fuel OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 1394 of 6000

6E–277 ENGINE DRIVEABILITY AND EMISSIONS

Excessive Exhaust Emissions or Odors Symptom

StepActionVa l u e ( s )Ye sNo

1DEFINITION:

Vehicle fails an emission test. Vehicle has excessive

“rotten egg” smell. (Excessive odors do not necessarily

indicate excessive emissions.)

Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Perform a bulletin search.

2. If a bulletin that addresses the symptom is found,

correct the condition as instructed in the bulletin.

Was a bulletin found that addresses the symptom?

—Go to Step 12Go to Step 3

3Was a thorough visual/physical check performed?

—Go to Step 4

Go to

Visual/Physic

al Check

41. Check for vacuum leaks. Check vacuum lines,

intake manifold, throttle body, etc.

2. If a problem is found, repair as necessary.

Were any vacuum leaks located?

—Go to Step 12Go to Step 5

51. Check the fuel cap for proper installation.

2. Secure the fuel cap if necessary.

Was the fuel cap installed properly?

—Go to Step 6Go to Step 12

61. Check the fuel pressure. Perform the procedure in

Fuel System Pressure Test.

2. If a problem is found, repair as necessary.

Was a problem found?

—Go to Step 12Go to Step 7

71. Check for a faulty, plugged, or incorrectly installed

crankcase ventilation valve; also check the

crankcase ventilation system for plugging.

2. If a problem is found, repair as necessary.

Was a problem found?

—Go to Step 12Go to Step 8

81. Check the injector connections.

2. If any of the injectors are connected to an incorrect

cylinder, correct as necessary.

Was a problem found?

—Go to Step 12Go to Step 9

91. Perform the “Injector Coil/Balance Test” in Fuel

Metering System

.

2. If a problem is found, repair as necessary.

Was a problem found?

—Go to Step 12Go to Step 10

101. Refer to Engine Cooling for cooling system

diagnosis.

2. If a problem is found, repair as necessary.

Was a problem found?

—Go to Step 12Go to Step 11

111. Remove excessive carbon buildup with a top engine

cleaner. Refer to the instructions on the top engine

cleaner can.

2. Perform the exhaust emission test.

Does the vehicle pass the test?

—System OKGo to Step 13

12Perform the exhaust emission test.

Does the vehicle pass the test?

—System OKGo to Step 13

Page 1395 of 6000

6E–278

ENGINE DRIVEABILITY AND EMISSIONS

Excessive Exhaust Emissions or Odors Symptom

StepNo Ye s Va l u e ( s ) Action

13Does the exhaust emission test indicate excessive CO

and HC levels or is long term fuel trim significantly in the

negative range (rich condition)?

—Go to Step 14Go to Step 15

141. Check items that can cause the engine to run rich.

Refer to

Diagnostic Aids in DTC P0172 Diagnostic

Support

. Make any necessary repairs.

2. Perform the exhaust emission test.

Does the vehicle pass the test?

—System OKGo to Step 16

151. Check items that can cause the engine to run lean.

Refer to

Diagnostic Aids in DTC P0171 Diagnostic

Support

. Make any necessary repairs.

2. Perform the exhaust emission test.

Does the vehicle pass the test?

—System OKGo to Step 16

161. Check the EGR system.

2. If a problem is found, repair as necessary.

Was a problem found?

—Go to Step 12Go to Step 17

171. Check for an engine mechanical problem.

Perform a cylinder compression check (refer to

Engine Mechanical).

2. If a problem is found, repair as necessary.

Was a problem found?

—Go to Step 12Go to Step 18

181. Review all diagnostic procedures within this table.

2. If all procedures have been completed and no

malfunctions have been found, review/inspect the

following:

Visual/physical inspection

Te c h 2 d a t a

Freeze Frame data/Failure Records butter

All electrical connections within a suspected

circuit and/or system.

3. If a problem is found, repair as necessary.

Was a problem found?

—Verify repair

Contact

Te c h n i c a l

Assistance

Page 1397 of 6000

6E–280

ENGINE DRIVEABILITY AND EMISSIONS

Backfire Symptom

StepActionVa l u e ( s )Ye sNo

1DEFINITION:

Fuel ignites in the intake manifold, or in the exhaust

system, making a loud popping noise.

Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Perform a bulletin search.

2. If a bulletin that addresses the symptom is found,

correct the condition as instructed in the bulletin.

Was a bulletin found that addresses the symptom?

