automatic transmission OPEL GT-R 1973 Owner's Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 405 of 625

causes the sprags to wedge and prevent rotation in

one direction, and to allow free rotation in the oppo-

site direction.7C. 441973 OPEL SERVICE MANUAL

The clutch is released by exhausting the oil from

behind the piston. The release springs push the pis-

ton to the released position, thereby removing the

force from the plates. See Figure 7C-16.Band

A band is used to hold one planetary member sta-

tionary with relation to the other planetary mem-

bers.

!See Figure 7C-19. The band is connected to the

SPR

7C-16Figure

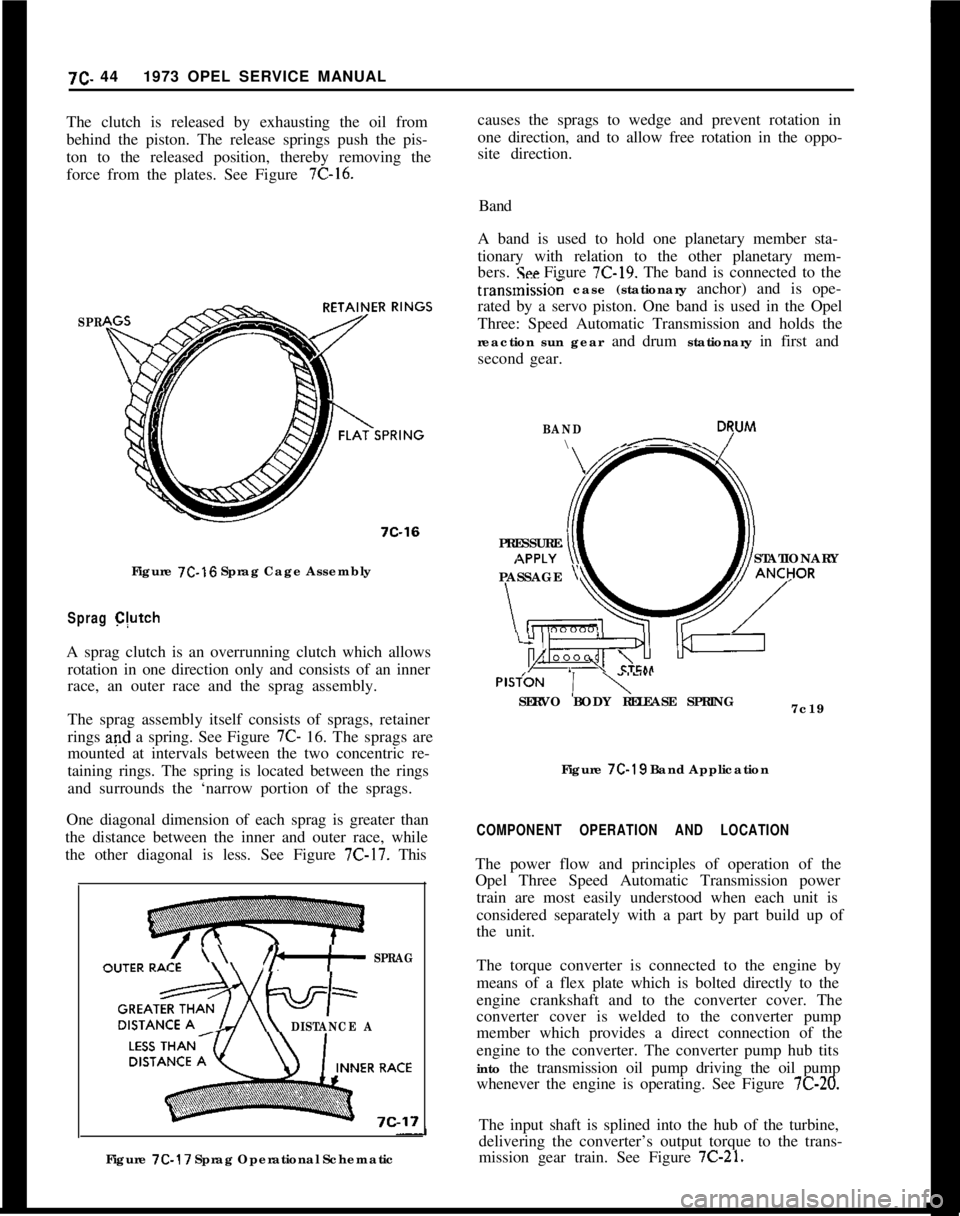

7C-16 Sprag Cage Assembly

Sprag C(utchA sprag clutch is an overrunning clutch which allows

rotation in one direction only and consists of an inner

race, an outer race and the sprag assembly.

The sprag assembly itself consists of sprags, retainer

rings and a spring. See Figure 7C- 16. The sprags are

mounted at intervals between the two concentric re-

taining rings. The spring is located between the rings

and surrounds the ‘narrow portion of the sprags.

One diagonal dimension of each sprag is greater than

the distance between the inner and outer race, while

the other diagonal is less. See Figure

7C-17. This

\ \I’b+ SPRAG

DISTANCE AFigure

7C-17 Sprag Operational Schematictransmissio; case (stationary anchor) and is ope-

rated by a servo piston. One band is used in the Opel

Three: Speed Automatic Transmission and holds the

reaction sun gear and drum stationary in first and

second gear.

BAND\- D7uM

PRESSURE

STATIONARY

PASSAGE

yPlSfON

1 y””SERVO BODY RELEASE SPRING

7c19

Figure

7C-19 Band Application

COMPONENT OPERATION AND LOCATIONThe power flow and principles of operation of the

Opel Three Speed Automatic Transmission power

train are most easily understood when each unit is

considered separately with a part by part build up of

the unit.

