parking brake OPEL KARL 2017 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2017, Model line: KARL, Model: OPEL KARL 2017Pages: 203, PDF Size: 5.39 MB

Page 116 of 203

114Driving and operatingParking9Warning

● Do not park the vehicle on an

easily ignitable surface. The

high temperature of the

exhaust system could ignite the

surface.

● Always apply the parking brake. Activate the manual

parking brake without pressing the release button. Apply as

firmly as possible on a downhill slope or uphill slope. Depress

brake pedal at the same time to

reduce operating force.

● Switch off the engine.

● If the vehicle is on a level surface or uphill slope, engage

first gear before removing the ignition key. On an uphill slope,

turn the front wheels away from

the kerb.

If the vehicle is on a downhill

slope, engage reverse gear

before removing the ignition

key. Turn the front wheels

towards the kerb.

● Close the windows and the sunroof.

● Remove the ignition key from the ignition switch. Turn the

steering wheel until the

steering wheel lock is felt to

engage.

For vehicles with manual

transmission automated, the key

can only be removed from the

ignition switch when the parking

brake is applied.

● Lock the vehicle.

● Activate the anti-theft alarm system.

● The engine cooling fans may run

after the engine has been

switched off 3 139.

Caution

After running at high engine

speeds or with high engine loads,

operate the engine briefly at a low

load or run in neutral for

approx. 30 seconds before

switching off, in order to protect

the turbocharger.

Note

In the event of an accident with

airbag deployment, the engine is

switched off automatically if the

vehicle comes to a standstill within a

certain time.

Page 120 of 203

118Driving and operatingEngine braking

Automatic mode

When driving downhill, the manual transmission automated does not

shift into higher gears until a fairly

high engine speed has been reached. It shifts down in good time when

braking.

Manual mode

To utilise the engine braking effect, select a lower gear in good time when driving downhill. Changing into

manual mode is only possible while

the engine is running.

Rocking the vehicle

Rocking the vehicle is only

permissible if the vehicle is stuck in

sand, mud or snow. Move the selector

lever between R and D in a repeat

pattern. Do not race the engine and

avoid sudden acceleration.

Parking

The most recently engaged gear (see transmission display) remains

engaged when switching off ignition.

With N, no gear is engaged.Therefore always apply the parking

brake when switching off ignition. If

parking brake is not applied, P flashes

in the transmission display and the

key cannot be removed from the

ignition switch. P stops flashing in the

transmission display as soon as the

parking brake is slightly applied.

When the ignition is switched off, the

transmission no longer responds to

movement of the selector lever.

Manual mode

If a higher gear is selected when the

engine speed is too low, or a lower

gear when the speed is too high, the

shift is not executed. This prevents

the engine from running at too low or too high an engine speed. M and the

number of the selected gear will be

flashed, then the current gear is

displayed again..

If engine speed is too low, the

transmission automatically shifts to a

lower gear.

When + or - is selected in automatic

mode, the transmission switches to

manual mode and shifts accordingly.Gear shift indication

The symbol R with a number

alongside it, is indicated when

gearshifting is recommended for fuel

saving reasons.

Shift indication appears only in

manual mode.

Electronic driving programmes

The adaptive programme tailors

gearshifting to the driving conditions, e.g. greater load or gradients.

Fault

To prevent damage to the manual

transmission automated, the clutch is engaged automatically at high clutch

temperatures.

In the event of a fault, control indicator

g illuminates. Additionally, a

warning message is displayed in the

Driver Information Centre. Vehicle

messages 3 83.

Continued driving is restricted or not

possible, depending on the fault.

Page 122 of 203

120Driving and operatingFault9Warning

If there is a fault in the ABS, the

wheels may be liable to lock due

to braking that is heavier than

normal. The advantages of ABS are no longer available. During

hard braking, the vehicle can no longer be steered and may

swerve.

Have the cause of the fault remedied

by a workshop.

Parking brake

Manual parking brake9 Warning

Always apply parking brake firmly

without operating the release

button, and apply as firmly as

possible on a downhill or uphill

slope.

To release the parking brake, pull

the lever up slightly, press the

release button and fully lower the

lever.

To reduce the operating forces of

the parking brake, depress the

brake pedal at the same time.

Control indicator R 3 73.

