ESP OPEL KARL 2018 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2018, Model line: KARL, Model: OPEL KARL 2018Pages: 203, PDF Size: 5.44 MB

Page 128 of 203

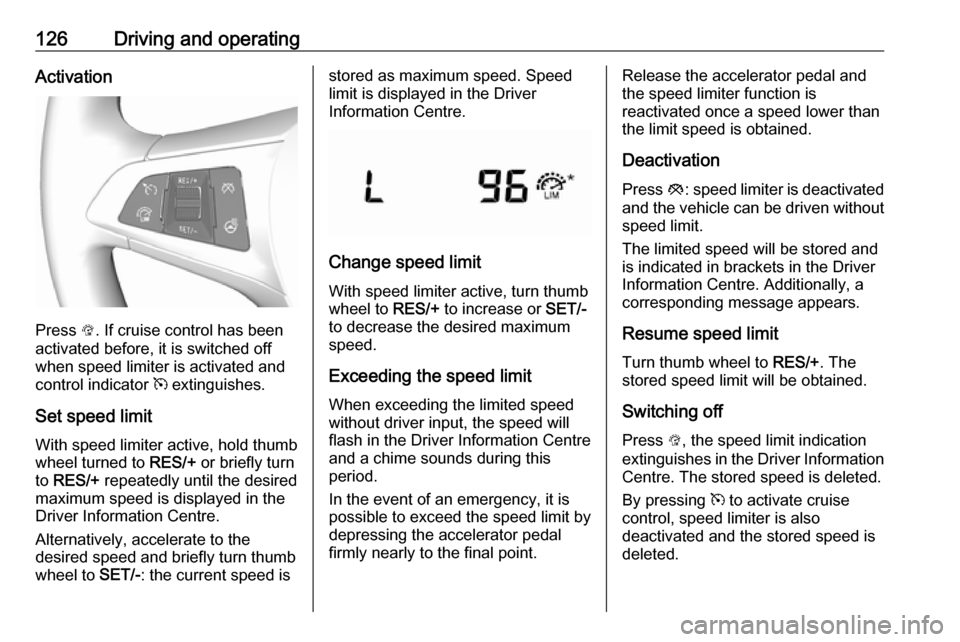

126Driving and operatingActivation

Press L. If cruise control has been

activated before, it is switched off when speed limiter is activated and

control indicator m extinguishes.

Set speed limit With speed limiter active, hold thumb

wheel turned to RES/+ or briefly turn

to RES/+ repeatedly until the desired

maximum speed is displayed in the

Driver Information Centre.

Alternatively, accelerate to the

desired speed and briefly turn thumb

wheel to SET/-: the current speed is

stored as maximum speed. Speed

limit is displayed in the Driver

Information Centre.

Change speed limit

With speed limiter active, turn thumb

wheel to RES/+ to increase or SET/-

to decrease the desired maximum

speed.

Exceeding the speed limit

When exceeding the limited speed

without driver input, the speed will

flash in the Driver Information Centre

and a chime sounds during this

period.

In the event of an emergency, it is

possible to exceed the speed limit by

depressing the accelerator pedal

firmly nearly to the final point.

Release the accelerator pedal and

the speed limiter function is

reactivated once a speed lower than

the limit speed is obtained.

Deactivation Press y: speed limiter is deactivated

and the vehicle can be driven without speed limit.

The limited speed will be stored and

is indicated in brackets in the Driver

Information Centre. Additionally, a

corresponding message appears.

Resume speed limit

Turn thumb wheel to RES/+. The

stored speed limit will be obtained.

Switching off Press L, the speed limit indication

extinguishes in the Driver Information

Centre. The stored speed is deleted.

By pressing m to activate cruise

control, speed limiter is also

deactivated and the stored speed is

deleted.

Page 129 of 203

Driving and operating127By switching off the ignition, speed

limiter is also deactivated, but the

speed limit will be stored for next

speed limiter activation.