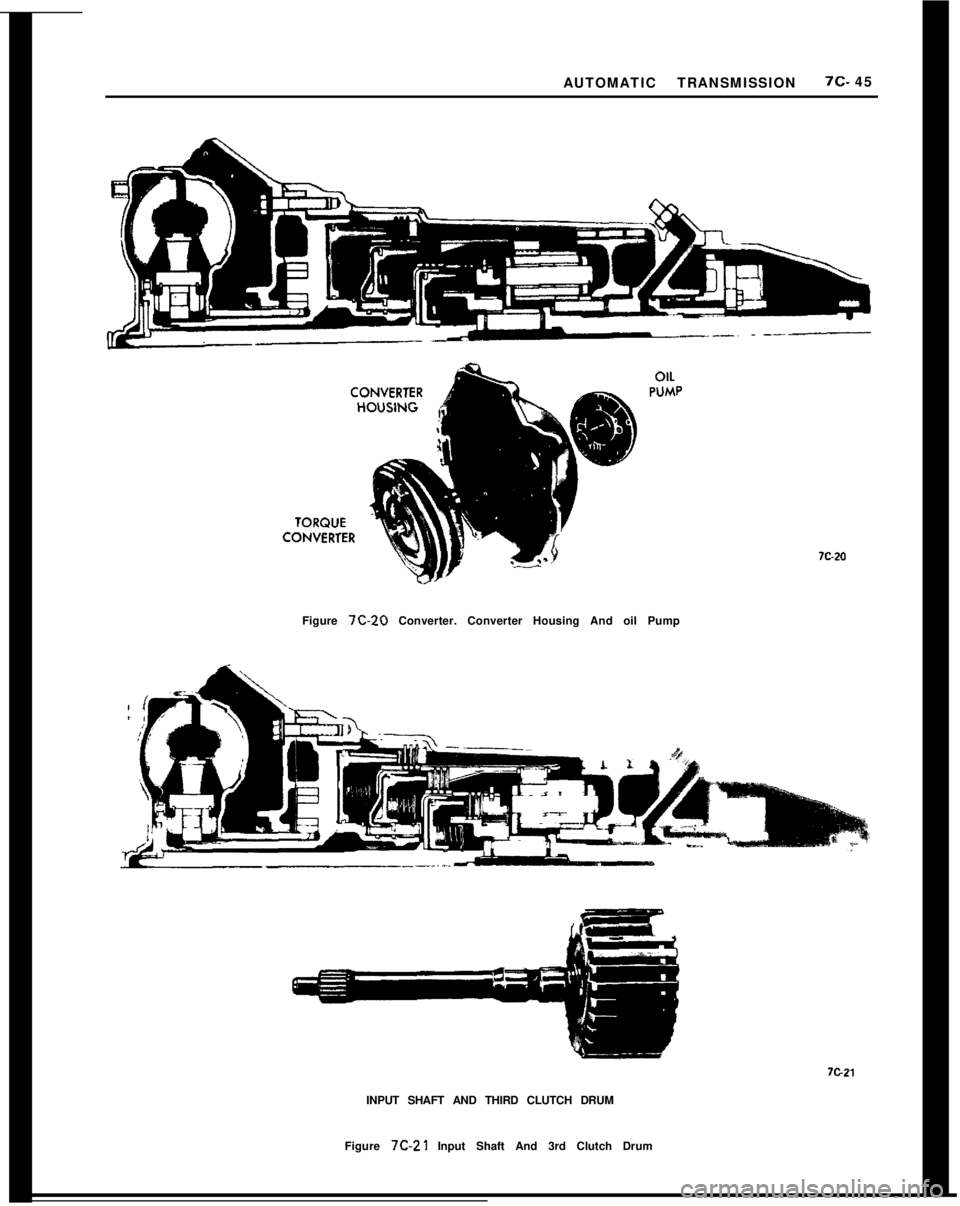

The torque converter is connected to the engine by

means of a flex plate which is bolted directly to the

engine crankshaft and to the converter cover. The

converter cover is welded to the converter pump

member which provides a direct connection of the

engine to the converter. The converter pump hub tits

into the transmission oil pump driving the oil pump

whenever the engine is operating. See Figure

7C-20.The input shaft is splined into the hub of the turbine,

delivering the converter’s output torque to the trans-

mission gear train. See Figure

7C-21.

Page 406 of 625

AUTOMATIC TRANSMISSION7c- 45

Figure 7C-20 Converter. Converter Housing And oil Pump

INPUT SHAFT AND THIRD CLUTCH DRUM

Figure 7C-21 Input Shaft And 3rd Clutch Drum

Page 408 of 625

AUTOMATIC TRANSMISSION7c- 47

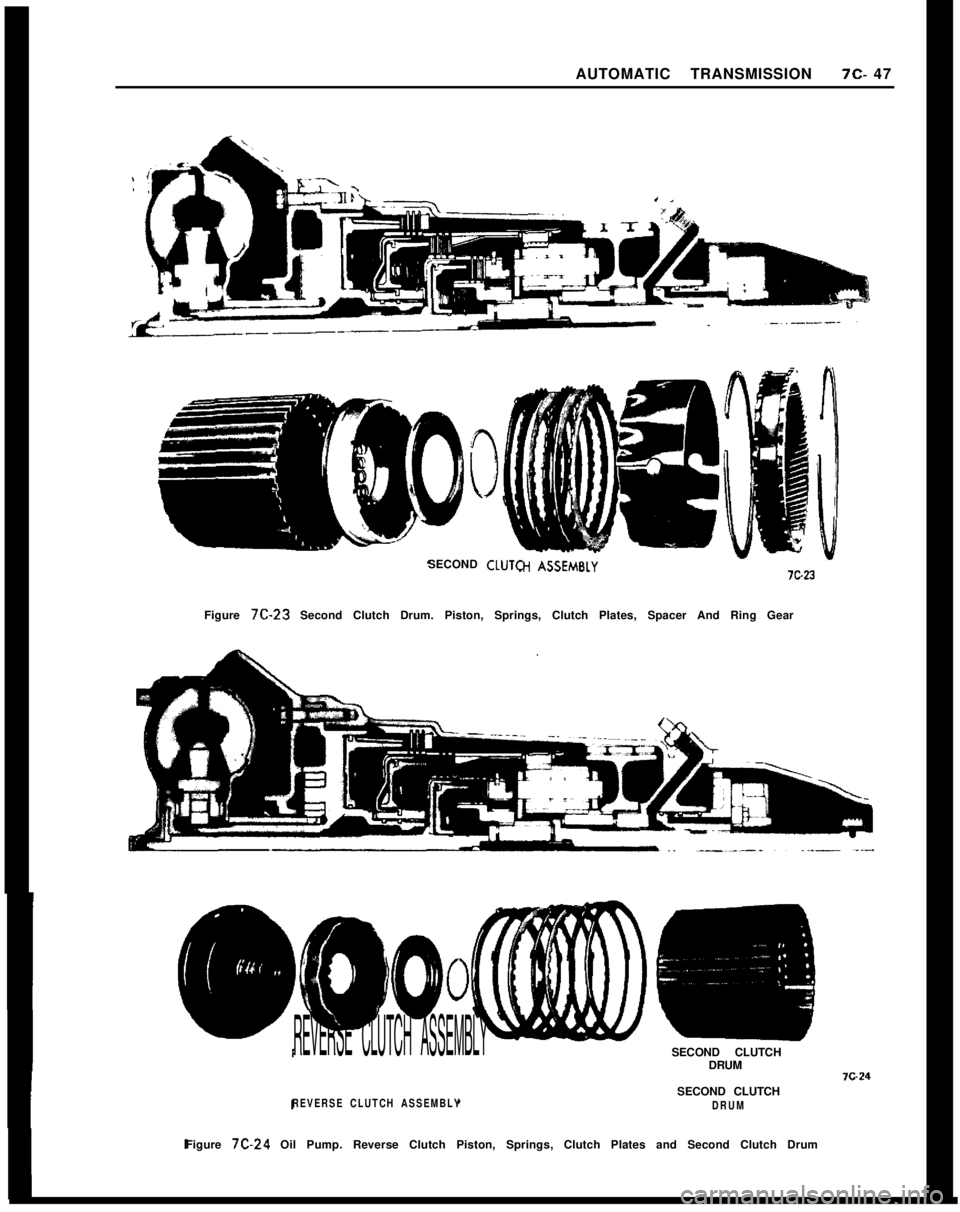

SECOND CtUTC7cz3

Figure 7C.23 Second Clutch Drum. Piston, Springs, Clutch Plates, Spacer And Ring Gear

