tow bar OPEL CROSSLAND X 2019 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2019, Model line: CROSSLAND X, Model: OPEL CROSSLAND X 2019Pages: 263, PDF Size: 8.11 MB

Page 54 of 263

52Seats, restraintsgeschützt ist, da dies den TOD oder

SCHWERE VERLETZUNGEN DES

KINDES zur Folge haben kann.

FR: NE JAMAIS utiliser un siège

d'enfant orienté vers l'arrière sur un

siège protégé par un COUSSIN

GONFLABLE ACTIF placé devant lui, sous peine d'infliger des

BLESSURES GRAVES, voire

MORTELLES à l'ENFANT.

ES: NUNCA utilice un sistema de

retención infantil orientado hacia

atrás en un asiento protegido por un

AIRBAG FRONTAL ACTIVO. Peligro de MUERTE o LESIONES GRAVES

para el NIÑO.

RU: ЗАПРЕЩАЕТСЯ

устанавливать детское

удерживающее устройство лицом

назад на сиденье автомобиля,

оборудованном фронтальной

подушкой безопасности, если

ПОДУШКА НЕ ОТКЛЮЧЕНА! Это

может привести к СМЕРТИ или

СЕРЬЕЗНЫМ ТРАВМАМ

РЕБЕНКА.NL: Gebruik NOOIT een achterwaarts

gericht kinderzitje op een stoel met

een ACTIEVE AIRBAG ervoor, om

DODELIJK of ERNSTIG LETSEL van het KIND te voorkomen.

DA: Brug ALDRIG en bagudvendt

autostol på et forsæde med AKTIV

AIRBAG, BARNET kan komme i

LIVSFARE eller komme ALVORLIGT

TIL SKADE.

SV: Använd ALDRIG en bakåtvänd

barnstol på ett säte som skyddas med en framförvarande AKTIV AIRBAG.

DÖDSFALL eller ALLVARLIGA

SKADOR kan drabba BARNET.

FI: ÄLÄ KOSKAAN sijoita taaksepäin

suunnattua lasten turvaistuinta

istuimelle, jonka edessä on

AKTIIVINEN TURVATYYNY, LAPSI

VOI KUOLLA tai VAMMAUTUA

VAKAVASTI.

NO: Bakovervendt

barnesikringsutstyr må ALDRI brukes

på et sete med AKTIV

KOLLISJONSPUTE foran, da det kan

føre til at BARNET utsettes for

LIVSFARE og fare for ALVORLIGE

SKADER.PT: NUNCA use um sistema de

retenção para crianças voltado para

trás num banco protegido com um AIRBAG ACTIVO na frente do

mesmo, poderá ocorrer a PERDA DE VIDA ou FERIMENTOS GRAVES na

CRIANÇA.

IT: Non usare mai un sistema di

sicurezza per bambini rivolto

all'indietro su un sedile protetto da

AIRBAG ATTIVO di fronte ad esso:

pericolo di MORTE o LESIONI

GRAVI per il BAMBINO!

EL: ΠΟΤΕ μη χρησιμοποιείτε παιδικό

κάθισμα ασφαλείας με φορά προς τα πίσω σε κάθισμα που προστατεύεται

από μετωπικό ΕΝΕΡΓΟ ΑΕΡΟΣΑΚΟ, διότι το παιδί μπορεί να υποστεί

ΘΑΝΑΣΙΜΟ ή ΣΟΒΑΡΟ

ΤΡΑΥΜΑΤΙΣΜΟ.

PL: NIE WOLNO montować fotelika

dziecięcego zwróconego tyłem do

kierunku jazdy na fotelu, przed

którym znajduje się WŁĄCZONA

PODUSZKA POWIETRZNA.

Niezastosowanie się do tego

zalecenia może być przyczyną

ŚMIERCI lub POWAŻNYCH

OBRAŻEŃ u DZIECKA.