Brake assist

If the brake pedal is depressed

quickly and forcefully, maximum

brake force is automatically applied

(full braking).

Maintain steady pressure on the

brake pedal for as long as full braking is required. Maximum brake force is

automatically reduced when the

brake pedal is released.

Hill start assist

The system helps prevent unintended movement when driving away on

inclines.

When releasing the brake pedal after

stopping on an incline, the brakes

remain on for a further two seconds.

The brakes release automatically as

Page 130 of 203

128Driving and operatingBasic notes on parking assist

systems9 Warning

Under certain circumstances,

various reflective surfaces on

objects or clothing as well as

external noise sources may cause the system to fail to detect

obstacles.

Special attention must be paid to

low obstacles which can damage

the lower part of the bumper.

Caution

Performance of the system can be reduced when sensors are

covered, e.g. by ice or snow.

Performance of the parking assist

system can be reduced due to

heavy loading.

Special conditions apply if there

are taller vehicles in the vicinity

(e.g. off-road vehicles, mini vans,

vans). Object identification and

correct distance indication in the

upper part of these vehicles

cannot be guaranteed.

Objects with a very small reflection

cross-section, e.g. objects of

narrow size or soft materials, may

not be detected by the system.

Parking assist systems do not

detect objects outside the

detection range.

Lane departure warning

The lane departure warning system

observes the lane markings between

which the vehicle is driving via a front camera. The system detects lane

changes and warns the driver in the

event of an unintended lane change

via visual and acoustic signals.

Criteria for the detection of an

unintended lane change are:

● No operation of turn signals.

● No brake pedal operation.

● No active accelerator operation or speeding-up.

● No active steering.

If the driver is performing these

actions, no warning will be issued.

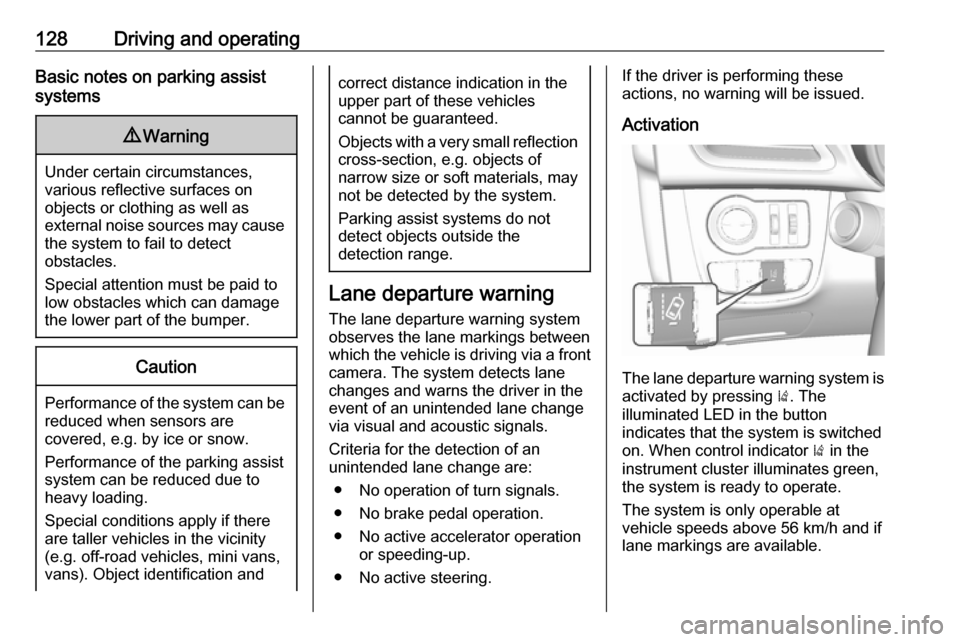

Activation

The lane departure warning system is activated by pressing ). The

illuminated LED in the button

indicates that the system is switched

on. When control indicator ) in the

instrument cluster illuminates green, the system is ready to operate.

The system is only operable at

vehicle speeds above 56 km/h and if lane markings are available.

Page 140 of 203

138Vehicle careCaution

When transporting the vehicle on

a train or on a recovery vehicle, the

mud flaps might be damaged.

Vehicle storage

Storage for a long period of time

If the vehicle is to be stored for several months:

● Wash and wax the vehicle.

● Have the wax in the engine compartment and underbody

checked.