REVERSE CLUTCH ASSEMBLYSECOND CLUTCH

DRUM

SECOND CLUTCH

REVERSE CLUTCH ASSEMBLY

DRUMFigure 7C-24 Oil Pump. Reverse Clutch Piston, Springs, Clutch Plates and Second Clutch Drum

Page 409 of 625

7C- 481973 OPEL SERVICE MANUAL

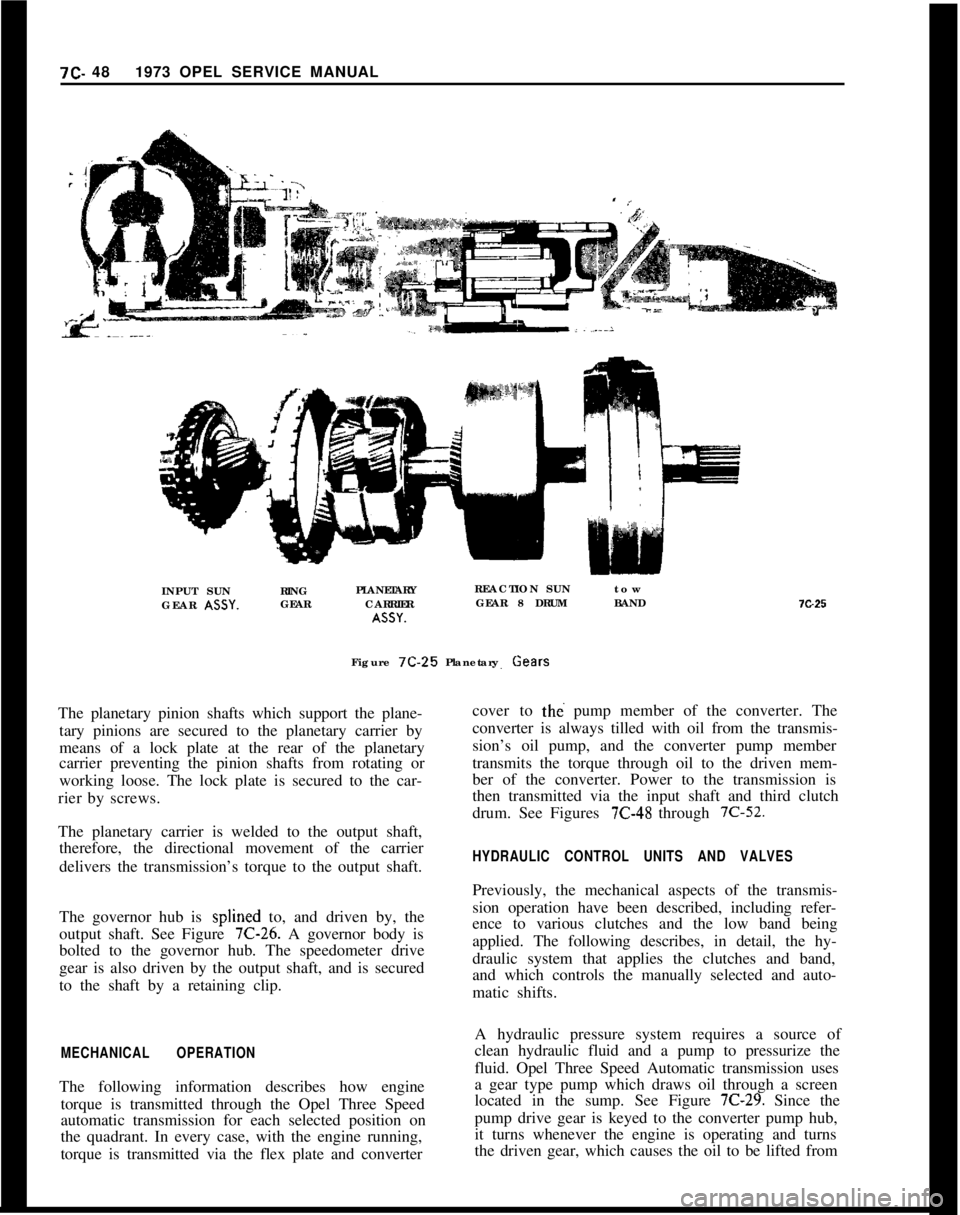

INPUT SUNRING

GEAR ASSY.GEARPLANETARY

CARRIERASSY.REACTION SUNtow

GEAR 8 DRUMBAND

Figure 7C-25Planetary Gears

The planetary pinion shafts which support the plane-

tary pinions are secured to the planetary carrier by

means of a lock plate at the rear of the planetary

carrier preventing the pinion shafts from rotating or

working loose. The lock plate is secured to the car-

rier by screws.

The planetary carrier is welded to the output shaft,

therefore, the directional movement of the carrier

delivers the transmission’s torque to the output shaft.

