spare wheel OPEL INSIGNIA BREAK 2020 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2020, Model line: INSIGNIA BREAK, Model: OPEL INSIGNIA BREAK 2020Pages: 315, PDF Size: 9.45 MB

Page 111 of 315

Instruments and controls109If there is sufficient coolant, consult a

workshop.

Preheating

! illuminates yellow.

Preheating of Diesel engine is

activated. Only activates when

outside temperature is low. Start the

engine when control indicator

extinguishes.

AdBlue Y flashes yellow.

AdBlue level is low. Refill AdBlue soon to avoid prevention of the

engine start.

AdBlue 3 162.

Tyre pressure monitoring system

w illuminates or flashes yellow.

Illuminates

Tyre pressure loss. Stop immediately

and check tyre pressure.Flashes

Fault in system or tyre without

pressure sensor mounted (e.g. spare

wheel). After 60 to 90 seconds the

control indicator illuminates

continuously. Consult a workshop.

Engine oil pressure I illuminates red.

Illuminates when the ignition is

switched on and extinguishes shortly after the engine starts.

Illuminates when the engine is

runningCaution

Engine lubrication may be

interrupted. This may result in

damage to the engine and / or

locking of the drive wheels.

1. Depress clutch.

2. Select neutral gear.

3. Move out of the flow of traffic as quickly as possible without

impeding other vehicles.

4. Switch off ignition.9 Warning

When the engine is off,

considerably more force is needed

to brake and steer.

During an Autostop, the brake

servo unit will still be operational.

Do not remove key until vehicle is stationary, otherwise the steeringwheel lock could engage

unexpectedly.

Keep engine turned off and let the

vehicle be towed to a workshop.

Low fuel Y illuminates or flashes yellow.

Illuminates

Level in fuel tank is too low.

Page 231 of 315

Vehicle care229Vehicle careGeneral Information...................229

Accessories and vehicle modifications .......................... 229

Vehicle storage ........................230

End-of-life vehicle recovery .....230

Vehicle checks ........................... 231

Performing work ......................231

Bonnet ..................................... 231

Engine oil ................................. 232

Engine coolant ......................... 233

Washer fluid ............................ 234

Brakes ..................................... 234

Brake fluid ............................... 234

Vehicle battery ......................... 235

Diesel fuel system bleeding .....237

Wiper blade replacement ........237

Bulb replacement .......................238

Halogen headlights ..................238

LED headlights ........................ 240

Front fog lights ......................... 240

Tail lights ................................. 242

Side turn lights ......................... 247

Number plate light ...................248

Interior lights ............................ 248Electrical system........................248

Fuses ....................................... 248

Engine compartment fuse box . 249

Instrument panel fuse box .......252

Vehicle tools .............................. 253

Tools ........................................ 253

Wheels and tyres .......................254

Winter tyres ............................. 254

Tyre designations ....................255

Tyre pressure .......................... 255

Tyre pressure monitoring system .................................... 256

Tread depth ............................. 258

Changing tyre and wheel size . 259

Wheel covers ........................... 259

Tyre chains .............................. 260

Tyre repair kit .......................... 260

Wheel changing .......................265

Spare wheel ............................ 265

Jump starting ............................. 269

Towing ....................................... 271

Towing the vehicle ...................271

Towing another vehicle ...........272

Appearance care .......................273

Exterior care ............................ 273

Interior care ............................. 275

Floor mats ............................... 276General Information

Accessories and vehicle modifications

We recommend the use of genuine parts and accessories and factory

approved parts specific for your

vehicle type. We cannot assess or

guarantee reliability of other products - even if they have a regulatory or

otherwise granted approval.

Any modification, conversion or other

changes made to standard vehicle

specifications (including, without

limitation, software modifications,

modifications of the electronic control units) may invalidate the warranty

offered by Opel. Furthermore, such

changes may affect driver assistance

systems, fuel consumption, CO 2

emissions and other emissions of the

vehicle. They may also invalidate the

vehicle operating permit.