● Clean and preserve the rubber seals.

● Fill up fuel tank completely.

● Change the engine oil.

● Drain the washer fluid reservoir.

● Check the coolant antifreeze and

corrosion protection.

● Adjust tyre pressure to the value specified for full load.

● Park the vehicle in a dry, wellventilated place. Engage first or

reverse gear. Prevent the vehicle from rolling.

● Do not apply the parking brake.

● Open the bonnet, close all doors and lock the vehicle.

● Disconnect the clamp from the negative terminal of the vehicle

battery. Beware that all systems are not functional, e.g. anti-theft

alarm system.

Putting back into operation When the vehicle is to be put back into

operation:

● Connect the clamp to the negative terminal of the vehicle

battery. Activate the electronics

of the power windows.

● Check tyre pressure.

● Fill up the washer fluid reservoir.

● Check the engine oil level.

● Check the coolant level.

● Fit the number plate if necessary.End-of-life vehicle recovery

Information on end-of-life vehicle

recovery centres and the recycling of

end-of-life vehicles is available on our

website. Only entrust this work to an

authorised recycling centre.

Gas vehicles must be recycled by a

service centre authorised for gas

vehicles.

Page 162 of 203

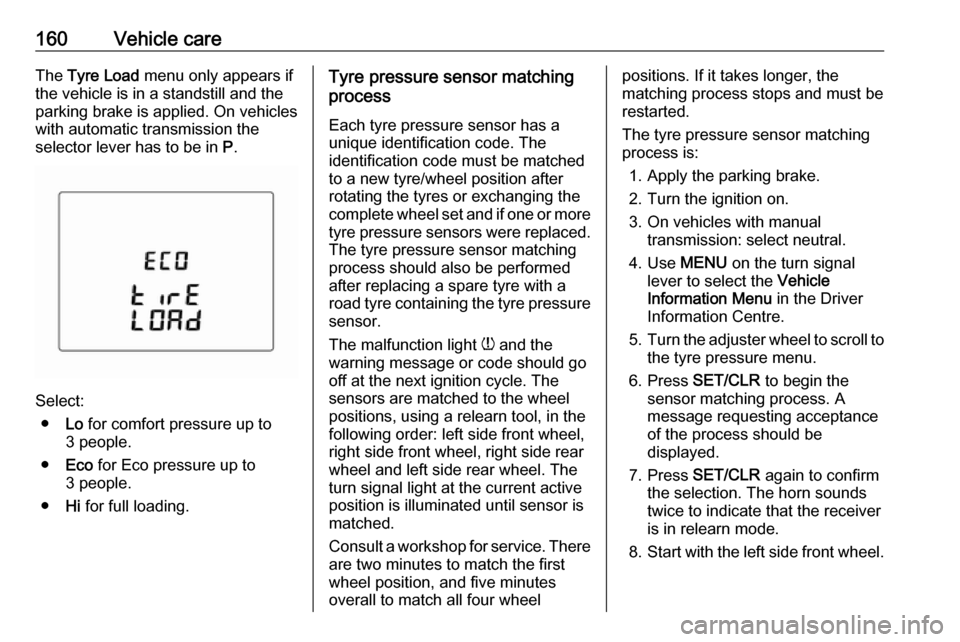

160Vehicle careThe Tyre Load menu only appears if

the vehicle is in a standstill and the

parking brake is applied. On vehicles

with automatic transmission the

selector lever has to be in P.

Select:

● Lo for comfort pressure up to

3 people.

● Eco for Eco pressure up to

3 people.

● Hi for full loading.

Tyre pressure sensor matching

process

Each tyre pressure sensor has a

unique identification code. The

identification code must be matched

to a new tyre/wheel position after

rotating the tyres or exchanging the

complete wheel set and if one or more

tyre pressure sensors were replaced. The tyre pressure sensor matching

process should also be performed

after replacing a spare tyre with a

road tyre containing the tyre pressure sensor.

The malfunction light w and the

warning message or code should go

off at the next ignition cycle. The

sensors are matched to the wheel

positions, using a relearn tool, in the

following order: left side front wheel,

right side front wheel, right side rear

wheel and left side rear wheel. The

turn signal light at the current active

position is illuminated until sensor is

matched.