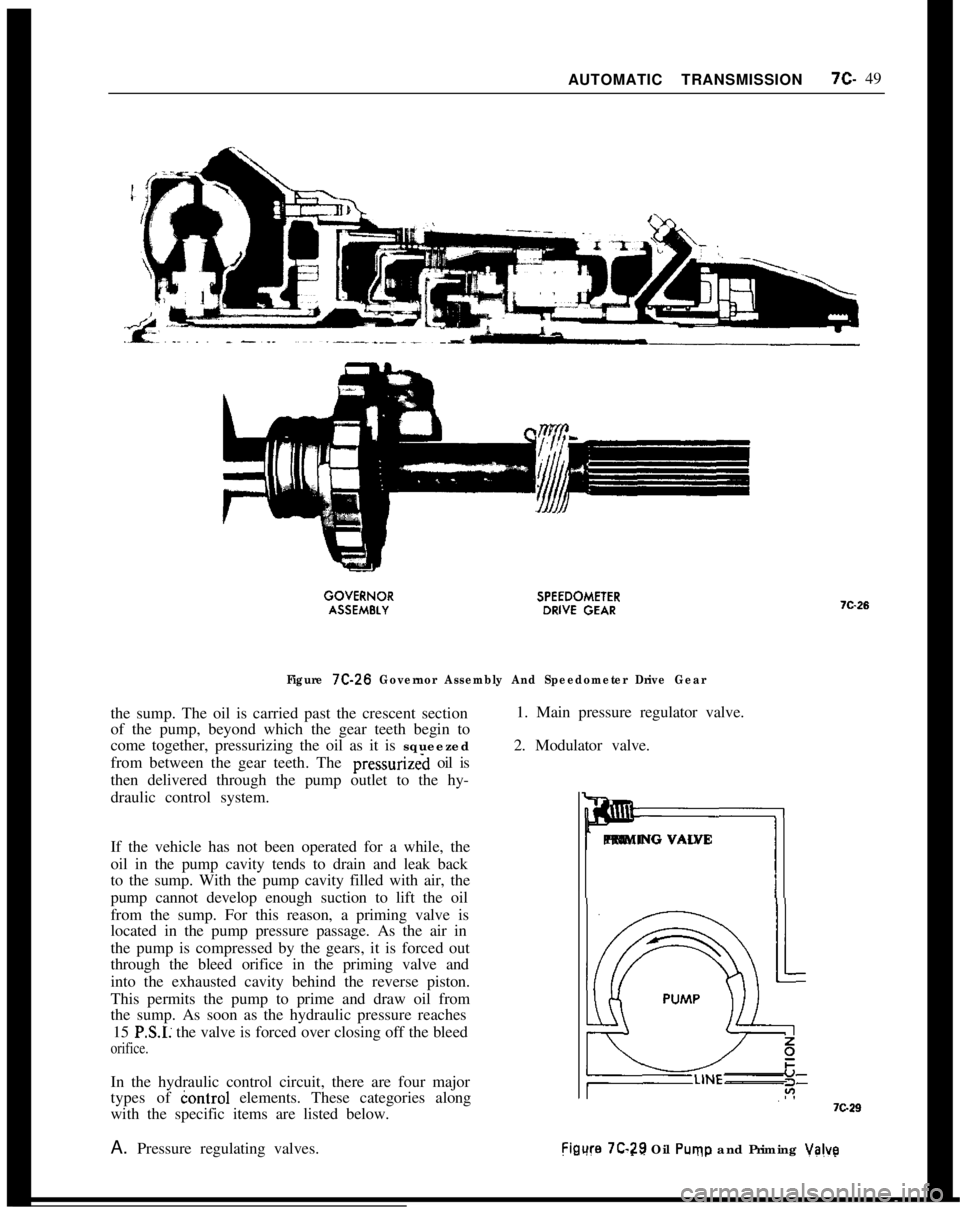

The governor hub is splined to, and driven by, the

output shaft. See Figure 7C-26. A governor body is

bolted to the governor hub. The speedometer drive

gear is also driven by the output shaft, and is secured

to the shaft by a retaining clip.

MECHANICAL OPERATIONThe following information describes how engine

torque is transmitted through the Opel Three Speed

automatic transmission for each selected position on

the quadrant. In every case, with the engine running,

torque is transmitted via the flex plate and converter7G25

cover to

tht? pump member of the converter. The

converter is always tilled with oil from the transmis-

sion’s oil pump, and the converter pump member

transmits the torque through oil to the driven mem-

ber of the converter. Power to the transmission is

then transmitted via the input shaft and third clutch

drum. See Figures

7C-48 through 7C-52.

HYDRAULIC CONTROL UNITS AND VALVESPreviously, the mechanical aspects of the transmis-

sion operation have been described, including refer-

ence to various clutches and the low band being

applied. The following describes, in detail, the hy-

draulic system that applies the clutches and band,

and which controls the manually selected and auto-

matic shifts.

A hydraulic pressure system requires a source of

clean hydraulic fluid and a pump to pressurize the

fluid. Opel Three Speed Automatic transmission uses

a gear type pump which draws oil through a screen

located in the sump. See Figure

7C-29. Since the

pump drive gear is keyed to the converter pump hub,

it turns whenever the engine is operating and turns

the driven gear, which causes the oil to be lifted from

Page 410 of 625

AUTOMATIC TRANSMISSION7c- 49Figure 7C-26 Governor Assembly And Speedometer Drive Gearthe sump. The oil is carried past the crescent section

of the pump, beyond which the gear teeth begin to

come together, pressurizing the oil as it is squeezed

from between the gear teeth. The pressurizeh oil is

then delivered through the pump outlet to the hy-

draulic control system.1. Main pressure regulator valve.

2. Modulator valve.

mPRIMING VALVE

If the vehicle has not been operated for a while, the

oil in the pump cavity tends to drain and leak back

to the sump. With the pump cavity filled with air, the

pump cannot develop enough suction to lift the oil

from the sump. For this reason, a priming valve is

located in the pump pressure passage. As the air in

the pump is compressed by the gears, it is forced out

through the bleed orifice in the priming valve and

into the exhausted cavity behind the reverse piston.

This permits the pump to prime and draw oil from

the sump. As soon as the hydraulic pressure reaches

15

PSI: the valve is forced over closing off the bleed

orifice.PRIMING VALVE

In the hydraulic control circuit, there are four major

types of iontrol elements. These categories along

with the specific items are listed below.

