light OPEL INSIGNIA 2017 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2017, Model line: INSIGNIA, Model: OPEL INSIGNIA 2017Pages: 327, PDF Size: 9.3 MB

Page 218 of 327

216Driving and operatingPress LPG to switch between petrol

and liquid gas operation as soon as

the required parameters (coolant

temperature, gas temperature and

minimum engine speed) have been

reached. The requirements are

usually fulfilled after approximately

60 seconds (depending on exterior

temperature) and the first firm press

on the accelerator. The status LED

shows the current operating mode.1 off:petrol operation1 flashes:checking conditions

for fuel transition to

liquid gas operation.

Illuminates if

conditions are fulfilled.1 illumi‐

nates:liquid gas operation1 flashes

five times

and extin‐

guishes:liquid gas tank is

empty or failure in

liquid gas system. A

message is displayed

in the Driver

Information Centre.

If the fuel tank is empty, the engine

will not start.

The selected fuel mode is stored and

reactivated at the next ignition cycle if conditions allow.

As soon as the liquid gas tank is

empty, petrol operation is

automatically engaged until the

ignition is switched off.

When switching automatically

between petrol or gas operation, a

brief delay of engine tractive power

may be noticeable.

Every six months, run the petrol tank

down until control indicator I or

Y illuminates, then refuel. This helps

maintain fuel quality and system

function for petrol operation.

Fill the tank completely at regular intervals to prevent corrosion in the

tank.

Faults and remedies

If gas mode is not possible, check the

following:

● Is there enough liquid gas present?

● Is there enough petrol present for

starting?Due to extreme temperatures in

combination with the gas

composition, it may take slightly

longer before the system switches

from petrol to gas mode.

In extreme situations, the system may also switch back to petrol mode if the

minimum requirements are not

fulfilled. If conditions allow, it may be

possible to manually switch back to

liquid gas operation.

Seek the assistance of a workshop in

the event of all other faults.Caution

Repairs and adjustments may only be made by trained specialists in

order to maintain the safety and

warranty on the LPG system.

Liquid gas is given a particular odour

(odorised) so that any leaks can be

detected easily.

Page 219 of 327

Driving and operating2179Warning

If you smell gas in the vehicle or in

the immediate vicinity, switch to petrol mode immediately. No

smoking. No naked flames or

ignition sources.

If the gas odour persists, do not start

the engine. If possible, close the

manual shut-off valve on the

multivalve. The multivalve is located

on the liquid gas tank in the load

compartment, underneath the rear

floor storage cover 3 75.

Turn the thumb wheel clockwise.

If no further gas odour is perceptible

when the manual shut-off valve is

closed, the vehicle can be used in

petrol mode. If the gas odour persists, do not start the engine. Have the

cause of the fault remedied by a workshop.

When using underground car parks,

follow the instructions of the operator

and local laws.

Note

In the event of an accident, switch off

the ignition and lights. Close the

manual shut-off valve on multivalve.

Refuelling9 Danger

Before refuelling, switch off

ignition and any external heaters

with combustion chambers.

Follow the operating and safety

instructions of the filling station

when refuelling.

9 Danger

Fuel is flammable and explosive.

No smoking. No naked flames or

sparks.

If you can smell fuel in your

vehicle, have the cause of this

remedied immediately by a

workshop.

Caution

In case of misfuelling, do not

switch on ignition.

Fuel filler flap is located at right rear

side of vehicle.

Page 221 of 327

Driving and operating219The misfuel inhibitor ensures that the

flap of the fuel filler neck can only be

opened by using a nozzle for diesel

fuel or a funnel for emergency

refilling.

Turn the fuel filler cap slowly anti-

clockwise.

The cap can be retained in the

bracket on the fuel filler flap.

Place the nozzle in straight position to the filler neck and press with slight

force to insert.

In case of an emergency, refil with a canister. A funnel must be used to

open the cap of the filler neck.The funnel is located in the load

compartment.

Place the funnel in straight position to the filler neck and press with slight

force to insert.

Use the funnel to fill in the diesel fuel

into the filler neck.

After topping-up, put the funnel into

the plastic bag and stow it in the load

compartment.

Selective catalytic reduction system

3 165.

Liquid gas refuelling Follow the operating and safety

instructions of the filling station when refuelling.

The filling valve for the liquid gas is

behind the fuel filler cap.