—Verify repairGo to Step 3

3Was a visual/physical check performed?

—Go to Step 4

Go to

Visual/Physic

al Check

41. Check for proper ignition voltage coil output with

spark tester 5-8840-0383-0. Refer to

Electric

Ignition System

for procedure.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 5

51. Remove spark plugs and check for wet plugs,

cracks, wear, improper gap, burned electrodes, or

heavy deposits. Refer to

Electronic Ignition

System

.

NOTE: If spark plugs are gas or oil fouled, the cause of

the fouling must be determined before replacing the

spark plugs. Refer to

DTC P0172 to determine the

cause of a rich condition or

Engine Mechanical for an oil

fouling condition.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 6

61. Visually/physically inspect the ignition coils for

cracks.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 7

71. Check for an intermittent ignition system

malfunction:

Intermittent CKP 58X signal.

Intermittent ignition feed circuit or sensor

ground circuit to the crankshaft position

sensor.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 8

81. Check the fuel pressure. Refer to Fuel System

Pressure Test

.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 9

Page 1399 of 6000

6E–282

ENGINE DRIVEABILITY AND EMISSIONS

Cuts Out, Misses Symptom

StepActionVa l u e ( s )Ye sNo

1DEFINITION:

Steady pulsation or jerking that follows engine speed;

usually more pronounced as engine load increases.

Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Perform a bulletin search.

2. If a bulletin that addresses the symptom is found,

correct the condition as instructed in the bulletin.

Was a bulletin found that addresses the symptom?

—Go to Step 13Go to Step 3

3Was a visual/physical check performed?

—Go to Step 4

Go to

Visual/Physic

al Check

41. Check the PCM grounds for clearness, tightness

and proper routing. Refer to the PCM wiring

diagrams in

Electrical Diagnosis.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 5

5Observe the long term fuel trim on Tech 2.

Is the long term fuel trim significantly in the negative

range (rich condition)?

—Go to Step 6Go to Step 7

61. Check items that can cause the engine to run rich.

Refer to

Diagnostic Aids in DTC P0172 Diagnostic

Support

.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 9

7Is the long term fuel trim significantly in the positive

range (lean condition)?

—Go to Step 8Go to Step 9

81. Check items that can cause the engine to run lean.

Refer to

Diagnostic Aids in DTC P0171 Diagnostic

Support

.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 9

91. Check for incorrect idle speed. Ensure that the

following conditions are present:

The engine is fully warm.

The accessories are “off.”

2. Using Tech 2, monitor the IAC position.

Is the IAC position within the specified values?Between 5

and 50

counts

Go to Step 11Go to Step 10

Page 1400 of 6000

6E–283 ENGINE DRIVEABILITY AND EMISSIONS

Cuts Out, Misses Symptom

StepNo Ye s Va l u e ( s ) Action

101. Visually/physically inspect for the following

conditions:

Restricted air intake system. Check for a

possible collapsed air intake duct, restricted

air filter element, or foreign objects blocking

the air intake system.

Throttle body. Check for objects blocking the

IAC passage or throttle bore, excessive

deposits in the IAC passage and on the IAC

pintle, and excessive deposits in the throttle

bore and on the throttle plate.

Large vacuum leak. Check for a condition that

causes a large vacuum leak, such as an

incorrectly installed or faulty PCV valve or

brake booster hose disconnected .

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 8

11Check the injector connections. If any of the injectors

are connected to an incorrect cylinder, correct as

necessary.

Was a problem found?

—Verify repairGo to Step 12

121. Perform the “Injector Coil/Balance Test” in Fuel

Metering System

.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 13

131. Check for fuel in the pressure regulator vacuum

hose.

2. If fuel is present, replace the fuel pressure regulator

assembly. Refer to

Fuel Metering System.

3. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 14

141. Check for proper ignition voltage output with spark

tester J 26792 (ST-125). Refer to

Electronic Ignition

System

for the procedure.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 15

151. Remove spark plugs. Check for wet plugs, cracks,

wear, improper gap, burned electrodes, or heavy

deposits. Refer to

Electronic Ignition System.

NOTE: If spark plugs are gas or oil fouled, the cause of

the fouling must be determined before replacing the

spark plugs.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 16

161. Check for a loose ignition coil ground.

Refer to

Electronic Ignition System.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 17

Page 1402 of 6000

6E–285 ENGINE DRIVEABILITY AND EMISSIONS

Hesitation, Sag, Stumble Symptom

StepActionVa l u e ( s )Ye sNo

1DEFINITION:

Momentary lack of response as the accelerator is

pushed down. Can occur at any vehicle speed. Usually

most pronounced when first trying to make the vehicle

move, as from a stop sign. May cause the engine to stall

if severe enough.

Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Perform a bulletin search.

2. If a bulletin that addresses the symptom is found,

correct the condition as instructed in the bulletin.

Was a bulletin found that addresses the symptom?

—Verify repairGo to Step 3

3Was a visual/physical check performed?

—Go to Step 4

Go to

Visual/Physic

al Check

41. Check the fuel control heated oxygen sensors

(HO2S, B1S1 and B2S1). The fuel control heated

oxygen sensors (HO2S) should respond quickly to

different throttle positions. If they don’t, check them

for silicon or other contaminants from fuel or use of

improper RTV sealant. The sensors may have a

white powdery coating.

Silicon contamination causes a high but false

HO2S signal voltage (rich exhaust indication).

The PCM will then reduce the amount of fuel

delivered to the engine, causing a severe

driveability problem. For more information, refer

to

Powertrain Control Module (PCM) and Sensors.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 5

51. Check the fuel pressure. Refer to Fuel System

Pressure Test.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 6

6Observe the TP angle display on Tech 2 while slowly

increasing throttle pedal.

Does the TP angle display steadily increase from 0% at

closed throttle to 100% at WOT?

—Go to Step 7Go to Step 18

7Monitor the long term fuel trim on Tech 2.

Is the long term fuel trim significantly in the negative

range (rich condition)?

—Go to Step 8Go to Step 9

81. Check items that can cause the engine to run rich.

Refer to

Diagnostic Aids in DTC P0172 Diagnostic

Support

.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 10

91. Check items that can cause the engine to run lean.

Refer to

Diagnostic Aids in DTC P0171 Diagnostic

Support

.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 10

Page 1405 of 6000

6E–288

ENGINE DRIVEABILITY AND EMISSIONS

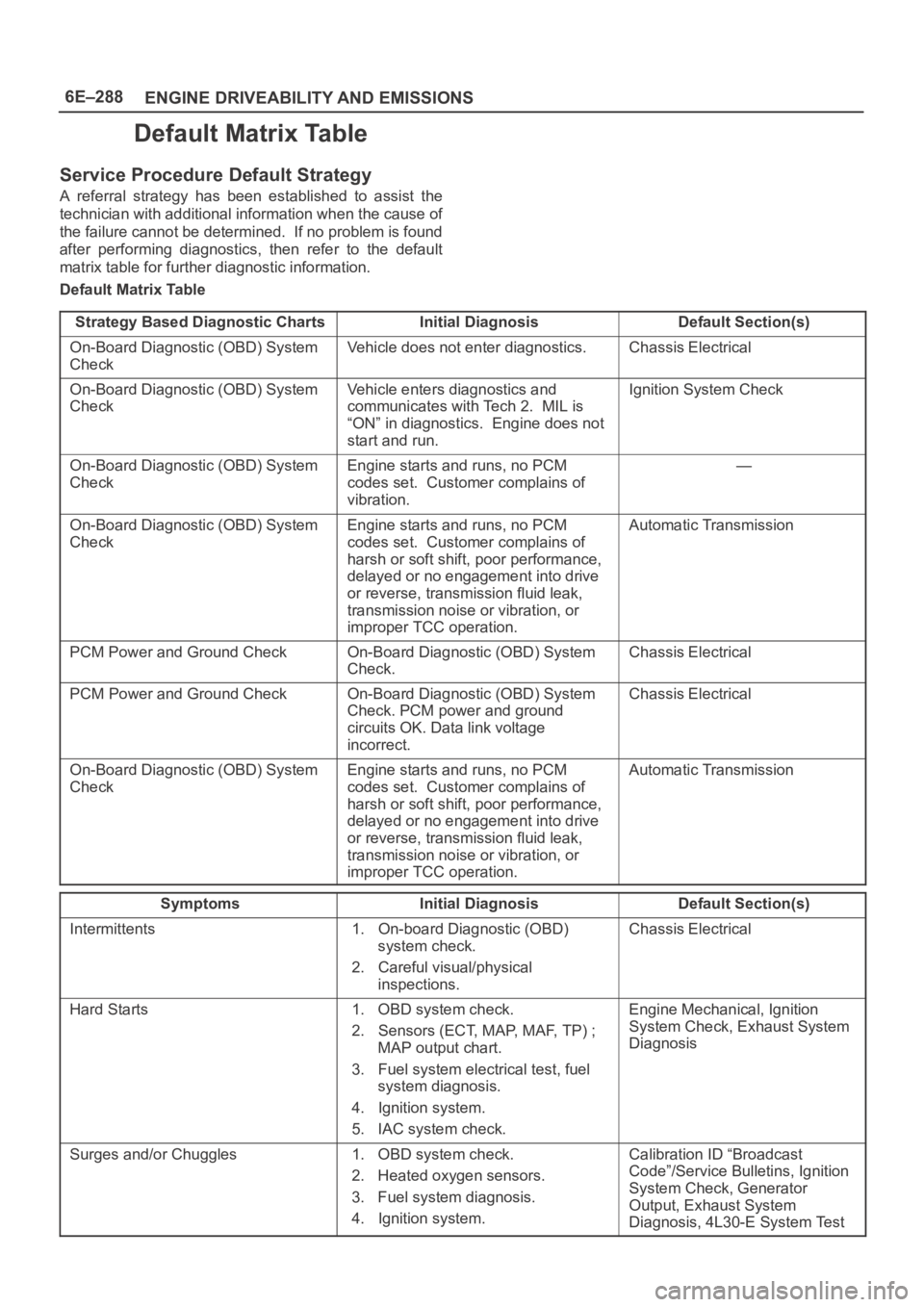

Default Matrix Table

Service Procedure Default Strategy

A referral strategy has been established to assist the

technician with additional information when the cause of

the failure cannot be determined. If no problem is found

after performing diagnostics, then refer to the default

matrix table for further diagnostic information.

Default Matrix Table

Strategy Based Diagnostic Charts

Initial DiagnosisDefault Section(s)

On-Board Diagnostic (OBD) System

CheckVehicle does not enter diagnostics.Chassis Electrical

On-Board Diagnostic (OBD) System

CheckVehicle enters diagnostics and

communicates with Tech 2. MIL is

“ON” in diagnostics. Engine does not

start and run.Ignition System Check

On-Board Diagnostic (OBD) System

CheckEngine starts and runs, no PCM

codes set. Customer complains of

vibration.—

On-Board Diagnostic (OBD) System

CheckEngine starts and runs, no PCM

codes set. Customer complains of

harsh or soft shift, poor performance,

delayed or no engagement into drive

or reverse, transmission fluid leak,

transmission noise or vibration, or

improper TCC operation.Automatic Transmission

PCM Power and Ground CheckOn-Board Diagnostic (OBD) System

Check.Chassis Electrical

PCM Power and Ground CheckOn-Board Diagnostic (OBD) System

Check. PCM power and ground

circuits OK. Data link voltage

incorrect.Chassis Electrical

On-Board Diagnostic (OBD) System

CheckEngine starts and runs, no PCM

codes set. Customer complains of

harsh or soft shift, poor performance,

delayed or no engagement into drive

or reverse, transmission fluid leak,

transmission noise or vibration, or

improper TCC operation.Automatic Transmission

SymptomsInitial DiagnosisDefault Section(s)

Intermittents1. On-board Diagnostic (OBD)

system check.

2. Careful visual/physical

inspections.Chassis Electrical

Hard Starts1. OBD system check.

2. Sensors (ECT, MAP, MAF, TP) ;

MAP output chart.

3. Fuel system electrical test, fuel

system diagnosis.

4. Ignition system.

5. IAC system check.Engine Mechanical, Ignition

System Check, Exhaust System

Diagnosis

Surges and/or Chuggles1. OBD system check.

2. Heated oxygen sensors.

3. Fuel system diagnosis.

4. Ignition system.Calibration ID “Broadcast

Code”/Service Bulletins, Ignition

System Check, Generator

Output, Exhaust System

Diagnosis, 4L30-E System Test

Page 1406 of 6000

6E–289 ENGINE DRIVEABILITY AND EMISSIONS

Symptoms Default Section(s)Initial Diagnosis

Lack of Power, Sluggish or Spongy1. OBD system check.

2. Fuel system diagnosis.

3. Ignition system.

4. Knock sensor.

5. EGR operation.

6. EGR system check.Refer to Exhaust System in

Engine Exhaust, TCC Operation,

Calibration ID/Service Bulletins

Detonation/Spark Knock1. OBD system check.