A. Pressure regulating valves.

Fieure 7C-7.9 Oil Puvp and Priming Valve

Page 412 of 625

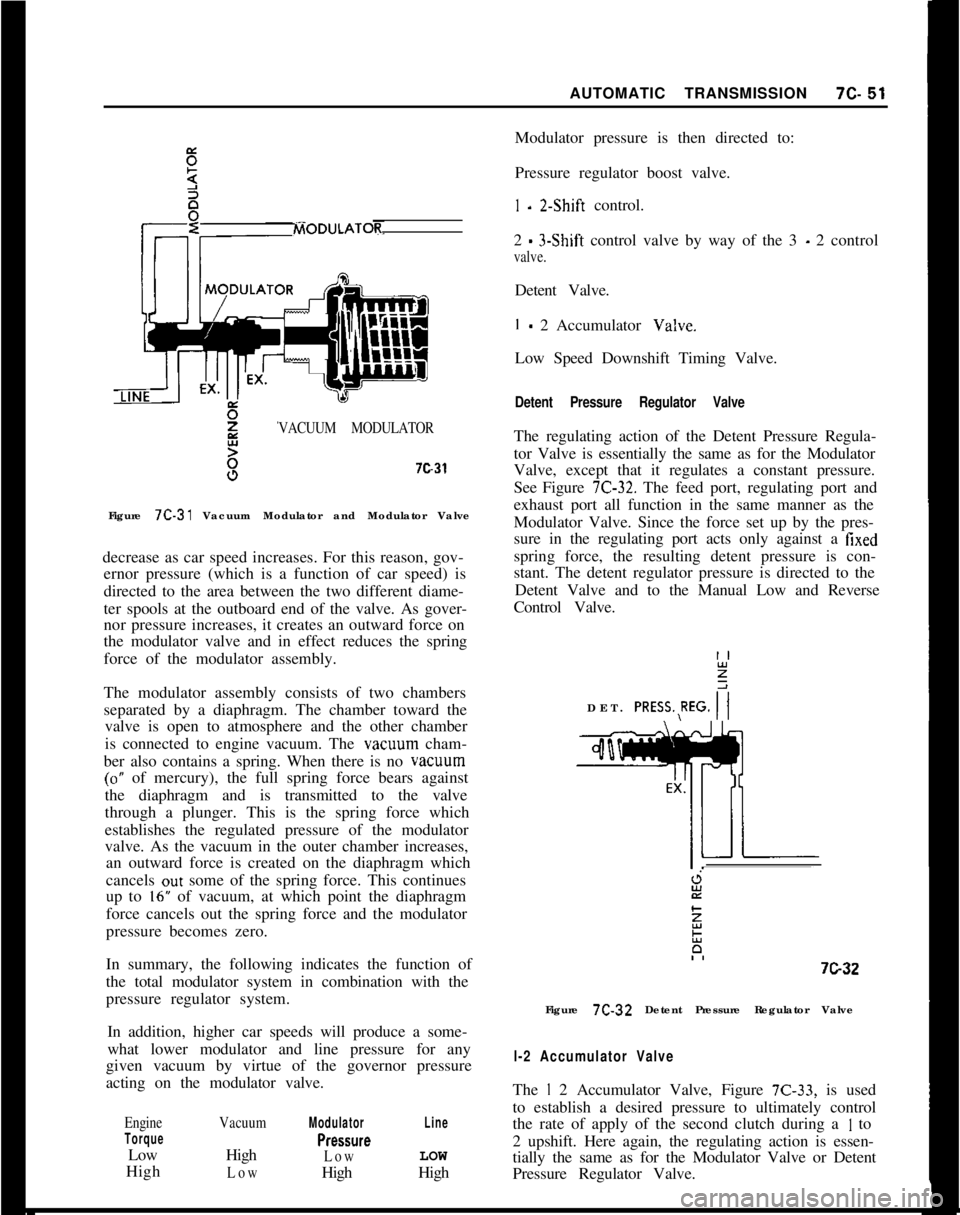

AUTOMATIC TRANSMISSION7c-51VACUUM MODULATOR7c31

Figure 7C-31 Vacuum Modulator and Modulator Valve

decrease as car speed increases. For this reason, gov-

ernor pressure (which is a function of car speed) is

directed to the area between the two different diame-

ter spools at the outboard end of the valve. As gover-

nor pressure increases, it creates an outward force on

the modulator valve and in effect reduces the spring

force of the modulator assembly.

The modulator assembly consists of two chambers

separated by a diaphragm. The chamber toward the

valve is open to atmosphere and the other chamber

is connected to engine vacuum. The vacwm cham-

ber also contains a spring. When there is no vacuum

(0” of mercury), the full spring force bears against

the diaphragm and is transmitted to the valve

through a plunger. This is the spring force which

establishes the regulated pressure of the modulator

valve. As the vacuum in the outer chamber increases,

an outward force is created on the diaphragm which

cancels out some of the spring force. This continues

up to

16” of vacuum, at which point the diaphragm

force cancels out the spring force and the modulator

pressure becomes zero.

In summary, the following indicates the function of

the total modulator system in combination with the

pressure regulator system.

In addition, higher car speeds will produce a some-

what lower modulator and line pressure for any

given vacuum by virtue of the governor pressure

acting on the modulator valve.

Engine

TorqueLow

High

VacuumHigh

Low

Modulator

PreSSWe

LowHigh

LineLOW

HighModulator pressure is then directed to:

Pressure regulator boost valve.

I - 2.Shift control.

2

- 3-Shift control valve by way of the 3 - 2 control

valve.Detent Valve.

I - 2 Accumulator Va!ve.

Low Speed Downshift Timing Valve.

Detent Pressure Regulator ValveThe regulating action of the Detent Pressure Regula-

tor Valve is essentially the same as for the Modulator

Valve, except that it regulates a constant pressure.

See Figure

7C-32. The feed port, regulating port and

exhaust port all function in the same manner as the

Modulator Valve. Since the force set up by the pres-

sure in the regulating port acts only against a

fixedspring force, the resulting detent pressure is con-

stant. The detent regulator pressure is directed to the

Detent Valve and to the Manual Low and Reverse

Control Valve.

DET. PRESS.,REG.

i7G3-2

Figure 7C-32 Detent Pressure Regulator Valve

l-2 Accumulator ValveThe

I 2 Accumulator Valve, Figure 7C-33, is used

to establish a desired pressure to ultimately control

the rate of apply of the second clutch during a

I to

2 upshift. Here again, the regulating action is essen-

tially the same as for the Modulator Valve or Detent

Pressure Regulator Valve.

Page 414 of 625

AUTOMATIC TRANSMISSIONlC- 53

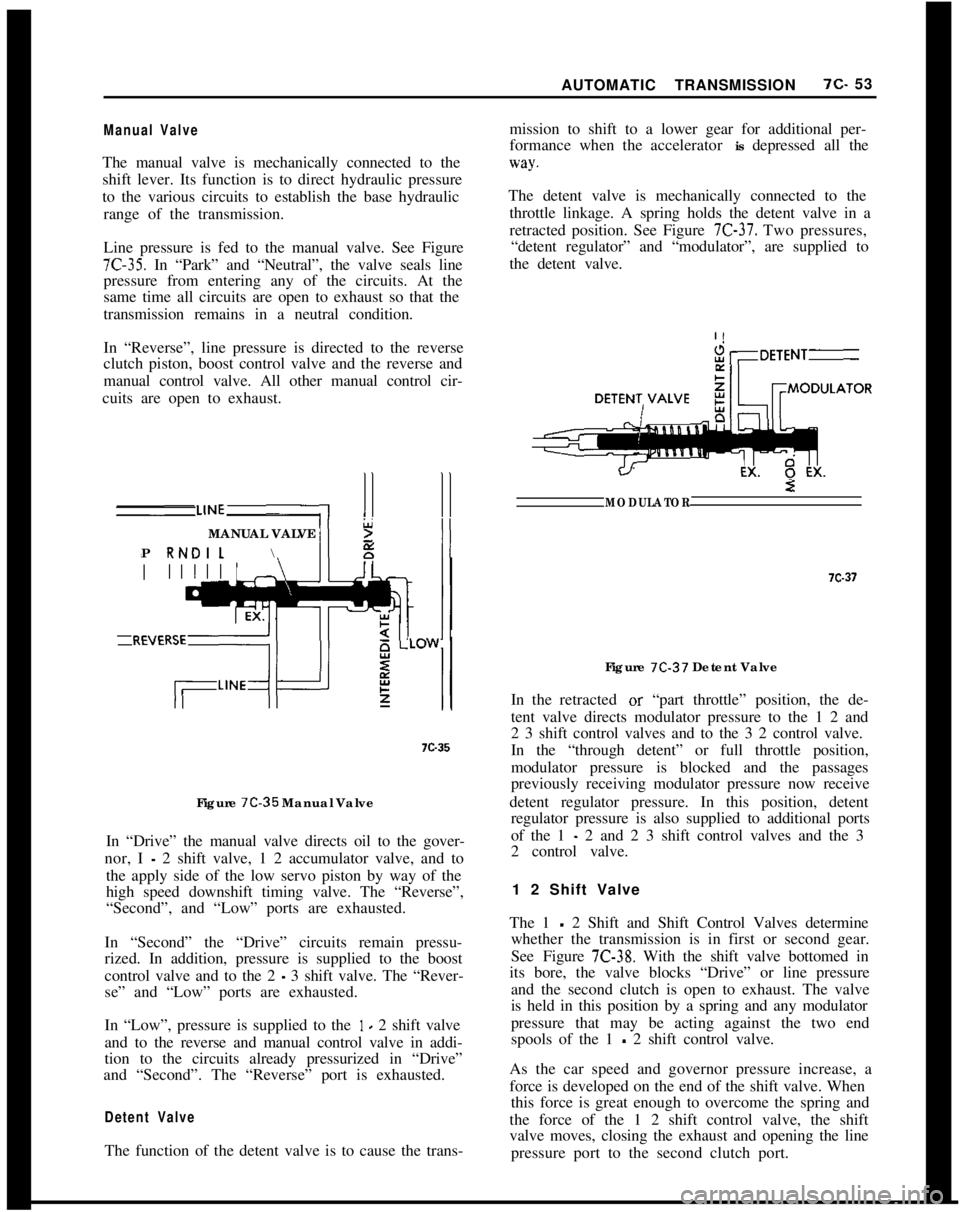

Manual ValveThe manual valve is mechanically connected to the

shift lever. Its function is to direct hydraulic pressure

to the various circuits to establish the base hydraulic

range of the transmission.

