clutch OPEL FRONTERA 1998 Owners Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 1874 of 6000

ENGINE ELECTRICAL 6D – 7

ON-VEHICLE SERVICE

STARTER

REMOVAL

1 Battery ground cable

2 Remove the slave cylinder and bind with wire it to

the frame.

3 Disconnect the connector from terminals “B” and

“S”.

4. Remove mounting bolts

5. Remove starter assembly

INSTALLATION

1. Install starter assembly, tighten the fixing bolt and

nut to the specified torque.

Torque: 94 Nꞏm (9.6 kgꞏm/69 lb ft)

2. Reconnect the starter terminals.

CAUTION: When installing the starter motor wiring,

do not allow the S-circuit wiring to obstruct the B-

circuit terminal.

Install the wiring exactly as shown on the attached

illustration.

If S-circuit wiring obstructs the B-circuit terminal,

harness cover breakage and short circuiting may

occur.2-1. Install the wire harness from the battery to the

terminal “B” with tightening torque 8.6 Nꞏm

(0.88 kgꞏm/6.4 lbꞏft).

2-2. Cover the terminal “B” together with wire

harness.

2-3. Connect the wire harness from starter relay to

the terminal “S”.

3. Install the clutch slave cylinder, tighten the fixing

bolt and nut to the specified torque.

Torque: 78 Nꞏm (8.0 kgꞏm/58 lbꞏft)

1

32

4

Legend

(1) Clutch Slave Cylinder

(2) Magnetic Switch(3) Bolt

(4) Starter Assembly

065RW00003

Do not recommend

wiring route.

Recommend wiring route

from S terminal.From

battery

From

starter relay Terminal B

Terminal MTerminal SIn this area,

Scratch to break the wire

cover and make shortage.

065RW00002

Page 1875 of 6000

6D – 8 ENGINE ELECTRICAL

UNIT REPAIR

8

241 3

23

25

2

14

15 21222019181716

109

11

13

127

6

5

4

Legend

(1) Terminal

(2) Bolt

(3) Magnetic Switch

(4) Torsion Spring

(5) Plunger

(6) Shim

(7) Magnetic Switch

(8) Through Bolt

(9) Rear Cover

(10) Motor Assembly

(11) Brush Holder

(12) Armature(13) Yoke Assembly

(14) Bearing Retainer

(15) Pinion Assembly

(16) Bearing Holder

(17) Bearing

(18) Clip

(19) Stopper

(20) Spring

(21) Pinion Shaft

(22) Clutch

(23) Dust Cover

(24) Shift Lever

(25) Gear Case

065RW040

Page 1876 of 6000

ENGINE ELECTRICAL 6D – 9

DISASSEMBLY

1. Terminal Nut

1) Loosen the nut on terminal “M” of magnetic

switch and disconnect the connector cable.

2. Bolt (2 pcs)

3. Magnetic Switch Assembly

4. Torsion Spring

1) Remove torsion spring from magnetic switch

assembly.

5. Plunger

6. Shim

7. Magnetic Switch

8. Through Bolt

9. Rear Cover

1) Remove the through bolts, then remove the rear

cover.10. Motor Assembly

11. Brush Holder

1) Raise a brush spring to detach the negative side

of the brushes (2 pcs) from the commutator face

and remove the positive side of brushes (2 pcs)

from the positive side of brushes (2 pcs) from

the brush holder.

12. Armature

13. Yoke Assembly

14. Bearing Retainer

15. Pinion Assembly

16. Bearing Holder

17. Bearing

18. Pinion Stopper Clip

1) Remove the stopper clip using a screw driver of

equivalent size.

19. Pinion Stopper

20. Return Spring

21. Pinion Shaft

22. Clutch

23. Dust Cover

24. Shift Lever

25. Gear Case

065RW044

065RW043

065RW042

Page 1899 of 6000

6E–6

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Removal Procedure 6E–212. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–212. . . . . . . . . . . . . . . . . .