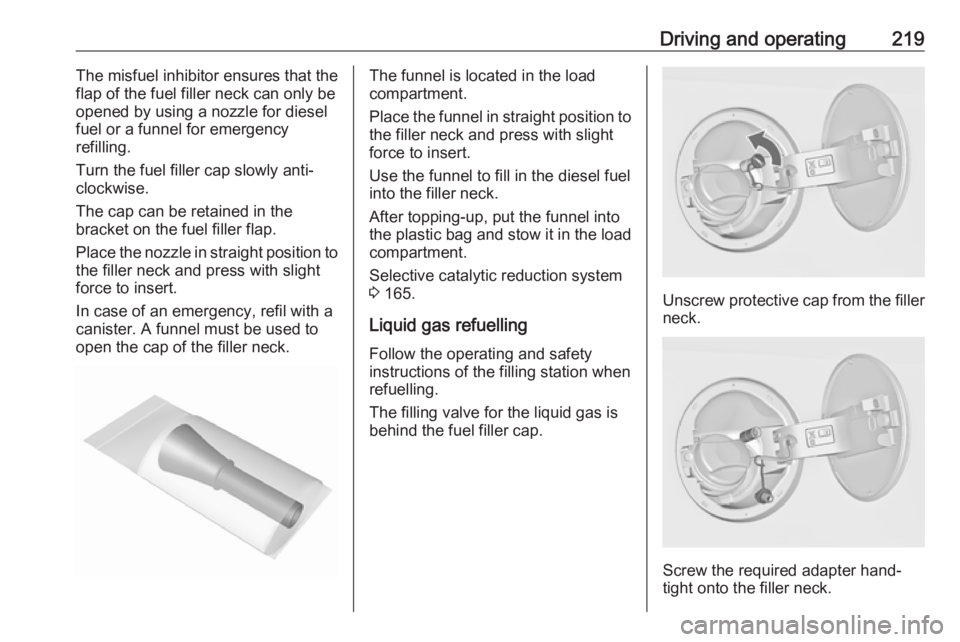

Unscrew protective cap from the filler neck.

Screw the required adapter hand-

tight onto the filler neck.

Page 224 of 327

222Driving and operatingFuel consumption data and CO2

emission data are determined

according to regulation R (EC) No.

715/2007 (in the version respectively

applicable), taking into consideration

the vehicle weight in running order, as specified by the regulation.

The figures are provided only for the

purpose of comparison between

different vehicle variants and must not be taken as a guarantee for the

actual fuel consumption of a

particular vehicle. Additional

equipment may result in slightly

higher results than the stated

consumption and CO 2 figures.

Furthermore, fuel consumption is

dependent on personal driving style

as well as road and traffic conditions.Trailer hitch

General information

The factory-fitted towing equipment is

folded up under the rear bumper

fascia.

Entrust retrofitting of towing

equipment to a workshop. It may be

necessary to make changes that

affect the cooling system, heat

shields or other equipment. Only use

towing equipment that has been

approved for your vehicle.

To avoid vehicle damage, the power

tailgate cannot be operated with the

radio remote control when a trailer is

electrically connected.

The bulb outage detection function for trailer brake light cannot detect a

partial bulb outage, e.g. in case of four

times five watt bulbs, the function only detects lamp outage when only a

single five Watt lamp remains or none

remain.

Fitting of towing equipment could

cover the opening of the towing eye.

If this is the case use the coupling ball bar for towing.Driving characteristics and

towing tips

Before attaching a trailer, lubricate the coupling ball. However, do not do

so if a stabiliser, which acts on the

coupling ball, is being used to reduce snaking movements.

For trailers with low driving stability

and trailers with a permitted gross

vehicle weight of more than 1400 kg (Front-wheel drive)/1600 kg (All-

wheel drive) the use of a stabiliser is

strongly recommended when driving

above 80 km/h.

If the trailer starts snaking, drive more

slowly, do not attempt to correct the

steering and brake sharply if

necessary.

When driving downhill, drive in the

same gear as if driving uphill and

drive at a similar speed.

Adjust tyre pressure to the value

specified for full load 3 295.

Page 225 of 327

Driving and operating223Trailer towingTrailer loads

The permissible trailer loads are

vehicle and engine-dependent

maximum values which must not be

exceeded. The actual trailer load is

the difference between the actual

gross weight of the trailer and the

actual coupling socket load with the

trailer coupled.

The permissible trailer loads are

specified in the vehicle documents. In general, they are valid for gradients

up to 12%.

The permissible trailer load applies

up to the specified incline and at sea

level. Since engine power decreases

as altitude increases due to the air

becoming thinner, therefore reducing

climbing ability, the permissible gross train weight also decreases by 10%for every 1000 metres of altitude. The

gross train weight does not have to be reduced when driving on roads with

slight inclines (less than 8%, e.g.

motorways).The permissible gross train weight must not be exceeded. This weight is

specified on the identification plate

3 279.

