engine OPEL KARL 2018.5 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2018.5, Model line: KARL, Model: OPEL KARL 2018.5Pages: 203, PDF Size: 5.64 MB

Page 145 of 203

Vehicle care143Bulb replacement

Switch off the ignition and switch off

the relevant switch or close the doors.

Only hold a new bulb at the base! Do

not touch the bulb glass with bare

hands.

Use only the same bulb type for

replacement.

Replace headlight bulbs from within

the engine compartment.

Bulb check After a bulb replacement switch on

the ignition, operate and check the

lights.Halogen headlights

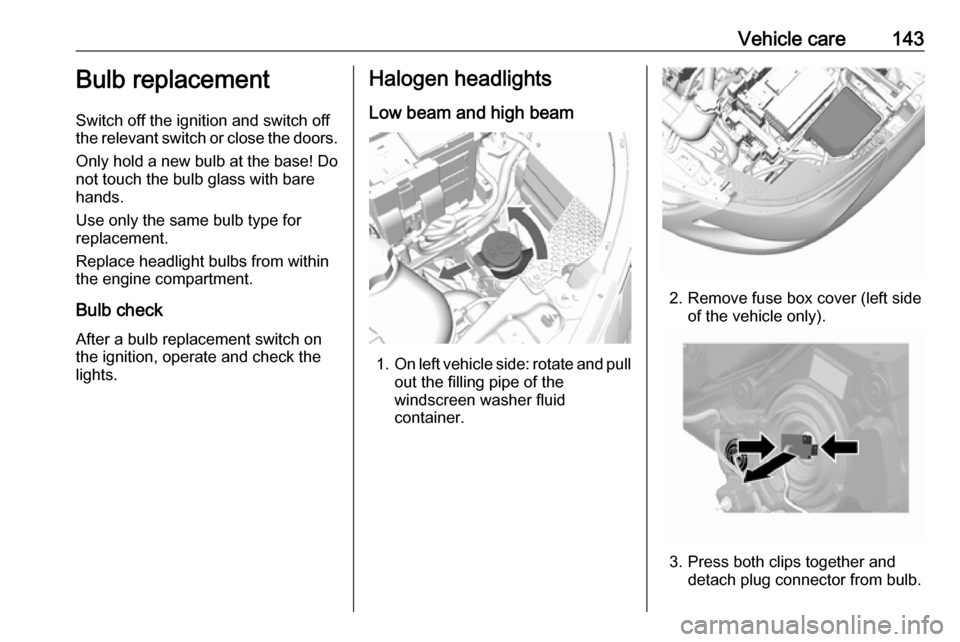

Low beam and high beam

1. On left vehicle side: rotate and pull

out the filling pipe of the

windscreen washer fluid

container.

2. Remove fuse box cover (left side of the vehicle only).

3. Press both clips together anddetach plug connector from bulb.

Page 151 of 203

Vehicle care149Electrical system

Fuses Data on the replacement fuse must

match the data on the defective fuse.

There are two fuse boxes in the

vehicle:

● In the front left of the engine compartment.

● On the driver's side behind a cover in the instrument panel.

Before replacing a fuse, turn off the

respective switch and the ignition.There are different kinds of fuses in

the vehicle. Some types of fuses in

the vehicle may differ from the ones

illustrated.

Depending on the type of fuse, a

blown fuse can be recognized by its

melted wire. Do not replace the fuse until the cause of the fault has been

remedied.

Some functions are protected by

several fuses.

Fuses may also be inserted without existence of a function.