Parking assist

Rear parking assist9 Warning

It is the driver who bears full

responsibility for the parking

manoeuvre.

Always check the surrounding

area while reversing and using the rear parking assist system.

The rear parking assist makes

parking easier by measuring the

distance between the vehicle and

rear obstacles. It informs and warns

the driver by giving acoustic signals

and display indication.

The system has three ultrasonic

parking sensors in the rear bumper.

Activation

When reverse gear is engaged, the

system is ready to operate

automatically.

Indication

The system warns the driver with

acoustic signals against potentially

hazardous obstacles behind the

vehicle. The interval between the

sounds becomes shorter as the

vehicle gets closer to that obstacle.

When the distance is less than

approx. 40 cm, the sound is

continuous.

Deactivation

The system automatically switches

off when reverse gear is disengaged.

The system might not detect the

obstacle when the vehicle is driven above a 10 km/h.

Fault

In the event of a fault in the system,

control indicator r illuminates in the

instrument cluster 3 74.

Additionally if the system does not work due to temporary conditions like

snow covered sensors, r

illuminates.

Page 152 of 203

150Vehicle careInterior lightsCourtesy light, reading lights 1. To remove, prise the opposite side of the lamp switch using a

flat-blade screwdriver. (Be careful

not to make scratches.)

2. Remove the bulb.

3. Replace the bulb.

4. Reinstall the lamp assembly.

Load compartment light

1. Prise the lamp out with a screwdriver.

2. Remove bulb.

3. Insert new bulb.

4. Install lamp.

Instrument panel illumination

Have bulbs replaced by a workshop.

Electrical system

Fuses

Data on the replacement fuse must

match the data on the defective fuse.

There are two fuse boxes in the

vehicle:

● In the front left of the engine compartment.

● On the driver's side behind a cover in the instrument panel.

Before replacing a fuse, turn off the

respective switch and the ignition.

Page 159 of 203

Vehicle care157The tyre pressure information label

on the driver's door frame indicates the original equipment tyres and the

correspondent tyre pressures.

The tyre pressure data refers to cold

tyres. It applies to summer and winter

tyres.

The ECO tyre pressure serves to

achieve the smallest amount of fuel

consumption possible.

Incorrect tyre pressures will impair

safety, vehicle handling, comfort and

fuel economy and will increase tyre

wear.

Tyre pressures differ depending on

various options.

For the correct tyre pressure value,

follow the procedure below:

● Identify the engine identifier code. Engine data 3 184.

● Identify the respective tyre.

For the tyres approved for your

vehicle, refer to the EEC Certificate of Conformity provided with your vehicle

or other national registration

documents.The driver is responsible for correct

adjustment of tyre pressure.9 Warning

If the pressure is too low, this can

result in considerable tyre warm-

up and internal damage, leading to tread separation and even to tyre

blow-out at high speeds.

9 Warning

For specific tyres the

recommended tyre pressure as

shown in the tyre pressure table may exceed the maximum tyre

pressure as indicated on the tyre.

Never exceed the maximum tyre

pressure as indicated on the tyre.

If the tyre pressure must be reduced

or increased, switch off ignition. After

adjusting tyre pressure switch on

ignition and select the relevant setting on the page Tyre Load in the Driver

Information Centre 3 77.

Temperature dependency

The tyre pressure depends on the temperature of the tyre. During

driving, tyre temperature and

pressure increase. Tyre pressure

values provided on the tyre

information label and tyre pressure

chart are valid for cold tyres, which

means at 20 °C.

The pressure increases by nearly

10 kPa for a 10 °C temperature

increase. This must be considered

when warm tyres are checked.

The tyre pressure value displayed in

the Driver Information Centre shows

the real tyre pressure. A cooled down tyre will show a decreased value,

which does not indicate an air leak.

Tyre pressure monitoringsystem

The tyre pressure monitoring system

checks the pressure of all four tyres

once a minute when vehicle speed

exceeds a certain limit.