Fuel Filter Cap 6E–213. . . . . . . . . . . . . . . . . . . . . . . . . .

General Description 6E–213. . . . . . . . . . . . . . . . . . . .

Inspection Procedure 6E–213. . . . . . . . . . . . . . . . . .

Fuel Filter 6E–213. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal and Installation Procedure 6E–213. . . . . .

Fuel Gauge Unit 6E–213. . . . . . . . . . . . . . . . . . . . . . . .

Removal Procedure 6E–213. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–214. . . . . . . . . . . . . . . . . .

Fuel Injectors 6E–214. . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal and Installation Procedure 6E–214. . . . . .

Fuel Temperature Sensor 6E–214. . . . . . . . . . . . . . . .

Removal Procedure 6E–214. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–215. . . . . . . . . . . . . . . . . .

Rail Pressure (RP) Sensor 6E–216. . . . . . . . . . . . . . .

Removal Procedure 6E–216. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–216. . . . . . . . . . . . . . . . . .

Fuel Tank 6E–216. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal Procedure 6E–216. . . . . . . . . . . . . . . . . . . .

Throttle Body (TB) 6E–217. . . . . . . . . . . . . . . . . . . . . . .

Removal Procedure 6E–217. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–217. . . . . . . . . . . . . . . . . .

Air Conditioning (A/C) Relay 6E–217. . . . . . . . . . . . . .

Removal Procedure 6E–217. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–217. . . . . . . . . . . . . . . . . .

Exhaust Gas Recirculation (EGR) Vacuum

Switch Valve (VSV) 6E–217. . . . . . . . . . . . . . . . . . . . .

Removal Procedure 6E–217. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–218. . . . . . . . . . . . . . . . . .

Electronic Vacuum Regurating Valve (EVRV) 6E–219

Removal Procedure 6E–219. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–220. . . . . . . . . . . . . . . . . .

Wiring and Connectors 6E–220. . . . . . . . . . . . . . . . . . .

Wiring Harness Service 6E–220. . . . . . . . . . . . . . . .

Connectors and Terminals 6E–220. . . . . . . . . . . . . .

Wire Harness Repair: Twisted Shielded

Cable 6E–220. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal Procedure 6E–220. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–221. . . . . . . . . . . . . . . . . .

Twisted Leads 6E–221. . . . . . . . . . . . . . . . . . . . . . . . . .

Removal Procedure 6E–221. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–222. . . . . . . . . . . . . . . . . .

Weather-Pack Connector 6E–223. . . . . . . . . . . . . . . . .

Tools Required 6E–223. . . . . . . . . . . . . . . . . . . . . . . .

Removal Procedure 6E–223. . . . . . . . . . . . . . . . . . . . Installation Procedure 6E–223. . . . . . . . . . . . . . . . . .

Com-Pack III 6E–224. . . . . . . . . . . . . . . . . . . . . . . . . . .

General Information 6E–224. . . . . . . . . . . . . . . . . . . .

Metri-Pack 6E–224. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tools Required 6E–224. . . . . . . . . . . . . . . . . . . . . . . .

Removal Procedure 6E–224

. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–224. . . . . . . . . . . . . . . . . .

General Description

(ECM and Sensors) 6E–225. . . . . . . . . . . . . . . . . . . . .

57X Reference ECM Input 6E–225. . . . . . . . . . . . . .

A/C Request Signal 6E–225. . . . . . . . . . . . . . . . . . . .

Crankshaft Position (CKP) Sensor 6E–225. . . . . . .

Camshaft Position (CMP) Sensor and

Signal 6E–225. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Coolant Temperature (ECT) Sensor 6E–225

Electrically Erasable Programmable Read

Only Memory (EEPROM) 6E–225. . . . . . . . . . . . . .

Intake Air Temperature (IAT) Sensor 6E–225. . . . .

Manifold Absolute Pressure (MAP) Sensor 6E–226

Engine Control Module (ECM) 6E–226. . . . . . . . . . .