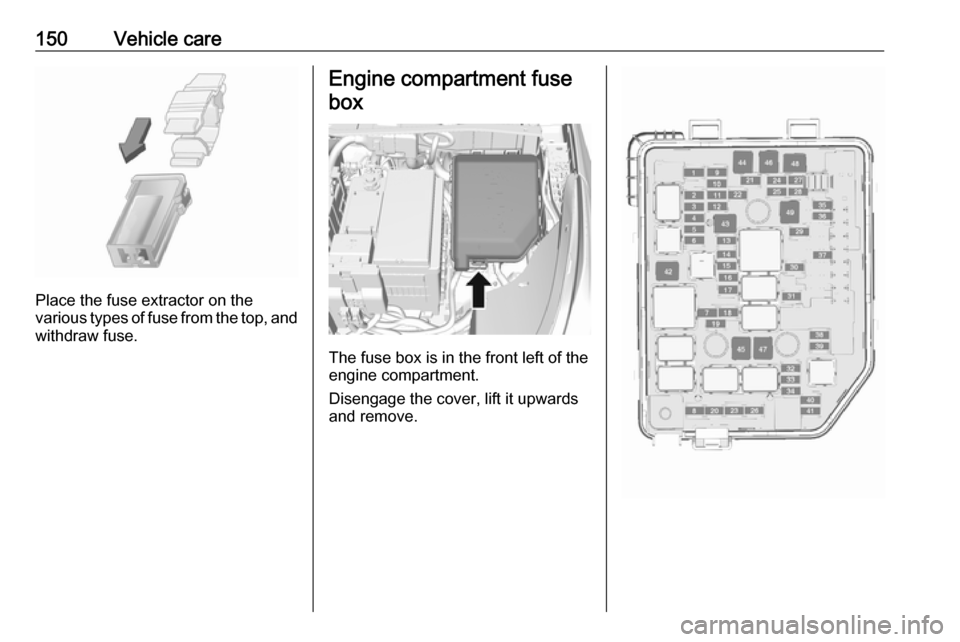

Fuse extractor

A fuse extractor may be located in the

fuse box in the engine compartment.

Page 152 of 203

150Vehicle care

Place the fuse extractor on the

various types of fuse from the top, and

withdraw fuse.

Engine compartment fuse

box

The fuse box is in the front left of the

engine compartment.

Disengage the cover, lift it upwards

and remove.

Page 153 of 203

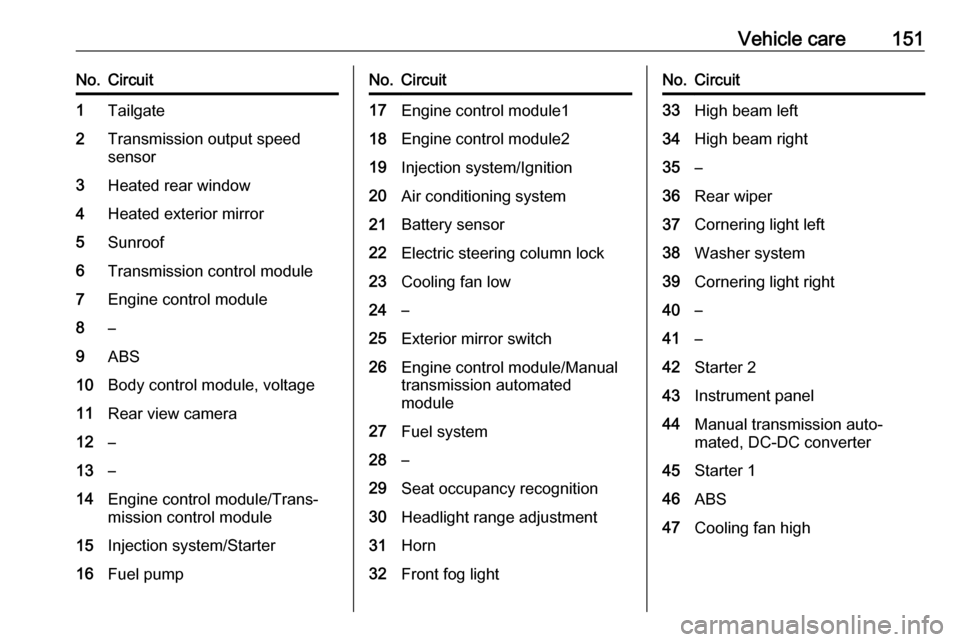

Vehicle care151No.Circuit1Tailgate2Transmission output speed

sensor3Heated rear window4Heated exterior mirror5Sunroof6Transmission control module7Engine control module8–9ABS10Body control module, voltage11Rear view camera12–13–14Engine control module/Trans‐