Page 161 of 263

Driving and operating159Forward looking brake assist

In addition to emergency automatic

braking, the forward looking brake

assist function makes the brake assist more sensitive. Therefore, pressing

the brake pedal less strongly results

in immediate hard braking. This

function helps the driver brake

quicker and harder before the

imminent collision.9 Warning

Active emergency braking is not

designed to apply hard

autonomous braking or to

automatically avoid a collision. It is designed to reduce the vehicle

speed before a collision. It may not

react to animals. After a sudden

lane change, the system needs a

certain time to detect the next

preceding vehicle.

The complete attention of the

driver is always required while

driving. The driver must always be

ready to take action and apply the brakes and steer to avoid

collisions.

The system is designed to work with

all occupants wearing their seat belts.

Forward collision alert 3 156.

Front pedestrian protection 3 160.

Deactivation Active emergency braking can be

deactivated in the personalisation

menu 3 102. If deactivated, m

illuminates in the instrument cluster and a warning message is displayed

in the Driver Information Centre.

We recommend to deactivate the

system in the vehicle personalisation

in the following cases:

● when towing a trailer or caravan

● when carrying long objects on roof bars or a roof rack

● when the vehicle is being towed with the engine running

● when a spare wheel is fitted that is smaller than the other wheels

● before using an automatic carwash with the engine running

● before placing the vehicle on a rolling road in a workshop

● if the windscreen has been damaged close to the camera

● if the front bumper has been damaged

● if the brake lamps are not working

System limitations In some cases, the active emergencybraking system may provide an

automatic braking in situations that

seem to be unnecessary, for instance

in parking garages, due to traffic signs in a curve or due to vehicles in

another lane. This is normal

operation, the vehicle does not need

service. Firmly apply the accelerator

pedal to override the automatic

braking if the situation and the

surroundings permit.

Page 172 of 263

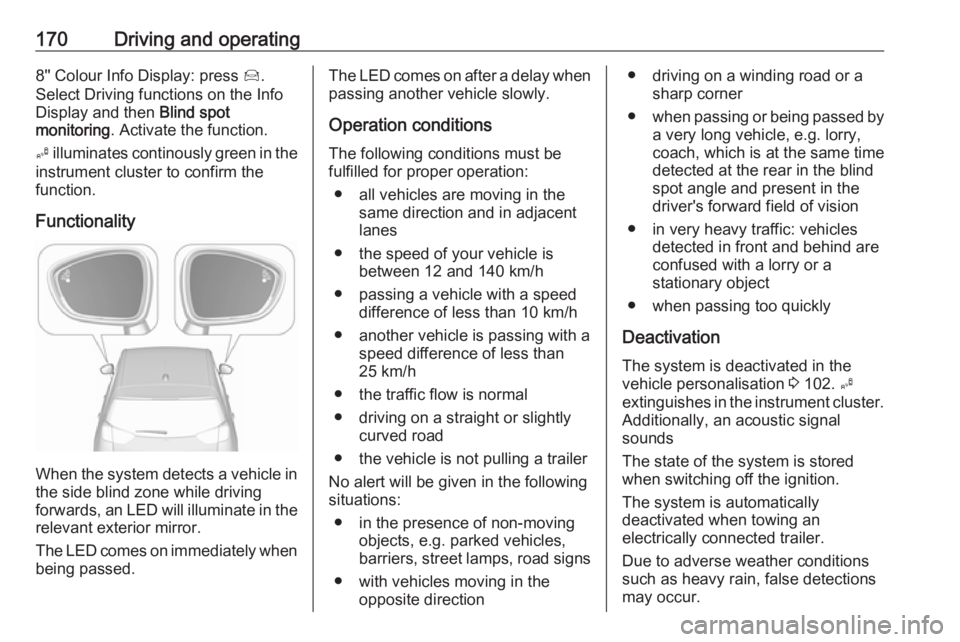

170Driving and operating8'' Colour Info Display: press Í.

Select Driving functions on the Info

Display and then Blind spot

monitoring . Activate the function.

B illuminates continously green in the

instrument cluster to confirm the

function.

Functionality

When the system detects a vehicle in the side blind zone while driving

forwards, an LED will illuminate in the

relevant exterior mirror.

The LED comes on immediately when being passed.