ECM Function 6E–226. . . . . . . . . . . . . . . . . . . . . . . . .

ECM Components 6E–226. . . . . . . . . . . . . . . . . . . . .

ECM Voltage Description 6E–226. . . . . . . . . . . . . . .

ECM Input/Outputs 6E–226. . . . . . . . . . . . . . . . . . . .

ECM Service Precautions 6E–227. . . . . . . . . . . . . .

Intake Throttle Position (ITP) Sensor 6E–227. . . . .

Transmission Range Switch 6E–227. . . . . . . . . . . . .

Accelerator Position Sensor (AP) 6E–227. . . . . . . .

Aftermarket Electrical and Vacuum

Equipment 6E–227. . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrostatic Discharge Damage 6E–227. . . . . . . . .

General Description (Air Induction) 6E–228. . . . . . . .

Air Induction System 6E–228. . . . . . . . . . . . . . . . . . .

General Description (Fuel Metering) 6E–228. . . . . . .

Deceleration Mode 6E–228. . . . . . . . . . . . . . . . . . . .

Fuel Injector 6E–228. . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Metering System Components 6E–228. . . . . .

A/C Clutch Diagnosis 6E–228. . . . . . . . . . . . . . . . . . . .

A/C Request Signal 6E–228. . . . . . . . . . . . . . . . . . . .

General Description Exhaust Gas

Recirculation (EGR) System 6E–228. . . . . . . . . . . . .

EGR Purpose 6E–228. . . . . . . . . . . . . . . . . . . . . . . . .

Fuse and Relay Panel

(Underhood Electrical Center) RHD 6E–229. . . . . . .

Fuse and Relay Panel

(Underhood Electrical Center) LHD 6E–230. . . . . . .

Page 1934 of 6000

6E–41 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

EGR (Exhaust Gas Recirculation)

Diagnosis

A diagnosis of the EGR system is covered by DTC

P1403.

EGR VSV circuit diagnosis is covered by DTC P1404.

EGR pressure sensor diagnosis is covered by DTC

P405 and/or P406.

EGR EVRV circuit diagnosis is covered by DTC

P1405. Refer to the DTC charts.

Tech 2 Data Definitions and Ranges

A/C CLUTCH–Tech 2 Displays ON or OFF–

Indicates whether the A/C has commanded the A/C

clutch ON.

MAP kPa — Tech 2 Range 10-105 kPa/0.00-5.00

Vo l t s —

The manifold absolute pressure reading is determined

from the MAP sensor signal monitored during key up and

wide open throttle (WOT) conditions. The manifold

absolute pressure is used to compensate for altitude

differences and is normally displayed around “61-104”

depending on altitude and manifold absolute pressure.

CMP ACT. COUNTER –Cam Position

DESIRED IDLE — Tech 2 Range 0-3187 RPM —

The idle speed that the ECM is commanding. The ECM

will compensate for various engine loads based on engine

coolant temperature, to keep the engine at the desired

speed.

ECT — (Engine Coolant Temperature) Tech 2

Range –40

C to 151C (–40F to 304F) —

The engine coolant temperature (ECT) is mounted in the

coolant stream and sends engine temperature

information to the ECM. The ECM applies 5 volts to the

ECT sensor circuit. The sensor is a thermistor which

changes internal resistance as temperature changes.

When the sensor is cold (high resistance), the ECM

monitors a high signal voltage and interprets that as a cold

engine. As the sensor warms (decreasing resistance),

the voltage signal will decrease and the ECM will interpret

the lower voltage as a warm engine.

ENGINE RUN TIME — Tech 2 Range

00:00:00-99:99:99 Hrs:Min:Sec —

Indicates the time elapsed since the engine was started.

If the engine is stopped, engine run time will be reset to

00:00:00.

