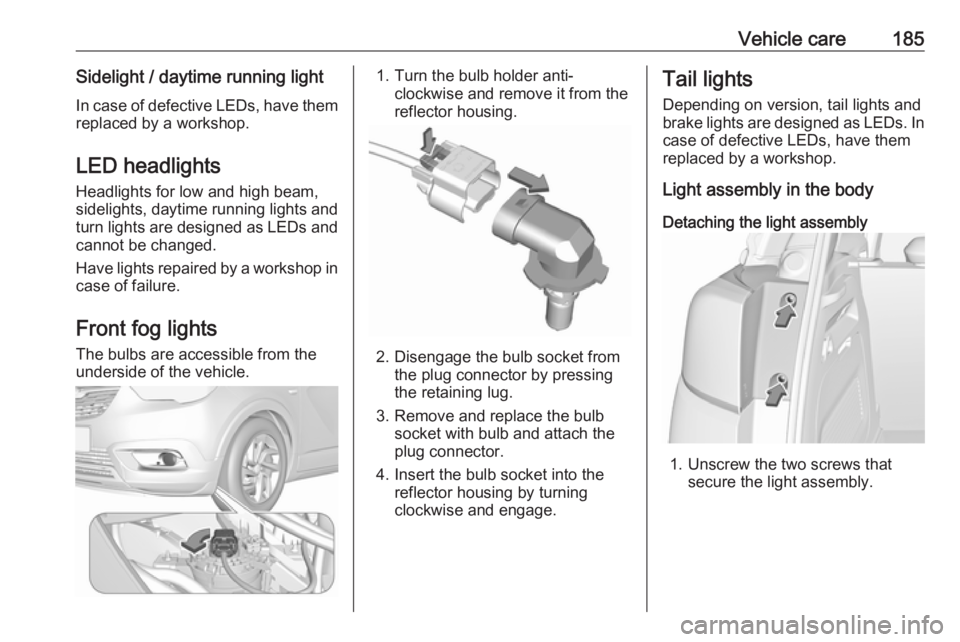

Front fog lights

The bulbs are accessible from the

underside of the vehicle.1. Turn the bulb holder anti- clockwise and remove it from the

reflector housing.

2. Disengage the bulb socket from the plug connector by pressing

the retaining lug.

3. Remove and replace the bulb socket with bulb and attach the

plug connector.

4. Insert the bulb socket into the reflector housing by turning

clockwise and engage.

Tail lights

Depending on version, tail lights and

brake lights are designed as LEDs. In case of defective LEDs, have them

replaced by a workshop.

Light assembly in the body

Detaching the light assembly

1. Unscrew the two screws that secure the light assembly.

Page 189 of 253

Vehicle care187Pull straight out to remove from

the socket and replace.

Attaching the light assembly 1. Depending on version, attach the bulb carrier to the light assembly

and secure with the three screws

or attach turn light bulb socket.

2. Attach the light assembly to the vehicle body and secure with the

two screws.

Light assembly in the tailgate

Detaching the light assembly

1. Release the cover in the tailgate and remove it.

2. Unscrew the plastic nut by hand.

3. Carefully withdraw the lightassembly from the recesses and

remove.

4. Remove bulb socket. a) Version without LED:

Page 191 of 253

Vehicle care189

2. Attach the light assembly to thetailgate.

3. Secure the light assembly with the

plastic nut.