mission control module15Injection system/Starter16Fuel pumpNo.Circuit17Engine control module118Engine control module219Injection system/Ignition20Air conditioning system21Battery sensor22Electric steering column lock23Cooling fan low24–25Exterior mirror switch26Engine control module/Manual

transmission automated

module27Fuel system28–29Seat occupancy recognition30Headlight range adjustment31Horn32Front fog lightNo.Circuit33High beam left34High beam right35–36Rear wiper37Cornering light left38Washer system39Cornering light right40–41–42Starter 243Instrument panel44Manual transmission auto‐

mated, DC-DC converter45Starter 146ABS47Cooling fan high

Page 157 of 203

Vehicle care155Directional tyresDirectional tyres must be mounted so

that they rotate in the correct

direction. The proper rotation

direction is indicated by a symbol

(e.g. an arrow) on the sidewall.

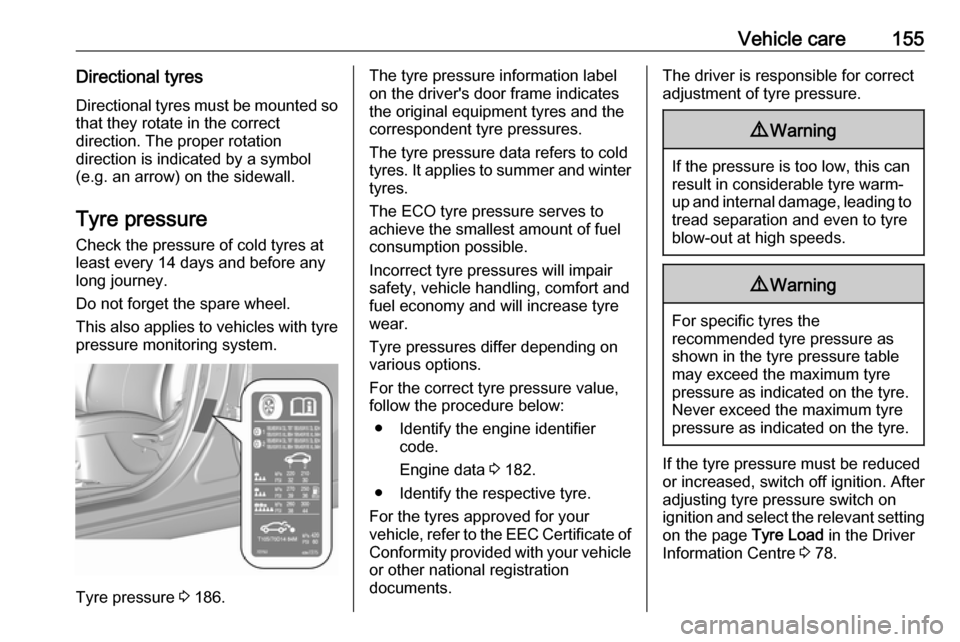

Tyre pressure

Check the pressure of cold tyres at least every 14 days and before any

long journey.

Do not forget the spare wheel.

This also applies to vehicles with tyre pressure monitoring system.

Tyre pressure 3 186.

The tyre pressure information label

on the driver's door frame indicates

the original equipment tyres and the

correspondent tyre pressures.

The tyre pressure data refers to cold

tyres. It applies to summer and winter tyres.

The ECO tyre pressure serves to

achieve the smallest amount of fuel

consumption possible.

Incorrect tyre pressures will impair

safety, vehicle handling, comfort and fuel economy and will increase tyre

wear.

Tyre pressures differ depending on

various options.

For the correct tyre pressure value,

follow the procedure below:

● Identify the engine identifier code.

Engine data 3 182.

● Identify the respective tyre.

For the tyres approved for your

vehicle, refer to the EEC Certificate of

Conformity provided with your vehicle or other national registration

documents.The driver is responsible for correct adjustment of tyre pressure.9 Warning

If the pressure is too low, this can

result in considerable tyre warm-

up and internal damage, leading to tread separation and even to tyre

blow-out at high speeds.