Consult a workshop for service. There

are two minutes to match the first

wheel position, and five minutes

overall to match all four wheelpositions. If it takes longer, the

matching process stops and must be

restarted.

The tyre pressure sensor matching

process is:

1. Apply the parking brake.

2. Turn the ignition on.

3. On vehicles with manual transmission: select neutral.

4. Use MENU on the turn signal

lever to select the Vehicle

Information Menu in the Driver

Information Centre.

5. Turn the adjuster wheel to scroll to

the tyre pressure menu.

6. Press SET/CLR to begin the

sensor matching process. A

message requesting acceptance

of the process should be

displayed.

7. Press SET/CLR again to confirm

the selection. The horn sounds

twice to indicate that the receiver

is in relearn mode.

8. Start with the left side front wheel.

Page 165 of 203

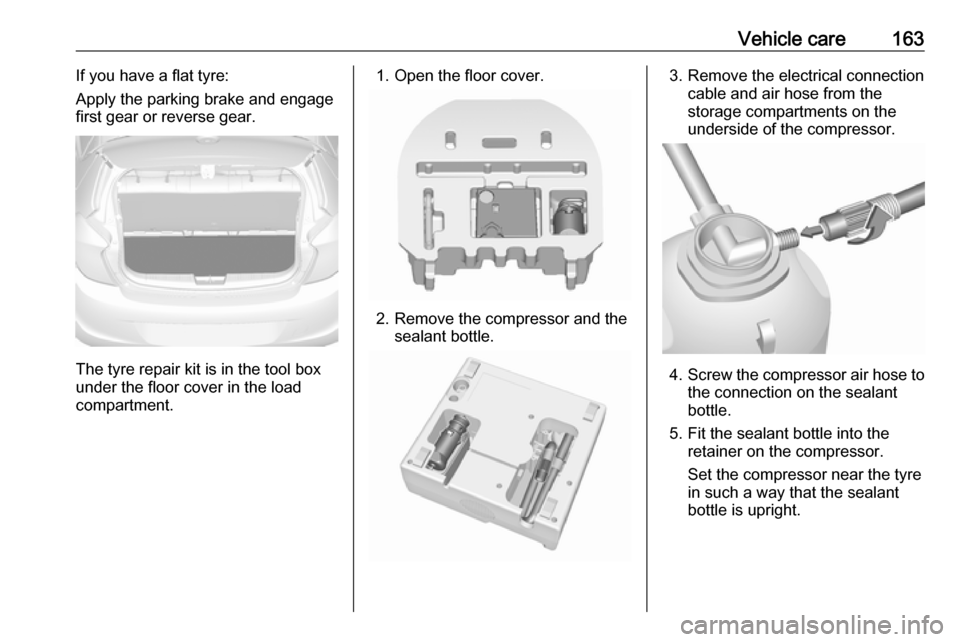

Vehicle care163If you have a flat tyre:

Apply the parking brake and engage first gear or reverse gear.

The tyre repair kit is in the tool box

under the floor cover in the load

compartment.

1. Open the floor cover.

2. Remove the compressor and the sealant bottle.

3. Remove the electrical connectioncable and air hose from the

storage compartments on the

underside of the compressor.

4. Screw the compressor air hose to

the connection on the sealant

bottle.

5. Fit the sealant bottle into the retainer on the compressor.

Set the compressor near the tyre

in such a way that the sealant

bottle is upright.