Page 255 of 315

Vehicle care253No.Circuit18Body control module19AdBlue module20Body control module21Body control module22Body control module23Electric steering wheel lock24Airbag25Diagnostic connector26Power outlet load compartment27EBCM valve28Police provision29–30–31Steering wheel controls32Ignition switch33Climate control34Central gateway moduleNo.Circuit35AUX / USB connector36Wireless charger37Rear wiper38Emergency call39Display40Parking assist41Overhead console42Infotainment SystemVehicle tools

Tools

Vehicles with spare wheel

The jack with wheel wrench, the tools,

an extension bolt for securing a

damaged wheel and the towing eye

are placed in the tool box below the

spare wheel in the load compartment.

Spare wheel 3 265.

Page 256 of 315

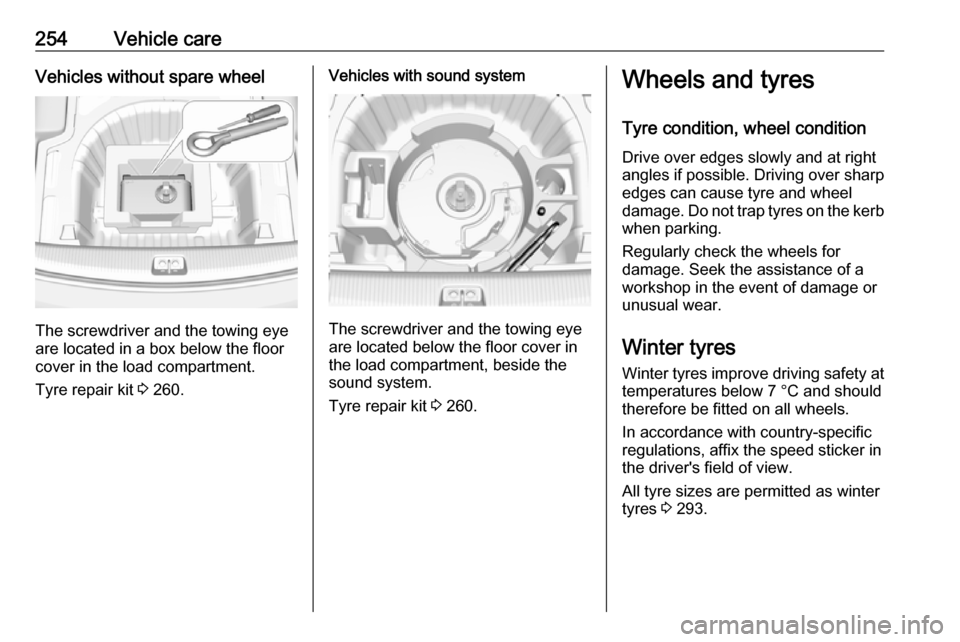

254Vehicle careVehicles without spare wheel

The screwdriver and the towing eye

are located in a box below the floor

cover in the load compartment.

Tyre repair kit 3 260.

Vehicles with sound system

The screwdriver and the towing eye

are located below the floor cover in

the load compartment, beside the

sound system.

Tyre repair kit 3 260.

Wheels and tyres

Tyre condition, wheel condition Drive over edges slowly and at right

angles if possible. Driving over sharp

edges can cause tyre and wheel

damage. Do not trap tyres on the kerb when parking.

Regularly check the wheels for

damage. Seek the assistance of a

workshop in the event of damage or

unusual wear.

Winter tyres

Winter tyres improve driving safety at temperatures below 7 °C and shouldtherefore be fitted on all wheels.

In accordance with country-specific

regulations, affix the speed sticker in

the driver's field of view.

All tyre sizes are permitted as winter

tyres 3 293.

Page 257 of 315

Vehicle care255GSi with Michelin Pilot Super Sport or

Pilot Sport 4 S tyres

This model is factory-fitted with high

performance sports tyres, which have

a reduced performance at low

temperature.9 Danger

Use winter tyres at temperatures

below 0 °C, otherwise damage of

the high performance sports tyres

is possible.