Page 160 of 203

158Vehicle careCaution

Tyre pressure monitoring system

warns only about low tyre pressure condition and does not replace

regular tyre maintenance by the

driver.

All wheels must be equipped with pressure sensors and the tyres must

have the prescribed pressure.

Note

In countries where the tyre pressure

monitoring system is legally

required, the use of wheels without

pressure sensors will invalidate the

vehicle operating permit.

The current tyre pressures can be

shown in the Vehicle Information

Menu in the Driver Information

Centre.

The menu can be selected by

pressing the buttons on the turn

signal lever.

Press MENU to select the Vehicle

Information Menu X.

Turn the adjuster wheel to select the

tyre pressure monitoring system.

System status and pressure warnings

are displayed by a message with the

corresponding tyre flashing in the

Driver Information Centre.

The system considers the tyre

temperature for the warnings.

Temperature dependency 3 156.

A detected low tyre pressure

condition is indicated by the control

indicator w 3 75.

If w illuminates, stop as soon as

possible and inflate the tyres as

recommended 3 188.

Page 163 of 203

Vehicle care16114. Set all four tyres to therecommended air pressure level

as indicated on the tyre

information label.

15. Ensure the tyre loading status is set according to the selected

pressure 3 77.

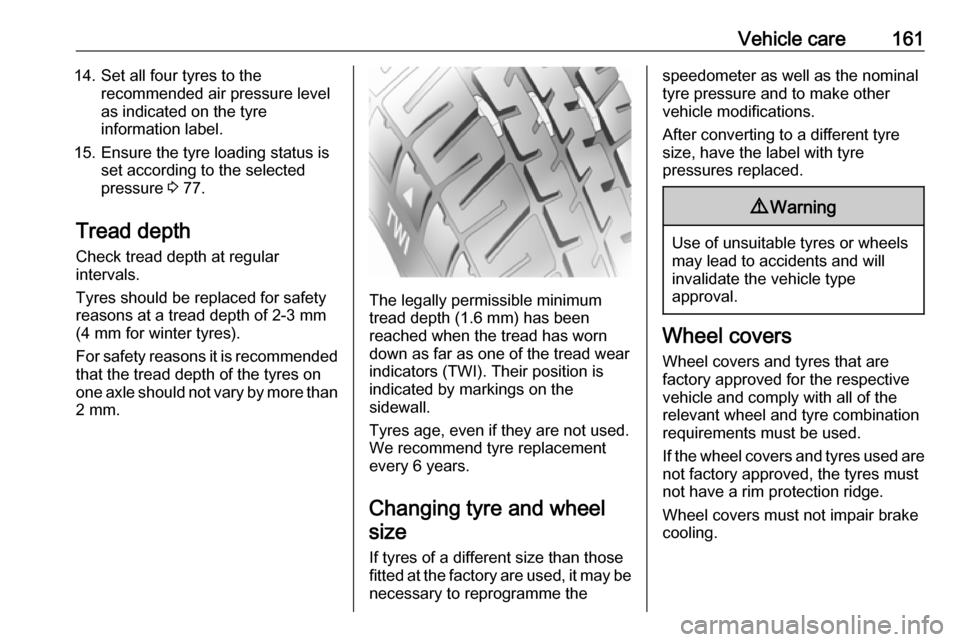

Tread depth

Check tread depth at regular

intervals.

Tyres should be replaced for safety

reasons at a tread depth of 2-3 mm

(4 mm for winter tyres).

For safety reasons it is recommended

that the tread depth of the tyres on

one axle should not vary by more than 2 mm.

The legally permissible minimum

tread depth (1.6 mm) has been

reached when the tread has worn

down as far as one of the tread wear

indicators (TWI). Their position is

indicated by markings on the

sidewall.

Tyres age, even if they are not used.

We recommend tyre replacement

every 6 years.