4. Attach the cover to the tailgate.

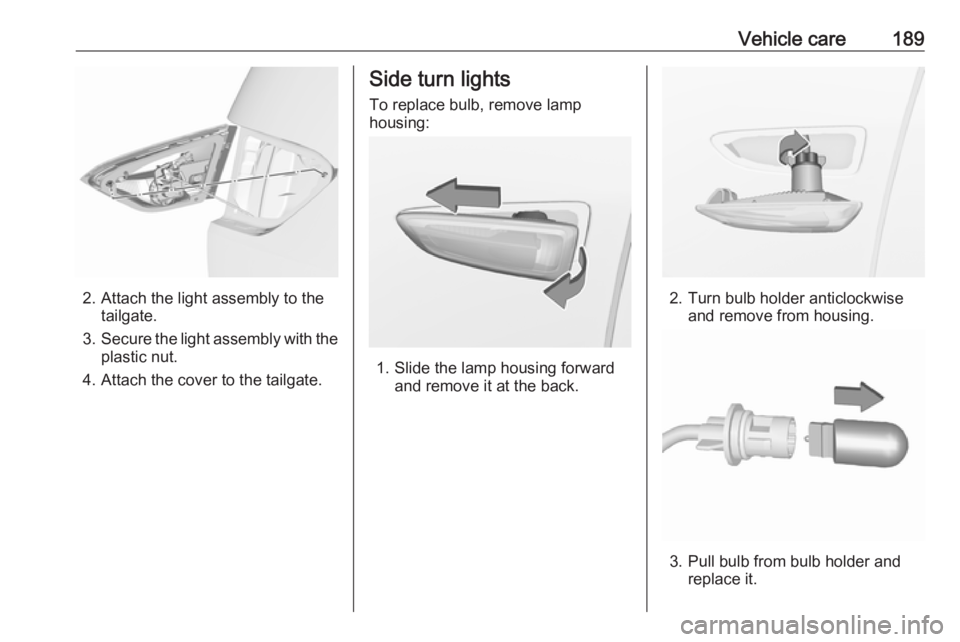

Side turn lights

To replace bulb, remove lamp

housing:

1. Slide the lamp housing forward and remove it at the back.

2. Turn bulb holder anticlockwiseand remove from housing.

3. Pull bulb from bulb holder and replace it.

Page 196 of 253

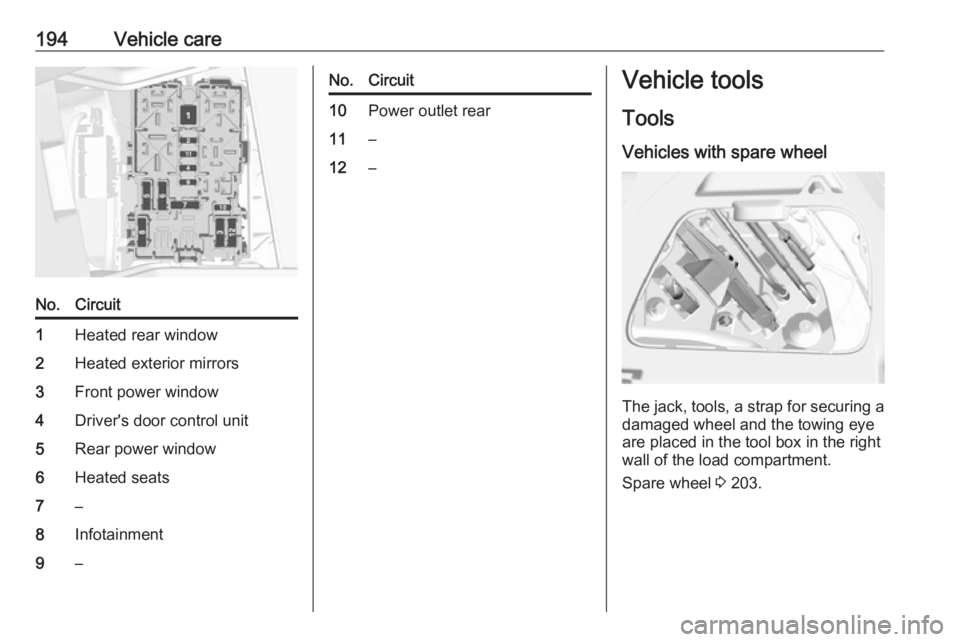

194Vehicle careNo.Circuit1Heated rear window2Heated exterior mirrors3Front power window4Driver's door control unit5Rear power window6Heated seats7–8Infotainment9–No.Circuit10Power outlet rear11–12–Vehicle tools

Tools

Vehicles with spare wheel

The jack, tools, a strap for securing a damaged wheel and the towing eye

are placed in the tool box in the right

wall of the load compartment.