Tyre designations

E.g. 215/60 R 16 95 V

215:tyre width, mm60:cross-section ratio (tyre height

to tyre width), %R:belt type: RadialRF:type: RunFlat16:wheel diameter, inches95:load index e.g. 95 is equivalent

to 690 kgV:speed code letter

Speed code letter:

Q:up to 160 km/hS:up to 180 km/hT:up to 190 km/hH:up to 210 km/hV:up to 240 km/hW:up to 270 km/h

Choose a tyre appropriate for the

maximum speed of this vehicle. Refer

to the EEC Certificate of Conformity

provided with the vehicle or other

national registration documents.

Optional equipment could reduce the

maximum speed of the vehicle.

Directional tyres

Directional tyres should be mounted

so that they rotate in the correct

direction. The proper rotation

direction is indicated by a symbol (e.g. an arrow) on the sidewall.

Tyre pressure

Check the pressure of cold tyres at

least every 14 days and before any

long journey. Do not forget the spare

wheel.

This also applies to vehicles with tyre pressure monitoring system.

Tyre pressure 3 293.

The tyre pressure information label

on the left door frame indicates the

original equipment tyres and the

correspondent tyre pressures.

The tyre pressure data refers to cold

tyres. It applies to summer and winter tyres.

Always inflate the spare tyre to the

pressure specified for full load.

The ECO tyre pressure serves to

achieve the smallest amount of fuel

consumption possible.

Make sure tyre loading setting

matches the current tyre pressure.

Tyre loading 3 256.

Page 259 of 315

Vehicle care257All wheels must be equipped with

pressure sensors and the tyres must have the prescribed pressure.

Note

In countries where the tyre pressure

monitoring system is legally

required, the use of wheels without

pressure sensors will invalidate the

vehicle operating permit.

Select the Tyre pressure monitoring

page under the Info Menu in the

Driver Information Centre 3 111.

System status and pressure warnings

are displayed by a message

indicating the corresponding tyre in the Driver Information Centre.

The system considers the tyre

temperature and the tyre loading

setting for the warnings.

Tyre loading setting, see below in this chapter.

Temperature dependency 3 255.

Baselevel display: If the pressure of a

tyre decreases significantly, the

respective tyre pressure value is displayed inverted.

Uplevel display: Tyre pressure values in normal range are shown in greenletters. If the pressure of a tyre

decreases significantly, the

respective value will turn its colour to

amber.

A detected low tyre pressure

condition is indicated by the control

indicator w 3 109.

If

w illuminates, stop as soon as

possible and inflate the tyres as

recommended 3 293.

Ensure that vehicle loading status

matches selected tyre pressure.

Vehicle loading status, see below in

this chapter.

After inflating, some driving may be

required to update the tyre pressure

values in the Driver Information

Centre. During this time w may

continue to illuminate.

If w illuminates at lower temperatures

and extinguishes after some driving,

this could be an indicator for

approaching a low tyre pressure

condition. Check tyre pressure.

Vehicle messages 3 122.

Only mount wheels with pressure

sensors, otherwise the tyre pressure

will not be displayed and w

illuminates continuously.

A spare wheel or temporary spare

wheel is not equipped with pressure

sensors. The tyre pressure

monitoring system is not operational

for these wheels. Control indicator w

Page 262 of 315

260Vehicle careTyre chains

Tyre chains are only permitted on the

front wheels.

Always use fine mesh chains that add no more than 10 mm to the tyre tread

and the inboard sides (including chain lock).

9 Warning

Damage may lead to tyre blowout.

Tyre chains are only permitted on

tyres of size 215/60 R16, 215/55 R17 ,

225/55 R17 and 235/45 R18.

Temporary spare wheel

The use of tyre chains is not permitted on the temporary spare wheel.

Tyre repair kit

Minor damage to the tyre tread can be

repaired with the tyre repair kit.

Do not remove foreign bodies from

the tyres.

Tyre damage exceeding 4 mm or that is at tyre's side wall cannot be

repaired with the tyre repair kit.9 Warning

Do not drive faster than 80 km/h.

Do not use for a lengthy period.

Steering and handling may be

affected.