ENGINE SPEED — Range 0-9999 RPM —

Engine speed is computed by the ECM from the 57X

reference input. It should remain close to desired idle

under various engine loads with engine idling.Air Intake Valve meter POSITION — Tech 2 Range

0-100 % —

IAT (INTAKE AIR TEMPERATURE)— Tech 2 Range

–40

C to 151C (–40F to 304F) —

The ECM converts the resistance of the intake air

temperature sensor to degrees. Intake air temperature

(IAT) is used by the ECM to adjust fuel delivery and spark

timing according to incoming air density.

MAP — Tech 2 Range 10-105 kPa (0.00-4.97 Volts)—

The manifold absolute pressure (MAP) sensor measures

the change in the boost pressure.

MIL — Tech 2 Displays ON or OFF —

Indicates the ECM commanded state of the malfunction

indicator lamp.

AP — Tech 2 Range 0%-100% —

AP (Accelerator position) angle is computed by the ECM

from the AP sensor voltage. AP angle should display

“0%” at idle and “100%” at wide open throttle.

AP SENSOR — Tech 2 Range 0.00-5.00 Volts —

The voltage being monitored by the ECM on the AP

sensor signal circuit.

VEHICLE SPEED—Tech 2 Range 0-255 km/h (0-155

mph)–

The vehicle speed sensor signal is converted into km/h

and mph for display.

Typical Scan Data Values

Use the Typical Scan Data Values Table only after the

On-Board Diagnostic System Check has been

completed, no DTC(s) were noted, and you have

determined that the on-board diagnostics are functioning

properly. Tech 2 values from a properly-running engine

may be used for comparison with the engine you are

diagnosing. The typical scan data values represent

values that would be seen on a normally-running engine.

NOTE: A Tech 2 that displays faulty data should not be

used, and the problem should be reported to the Tech 2

manufacturer. Use of a faulty Tech 2 can result in

misdiagnosis and unnecessary replacement of parts.

Only the parameters listed below are referred to in this

service manual for use in diagnosis. For further

information on using the Tech 2 to diagnose the ECM and

related sensors, refer to the applicable reference section

listed below. If all values are within the typical range

described below, refer to the

Symptoms section for

diagnosis.

Test Conditions

Engine running, lower radiator hose hot, transmission in

park or neutral, accessaries off, brake not applied and air

conditioning off.

Page 1936 of 6000

6E–43 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Te c h 2

ParameterData ListUnits

DisplayedTy p i c a l D a t a

Values (IDLE)Typical Data

Va l u e s

(2500 RPM)Refer To

Exhaust VSV1EngineOn/OffOffOffDTC P0475

Exhaust VSV2EngineOn/OffOffOffDTC P1475

Decelevation

Fuel Cut OffEngineInactive/

Active——General Description

Glow Time

LampEngineOn/OffOffOffDTC P0381

Glow Time

RelayEngineOn/OffOffOffDTC P0380

Diagnostic

RequestEngineInactive

12V/

Active 0V——General Description

A/C ClutchEngineOn/OffOffOffGeneral Description

Desired IdleEngineRPM720—General Description

ECT (Engine

Coolant Temp)EngineC (F)80 9080 90General Description

ECT

Engine SpeedEngineRPM7202500DTC P0219

MAT (Intake Air

Te m p )EngineC (F)65 8065 80DTC P0112, P0113

MAP KPa

(Manifold

Absolute

Pressure)EngineKilopascals——General Description

DTC P0107, P0108

MILEngineOn/OffOffOffGeneral Description

AP (Accel

Position)EnginePercent08 14DTC P0121, P0122,

P0123

AP (Accel

Position)EngineVo l t s0.25 0.450.8 1.0DTC P0121, P0122,

P0123

Rail Oil

TemperatureEngineC (F)——DTC P0197, P0198

Desired Throttle

Motor PositionEngineSteps———

Learned Idle

Fuel QuantityEnginemm 3/st———

Page 2069 of 6000

6E–176

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Symptom Diagnosis

Preliminary Checks

Before using this section, perform the “On–Board

Diagnostic (OBD) System Check” and verify all of the

following items:

The powertrain control module (ECM) and

malfunction indicator lamp (MIL) (CHECK ENGINE

lamp) are operating correctly.