The LED comes on after a delay when

passing another vehicle slowly.

Operation conditions

The following conditions must be

fulfilled for proper operation:

● all vehicles are moving in the same direction and in adjacent

lanes

● the speed of your vehicle is between 12 and 140 km/h

● passing a vehicle with a speed difference of less than 10 km/h

● another vehicle is passing with a speed difference of less than

25 km/h

● the traffic flow is normal

● driving on a straight or slightly curved road

● the vehicle is not pulling a trailer

No alert will be given in the following

situations:

● in the presence of non-moving objects, e.g. parked vehicles,

barriers, street lamps, road signs

● with vehicles moving in the opposite direction● driving on a winding road or a sharp corner

● when passing or being passed by

a very long vehicle, e.g. lorry,

coach, which is at the same time

detected at the rear in the blind spot angle and present in the

driver's forward field of vision

● in very heavy traffic: vehicles detected in front and behind are

confused with a lorry or a

stationary object

● when passing too quickly

Deactivation The system is deactivated in the

vehicle personalisation 3 102. B

extinguishes in the instrument cluster.

Additionally, an acoustic signal

sounds

The state of the system is stored

when switching off the ignition.

The system is automatically

deactivated when towing an

electrically connected trailer.

Due to adverse weather conditions

such as heavy rain, false detections

may occur.

Page 185 of 263

Driving and operating183Fitting of towing equipment could

cover the opening of the towing eye. If this is the case use the coupling ball

bar for towing.

Driving characteristics and towing tips

Before attaching a trailer, lubricate

the coupling ball. However, do not do

so if a stabiliser, which acts on the

coupling ball, is being used to reduce snaking movements.

During trailer towing do not exceed a

speed of 80 km/h. A maximum speed

of 100 km/h is only appropriate if an

oscillation damper is used and the

permissible gross trailer weight does

not exceed the vehicle’s curb weight.

For trailers with low driving stability

and caravan trailers, the use of an

oscillation damper is strongly

recommended.

If the trailer starts snaking, drive more slowly, do not attempt to correct the

steering and brake sharply if

necessary.When driving downhill, drive in the

same gear as if driving uphill and

drive at a similar speed.

Adjust tyre pressure to the value

specified for full load 3 244.

Trailer towing

Trailer loads The permissible trailer loads are

vehicle and engine-dependent

maximum values which must not be

exceeded. The actual trailer load is

the difference between the actual

gross weight of the trailer and the

actual coupling socket load with the

trailer coupled.

The permissible trailer loads are

specified in the vehicle documents. In general, they are valid for gradients

up to 12%.

The permissible trailer load applies

up to the specified incline and at sea

level. Since engine power decreases

as altitude increases due to the air becoming thinner, therefore reducing

climbing ability, the permissible gross

train weight also decreases by 10%for every 1000 m of altitude. The

gross train weight does not have to be reduced when driving on roads with

slight inclines (less than 8%, e.g.

motorways).

The permissible gross train weight must not be exceeded. This weight is

specified on the identification plate

3 233.

Vertical coupling load

The vertical coupling load is the load

exerted by the trailer on the coupling

ball. It can be varied by changing the

weight distribution when loading the

trailer.

The maximum permissible vertical

coupling load of 50 kg is specified on

the towing equipment identification

plate and in the vehicle documents.

Always aim for the maximum load,

especially in the case of heavy

trailers. The vertical coupling load

should never fall below 25 kg.

Page 186 of 263

184Driving and operatingRear axle load

When the trailer is coupled and the

towing vehicle fully loaded, the

permissible rear axle load (see

identification plate or vehicle

documents) may be exceeded by

60 kg , the gross vehicle weight rating

must not be exceeded. If the

permissible rear axle load is

exceeded, a maximum speed of

100 km/h applies.

Towing equipmentCaution

When operating without a trailer,

remove the coupling ball bar.

Stowage of coupling ball bar

The bag with the coupling ball bar is

stowed on the rear floor cover in the

load compartment.

Place the strap through the rear right

lashing eye, wrap around twice and

tighten the strap to secure the bag.