9 Warning

For specific tyres the

recommended tyre pressure as

shown in the tyre pressure table may exceed the maximum tyre

pressure as indicated on the tyre.

Never exceed the maximum tyre

pressure as indicated on the tyre.

If the tyre pressure must be reduced

or increased, switch off ignition. After

adjusting tyre pressure switch on

ignition and select the relevant setting on the page Tyre Load in the Driver

Information Centre 3 78.

Page 164 of 203

162Vehicle care

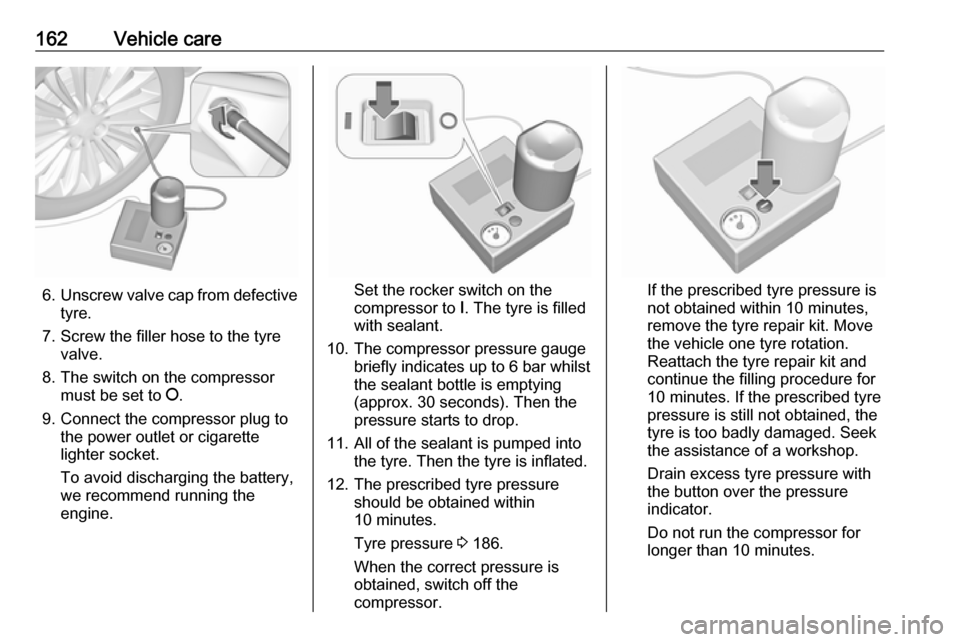

6.Unscrew valve cap from defective

tyre.

7. Screw the filler hose to the tyre valve.

8. The switch on the compressor must be set to J.

9. Connect the compressor plug to the power outlet or cigarette

lighter socket.

To avoid discharging the battery,

we recommend running the

engine.Set the rocker switch on the

compressor to I. The tyre is filled

with sealant.

10. The compressor pressure gauge briefly indicates up to 6 bar whilst

the sealant bottle is emptying

(approx. 30 seconds). Then the

pressure starts to drop.

11. All of the sealant is pumped into the tyre. Then the tyre is inflated.

12. The prescribed tyre pressure should be obtained within

10 minutes.

Tyre pressure 3 186.

When the correct pressure is

obtained, switch off the

compressor.If the prescribed tyre pressure is

not obtained within 10 minutes,

remove the tyre repair kit. Move

the vehicle one tyre rotation.

Reattach the tyre repair kit and

continue the filling procedure for 10 minutes. If the prescribed tyre

pressure is still not obtained, the

tyre is too badly damaged. Seek

the assistance of a workshop.

Drain excess tyre pressure with

the button over the pressure indicator.

Do not run the compressor for

longer than 10 minutes.

Page 171 of 203

Vehicle care1693. Connect the black lead to thenegative terminal of the booster

battery.

4. Connect the other end of the black

lead to a vehicle grounding point,

such as the engine block or an

engine mounting bolt. Connect as far away from the discharged

vehicle battery as possible,

however at least 60 cm.

Route the leads so that they cannot

catch on rotating parts in the engine

compartment.

To start the engine: 1. Start the engine of the vehicle providing the jump.

2. After 5 minutes, start the other engine. Start attempts should be

made for no longer than

15 seconds at an interval of

1 minute.

3. Allow both engines to idle for approx. 3 minutes with the leads

connected.4. Switch on electrical consumers (e.g. headlights, heated rear

window) of the vehicle receiving

the jump start.

5. Reverse above sequence exactly when removing leads.Towing

Towing the vehicle The towing eye is stowed with thevehicle tools 3 153.

1. Wrap a cloth around the tip of a flat

screwdriver to prevent paint

damage. Disengage cap by using

the screwdriver and remove the

cap.

Page 172 of 203

170Vehicle care

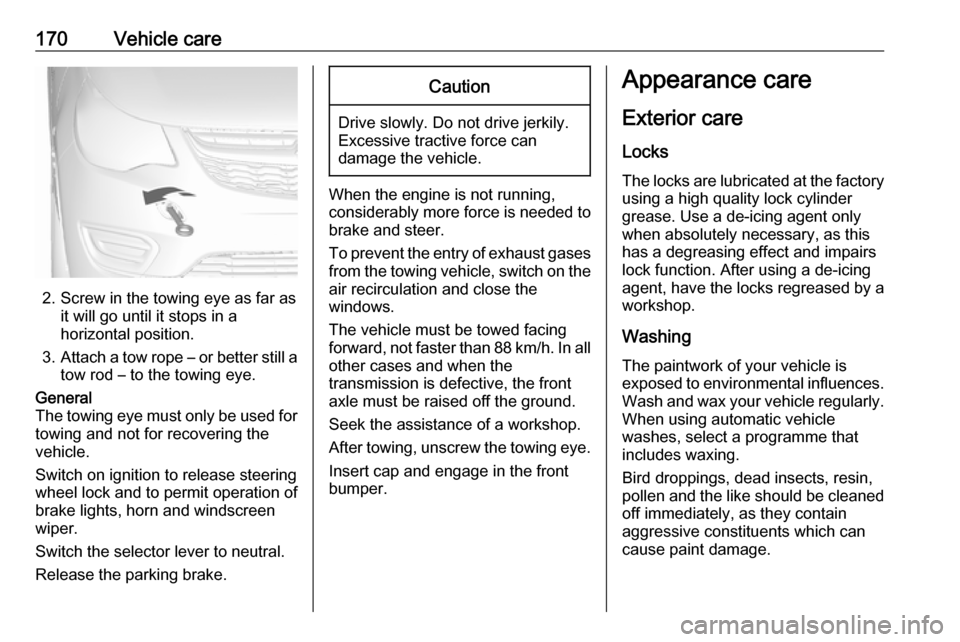

2. Screw in the towing eye as far asit will go until it stops in a

horizontal position.

3. Attach a tow rope – or better still a

tow rod – to the towing eye.

General

The towing eye must only be used for

towing and not for recovering the

vehicle.

Switch on ignition to release steering

wheel lock and to permit operation of

brake lights, horn and windscreen

wiper.

Switch the selector lever to neutral.

Release the parking brake.Caution

Drive slowly. Do not drive jerkily.

Excessive tractive force can

damage the vehicle.

When the engine is not running,

considerably more force is needed to

brake and steer.

To prevent the entry of exhaust gases from the towing vehicle, switch on the

air recirculation and close the

windows.

The vehicle must be towed facing

forward, not faster than 88 km/h. In all

other cases and when the

transmission is defective, the front

axle must be raised off the ground.

Seek the assistance of a workshop.

After towing, unscrew the towing eye.

Insert cap and engage in the front

bumper.

Appearance care

Exterior care

Locks The locks are lubricated at the factoryusing a high quality lock cylinder

grease. Use a de-icing agent only

when absolutely necessary, as this

has a degreasing effect and impairs

lock function. After using a de-icing

agent, have the locks regreased by a workshop.

Washing The paintwork of your vehicle is

exposed to environmental influences.

Wash and wax your vehicle regularly. When using automatic vehicle

washes, select a programme that

includes waxing.

Bird droppings, dead insects, resin,

pollen and the like should be cleaned

off immediately, as they contain

aggressive constituents which can

cause paint damage.

Page 173 of 203

Vehicle care171If using a car wash, comply with the

car wash manufacturer's instructions.

The windscreen wiper and rear

window wiper must be switched off.

Remove antenna and external

accessories such as roof racks etc.

If you wash your vehicle by hand,

make sure that the insides of the

wheel housings are also thoroughly

rinsed out.

Clean edges and folds on opened

doors and the bonnet as well as the

areas they cover.

Clean bright metal mouldings with a

cleaning solution approved for

aluminium to avoid damages.Caution

Always use a cleaning agent with

a pH value of four to nine.

Do not use cleaning agents on hot surfaces.

Have the door hinges of all doors

greased by a workshop.

Do not clean the engine compartment with a steam-jet or high-pressure jet

cleaner.

Thoroughly rinse and leather-off the vehicle. Rinse leather frequently. Use

separate leathers for painted and

glass surfaces: remnants of wax on

the windows will impair vision.

Do not use hard objects to remove

spots of tar. Use tar removal spray on

painted surfaces.

Exterior lights

Headlight and other light covers are

made of plastic. Do not use any

abrasive or caustic agents, do not use

an ice scraper, and do not clean them

dry.

Polishing and waxing

Wax painted parts of the vehicle

regularly (at the latest when water no longer beads). Otherwise, the

paintwork will dry out.

Polishing is necessary only if the paint

has become dull or if solid deposits

have become attached to it.

Paintwork polish with silicone forms a

protective film, making waxing

unnecessary.Unpainted plastic body parts must not

be treated with wax or polishing

agents.

Windows and windscreen wiper

blades

Use a soft lint-free cloth or chamois

leather together with window cleaner and insect remover.

When cleaning the rear window from

inside, always wipe in parallel to the

heating element to prevent damage.

For mechanical removal of ice, use a

sharp-edged ice scraper. Press the

scraper firmly against the glass so

that no dirt can get under it and

scratch the glass.

Clean smearing wiper blades with a

soft cloth and window cleaner.

Sunroof

Never clean with solvents or abrasive agents, fuels, aggressive media (e.g.

paint cleaner, acetone-containing

solutions etc.), acidic or highly

alkaline media or abrasive pads. Do

not apply wax or polishing agents to

the sunroof.

Page 176 of 203

174Service and maintenanceService and

maintenanceGeneral information ...................174

Service information ..................174

Recommended fluids, lubricants

and parts .................................... 175

Recommended fluids and lubricants ................................ 175General information

Service information In order to ensure economical and

safe vehicle operation and to

maintain the value of your vehicle, it

is of vital importance that all

maintenance work is carried out at the proper intervals as specified.

The detailed, up-to-date service

schedule for your vehicle is available

at the workshop.

Service display 3 69.

European service intervals

Maintenance of your vehicle is

required every 30,000 km or after one year, whichever occurs first.

Additional engine oil and filter change

is indicated by the engine oil life

system, when required earlier than

maintenance.

A shorter service interval can be valid for severe driving behaviour, e.g. for

taxis and police vehicles.

The European service intervals are

valid for the following countries:Andorra, Austria, Belgium, Bosnia-

Herzegovina, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark,

Estonia, Finland, France, Germany,

Greece, Greenland, Hungary,

Iceland, Ireland, Italy, Latvia,

Liechtenstein, Lithuania,

Luxembourg, Macedonia, Malta,

Monaco, Montenegro, Netherlands,

Norway, Poland, Portugal, Romania, San Marino, Serbia, Slovakia,

Slovenia, Spain, Sweden,

Switzerland, United Kingdom.

Service display 3 69.

International service intervals

Maintenance of your vehicle is

required every 15,000 km or after one year, whichever occurs first.

Additional engine oil and filter change

is indicated by the engine oil life

system, when required earlier than

maintenance.

Severe operating conditions exist if

one or more of the following

circumstances occur frequently: Cold

starting, stop and go operation, trailer operation, mountain driving, driving

on poor and sandy road surfaces,