Spare wheel 3 203.

Page 206 of 253

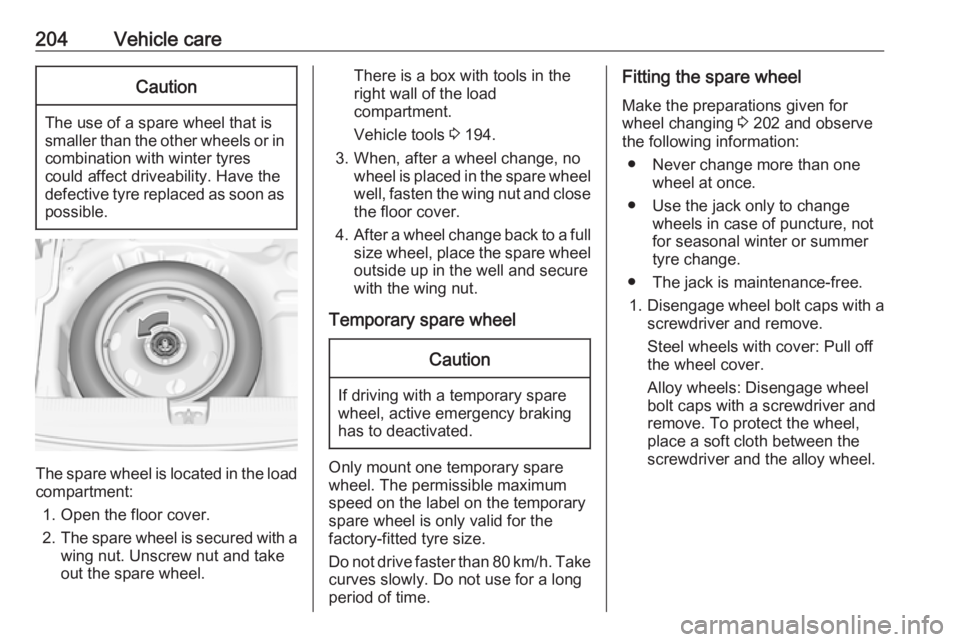

204Vehicle careCaution

The use of a spare wheel that issmaller than the other wheels or in combination with winter tyres

could affect driveability. Have the defective tyre replaced as soon as

possible.

The spare wheel is located in the load

compartment:

1. Open the floor cover.

2. The spare wheel is secured with a

wing nut. Unscrew nut and take

out the spare wheel.

There is a box with tools in the

right wall of the load compartment.

Vehicle tools 3 194.

3. When, after a wheel change, no wheel is placed in the spare wheelwell, fasten the wing nut and close

the floor cover.

4. After a wheel change back to a full

size wheel, place the spare wheel

outside up in the well and secure

with the wing nut.

Temporary spare wheelCaution

If driving with a temporary spare

wheel, active emergency braking

has to deactivated.

Only mount one temporary spare

wheel. The permissible maximum

speed on the label on the temporary

spare wheel is only valid for the

factory-fitted tyre size.

Do not drive faster than 80 km/h. Take

curves slowly. Do not use for a long

period of time.

Fitting the spare wheel

Make the preparations given for

wheel changing 3 202 and observe

the following information:

● Never change more than one wheel at once.

● Use the jack only to change wheels in case of puncture, not

for seasonal winter or summer

tyre change.

● The jack is maintenance-free.

1. Disengage wheel bolt caps with a

screwdriver and remove.

Steel wheels with cover: Pull off

the wheel cover.

Alloy wheels: Disengage wheel

bolt caps with a screwdriver and

remove. To protect the wheel,

place a soft cloth between the

screwdriver and the alloy wheel.