Changing tyre and wheel size

If tyres of a different size than those

fitted at the factory are used, it may be necessary to reprogramme the

speedometer as well as the nominal

tyre pressure and to make other

vehicle modifications.

After converting to a different tyre

size, have the label with tyre

pressures replaced.9 Warning

Use of unsuitable tyres or wheels

may lead to accidents and will

invalidate the vehicle type

approval.

Wheel covers

Wheel covers and tyres that are

factory approved for the respective

vehicle and comply with all of the

relevant wheel and tyre combination requirements must be used.

If the wheel covers and tyres used are

not factory approved, the tyres must

not have a rim protection ridge.

Wheel covers must not impair brake

cooling.

Page 169 of 203

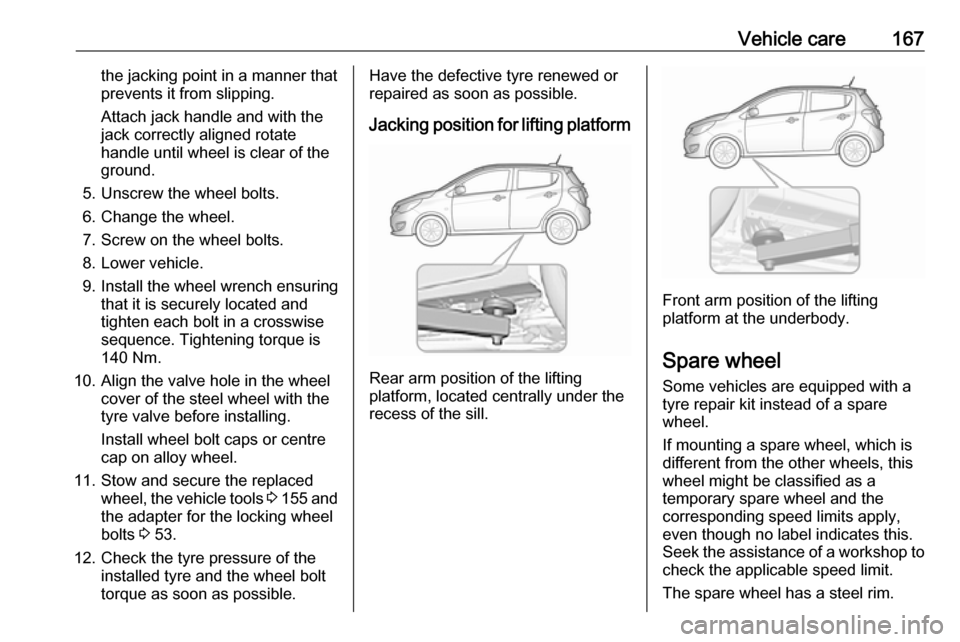

Vehicle care167the jacking point in a manner thatprevents it from slipping.

Attach jack handle and with the

jack correctly aligned rotate

handle until wheel is clear of the

ground.

5. Unscrew the wheel bolts.

6. Change the wheel.

7. Screw on the wheel bolts.

8. Lower vehicle.

9. Install the wheel wrench ensuring that it is securely located and

tighten each bolt in a crosswise

sequence. Tightening torque is

140 Nm.

10. Align the valve hole in the wheel cover of the steel wheel with thetyre valve before installing.

Install wheel bolt caps or centre

cap on alloy wheel.

11. Stow and secure the replaced wheel, the vehicle tools 3 155 and

the adapter for the locking wheel

bolts 3 53.

12. Check the tyre pressure of the installed tyre and the wheel bolt

torque as soon as possible.Have the defective tyre renewed or repaired as soon as possible.

Jacking position for lifting platform

Rear arm position of the lifting

platform, located centrally under the

recess of the sill.

Front arm position of the lifting platform at the underbody.

Spare wheel Some vehicles are equipped with a

tyre repair kit instead of a spare

wheel.