Line pressure is fed to the manual valve. See Figure

7C-35. In “Park” and “Neutral”, the valve seals line

pressure from entering any of the circuits. At the

same time all circuits are open to exhaust so that the

transmission remains in a neutral condition.

In “Reverse”, line pressure is directed to the reverse

clutch piston, boost control valve and the reverse and

manual control valve. All other manual control cir-

cuits are open to exhaust.

MANUAL VALVE

;i

\2

P RNDILII7D35

Figure

7C-35 Manual Valve

In “Drive” the manual valve directs oil to the gover-

nor, I

- 2 shift valve, 1 2 accumulator valve, and to

the apply side of the low servo piston by way of the

high speed downshift timing valve. The “Reverse”,

“Second”, and “Low” ports are exhausted.

In “Second” the “Drive” circuits remain pressu-

rized. In addition, pressure is supplied to the boost

control valve and to the 2

- 3 shift valve. The “Rever-

se” and “Low” ports are exhausted.

In “Low”, pressure is supplied to the

1 - 2 shift valve

and to the reverse and manual control valve in addi-

tion to the circuits already pressurized in “Drive”

and “Second”. The “Reverse” port is exhausted.

Detent ValveThe function of the detent valve is to cause the trans-mission to shift to a lower gear for additional per-

formance when the accelerator is depressed all the

way.The detent valve is mechanically connected to the

throttle linkage. A spring holds the detent valve in a

retracted position. See Figure

7C-37. Two pressures,

“detent regulator” and “modulator”, are supplied to

the detent valve.

iiiDETENTE2

MODULATORFigure

7C-37 Detent Valve

In the retracted or “part throttle” position, the de-

tent valve directs modulator pressure to the 1 2 and

2 3 shift control valves and to the 3 2 control valve.

In the “through detent” or full throttle position,

modulator pressure is blocked and the passages

previously receiving modulator pressure now receive

detent regulator pressure. In this position, detent

regulator pressure is also supplied to additional ports

of the 1

- 2 and 2 3 shift control valves and the 3

2 control valve.

1 2 Shift Valve

The 1

- 2 Shift and Shift Control Valves determine

whether the transmission is in first or second gear.

See Figure

7C-38. With the shift valve bottomed in

its bore, the valve blocks “Drive” or line pressure

and the second clutch is open to exhaust. The valve

is held in this position by a spring and any modulator

pressure that may be acting against the two end

spools of the 1

- 2 shift control valve.

As the car speed and governor pressure increase, a

force is developed on the end of the shift valve. When

this force is great enough to overcome the spring and

the force of the 1 2 shift control valve, the shift

valve moves, closing the exhaust and opening the line

pressure port to the second clutch port.

Page 416 of 625

AUTOMATIC TRANSMISSION7c- 55

valve will be held in downshifted, or second gear,

condition regardless of car speed.

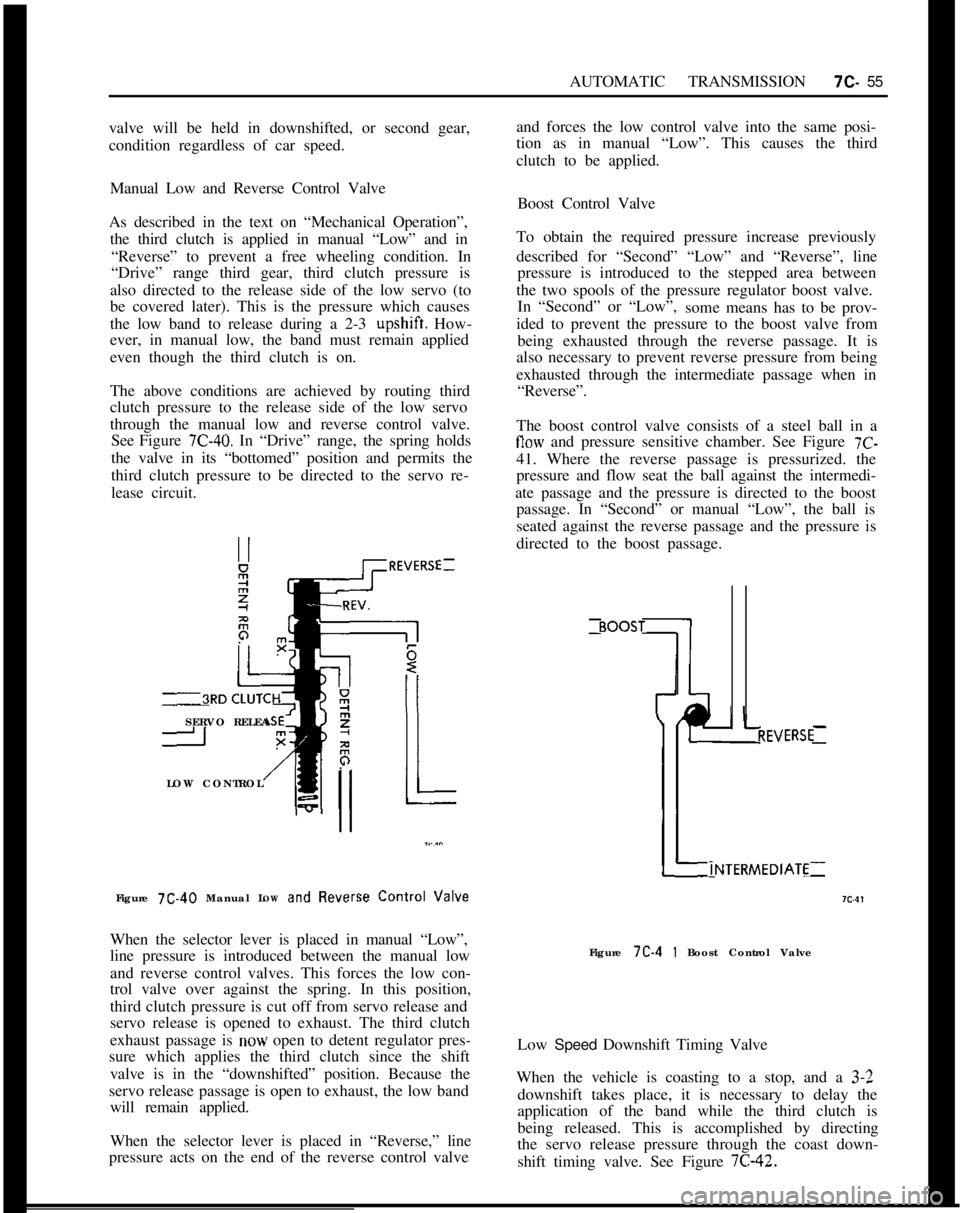

Manual Low and Reverse Control Valve

As described in the text on “Mechanical Operation”,

the third clutch is applied in manual “Low” and in

“Reverse” to prevent a free wheeling condition. In

“Drive” range third gear, third clutch pressure is

also directed to the release side of the low servo (to

be covered later). This is the pressure which causes

the low band to release during a 2-3 upshift. How-

ever, in manual low, the band must remain applied

even though the third clutch is on.