There are no DTC(s) stored.

Tech–2 data is within normal operating range. Refer

to

Typical Scan Data Values.

Verify the customer complaint and locate the correct

symptom in the table of contents. Perform the

procedure included in the symptom chart.

Visual/Physical Check

Several of the symptom procedures call for a careful

visual/physical check. This can lead to correcting a

problem without further checks and can save valuable

time.

This check should include the following items:

ECM grounds for cleanliness, tightness and proper

location.

Vacuum hoses for splits, kinks, and proper

connections, as shown on the “Vehicle Emission

Control Information” label. Check thoroughly for any

type of leak or restriction.

Air intake ducts for collapsed or damaged areas.

Injector wires for cracking, hardness, and carbon

tracking.

Wiring for proper connections, pinches and cuts.

Intermittents

IMPORTANT:An intermittent problem may or may not

turn on the malfunction indicator lamp (MIL) or store a

DTC. DO NOT use the Diagnostic Trouble Code (DTC)

charts for intermittent problems. The fault must be

present to locate the problem.

Most intermittent problems are caused by faulty electrical

connections or wiring. Perform a careful visual/physical

check for the following conditions:

Poor mating of the connector halves or a terminal not

fully seated in the connector (backed out).

Improperly formed or damaged terminal.

All connector terminals in the problem circuit should

be carefully checked for proper contact tension.

Poor terminal–to–wire connection. This requires

removing the terminal from the connector body to

check.

Road test the vehicle with a Digital Multimeter

(5-8840-0285-0) connected to a suspected circuit. An

abnormal voltage when the malfunction occurs is a good

indication that there is a fault in the circuit being

monitored.

Use a scan tool to help detect intermittent conditions. The

scan tools have several features that can be used to

locate an intermittent condition. Use the following feature

to find intermittent faults:

Using a Tech–2 “Freeze Frame” buffer or “Failure

Records” buffer can aid in locating an intermittent

condition. Review and record the information in the

freeze frame or failure record associated with the

intermittent DTC being diagnosed. The vehicle can

be driven within the conditions that were present

when the DTC originally set.

To check for loss of diagnostic code memory, disconnect

the MAP sensor and idle the engine until the MIL (CHECK

ENGINE lamp) comes on. DTC P0107 should be stored

and kept in memory when the ignition is turned “OFF.” If

not, the ECM is faulty. When this test is completed, make

sure that you clear the DTC P0107 from memory.

An intermittent MIL (CHECK ENGINE lamp) with no

stored DTC may be caused by the following:

MIL (CHECK ENGINE lamp) wire to ECM shorted to

ground.

Poor ECM grounds. Refer to the ECM wiring

diagrams.

Check for improper installation of electrical options such

as lights, cellular phones, etc.

Check for an open diode across the A/C compressor

clutch and check for other open diodes (refer to wiring

diagrams in

Electrical Diagnosis).

If problem has not been found, refer to

ECM Connector

Symptom

tables.

Page 2072 of 6000

6E–179 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Surges and/or Chuggles Symptom

StepActionVa l u e ( s )Ye sNo

1DEFINITION:

Engine power variation under steady throttle or cruise.

Feels like the vehicle speeds up and slows down with

no change in the accelerator pedal.

Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Perform a bulletin search.

2. If a bulletin that addresses the symptom is found,

correct the condition as instructed in the bulletin.

Was a bulletin found that addresses the symptom?

—Verify repairGo to Step 3

3Was a visual/physical check performed?

—Go to Step 4

Go to Visual/

Physical

Check

4Be sure that the driver understands transmission

torque converter clutch and A/C compressor operation

as explained in the owner’s manual.

Inform the customer how the TCC and the A/C clutch

operate.

Is the customer experiencing a normal condition?