Two types of tyre repair kit are

available:

● Type 1 indicated by the on/off

switch at the top of the

compressor.

Page 267 of 315

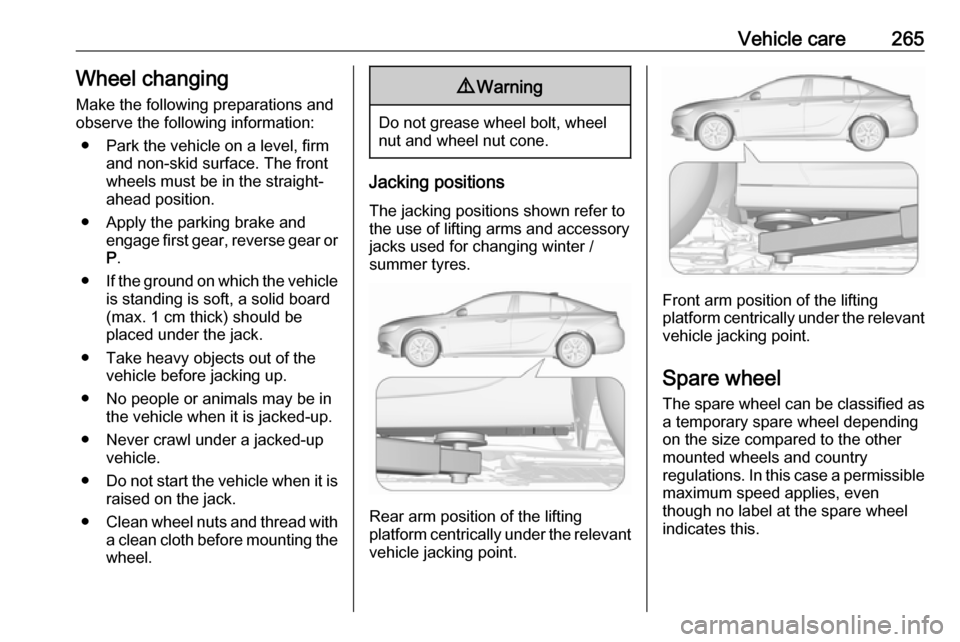

Vehicle care265Wheel changing

Make the following preparations and observe the following information:

● Park the vehicle on a level, firm and non-skid surface. The front

wheels must be in the straight- ahead position.

● Apply the parking brake and engage first gear, reverse gear or

P .

● If the ground on which the vehicle

is standing is soft, a solid board

(max. 1 cm thick) should be

placed under the jack.

● Take heavy objects out of the vehicle before jacking up.

● No people or animals may be in the vehicle when it is jacked-up.

● Never crawl under a jacked-up vehicle.

● Do not start the vehicle when it is

raised on the jack.

● Clean wheel nuts and thread with

a clean cloth before mounting the

wheel.9 Warning

Do not grease wheel bolt, wheel

nut and wheel nut cone.

Jacking positions

The jacking positions shown refer to

the use of lifting arms and accessory

jacks used for changing winter /

summer tyres.

Rear arm position of the lifting

platform centrically under the relevant

vehicle jacking point.

Front arm position of the lifting

platform centrically under the relevant vehicle jacking point.

Spare wheel The spare wheel can be classified as

a temporary spare wheel depending

on the size compared to the other

mounted wheels and country

regulations. In this case a permissible maximum speed applies, even

though no label at the spare wheel

indicates this.

Page 268 of 315

266Vehicle careOnly mount one temporary spare

wheel. Do not drive faster than

80 km/h. Take curves slowly. Do not

use for a long period of time.Caution

The use of a spare wheel that is smaller than the other wheels or in

combination with winter tyres

could affect driveability. Have the defective tyre replaced as soon as

possible.

Caution

If driving with a temporary spare

wheel, active emergency braking

has to deactivated.

The spare wheel is located in the load

compartment beneath the floor

covering.

To remove: 1. Open the floor cover.

2. The spare wheel is secured with a

wing nut. Unscrew the wing nut

and take out the spare wheel.

Under the spare wheel there is the

box with vehicle tools.