2. Transmission range switch.

3. EGR operation.

4. EGR system check.

5. TCC operation.

6. Fuel system diagnosis.

7. Ignition system.

8. Knock sensor.TCC operation, Cooling System,

Ignition System Check,

Calibration ID/Service Bulletins

Hesitation, Sag, Stumble1. OBD system check.

2. TP.

3. MAP output check.

4. Fuel system diagnosis.

5. Fuel injector and fuel injector

balance test.

6. Ignition system.EGR Operation, EGR System

Check, Generator Output

Voltage (refer to

Chassis

Electrical

), Calibration ID/Service

Bulletins, Ignition System Check

Cuts Out, Misses1. OBD system check.

2. Cylinder balance test.Ignition System Check

Rough, Unstable, or Incorrect Idle,

Stalling1. OBD system check.

2. Fuel injector and fuel injector

balance test.

3. Ignition system.

4. IAC operation.

5. EGR operation.MAP Output Check, Throttle

Linkage, IAC System Check,

EGR System Check, A/C Clutch

Control Circuit Diagnosis,

Crankcase Ventilation System,

Calibration ID/Service Bulletins,

Generator Output Voltage (refer

to

Chassis Electrical), Exhaust

Diagnosis

Poor Fuel Economy1. OBD system check.

2. Careful visual/physical inspection.

3. Ignition system.

4. Cooling system.TCC Operation, Exhaust System

(refer to

Engine Exhaust)

Engine Cranks But Will Not Run1. OBD system check.Fuel System Electrical

Diagnosis, Fuel System

Diagnosis, Fuel Injector and Fuel

Injector Balance Test.

Excessive Exhaust Emissions or

Odors1. OBD system check.

2. Emission test.

3. Cooling system.

4. Fuel system diagnosis.

5. Fuel injector and fuel injector

balance test.

6. Crankcase ventilation system.

7. Ignition system.

8. MAP output check.EGR System Check, Exhaust

Diagnosis, Calibration ID/Service

Bulletins

Dieseling, Run-On1. OBD system check.

2. Careful visual/physical inspection.

3. Fuel system diagnosis.—

Page 1407 of 6000

6E–290

ENGINE DRIVEABILITY AND EMISSIONS

Symptoms Default Section(s)Initial Diagnosis

Backfire1. OBD system check.

2. Ignition system.

3. Fuel system diagnosis.

4. Fuel injector and fuel injector

balance test.

5. EGR operation, EGR system

check.Exhaust System Diagnosis,

Intake Casting Flash, Ignition

System Check

Catalyst Monitor1. OBD system check.

2. Careful visual/physical inspection.

3. Heated oxygen sensors.Exhaust System

Fuel Trim1. OBD system check.

2. Careful visual/physical inspection.

3. Fuel system diagnosis.

4. Heated oxygen sensors, MAF

sensors.Exhaust System Intake Air

System

Evaporative Emissions1. OBD system check.

2. Careful visual/physical inspection.

3. Fuel system diagnosis.—

Heated Oxygen Sensors1. OBD system check.

2. Careful visual/physical inspection.Exhaust System

Page 1409 of 6000

6E–292

ENGINE DRIVEABILITY AND EMISSIONS

Crankshaft Position (CKP)

Sensor

Removal Procedure

1. Disconnect the negative battery cable.

2. Disconnect the electrical connector to the CKP

sensor.

3. Remove one bolt and the CKP sensor from the right

side of the engine block, just behind the mount.

NOTE: Use caution to avoid any hot oil that might drip

out.

TS22909

Inspection Procedure

1. Inspect the sensor O-ring for cracks or leaks.

2. Replace the O-ring if it is worn or damaged.

3. Lubricate the new O-ring with engine oil.

4. Install the lubricated O-ring.

Installation Procedure

1. Install the CKP sensor in the engine block.

2. Install the CKP sensor mounting bolt.

Tighten

Tighten the mounting bolt to 9 Nꞏm (78 lb in.).

TS22909

3. Connect the electrical connector to the CKP sensor.

4. Connect the negative battery cable.

Engine Coolant Temperature

(ECT) Sensor

Removal Procedure

NOTE: Care must be taken when handling the engine

coolant temperature (ECT) sensor. Damage to the ECT

sensor will affect proper operation of the fuel injection

system.

1. Disconnect the negative battery cable.

2. Drain the radiator coolant. Refer to

Draining and

Refilling Cooling System

in Engine Cooling.

3. Disconnect the electrical connector.

014RW127