The above conditions are achieved by routing third

clutch pressure to the release side of the low servo

through the manual low and reverse control valve.

See Figure 7C-40. In “Drive” range, the spring holds

the valve in its “bottomed” position and permits the

third clutch pressure to be directed to the servo re-

lease circuit.

_~RDSERVO RELEA

ILOW CONTROL

Figure 7C-40 Manual LOW

and Ftever~e Control Valve

When the selector lever is placed in manual “Low”,

line pressure is introduced between the manual low

and reverse control valves. This forces the low con-

trol valve over against the spring. In this position,

third clutch pressure is cut off from servo release and

servo release is opened to exhaust. The third clutch

exhaust passage is now open to detent regulator pres-

sure which applies the third clutch since the shift

valve is in the “downshifted” position. Because the

servo release passage is open to exhaust, the low band

will remain applied.

When the selector lever is placed in “Reverse,” line

pressure acts on the end of the reverse control valveand forces the low control valve into the same posi-

tion as in manual “Low”. This causes the third

clutch to be applied.

Boost Control Valve

To obtain the required pressure increase previously

described for “Second” “Low” and “Reverse”, line

pressure is introduced to the stepped area between

the two spools of the pressure regulator boost valve.

In “Second” or “Low”,

some means has to be prov-

ided to prevent the pressure to the boost valve from

being exhausted through the reverse passage. It is

also necessary to prevent reverse pressure from being

exhausted through the intermediate passage when in

“Reverse”.

The boost control valve consists of a steel ball in a

flow and pressure sensitive chamber. See Figure 7C-41. Where the reverse passage is pressurized. the

pressure and flow seat the ball against the intermedi-

ate passage and the pressure is directed to the boost

passage. In “Second” or manual “Low”, the ball is

seated against the reverse passage and the pressure is

directed to the boost passage.

t-INTERMEDIATE

7c.4,

I I

REVERSE:Figure 7C-4

1 Boost Control Valve

Low Speed Downshift Timing Valve

When the vehicle is coasting to a stop, and a

3-2downshift takes place, it is necessary to delay the

application of the band while the third clutch is

being released. This is accomplished by directing

the servo release pressure through the coast down-

shift timing valve. See Figure 7C-42.

Page 418 of 625

AUTOMATIC TRANSMISSION7c-57

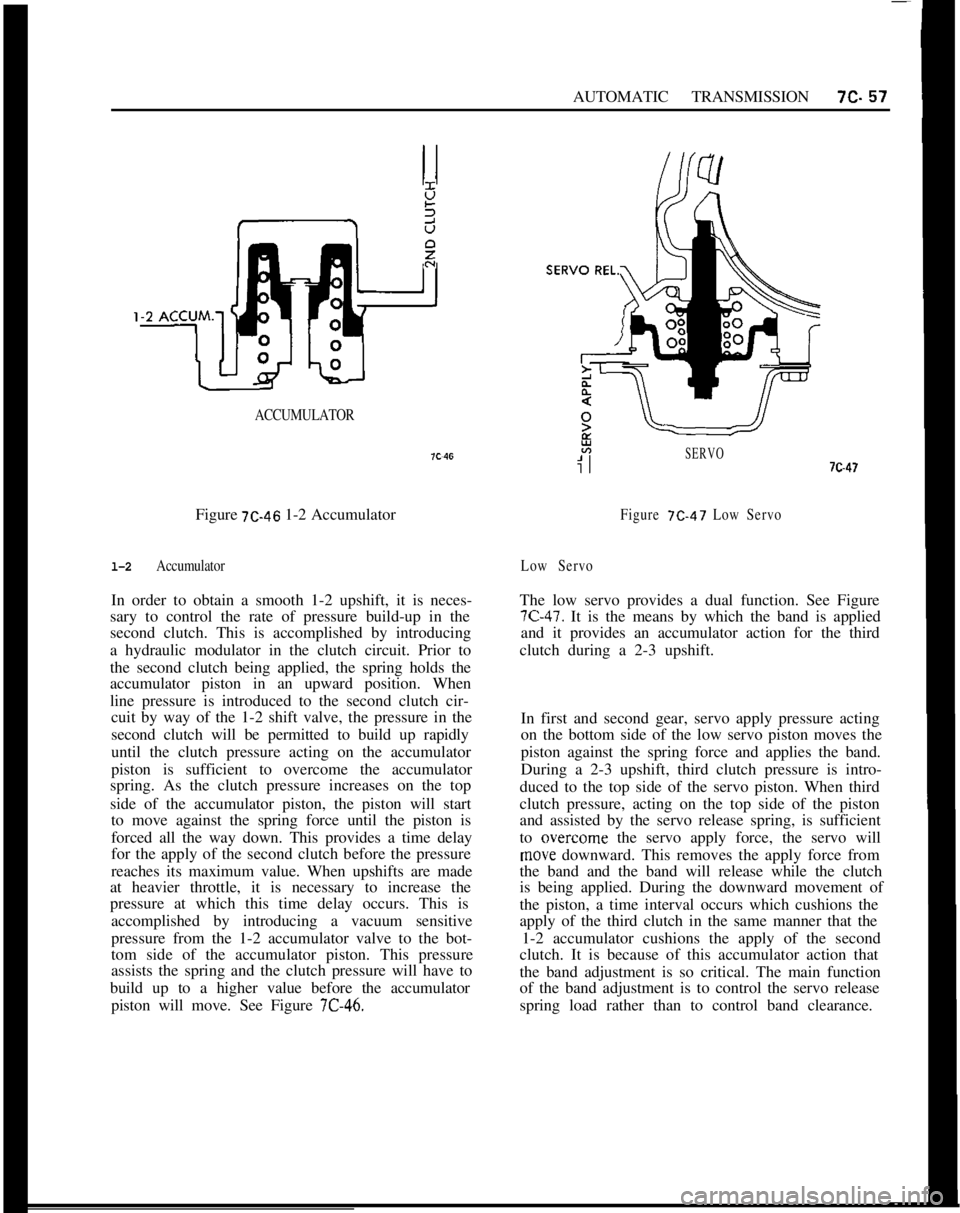

ACCUMULATORFigure

7C-46 1-2 Accumulator

l-2 AccumulatorIn order to obtain a smooth 1-2 upshift, it is neces-

sary to control the rate of pressure build-up in the

second clutch. This is accomplished by introducing

a hydraulic modulator in the clutch circuit. Prior to

the second clutch being applied, the spring holds the

accumulator piston in an upward position. When

line pressure is introduced to the second clutch cir-

cuit by way of the 1-2 shift valve, the pressure in the

second clutch will be permitted to build up rapidly

until the clutch pressure acting on the accumulator

piston is sufficient to overcome the accumulator

spring. As the clutch pressure increases on the top

side of the accumulator piston, the piston will start

to move against the spring force until the piston is

forced all the way down. This provides a time delay

for the apply of the second clutch before the pressure

reaches its maximum value. When upshifts are made

at heavier throttle, it is necessary to increase the

pressure at which this time delay occurs. This is

accomplished by introducing a vacuum sensitive

pressure from the 1-2 accumulator valve to the bot-

tom side of the accumulator piston. This pressure

assists the spring and the clutch pressure will have to

build up to a higher value before the accumulator

piston will move. See Figure

7C-46.

SERVO7c-47

Figure 7C-47 Low Servo

Low ServoThe low servo provides a dual function. See Figure

7C-47. It is the means by which the band is applied

and it provides an accumulator action for the third

clutch during a 2-3 upshift.

In first and second gear, servo apply pressure acting

on the bottom side of the low servo piston moves the

piston against the spring force and applies the band.

During a 2-3 upshift, third clutch pressure is intro-

duced to the top side of the servo piston. When third

clutch pressure, acting on the top side of the piston

and assisted by the servo release spring, is sufficient

to overcome the servo apply force, the servo will

move downward. This removes the apply force from

the band and the band will release while the clutch

is being applied. During the downward movement of

the piston, a time interval occurs which cushions the

apply of the third clutch in the same manner that the

1-2 accumulator cushions the apply of the second

clutch. It is because of this accumulator action that

the band adjustment is so critical. The main function

of the band adjustment is to control the servo release

spring load rather than to control band clearance.

Page 420 of 625

AUTOMATIC TRANSMISSION7c- 59

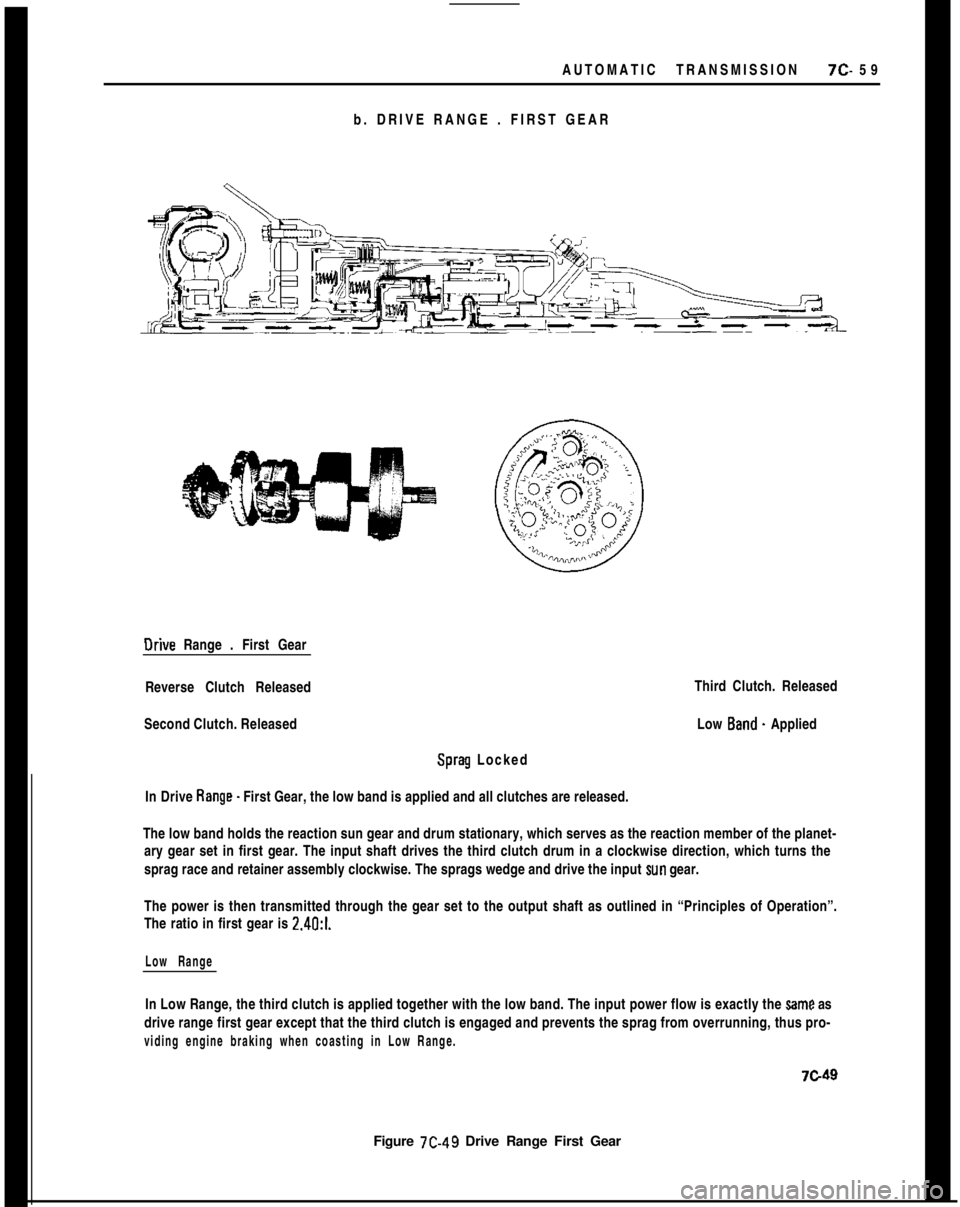

b. DRIVE RANGE . FIRST GEAROrive Range . First Gear

Reverse Clutch Released

Second Clutch. Released

Sprag Locked

In Drive Range. First Gear, the low band is applied and all clutches are released.

Figure 7C-49 Drive Range First GearThird Clutch. Released

Low Band. Applied

The low band holds the reaction sun gear and drum stationary, which serves as the reaction member of the planet-

ary gear set in first gear. The input shaft drives the third clutch drum in a clockwise direction, which turns the

sprag race and retainer assembly clockwise. The sprags wedge and drive the input

sun gear.

The power is then transmitted through the gear set to the output shaft as outlined in “Principles of Operation”.

The ratio in first gear is 2.4O:l.

Low RangeIn Low Range, the third clutch is applied together with the low band. The input power flow is exactly the

Same as

drive range first gear except that the third clutch is engaged and prevents the sprag from overrunning, thus pro-

viding engine braking when coasting in Low Range.

7c49