Fitting the coupling ball bar

Swivel the connecting socket

downwards. Remove the sealing plug from the opening for the coupling ball

bar and stow it.

Checking the tensioning of the

coupling ball bar

● Red marking on rotary knob must

point towards green marking on

coupling ball bar.

● The gap between the rotary knob

and the coupling ball bar must be approx. 6 mm.

● The key must be in position c.

Otherwise, the coupling ball bar must

be tensioned before being inserted:

Page 187 of 263

Driving and operating185● Unlock coupling ball bar byturning key to position c.

● Pull out rotary knob and turn

clockwise as far as it will go.

Inserting the coupling ball bar

Insert the tensioned coupling ball bar

in the opening and push firmly

upwards until it audibly engages.

The rotary handle snaps back into its

original position resting against the

coupling ball bar without a gap.

9 Warning

Do not touch rotary handle during

insertion.

Lock the coupling ball bar by turning

the key to position e. Remove the key

and close the protective flap.

Eye for break-away stopping cable

Attach breakaway stopping cable to

eye.

Check that the coupling ball bar is correctly installed

● Green marking on rotary knob must point towards green

marking on coupling ball bar.

● There must be no gap between the rotary handle and the

coupling ball bar.

● The coupling ball bar must be firmly engaged in the opening.

● The coupling ball bar must be locked and the key removed.

Page 188 of 263

186Driving and operating9Warning

Towing a trailer is permitted only

when a coupling ball bar is fitted correctly. If the coupling ball bardoes not engage correctly, seekthe assistance of a workshop.

Dismounting the coupling ball bar

Open the protective flap and turn the

key to position c to unlock the

coupling ball bar.

Pull out rotary handle and turn

clockwise as far as it will go. Pull out coupling ball bar downwards.

Insert sealing plug in opening.

Swivel the connecting socket

upwards.

Stow the coupling ball bar in the bag

and secure by fixing the strap through the rear right lashing eye. Wrap

around twice and tighten the strap to

secure the bag.

Page 215 of 263

Vehicle care213

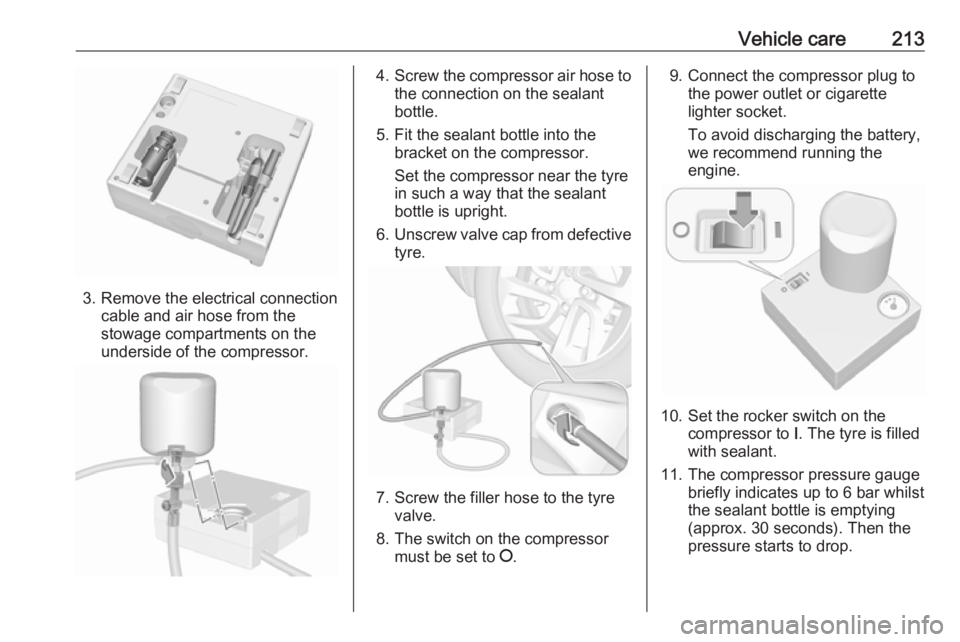

3. Remove the electrical connectioncable and air hose from the

stowage compartments on the

underside of the compressor.

4. Screw the compressor air hose to

the connection on the sealant

bottle.

5. Fit the sealant bottle into the bracket on the compressor.

Set the compressor near the tyre

in such a way that the sealant

bottle is upright.

6. Unscrew valve cap from defective

tyre.

7. Screw the filler hose to the tyre valve.

8. The switch on the compressor must be set to J.

9. Connect the compressor plug to

the power outlet or cigarette

lighter socket.

To avoid discharging the battery,

we recommend running the

engine.

10. Set the rocker switch on the compressor to I. The tyre is filled

with sealant.

11. The compressor pressure gauge briefly indicates up to 6 bar whilstthe sealant bottle is emptying

(approx. 30 seconds). Then the

pressure starts to drop.

Page 216 of 263

214Vehicle care12. All of the sealant is pumped intothe tyre. Then the tyre is being

inflated.

13. The prescribed tyre pressure should be obtained within

10 minutes.

Tyre pressure 3 244.

When the correct pressure is

obtained, switch off the

compressor.

If the prescribed tyre pressure is

not obtained within 10 minutes,

remove the tyre repair kit. Move

the vehicle one tyre rotation.

Reattach the tyre repair kit and

continue the filling procedure for

10 minutes. If the prescribed tyre

pressure is still not obtained, the

tyre is too badly damaged. Seek

the assistance of a workshop.

Drain excess tyre pressure with

the button on the air hose.

Do not run the compressor longer than 10 minutes.

14. Detach the tyre repair kit. Remove

sealant bottle from bracket. Screw the filler hose to the free

connection of the sealant bottle.

This prevents sealant from

escaping. Stow tyre repair kit in

load compartment.

15. Remove any excess sealant using a cloth.16. Continue driving immediately sothat sealant is evenly distributed

in the tyre. After driving approx.

5 km (but no more than 10 min),

stop and check tyre pressure.

Screw compressor air hose

directly onto tyre valve when

doing this. Fill tyre as described

before. Drain excess tyre

pressure with the button on the air

hose.

If tyre pressure hasn't decreased

under 1.5 bar, set it to the correct

value. Otherwise the vehicle must

not be used. Seek assistance of a workshop 3 244.

Page 217 of 263

Vehicle care215Repeat the checking procedure

once more after driving further

10 km (but no more than

10 minutes) to check that there is

no more loss of pressure

If the tyre pressure has fallen

below 1.5 bar, the vehicle must

not be used. Seek the assistance

of a workshop.

17. Stow away tyre repair kit in load compartment.

Note

The driving characteristics of the

repaired tyre are severely affected, therefore have this tyre replaced.

If unusual noise is heard or the

compressor becomes hot, turn

compressor off for at least

30 minutes.

The built-in safety valve opens at a

pressure of seven bar.

Note the expiry date of the kit. After

this date its sealing capability is no

longer guaranteed. Pay attention to

storage information on sealant

bottle.Replace the used sealant bottle. Dispose of the bottle as prescribed

by applicable laws.

The compressor and sealant can be

used from approx. -30 °C.

Wheel changing Make the following preparations and

observe the following information:

● Park the vehicle on a level, firm and non-skid surface. The front

wheels must be in the straight- ahead position.

● If necessary, place a chock under

the wheel diagonally opposite the wheel to be changed.

● Apply the parking brake and engage first gear, reverse gear or

P .

● If the ground on which the vehicle

is standing is soft, a solid board

(max. 1 cm thick) should be

placed under the jack.

● Take heavy objects out of the vehicle before jacking up.

● No people or animals may be in the vehicle when it is jacked-up.● Never crawl under a jacked-up vehicle.

● Do not start the vehicle when it is

raised on the jack.

● Before screwing in the wheel bolts, clean them.9Warning

Do not grease wheel bolts.

Tightening torques

Caution

If the vehicle is equipped with alloy

wheels, tighten the wheel bolts

manually at least for the first five

turns.

There are two different types of

wheels with two different bolts and tightening torques.