—System OKGo to Step 5

51. Check the priming pump. Refer to Fuel System.

2. If a problem is found, operate the priming pump.

Was a problem found?

—Verify repairGo to Step 6

61. Injector Test

Operate the each injector by Tech 2 with the

ignition “ON” and check if the working noise

confirm.

2. If a problem is found, check the harness and repair

as necessary.

Is the action complete?

—Verify repairGo to Step 7

71. Check ECM grounds for the cleanliness, tightness

and proper locations. Refer to the ECM wiring

diagrams in

Electrical Diagnosis.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 8

81. Check AP sensor connections.

2. If a problem is found, replace the faulty terminals as

necessary. Refer to

Electrical Diagnosis for wiring

repair procedures.

Was a problem found?

—Verify repairGo to Step 9

91. Visually/physically check vacuum hoses for splits,

kinks, and proper connections and routing as

shown on the “Vehicle Emission Control

Information” label.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 10

Page 2074 of 6000

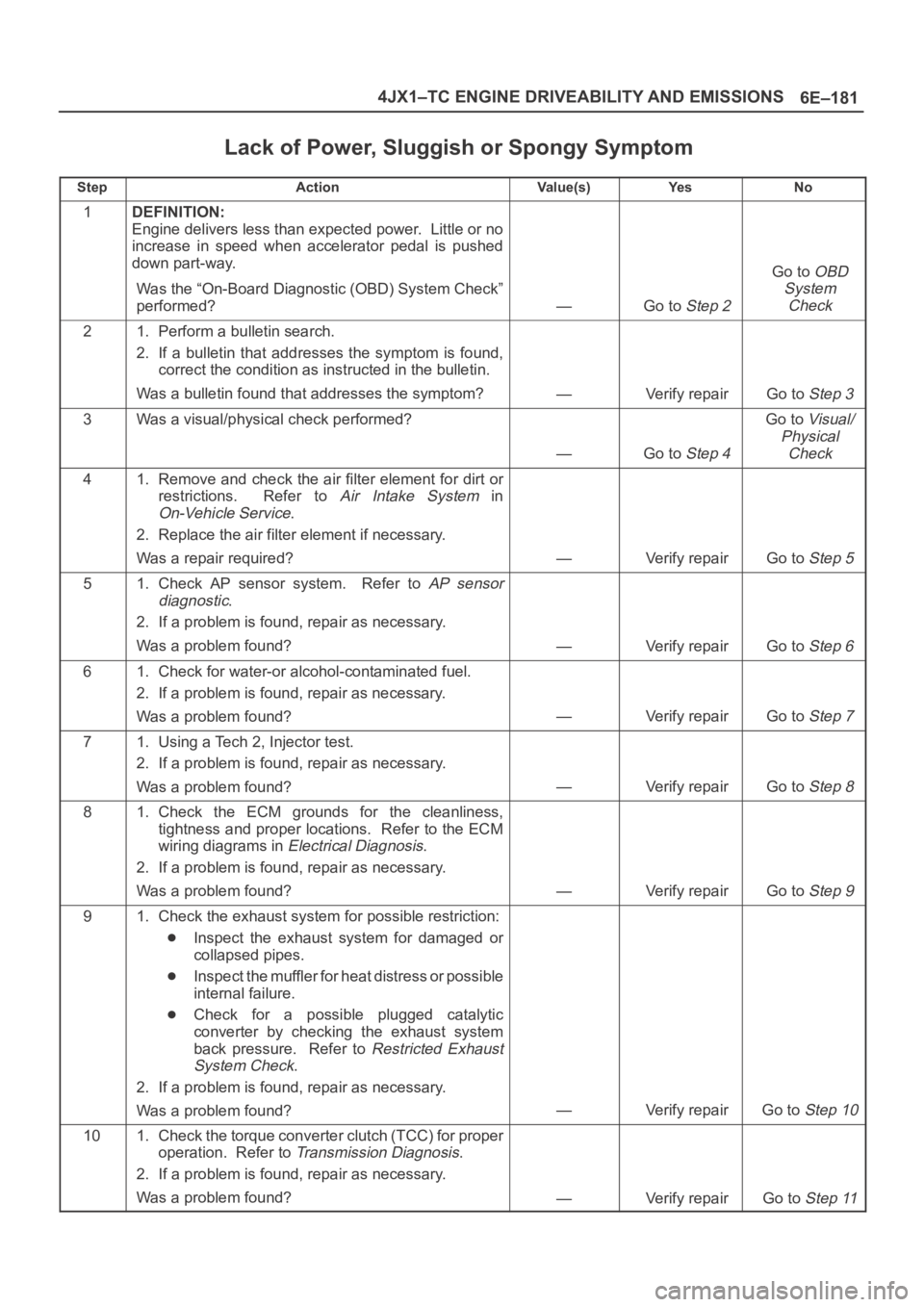

6E–181 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Lack of Power, Sluggish or Spongy Symptom

StepActionVa l u e ( s )Ye sNo

1DEFINITION:

Engine delivers less than expected power. Little or no

increase in speed when accelerator pedal is pushed

down part-way.

Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Perform a bulletin search.

2. If a bulletin that addresses the symptom is found,

correct the condition as instructed in the bulletin.

Was a bulletin found that addresses the symptom?

—Verify repairGo to Step 3

3Was a visual/physical check performed?

—Go to Step 4

Go to Visual/

Physical

Check

41. Remove and check the air filter element for dirt or

restrictions. Refer to

Air Intake System in

On-Vehicle Service.

2. Replace the air filter element if necessary.

Was a repair required?

—Verify repairGo to Step 5

51. Check AP sensor system. Refer to AP sensor

diagnostic

.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 6

61. Check for water-or alcohol-contaminated fuel.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 7