Page 168 of 203

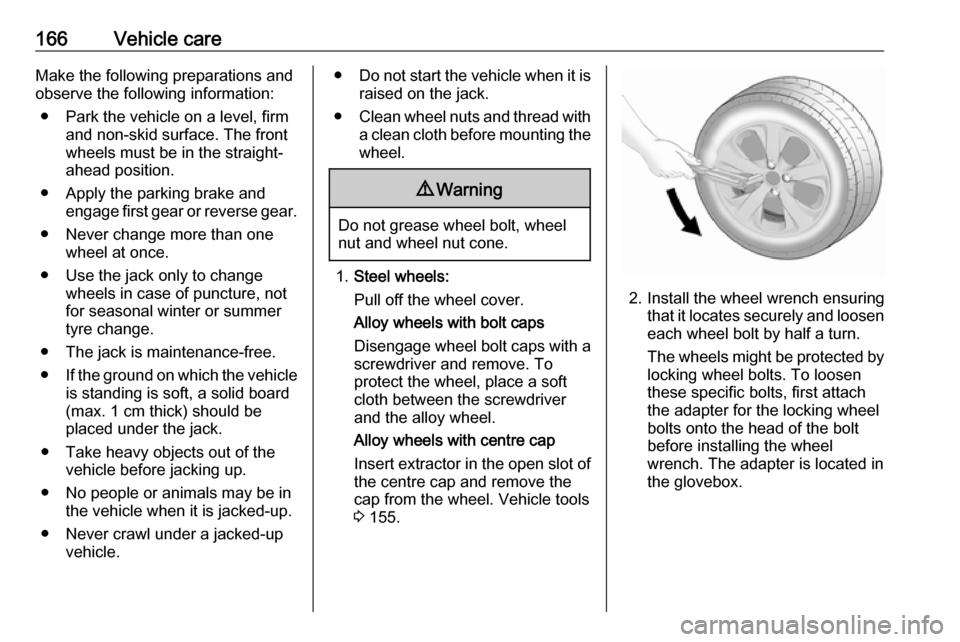

166Vehicle careMake the following preparations and

observe the following information:

● Park the vehicle on a level, firm and non-skid surface. The front

wheels must be in the straight- ahead position.

● Apply the parking brake and engage first gear or reverse gear.

● Never change more than one wheel at once.

● Use the jack only to change wheels in case of puncture, not

for seasonal winter or summer

tyre change.

● The jack is maintenance-free.

● If the ground on which the vehicle

is standing is soft, a solid board

(max. 1 cm thick) should be

placed under the jack.

● Take heavy objects out of the vehicle before jacking up.

● No people or animals may be in the vehicle when it is jacked-up.

● Never crawl under a jacked-up vehicle.●Do not start the vehicle when it is

raised on the jack.

● Clean wheel nuts and thread with

a clean cloth before mounting the wheel.9 Warning

Do not grease wheel bolt, wheel

nut and wheel nut cone.

1. Steel wheels:

Pull off the wheel cover.

Alloy wheels with bolt caps

Disengage wheel bolt caps with a

screwdriver and remove. To

protect the wheel, place a soft

cloth between the screwdriver

and the alloy wheel.

Alloy wheels with centre cap

Insert extractor in the open slot of

the centre cap and remove the

cap from the wheel. Vehicle tools 3 155.

2. Install the wheel wrench ensuring

that it locates securely and looseneach wheel bolt by half a turn.

The wheels might be protected by

locking wheel bolts. To loosen

these specific bolts, first attach

the adapter for the locking wheel

bolts onto the head of the bolt

before installing the wheel

wrench. The adapter is located in

the glovebox.

Page 172 of 203

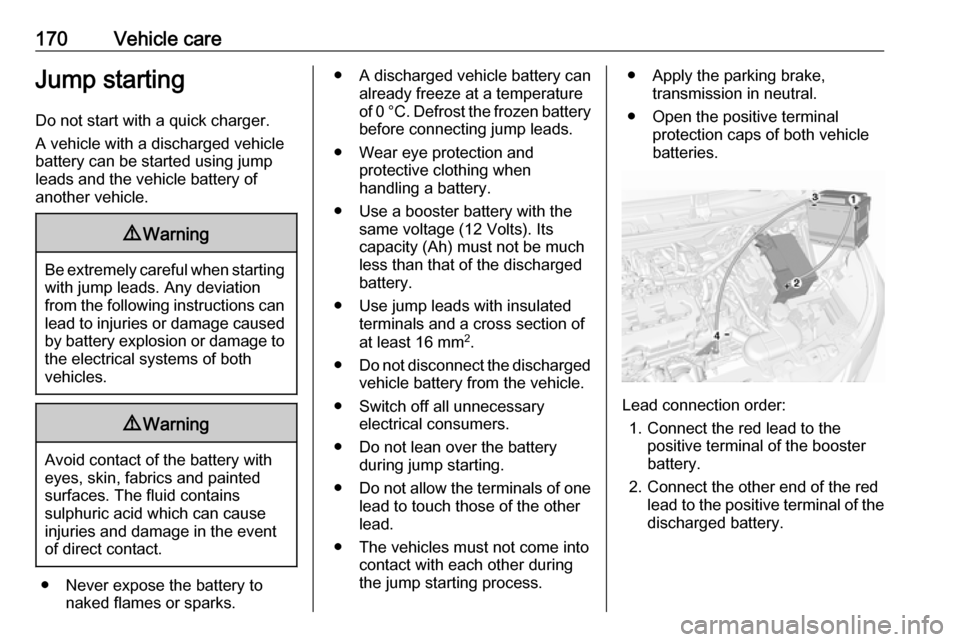

170Vehicle careJump startingDo not start with a quick charger.

