lock OPEL GRANDLAND X 2019.75 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2019.75, Model line: GRANDLAND X, Model: OPEL GRANDLAND X 2019.75Pages: 273, PDF Size: 7.85 MB

Page 197 of 273

Driving and operating195Insert the tensioned coupling ball bar

in the opening and push firmly

upwards until it audibly engages.

The rotary handle snaps back into its

original position resting against the

coupling ball bar without a gap.9 Warning

Do not touch rotary handle during

insertion.

Lock the coupling ball bar by turning

the key to position e. Remove the key

and close the protective flap.

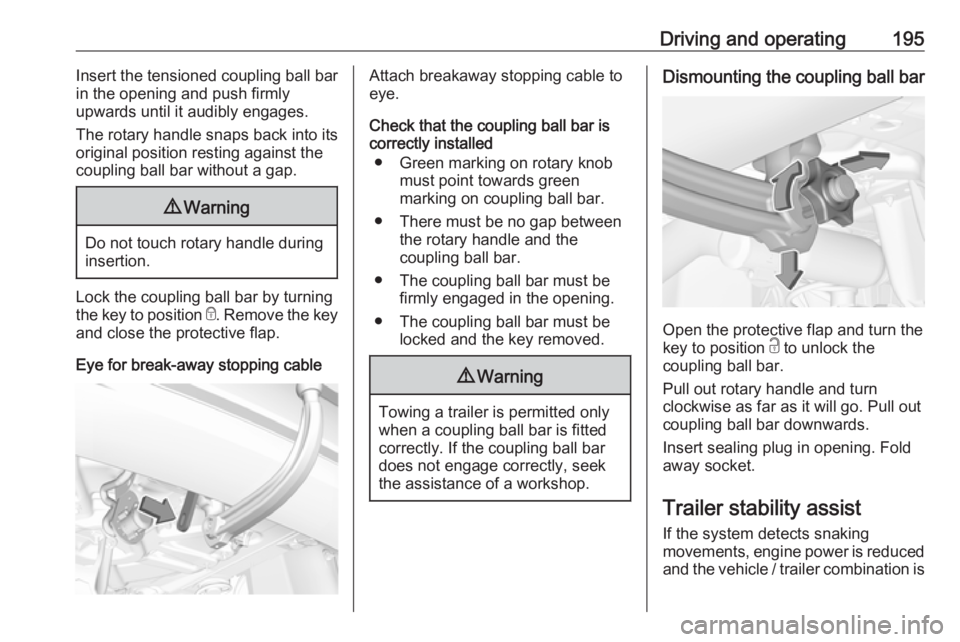

Eye for break-away stopping cable

Attach breakaway stopping cable to

eye.

Check that the coupling ball bar is correctly installed

● Green marking on rotary knob must point towards green

marking on coupling ball bar.

● There must be no gap between the rotary handle and the

coupling ball bar.

● The coupling ball bar must be firmly engaged in the opening.

● The coupling ball bar must be locked and the key removed.9Warning

Towing a trailer is permitted only

when a coupling ball bar is fitted correctly. If the coupling ball bardoes not engage correctly, seekthe assistance of a workshop.

Dismounting the coupling ball bar

Open the protective flap and turn the

key to position c to unlock the

coupling ball bar.

Pull out rotary handle and turn

clockwise as far as it will go. Pull out coupling ball bar downwards.

Insert sealing plug in opening. Fold away socket.

Trailer stability assist

If the system detects snaking

movements, engine power is reduced

and the vehicle / trailer combination is

Page 201 of 273

Vehicle care199Vehicle storageStorage for a long period of time

If the vehicle is to be stored for several months:

● Wash and wax the vehicle.

● Have the wax in the engine compartment and underbody

checked.

● Clean and preserve the rubber seals.

● Fill up fuel tank completely.

● Change the engine oil.

● Drain the washer fluid reservoir.

● Check the coolant antifreeze and

corrosion protection.

● Adjust tyre pressure to the value specified for full load.

● Park the vehicle in a dry, well ventilated place. Engage first or

reverse gear or set selector lever

to P. Prevent the vehicle from

rolling.

● Do not apply the parking brake.● Open the bonnet, close all doors and lock the vehicle.

● Disconnect the clamp from the negative terminal of the vehicle

battery. Note that all systems are

not functional, e.g. anti-theft

alarm system.

Putting back into operation

When the vehicle is to be put back into

operation:

● Connect the clamp to the negative terminal of the vehicle

battery. Initialize the power

windows 3 40.

● Check tyre pressure.

● Fill up the washer fluid reservoir.

● Check the engine oil level.

● Check the coolant level.

● Fit the number plate if necessary.End-of-life vehicle recovery

Information on end-of-life vehicle

recovery centres and the recycling of

end-of-life vehicles is available on our website, where legally required. Only

entrust this work to an authorised

recycling centre.

Page 211 of 273

Vehicle care209

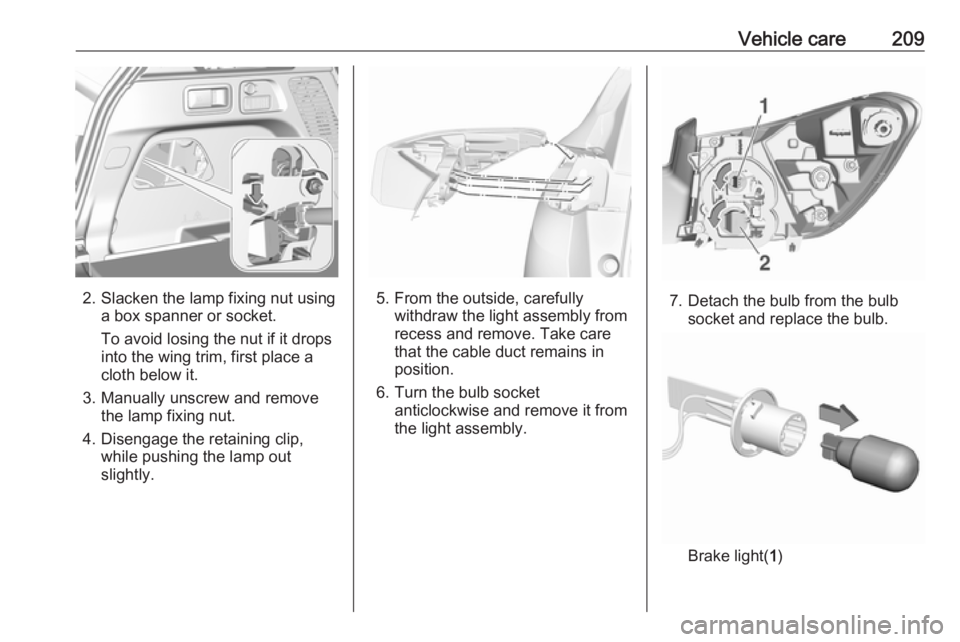

2. Slacken the lamp fixing nut usinga box spanner or socket.

To avoid losing the nut if it drops

into the wing trim, first place a

cloth below it.

3. Manually unscrew and remove the lamp fixing nut.

4. Disengage the retaining clip, while pushing the lamp out

slightly.5. From the outside, carefully withdraw the light assembly from

recess and remove. Take care

that the cable duct remains in

position.

6. Turn the bulb socket anticlockwise and remove it from

the light assembly.7. Detach the bulb from the bulb socket and replace the bulb.

Brake light( 1)