71. Using a Tech 2, Injector test.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 8

81. Check the ECM grounds for the cleanliness,

tightness and proper locations. Refer to the ECM

wiring diagrams in

Electrical Diagnosis.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 9

91. Check the exhaust system for possible restriction:

Inspect the exhaust system for damaged or

collapsed pipes.

Inspect the muffler for heat distress or possible

internal failure.

Check for a possible plugged catalytic

converter by checking the exhaust system

back pressure. Refer to

Restricted Exhaust

System Check

.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 10

101. Check the torque converter clutch (TCC) for proper

operation. Refer to

Transmission Diagnosis.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 11

Page 2093 of 6000

6E–200

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

SymptomsInitial DiagnosisDefault Section(s)

Hesitation, Sag, Stumble1. OBD system check.

2. AP.

3. MAP output check.

4. Fuel system diagnosis.

5. Injector system.Generator Output Voltage (refer

to

Chassis Electrical),

Calibration ID/Service Bulletins,

Ignition System Check

Rough, Unstable, or Incorrect Idle,

Stalling1. OBD system check.

2. Fuel injector test.MAP Output Check, Throttle

Linkage, A/C Clutch Control

Circuit Diagnosis, Calibration

ID/Service Bulletins, Generator

Output Voltage (refer to

Chassis

Electrical

), Exhaust Diagnosis

Poor Fuel Economy1. OBD system check.

2. Careful visual/physical inspection.

3. Injector system.

4. Cooling system.TCC Operation, Exhaust

System (refer to

Engine

Exhaust

)

Engine Cranks But Will Not Run1. OBD system check.Fuel System Electrical

Diagnosis, Fuel System

Diagnosis, Fuel Injector Test.

Excessive Exhaust Emissions or

Odors1. OBD system check.

2. Emission test.

3. Cooling system.

4. Fuel system diagnosis.

5. Fuel injector test.

6. Injector system.

7. MAP output check.Exhaust Diagnosis, Calibration

ID/Service Bulletins

Dieseling, Run-On1. OBD system check.

2. Careful visual/physical inspection.

3. Fuel system diagnosis.—