Vertical coupling load

The vertical coupling load is the load

exerted by the trailer on the coupling

ball. It can be varied by changing the

weight distribution when loading the

trailer.

The maximum permissible vertical

coupling load (85 kg) is specified on

the towing equipment identification

plate and in the vehicle documents.

Always aim for the maximum load,

especially in the case of heavy

trailers. The vertical coupling load

should never fall below 25 kg.Rear axle load

When the trailer is coupled and the

towing vehicle fully loaded, the

permissible rear axle load (see

identification plate or vehicle

documents) may be exceeded by 90 kg for the 5-door Hatchback/4-

door Saloon and 85 kg for the Sports

Tourer/Country Tourer, the gross

vehicle weight rating may be

exceeded by 65 kg for the 5-door

Hatchback/4-door Saloon and 60 kg for the Sports Tourer/Country Tourer. If the permissible rear axle load is

exceeded, a maximum speed of

100 km/h applies.

Towing equipmentCaution

The folding coupling ball bar

cannot be removed from the

vehicle. When driving without a

trailer, fold in the coupling ball bar.

Page 228 of 327

226Vehicle careVehicle careGeneral Information...................227

Accessories and vehicle modifications .......................... 227

Vehicle storage ........................227

End-of-life vehicle recovery .....228

Vehicle checks ........................... 228

Performing work ......................228

Bonnet ..................................... 228

Engine oil ................................. 229

Automatic transmission fluid ....230

Engine coolant ......................... 231

Power steering fluid .................232

Washer fluid ............................ 232

Brakes ..................................... 233

Brake fluid ............................... 233

Vehicle battery ......................... 233

Diesel fuel system bleeding .....235

Wiper blade replacement ........235

Bulb replacement .......................236

Halogen headlights ..................237

Xenon headlights .....................239

Fog lights ................................. 241

Tail lights ................................. 242

Side turn signal lights ..............244

Number plate light ...................245Interior lights ............................ 246

Instrument panel illumination ...246

Electrical system ........................246

Fuses ....................................... 246

Engine compartment fuse box . 248

Instrument panel fuse box .......250

Load compartment fuse box ....251

Vehicle tools .............................. 253

Tools ........................................ 253

Wheels and tyres .......................254

Winter tyres ............................. 254

Tyre designations ....................254

Tyre pressure .......................... 254

Tyre pressure monitoring system .................................... 256

Tread depth ............................. 257

Changing tyre and wheel size . 258

Wheel covers ........................... 258

Tyre chains .............................. 259

Tyre repair kit .......................... 259

Wheel changing .......................262

Spare wheel ............................ 264

Jump starting ............................. 267

Towing ....................................... 268

Towing the vehicle ...................268

Towing another vehicle ...........270Appearance care .......................272

Exterior care ............................ 272

Interior care ............................. 274

Page 230 of 327

228Vehicle care● Since the durability of AdBlue islimited to two years, fluid should

be exchanged if it is too old. Seek the assistance of a workshop.

● Fit the number plate if necessary.

End-of-life vehicle recovery

Information on end-of-life vehicle

recovery centres and the recycling of

end-of-life vehicles is available on our website, where legally required. Only

entrust this work to an authorised

recycling centre.