Page 212 of 273

210Vehicle care

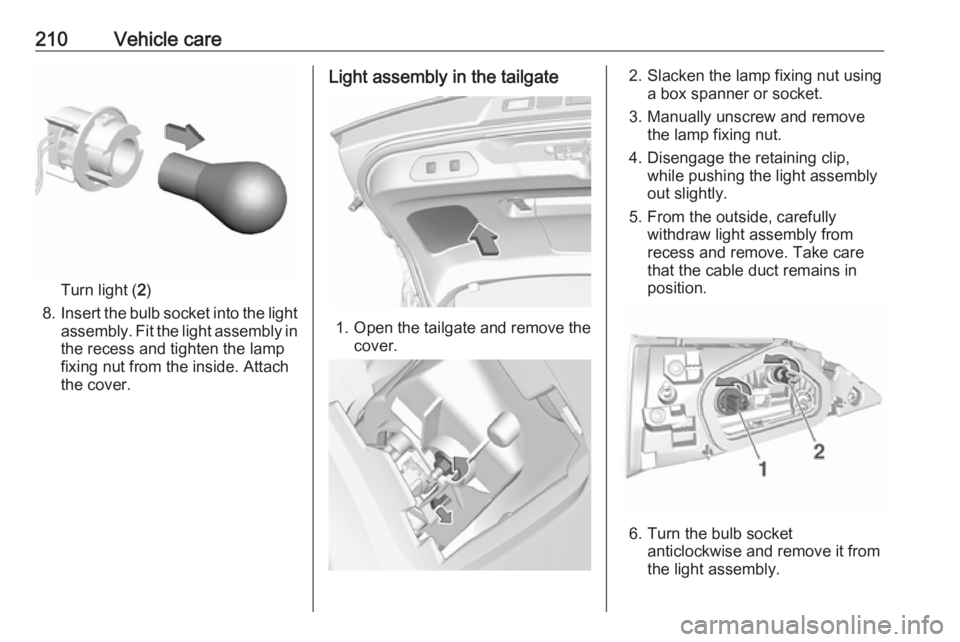

Turn light (2)

8. Insert the bulb socket into the light

assembly. Fit the light assembly in the recess and tighten the lamp

fixing nut from the inside. Attach

the cover.

Light assembly in the tailgate

1. Open the tailgate and remove the

cover.

2. Slacken the lamp fixing nut using a box spanner or socket.

3. Manually unscrew and remove the lamp fixing nut.

4. Disengage the retaining clip, while pushing the light assembly

out slightly.

5. From the outside, carefully withdraw light assembly from

recess and remove. Take care

that the cable duct remains in

position.

6. Turn the bulb socket anticlockwise and remove it from

the light assembly.

Page 214 of 273

212Vehicle care

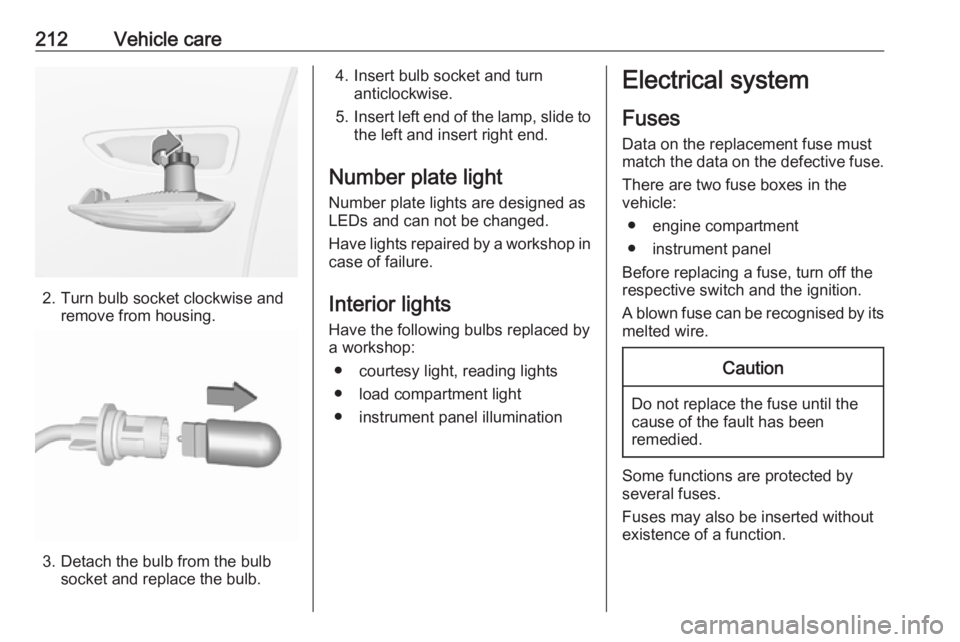

2. Turn bulb socket clockwise andremove from housing.

3. Detach the bulb from the bulbsocket and replace the bulb.

4. Insert bulb socket and turnanticlockwise.

5. Insert left end of the lamp, slide to

the left and insert right end.

Number plate light Number plate lights are designed as

LEDs and can not be changed.

Have lights repaired by a workshop in

case of failure.

Interior lightsHave the following bulbs replaced by

a workshop:

● courtesy light, reading lights

● load compartment light

● instrument panel illuminationElectrical system

Fuses Data on the replacement fuse must

match the data on the defective fuse.

There are two fuse boxes in the

vehicle:

● engine compartment

● instrument panel

Before replacing a fuse, turn off the

respective switch and the ignition.

A blown fuse can be recognised by its melted wire.Caution

Do not replace the fuse until the

cause of the fault has been

remedied.