If mounting a spare wheel, which is

different from the other wheels, this

wheel might be classified as a

temporary spare wheel and the

corresponding speed limits apply,

even though no label indicates this.

Seek the assistance of a workshop to

check the applicable speed limit.

The spare wheel has a steel rim.

Page 171 of 203

Vehicle care169

5. Pull back the backrests.

6. Mount the hook to the tailgate latch.

7. Tighten the strap and secure it using the buckle.

9 Warning

Storing a jack, a wheel or other

equipment in the load

compartment could cause injury if they are not fixed properly. During a sudden stop or a collision, loose

equipment could strike someone.

Store jack and tools always in the

respective storage compartments

and secure them by fixing.

Damaged wheel placed in the load

compartment must always be

secured by the strap.Jump starting

Do not start with a quick charger.

A vehicle with a discharged vehicle

battery can be started using jump

leads and the vehicle battery of

another vehicle.9 Warning

Be extremely careful when starting

with jump leads. Any deviation

from the following instructions can

lead to injuries or damage caused

by battery explosion or damage to the electrical systems of both

vehicles.

9 Warning

Avoid contact of the battery with

eyes, skin, fabrics and painted

surfaces. The fluid contains

sulphuric acid which can cause

injuries and damage in the event

of direct contact.

● Never expose the battery to naked flames or sparks.

Page 176 of 203

174Vehicle careBefore and after winter, wash the

underbody and have the protective

wax coating checked.

Liquid gas system9 Danger

Liquid gas is heavier than air and

can collect in sink points.

Take care when performing work

at the underbody in a pit.

For painting work and when using a

drying booth at a temperature above

60 °C, the liquid gas tank must be

removed.

Do not make any modifications to the

liquid gas system.

Interior care

Interior and upholstery

Only clean the vehicle interior,

including the instrument panel fascia

and panelling, with a dry cloth or

interior cleaner.

Clean the leather upholstery with

clear water and a soft cloth. In case of heavy soiling, use leather care.

The instrument cluster and the

displays should only be cleaned using

a soft damp cloth. If necessary use a

weak soap solution.

Clean fabric upholstery with a

vacuum cleaner and brush. Remove

stains with an upholstery cleaner.

Clothing fabrics may not be

colourfast. This could cause visible

discolourations, especially on light- coloured upholstery. Removable

stains and discolourations should be

cleaned as soon as possible.

Clean seat belts with lukewarm water or interior cleaner.Caution

Close Velcro fasteners as open

Velcro fasteners on clothing could damage seat upholstery.

The same applies to clothing with

sharp-edged objects, like zips or

belts or studded jeans.

Plastic and rubber parts

Plastic and rubber parts can be

cleaned with the same cleaner as

used to clean the body. Use interior cleaner if necessary. Do not use any

other agent. Avoid solvents and petrol in particular. Do not use high-

pressure jet cleaners.

Page 182 of 203

180Technical dataIdentification plate

The identification plate is located on

the left door frame.

Information on identification label:1:manufacturer2:type approval number3:vehicle identification number4:permissible gross vehicle weight rating in kg5:permissible gross train weight

in kg6:maximum permissible front axle

load in kg7:maximum permissible rear axle

load in kg

The combined total of front and rear

axle loads must not exceed the

permissible gross vehicle weight. For

example, if the front axle is bearing its

maximum permissible load, the rear

axle can only bear a load that is equal

to the gross vehicle weight minus the front axle load.

The technical data is determined in

accordance with European

Community standards. We reserve

the right to make modifications.

Specifications in the vehicle

documents always have priority over

those given in this manual.

Engine identification

The technical data tables use the

engine identifier code. Engine data

3 184.

To identify the respective engine,

refer to the EEC Certificate of

Conformity provided with your vehicle

or other national registration

documents.

The Certificate of Conformity shows

the engine identifier code, other

national publications may show the

engineering code. Check piston

displacement and engine power to

identify the respective engine.