Gas vehicles must be recycled by a

service centre authorised for gas

vehicles.Vehicle checks

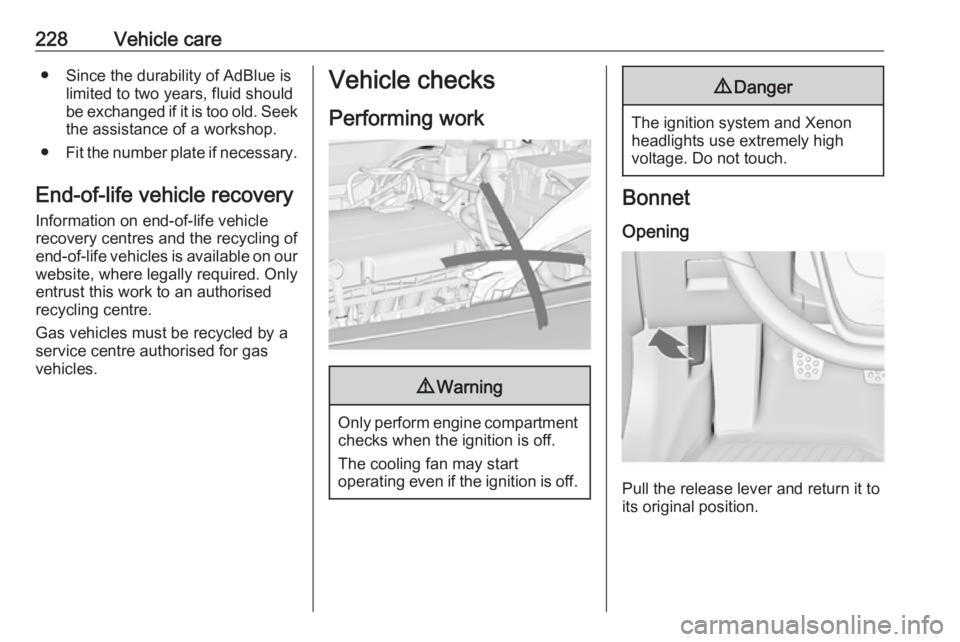

Performing work9 Warning

Only perform engine compartment

checks when the ignition is off.

The cooling fan may start

operating even if the ignition is off.

9 Danger

The ignition system and Xenon

headlights use extremely high

voltage. Do not touch.

Bonnet

Opening

Pull the release lever and return it to

its original position.

Page 238 of 327

236Vehicle care

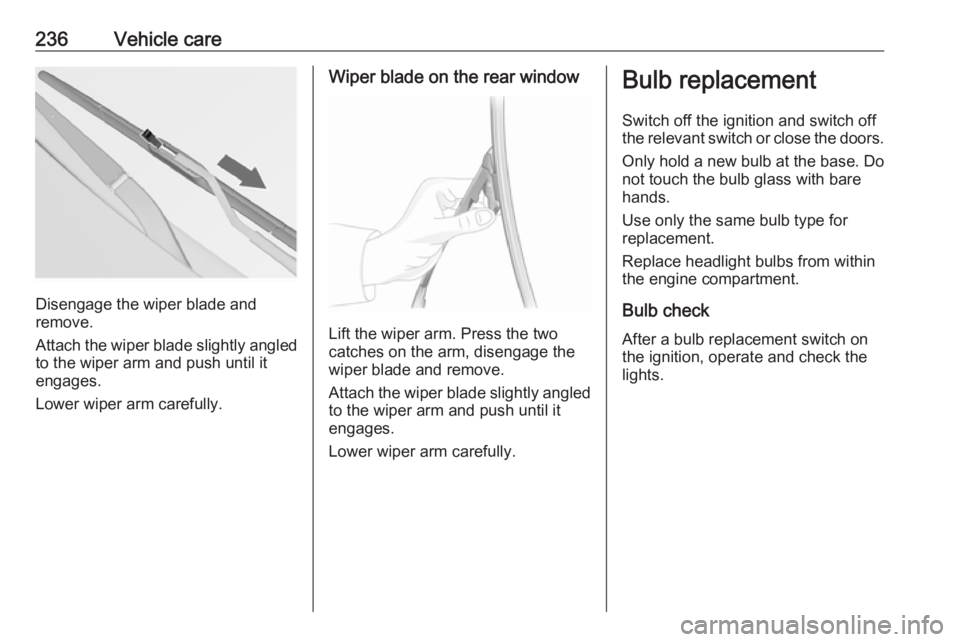

Disengage the wiper blade and

remove.

Attach the wiper blade slightly angled

to the wiper arm and push until it

engages.

Lower wiper arm carefully.

Wiper blade on the rear window

Lift the wiper arm. Press the two

catches on the arm, disengage the

wiper blade and remove.

Attach the wiper blade slightly angled

to the wiper arm and push until it

engages.

Lower wiper arm carefully.

Bulb replacement

Switch off the ignition and switch off

the relevant switch or close the doors.

Only hold a new bulb at the base. Do

not touch the bulb glass with bare

hands.

Use only the same bulb type for

replacement.

Replace headlight bulbs from within

the engine compartment.

Bulb check

After a bulb replacement switch on

the ignition, operate and check the

lights.

Page 239 of 327

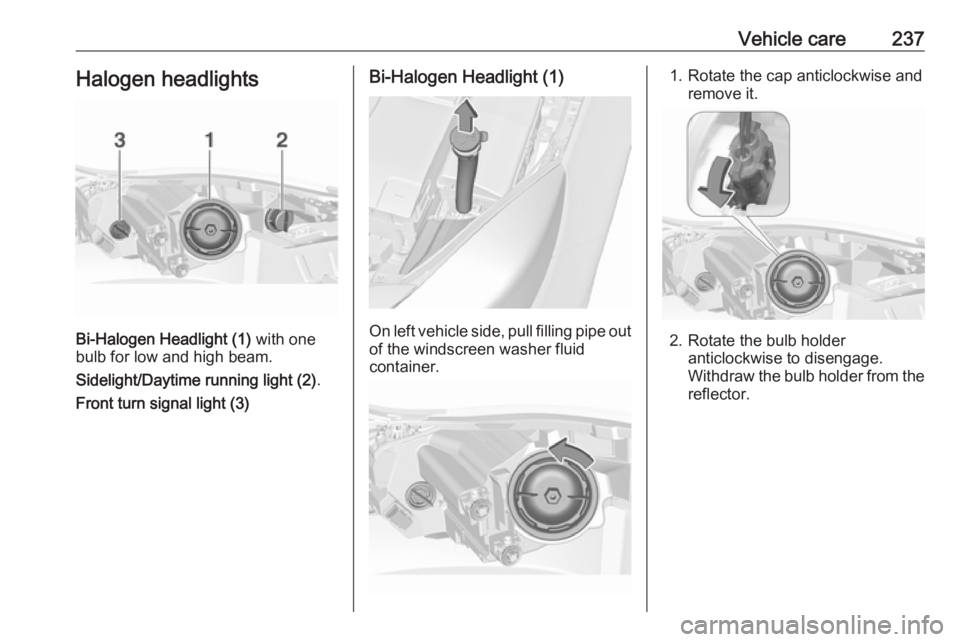

Vehicle care237Halogen headlights

Bi-Halogen Headlight (1) with one

bulb for low and high beam.

Sidelight/Daytime running light (2) .

Front turn signal light (3)

Bi-Halogen Headlight (1)

On left vehicle side, pull filling pipe out

of the windscreen washer fluid

container.

1. Rotate the cap anticlockwise and remove it.

2. Rotate the bulb holderanticlockwise to disengage.

Withdraw the bulb holder from the

reflector.

Page 240 of 327

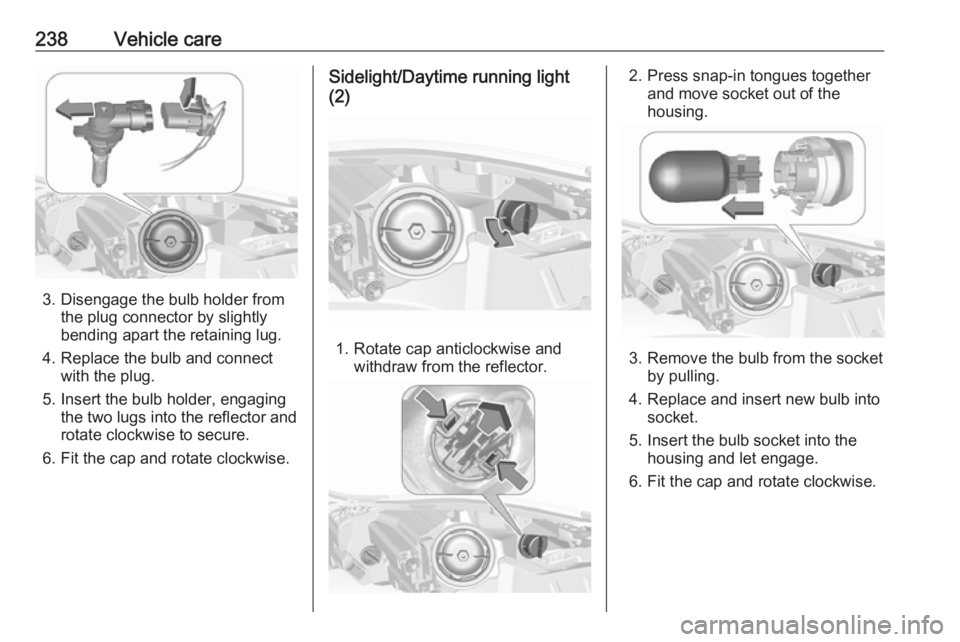

238Vehicle care

3. Disengage the bulb holder fromthe plug connector by slightly

bending apart the retaining lug.

4. Replace the bulb and connect with the plug.

5. Insert the bulb holder, engaging the two lugs into the reflector androtate clockwise to secure.

6. Fit the cap and rotate clockwise.

Sidelight/Daytime running light

(2)

1. Rotate cap anticlockwise and withdraw from the reflector.

2. Press snap-in tongues togetherand move socket out of the

housing.

3. Remove the bulb from the socket by pulling.

4. Replace and insert new bulb into socket.

5. Insert the bulb socket into the housing and let engage.

6. Fit the cap and rotate clockwise.