Some functions are protected by

several fuses.

Fuses may also be inserted without

existence of a function.

Page 216 of 273

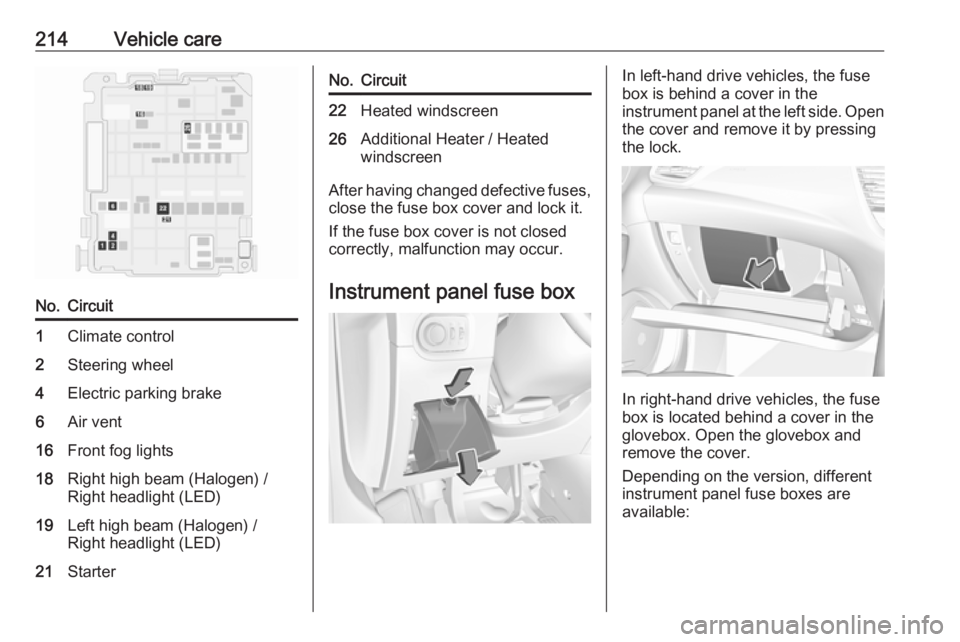

214Vehicle careNo.Circuit1Climate control2Steering wheel4Electric parking brake6Air vent16Front fog lights18Right high beam (Halogen) /

Right headlight (LED)19Left high beam (Halogen) /

Right headlight (LED)21StarterNo.Circuit22Heated windscreen26Additional Heater / Heated

windscreen

After having changed defective fuses,

close the fuse box cover and lock it.

If the fuse box cover is not closed

correctly, malfunction may occur.

Instrument panel fuse box

In left-hand drive vehicles, the fuse

box is behind a cover in the

instrument panel at the left side. Open

the cover and remove it by pressing

the lock.

In right-hand drive vehicles, the fuse

box is located behind a cover in the

glovebox. Open the glovebox and

remove the cover.

Depending on the version, different

instrument panel fuse boxes are

available:

Page 217 of 273

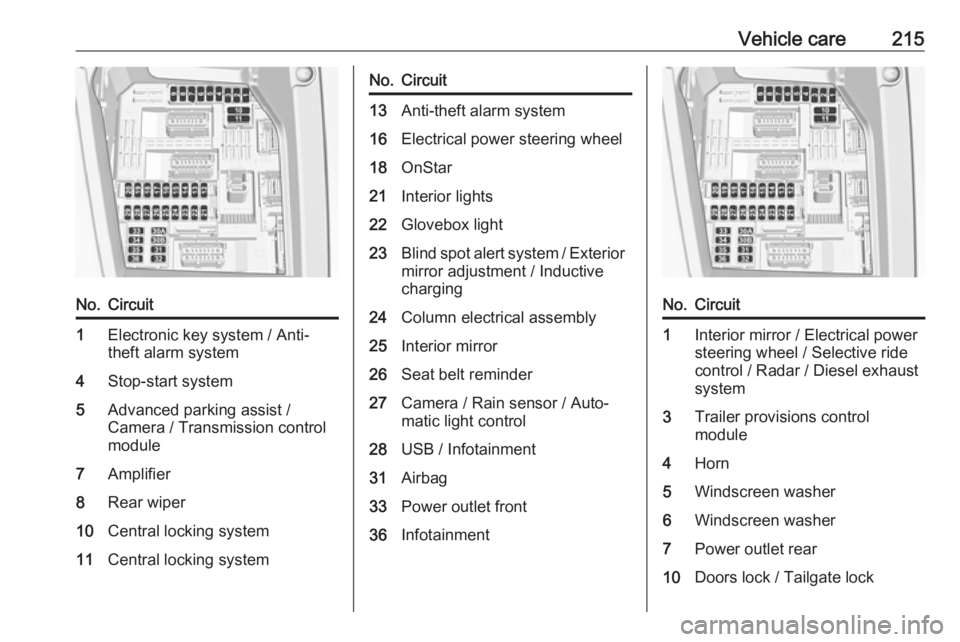

Vehicle care215No.Circuit1Electronic key system / Anti-

theft alarm system4Stop-start system5Advanced parking assist /

Camera / Transmission control

module7Amplifier8Rear wiper10Central locking system11Central locking systemNo.Circuit13Anti-theft alarm system16Electrical power steering wheel18OnStar21Interior lights22Glovebox light23Blind spot alert system / Exterior

mirror adjustment / Inductive

charging24Column electrical assembly25Interior mirror26Seat belt reminder27Camera / Rain sensor / Auto‐

matic light control28USB / Infotainment31Airbag33Power outlet front36InfotainmentNo.Circuit1Interior mirror / Electrical power

steering wheel / Selective ride

control / Radar / Diesel exhaust

system3Trailer provisions control

module4Horn5Windscreen washer6Windscreen washer7Power outlet rear10Doors lock / Tailgate lock

Page 218 of 273

216Vehicle careNo.Circuit11Doors lock / Tailgate lock12Stop-start system / Diagnostic

connector module / Brake

system13Infotainment / Climate control

system14Alarm siren15Climate control system16Stop-start system / Brake

system17Instrument cluster19Column electrical assembly /

Steering wheel controls21Anti-theft alarm system22Camera / Rain sensor / Auto‐

matic light control23Seat belt reminder24Automatic transmission /

Advanced parking assist /

Panoramic view systemNo.Circuit25Airbag26Electronic Stability Control27Alarm28OnStar29Infotainment32Cigarette lighter / Power outlet front34Heated rear window / Heated

windscreen / Inductive charging35Light switch / Diagnostic

connector module36LightingVehicle tools

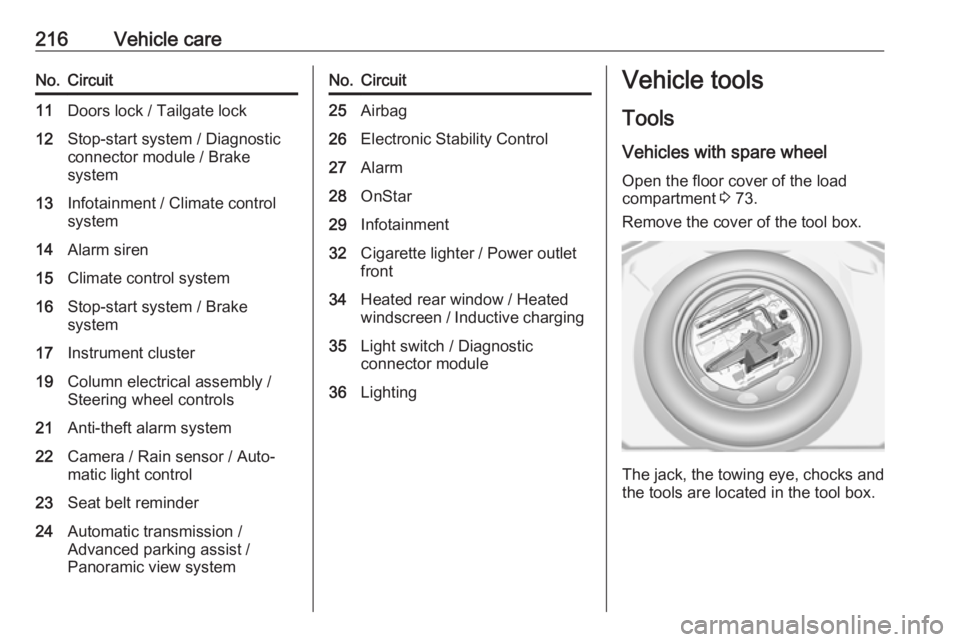

Tools

Vehicles with spare wheel Open the floor cover of the load

compartment 3 73.

Remove the cover of the tool box.

The jack, the towing eye, chocks and

the tools are located in the tool box.

Page 223 of 273

Vehicle care221Tyres age, even if they are not used.

We recommend tyre replacement

every 6 years.

Changing tyre and wheel size

If tyres of a different size than those

fitted at the factory are used, it may be necessary to reprogramme the tyre

deflation detection system and make

other vehicle modifications.

Tyre deflation detection system

3 219.

Have the label with tyre pressures

replaced.9 Warning

The use of unsuitable tyres or

wheels may lead to accidents and will invalidate the vehicle

operating permit.

Wheel covers

Wheel covers and tyres that are

factory approved for the respective

vehicle and comply with all of the

relevant wheel and tyre combination

requirements must be used.

If the wheel covers and tyres used are

not factory approved, the tyres must

not have a rim protection ridge.

Wheel covers must not impair brake

cooling.9 Warning

Use of unsuitable tyres or wheel

covers could lead to sudden

pressure loss and thereby

accidents.

Vehicles with steel wheels: When

using locking wheel nuts, do not

attach wheel covers.

Tyre chains

Tyre chains are only permitted on the

front wheels.

Always use fine mesh chains that add no more than 9 mm to the tyre tread

and the inboard sides (including chain

lock).

9 Warning

Damage may lead to tyre blowout.

Tyre chains are permitted on tyres of

size 215/70R16, 215/65 R17,

225/55 R18 and 205/55 R19.

Page 230 of 273

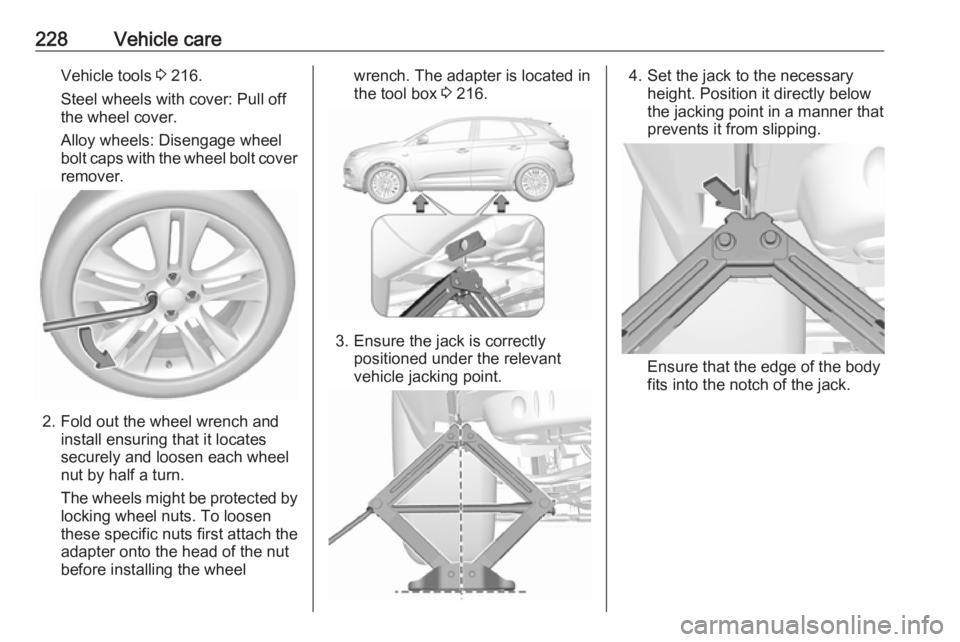

228Vehicle careVehicle tools 3 216.

Steel wheels with cover: Pull off

the wheel cover.

Alloy wheels: Disengage wheel

bolt caps with the wheel bolt cover

remover.

2. Fold out the wheel wrench and install ensuring that it locates

securely and loosen each wheel

nut by half a turn.

The wheels might be protected by

locking wheel nuts. To loosen

these specific nuts first attach the

adapter onto the head of the nut

before installing the wheel

wrench. The adapter is located in

the tool box 3 216.

3. Ensure the jack is correctly

positioned under the relevant

vehicle jacking point.

4. Set the jack to the necessary height. Position it directly below

the jacking point in a manner that

prevents it from slipping.

Ensure that the edge of the body

fits into the notch of the jack.