A vehicle with a discharged vehicle

battery can be started using jump

leads and the vehicle battery of

another vehicle.9 Warning

Be extremely careful when starting

with jump leads. Any deviation

from the following instructions can

lead to injuries or damage caused

by battery explosion or damage to the electrical systems of both

vehicles.

9 Warning

Avoid contact of the battery with

eyes, skin, fabrics and painted

surfaces. The fluid contains

sulphuric acid which can cause

injuries and damage in the event

of direct contact.

● Never expose the battery to naked flames or sparks.

● A discharged vehicle battery canalready freeze at a temperature

of 0 °C. Defrost the frozen battery

before connecting jump leads.

● Wear eye protection and protective clothing when

handling a battery.

● Use a booster battery with the same voltage (12 Volts). Its

capacity (Ah) must not be much less than that of the discharged

battery.

● Use jump leads with insulated terminals and a cross section of

at least 16 mm 2

.

● Do not disconnect the discharged

vehicle battery from the vehicle.

● Switch off all unnecessary electrical consumers.

● Do not lean over the battery during jump starting.

● Do not allow the terminals of one

lead to touch those of the other

lead.

● The vehicles must not come into contact with each other during

the jump starting process.● Apply the parking brake, transmission in neutral.

● Open the positive terminal protection caps of both vehicle

batteries.

Lead connection order:

1. Connect the red lead to the positive terminal of the booster

battery.

2. Connect the other end of the red lead to the positive terminal of the

discharged battery.

Page 200 of 203

198Instrument cluster ........................65

Instrument panel fuse box .........154

Instrument panel illumination .....150

Instrument panel illumination control ...................................... 96

Instrument panel overview ........... 10

Interior care ............................... 174

Interior lighting .............................. 96

Interior lights ........................ 97, 150

Interior mirrors .............................. 30

Introduction .................................... 3

ISOFIX child restraint systems ....52

J

Jump starting ............................. 170

K Key, memorised settings ..............23

Keys ............................................. 21

Keys, locks ................................... 21

L

Lane departure warning .......74, 128

Light switch .................................. 93

Load compartment ................26, 54

Load compartment cover .............56

Loading information .....................58

Low fuel ....................................... 76M

Malfunction indicator light ............73

Manual adjustment ......................29

Manual anti-dazzle ......................30

Manual mode ............................. 118

Manual transmission .................. 115

Manual transmission automated 116

Manual windows ..........................31

Memorised settings ......................23

Mirror adjustment ........................... 8

Mirrors ......................................... 29

Misted light covers .......................96

N

New vehicle running-in ..............109

Number plate light .....................150

O Object detection systems ...........127

Odometer ..................................... 66

Oil, engine .......................... 177, 181

OnStar .......................................... 88

Operate pedal ............................... 73

Outside temperature ....................63

Overrun cut-off ........................... 111

P Parking ................................ 20, 114

Parking assist ............................ 127

Parking brake ............................ 120

Parking lights ............................... 96Performance .............................. 185

Performing work ........................139

Pollen filter ................................. 107

Power outlets ............................... 65

Power steering.............................. 74

Power windows ............................ 31

Puncture ..................................... 165

R Radio Frequency Identification (RFID) ..................................... 195

Radio remote control ...................22

Reading lights .............................. 97

Rear doors ................................... 26

Rear floor storage cover ..............57

Rear fog light ......................... 76, 95

Rear window wiper/washer .......... 63

Recommended fluids and lubricants ........................ 177, 181

Reduced engine power ................76

Refuelling ................................... 132

Registered trademarks ...............194

Retained power off .....................110

Reversing lights ........................... 96

Ride control systems ..................121

Roof .............................................. 33

Roof load ...................................... 58

S Safety belts ................................... 39

Seat adjustment ....................... 7, 37