3. When, after a wheel change, no wheel is placed in the spare wheel

well, secure the tool box by

tightening the wing nut as far as it will go and close floor cover.

4. After wheel change back to full size wheel, place the spare wheel

outside up in the well and secure

with the wing nut.

Only mount one temporary spare

wheel. The permissible maximum

speed on the label on the temporary

spare wheel is only valid for the

factory-fitted tyre size.

Fitting the spare wheel Make the following preparations and

observe the following information:

● Park the vehicle on a level, firm and non-skid surface. The front

wheels must be in the straight-

ahead position.

● Apply the parking brake and engage first gear, reverse gear or

P .

● Remove the spare wheel.

● Never change more than one wheel at once.

Page 270 of 315

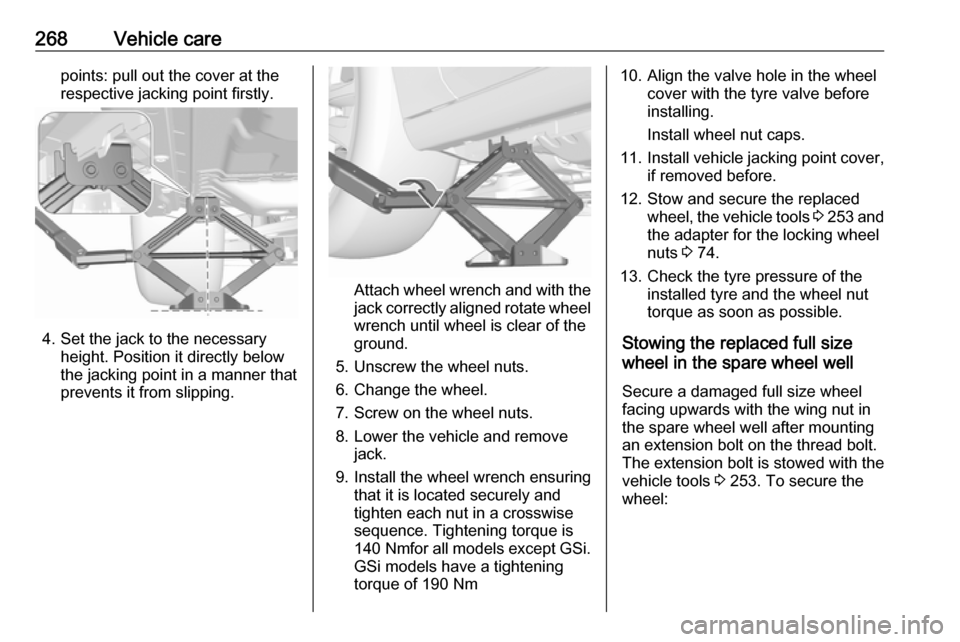

268Vehicle carepoints: pull out the cover at the

respective jacking point firstly.

4. Set the jack to the necessary height. Position it directly below

the jacking point in a manner that

prevents it from slipping.

Attach wheel wrench and with the

jack correctly aligned rotate wheel wrench until wheel is clear of the

ground.

5. Unscrew the wheel nuts. 6. Change the wheel.

7. Screw on the wheel nuts.

8. Lower the vehicle and remove jack.

9. Install the wheel wrench ensuring that it is located securely and

tighten each nut in a crosswise

sequence. Tightening torque is

140 Nm for all models except GSi.

GSi models have a tightening

torque of 190 Nm

10. Align the valve hole in the wheel cover with the tyre valve before

installing.

Install wheel nut caps.

11. Install vehicle jacking point cover,

if removed before.

12. Stow and secure the replaced wheel, the vehicle tools 3 253 and

the adapter for the locking wheel

nuts 3 74.

13. Check the tyre pressure of the installed tyre and the wheel nut

torque as soon as possible.

Stowing the replaced full size

wheel in the spare wheel well

Secure a damaged full size wheel facing upwards with the wing nut in

the spare wheel well after mounting

an extension bolt on the thread bolt.

The extension bolt is stowed with the

vehicle tools 3 253. To secure the

wheel: