automatic transmission OPEL MANTA 1973 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: MANTA, Model: OPEL MANTA 1973Pages: 625, PDF Size: 17.22 MB

Page 476 of 625

AUTOMATIC TRANSMISSION 7C-115INPUT SPRAG RACE

8 RETAINER ASSEMBLY/

GEAR

CLUTCH HUBFigure

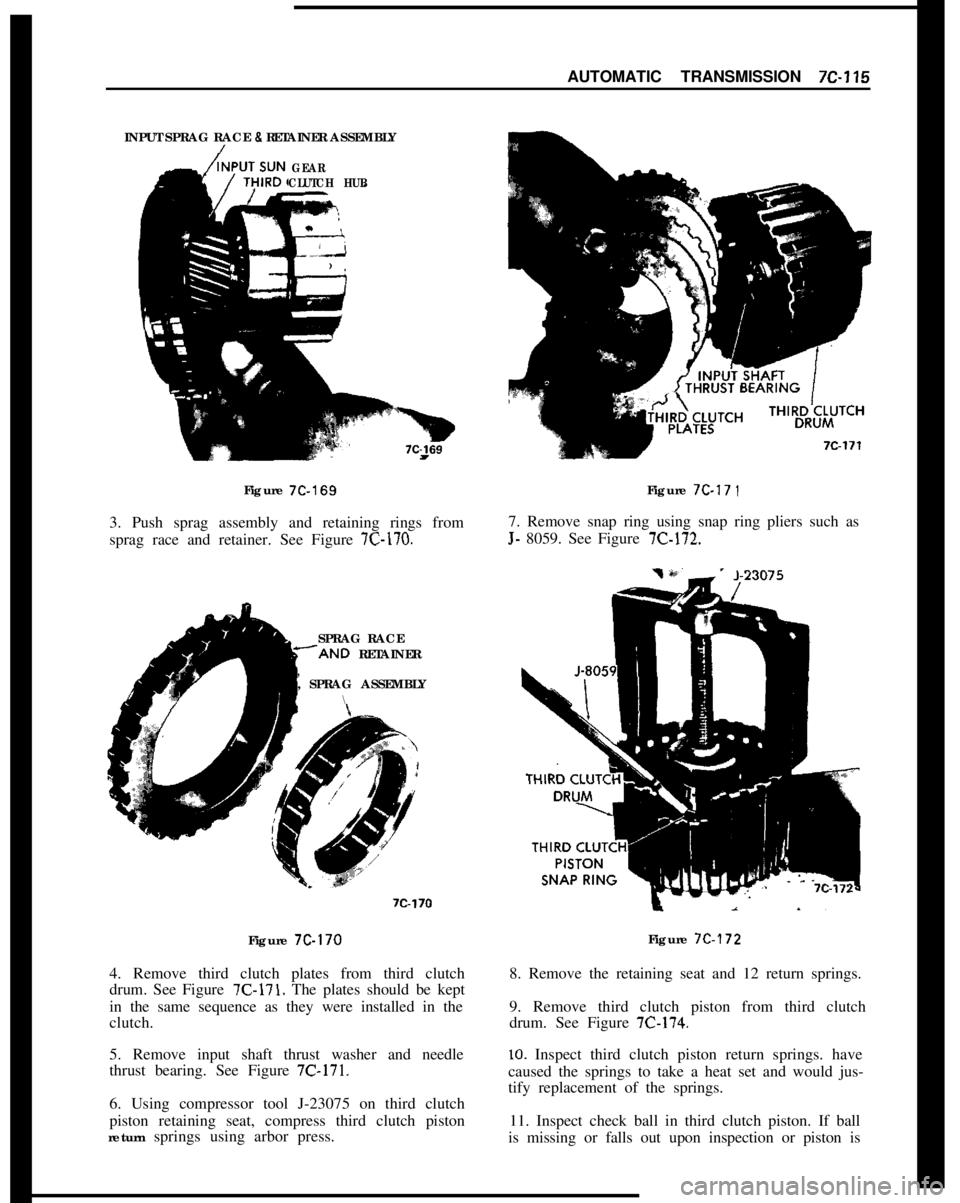

7C-1693. Push sprag assembly and retaining rings from

sprag race and retainer. See Figure

7C-170.Figure

7C.17 I7. Remove snap ring using snap ring pliers such as

J- 8059. See Figure 7C-172.SPRAG RACE

-AND RETAINER

,, SPRAG ASSEMBLY

\Figure

7C-1704. Remove third clutch plates from third clutch

drum. See Figure

7C-171. The plates should be kept

in the same sequence as they were installed in the

clutch.

5. Remove input shaft thrust washer and needle

thrust bearing. See Figure

7C-171.6. Using compressor tool J-23075 on third clutch

piston retaining seat, compress third clutch piston

return springs using arbor press.Figure 7C.172

8. Remove the retaining seat and 12 return springs.

9. Remove third clutch piston from third clutch

drum. See Figure

7C-174.

10. Inspect third clutch piston return springs. have

caused the springs to take a heat set and would jus-

tify replacement of the springs.

11. Inspect check ball in third clutch piston. If ball

is missing or falls out upon inspection or piston is

Page 478 of 625

AUTOMATIC TRANSMISSION 7C-117WIRE CRIMPED

INTO COPPERTUBING

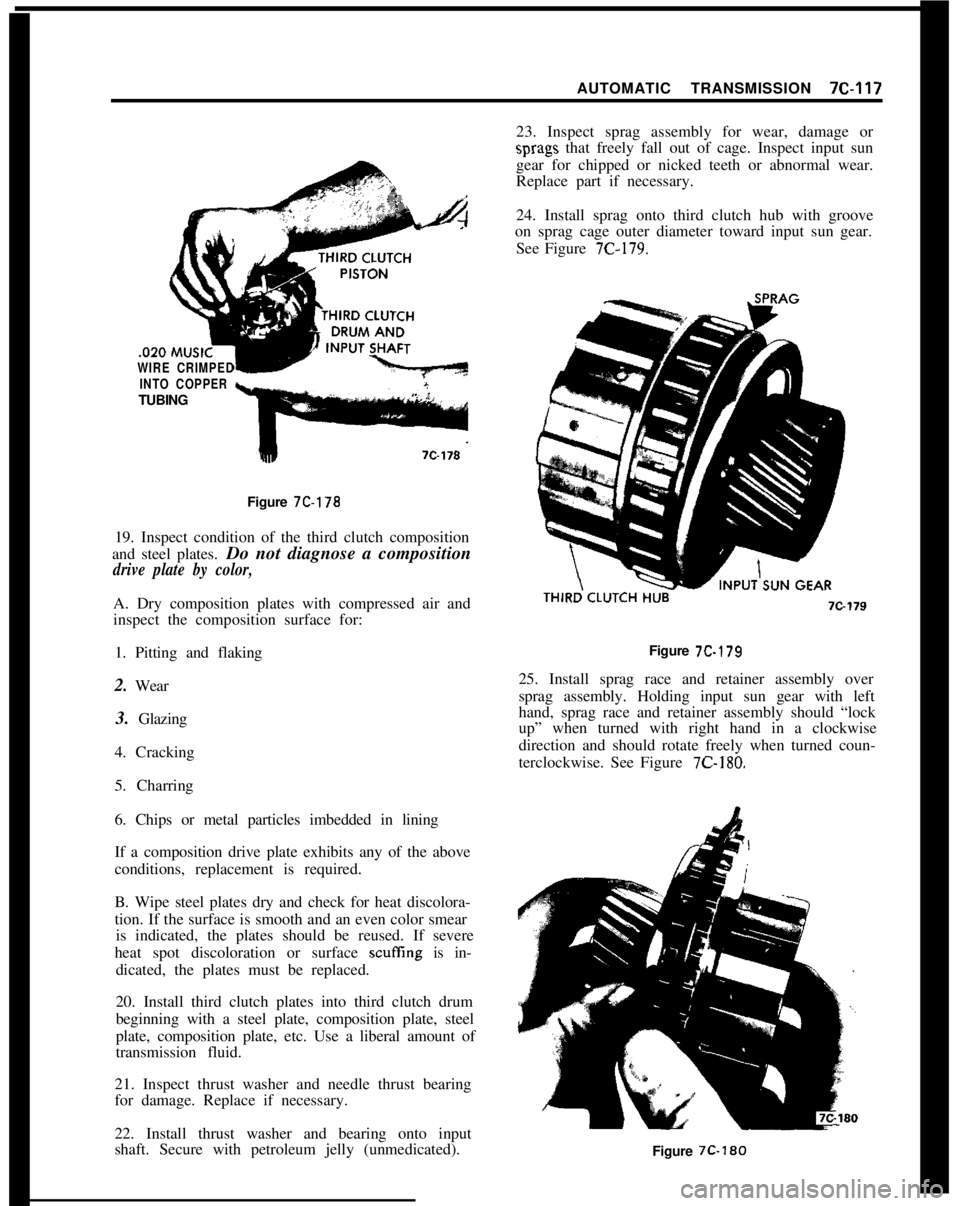

Figure 7C-178

19. Inspect condition of the third clutch composition

and steel plates. Do not diagnose a composition

drive plate by color,A. Dry composition plates with compressed air and

inspect the composition surface for:

1. Pitting and flaking

2. Wear

3. Glazing

4. Cracking

5. Charring

6. Chips or metal particles imbedded in lining

If a composition drive plate exhibits any of the above

conditions, replacement is required.

B. Wipe steel plates dry and check for heat discolora-

tion. If the surface is smooth and an even color smear

is indicated, the plates should be reused. If severe

heat spot discoloration or surface

scutXng is in-

dicated, the plates must be replaced.

20. Install third clutch plates into third clutch drum

beginning with a steel plate, composition plate, steel

plate, composition plate, etc. Use a liberal amount of

transmission fluid.

21. Inspect thrust washer and needle thrust bearing

for damage. Replace if necessary.

22. Install thrust washer and bearing onto input

shaft. Secure with petroleum jelly (unmedicated).23. Inspect sprag assembly for wear, damage orsprags that freely fall out of cage. Inspect input sun

gear for chipped or nicked teeth or abnormal wear.

Replace part if necessary.

24. Install sprag onto third clutch hub with groove

on sprag cage outer diameter toward input sun gear.

See Figure

7C-179.Figure 7C-179

25. Install sprag race and retainer assembly over

sprag assembly. Holding input sun gear with left

hand, sprag race and retainer assembly should “lock

up” when turned with right hand in a clockwise

direction and should rotate freely when turned coun-

terclockwise. See Figure

7C-180.Figure 7C-180

Page 482 of 625

AUTOMATIC TRANSMISSION 7C-121

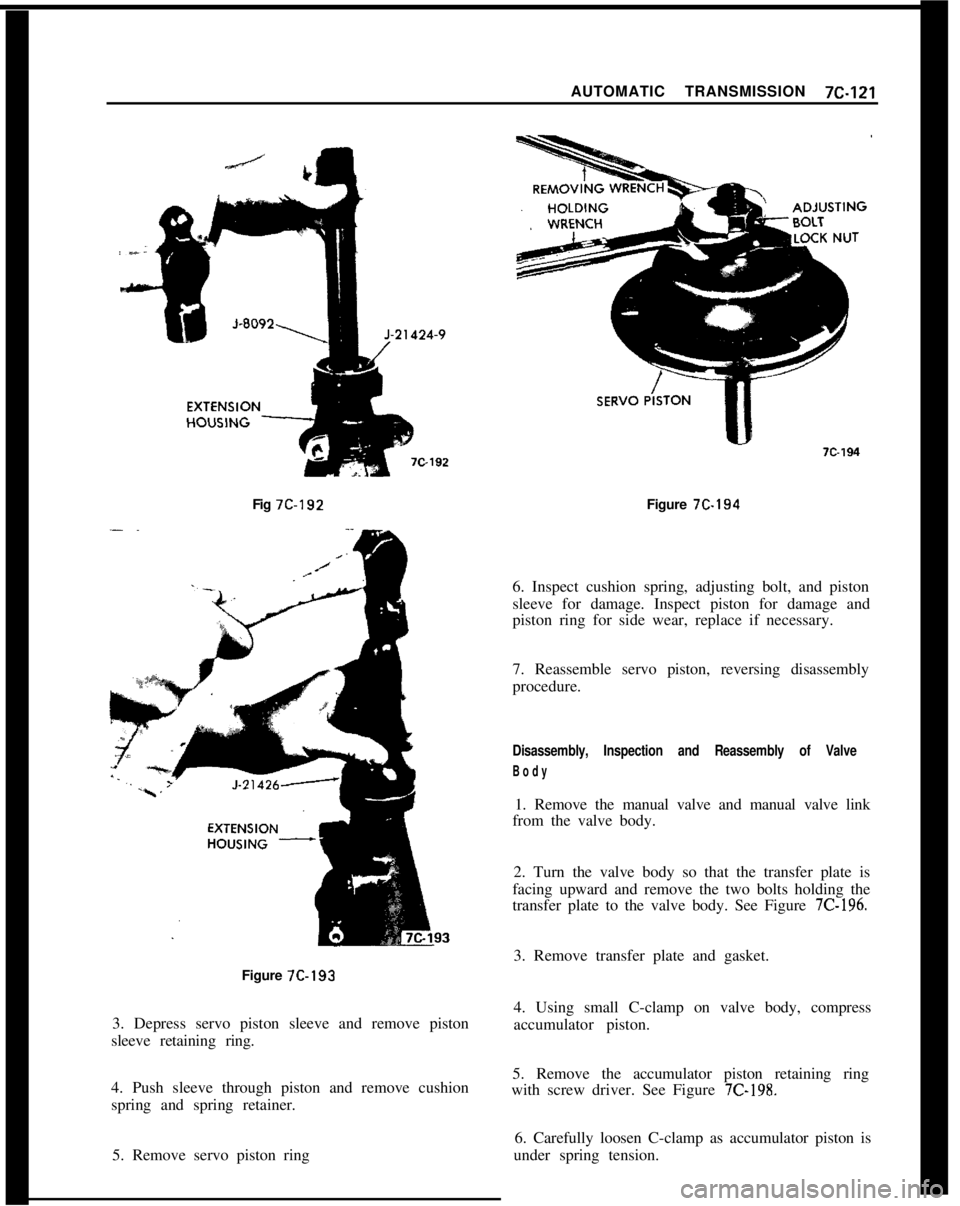

Fig 7C-192Figure 7C-194

6. Inspect cushion spring, adjusting bolt, and piston

sleeve for damage. Inspect piston for damage and

piston ring for side wear, replace if necessary.

7. Reassemble servo piston, reversing disassembly

procedure.Disassembly, Inspection and Reassembly of Valve

Body1. Remove the manual valve and manual valve link

from the valve body.

2. Turn the valve body so that the transfer plate is

facing upward and remove the two bolts holding the

transfer plate to the valve body. See Figure

7C-196.3. Remove transfer plate and gasket.

Figure 7C-193

3. Depress servo piston sleeve and remove piston

sleeve retaining ring.

4. Push sleeve through piston and remove cushion

spring and spring retainer.

5. Remove servo piston ring4. Using small C-clamp on valve body, compress

accumulator piston.

5. Remove the accumulator piston retaining ring

with screw driver. See Figure

7C-198.6. Carefully loosen C-clamp as accumulator piston is

under spring tension.

Page 484 of 625

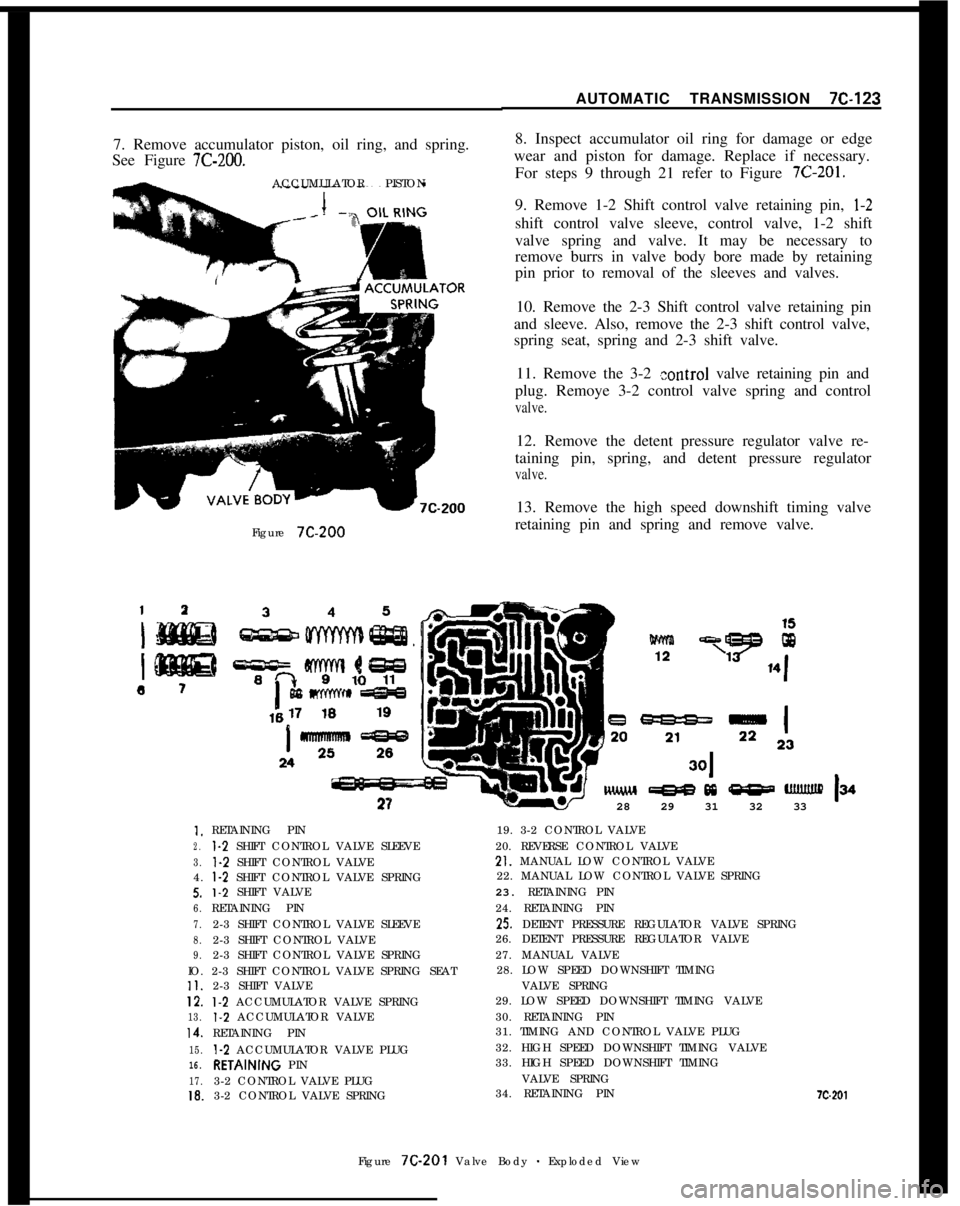

7. Remove accumulator piston, oil ring, and spring.

See Figure 7C-200.ACCUMULATOR PISTON

Figure 7C-200AUTOMATIC TRANSMISSION 7C-123

8. Inspect accumulator oil ring for damage or edge

wear and piston for damage. Replace if necessary.

For steps 9 through 21 refer to Figure 7C-201.9. Remove 1-2 Shift control valve retaining pin, l-2

shift control valve sleeve, control valve, 1-2 shift

valve spring and valve. It may be necessary to

remove burrs in valve body bore made by retaining

pin prior to removal of the sleeves and valves.

10. Remove the 2-3 Shift control valve retaining pin

and sleeve. Also, remove the 2-3 shift control valve,

spring seat, spring and 2-3 shift valve.

11. Remove the 3-2

,control valve retaining pin and

plug. Remoye 3-2 control valve spring and control

valve.12. Remove the detent pressure regulator valve re-

taining pin, spring, and detent pressure regulator

valve.13. Remove the high speed downshift timing valve

retaining pin and spring and remove valve.

1.RETAINING PIN

2.1-2 SHIFT CONTROL VALVE SLEEVE

3.1-2 SHIFT CONTROL VALVE

4. l-2 SHIFT CONTROL VALVE SPRING5.1-2 SHIFT VALVE

6.RETAINING PIN

7.2-3 SHIFT CONTROL VALVE SLEEVE

8.2-3 SHIFT CONTROL VALVE9.2-3 SHIFT CONTROL VALVE SPRING

IO. 2-3 SHIFT CONTROL VALVE SPRING SEAT

11.2-3 SHIFT VALVE

12.1-2 ACCUMULATOR VALVE SPRING13.1-2 ACCUMULATOR VALVE

14.RETAINING PIN

15.1-2 ACCUMULATOR VALVE PLUG16.RETAlNlNG PIN

17.3-2 CONTROL VALVE PLUG18.3-2 CONTROL VALVE SPRING

d 28 29 31 32 33uu44ucBBt?a~~19. 3-2 CONTROL VALVE

20. REVERSE CONTROL VALVE

21. MANUAL LOW CONTROL VALVE

22. MANUAL LOW CONTROL VALVE SPRING

23. RETAINING PIN

24. RETAINING PIN

25. DETENT PRESSURE REGULATOR VALVE SPRING

26. DETENT PRESSURE REGULATOR VALVE

27. MANUAL VALVE

28. LOW SPEED DOWNSHIFT TIMING

VALVE SPRING

29. LOW SPEED DOWNSHIFT TIMING VALVE

30. RETAINING PIN

31. TIMING AND CONTROL VALVE PLUG

32. HIGH SPEED DOWNSHIFT TIMING VALVE

33. HIGH SPEED DOWNSHIFT TIMING

VALVE SPRING

34. RETAINING PIN

7c-201Figure 7C-201 Valve Body

- Exploded View

Page 486 of 625

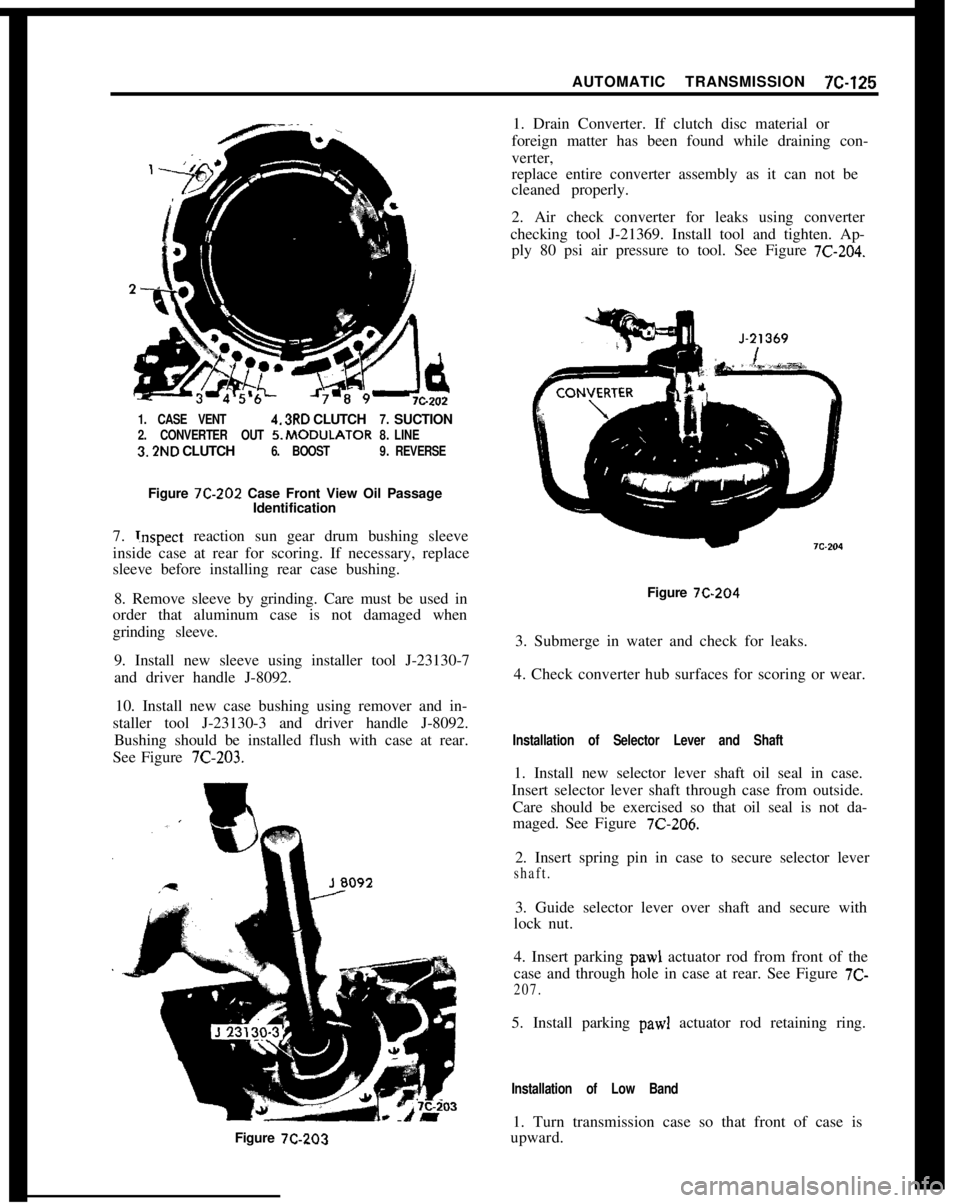

AUTOMATIC TRANSMISSION 7C-1251. CASE VENT4.3RD CLUTCH7.SUCTION

2. CONVERTER OUT5MODULATOR8.LINE/3.2ND CLUTCH

6. BOOST9.REVERSEFigure 7C-202 Case Front View Oil Passage

Identification

7.

!nspect reaction sun gear drum bushing sleeve

inside case at rear for scoring. If necessary, replace

sleeve before installing rear case bushing.

8. Remove sleeve by grinding. Care must be used in

order that aluminum case is not damaged when

grinding sleeve.

9. Install new sleeve using installer tool J-23130-7

and driver handle J-8092.

10. Install new case bushing using remover and in-

staller tool J-23130-3 and driver handle J-8092.

Bushing should be installed flush with case at rear.

See Figure

7C-203.Figure 7C-2031. Drain Converter. If clutch disc material or

foreign matter has been found while draining con-

verter,

replace entire converter assembly as it can not be

cleaned properly.

2. Air check converter for leaks using converter

checking tool J-21369. Install tool and tighten. Ap-

ply 80 psi air pressure to tool. See Figure

7C-204.Figure 7C-204

3. Submerge in water and check for leaks.

4. Check converter hub surfaces for scoring or wear.

Installation of Selector Lever and Shaft1. Install new selector lever shaft oil seal in case.

Insert selector lever shaft through case from outside.

Care should be exercised so that oil seal is not da-

maged. See Figure

7C-206.2. Insert spring pin in case to secure selector lever

shaft.3. Guide selector lever over shaft and secure with

lock nut.

4. Insert parking

paw1 actuator rod from front of the

case and through hole in case at rear. See Figure 7C-

207.5. Install parking

paw1 actuator rod retaining ring.

Installation of Low Band1. Turn transmission case so that front of case is

upward.

Page 488 of 625

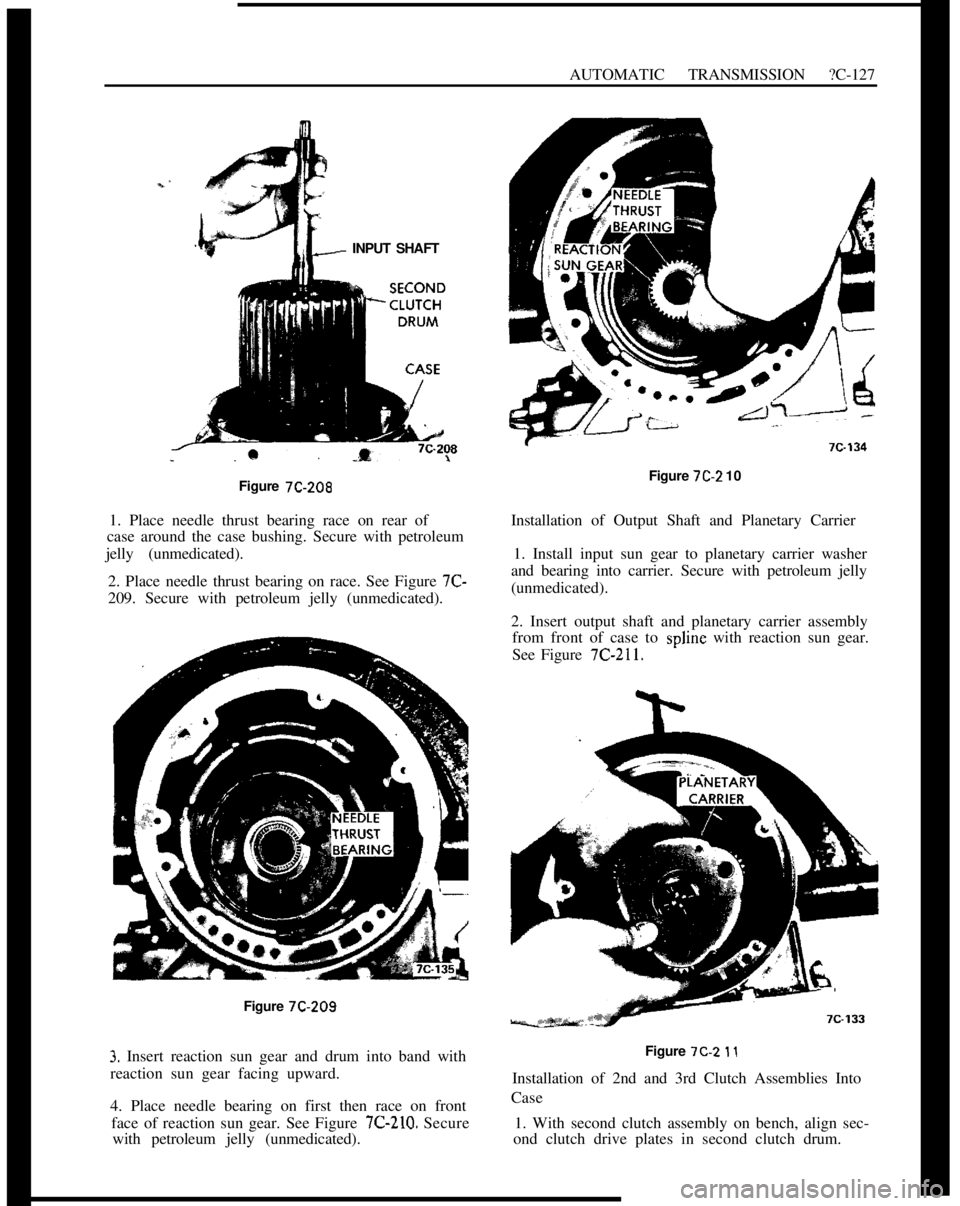

AUTOMATIC TRANSMISSION ?C-127

INPUT SHAFT

Figure 7C-208

1. Place needle thrust bearing race on rear of

case around the case bushing. Secure with petroleum

jelly (unmedicated).

2. Place needle thrust bearing on race. See Figure 7C-

209. Secure with petroleum jelly (unmedicated).

Figure 7C-2093. Insert reaction sun gear and drum into band with

reaction sun gear facing upward.

4. Place needle bearing on first then race on front

face of reaction sun gear. See Figure

7C-210. Secure

with petroleum jelly (unmedicated).Figure

7C-2 10

Installation of Output Shaft and Planetary Carrier

1. Install input sun gear to planetary carrier washer

and bearing into carrier. Secure with petroleum jelly

(unmedicated).

2. Insert output shaft and planetary carrier assembly

from front of case to spline with reaction sun gear.

See Figure

7C-211.Figure

7C-2 1 1Installation of 2nd and 3rd Clutch Assemblies Into

Case

1. With second clutch assembly on bench, align sec-

ond clutch drive plates in second clutch drum.

Page 490 of 625

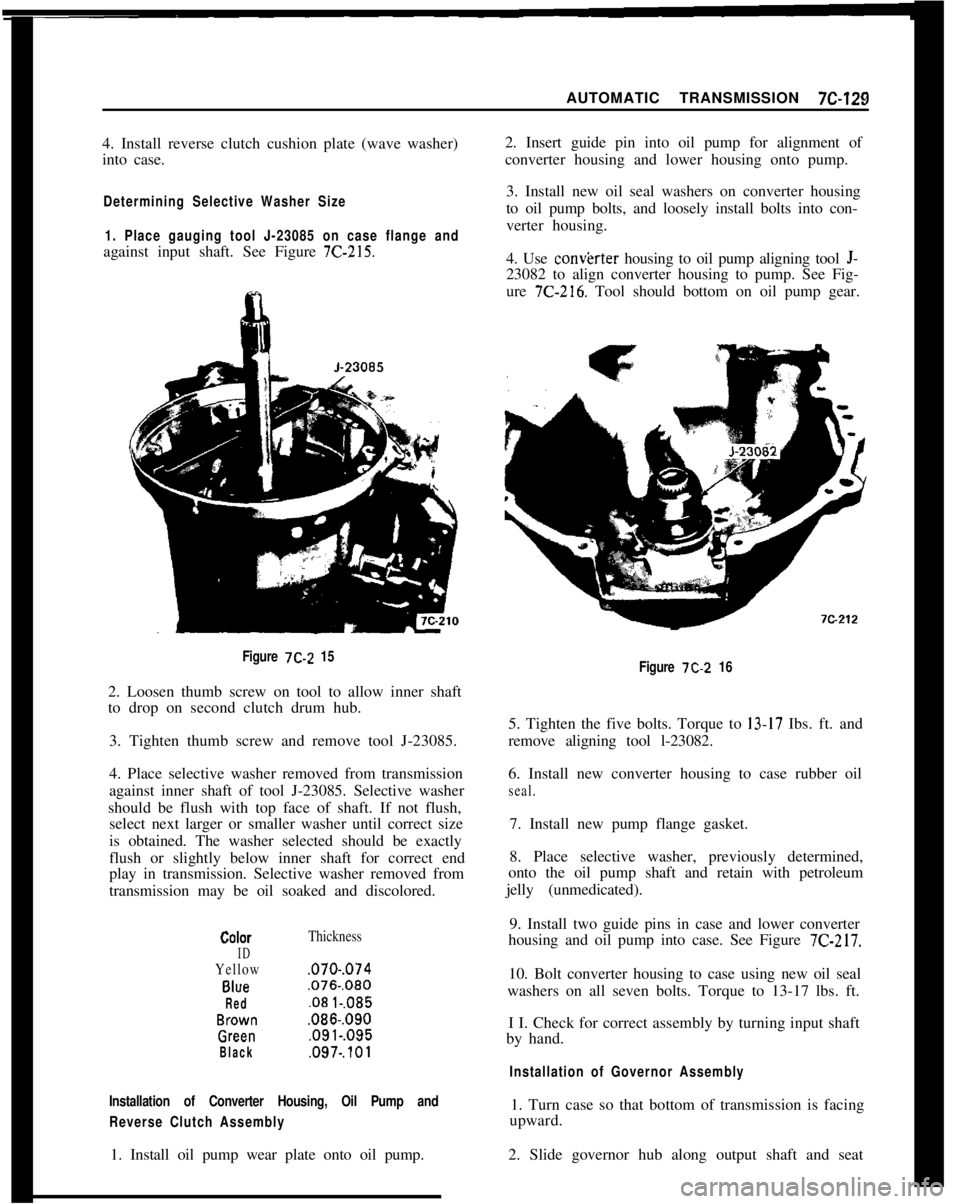

AUTOMATIC TRANSMISSION 7C-129

4. Install reverse clutch cushion plate (wave washer)2. Insert guide pin into oil pump for alignment of

into case.converter housing and lower housing onto pump.Determining Selective Washer Size

1. Place gauging tool J-23085 on case flange andagainst input shaft. See Figure

7C-215.3. Install new oil seal washers on converter housing

to oil pump bolts, and loosely install bolts into con-

verter housing.

4. Use convkrter housing to oil pump aligning tool J-23082 to align converter housing to pump. See Fig-

ure

7C-216. Tool should bottom on oil pump gear.

Figure 7C-2 152. Loosen thumb screw on tool to allow inner shaft

to drop on second clutch drum hub.

3. Tighten thumb screw and remove tool J-23085.

4. Place selective washer removed from transmission

against inner shaft of tool J-23085. Selective washer

should be flush with top face of shaft. If not flush,

select next larger or smaller washer until correct size

is obtained. The washer selected should be exactly

flush or slightly below inner shaft for correct end

play in transmission. Selective washer removed from

transmission may be oil soaked and discolored.

CObX

ID

Yellow

Blue

Red

BVSNIl

GPX3”

Black

Thickness,070.,074,076.,080

.08 l-.085,086.,090,091.,095

,097.,101

Installation of Converter Housing, Oil Pump and

Reverse Clutch Assembly1. Turn case so that bottom of transmission is facing

upward.

1. Install oil pump wear plate onto oil pump.2. Slide governor hub along output shaft and seat

Figure 7C-2 165. Tighten the five bolts. Torque to

13-17 Ibs. ft. and

remove aligning tool l-23082.

6. Install new converter housing to case rubber oil

seal.7. Install new pump flange gasket.

8. Place selective washer, previously determined,

onto the oil pump shaft and retain with petroleum

jelly (unmedicated).

9. Install two guide pins in case and lower converter

housing and oil pump into case. See Figure

7C-217.10. Bolt converter housing to case using new oil seal

washers on all seven bolts. Torque to 13-17 lbs. ft.

I I. Check for correct assembly by turning input shaft

by hand.

Installation of Governor Assembly

Page 492 of 625

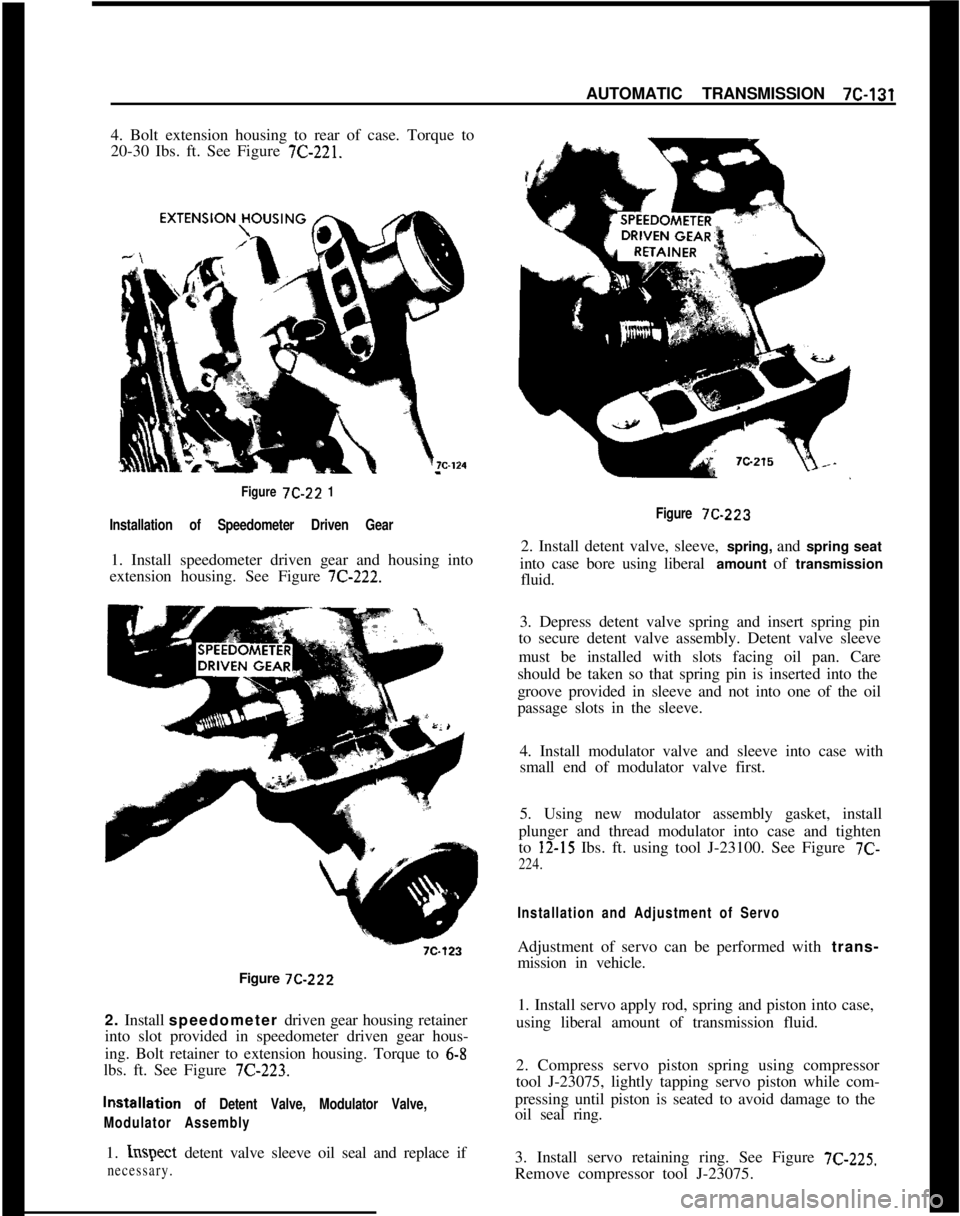

AUTOMATIC TRANSMISSION 7C-1314. Bolt extension housing to rear of case. Torque to

20-30 Ibs. ft. See Figure

7C-221.

Figure 7C-22

1

Installation of Speedometer Driven Gear1. Install speedometer driven gear and housing into

extension housing. See Figure

7C-222.Figure 7C-222

2. Install speedometer driven gear housing retainer

into slot provided in speedometer driven gear hous-

ing. Bolt retainer to extension housing. Torque to

6-Slbs. ft. See Figure

7C-223.

installation of Detent Valve, Modulator Valve,

Modulator Assembly1. inspect detent valve sleeve oil seal and replace if

necessary.Figure 7C-223

2. Install detent valve, sleeve, spring, and spring seat

into case bore using liberal amount of transmission

fluid.

3. Depress detent valve spring and insert spring pin

to secure detent valve assembly. Detent valve sleeve

must be installed with slots facing oil pan. Care

should be taken so that spring pin is inserted into the

groove provided in sleeve and not into one of the oil

passage slots in the sleeve.

4. Install modulator valve and sleeve into case with

small end of modulator valve first.

5. Using new modulator assembly gasket, install

plunger and thread modulator into case and tighten

to

12-15 Ibs. ft. using tool J-23100. See Figure 7C-

224.

Installation and Adjustment of ServoAdjustment of servo can be performed with trans-

mission in vehicle.

1. Install servo apply rod, spring and piston into case,

using liberal amount of transmission fluid.

2. Compress servo piston spring using compressor

tool J-23075, lightly tapping servo piston while com-

pressing until piston is seated to avoid damage to the

oil seal ring.

3. Install servo retaining ring. See Figure

7C-225.Remove compressor tool J-23075.

Page 494 of 625

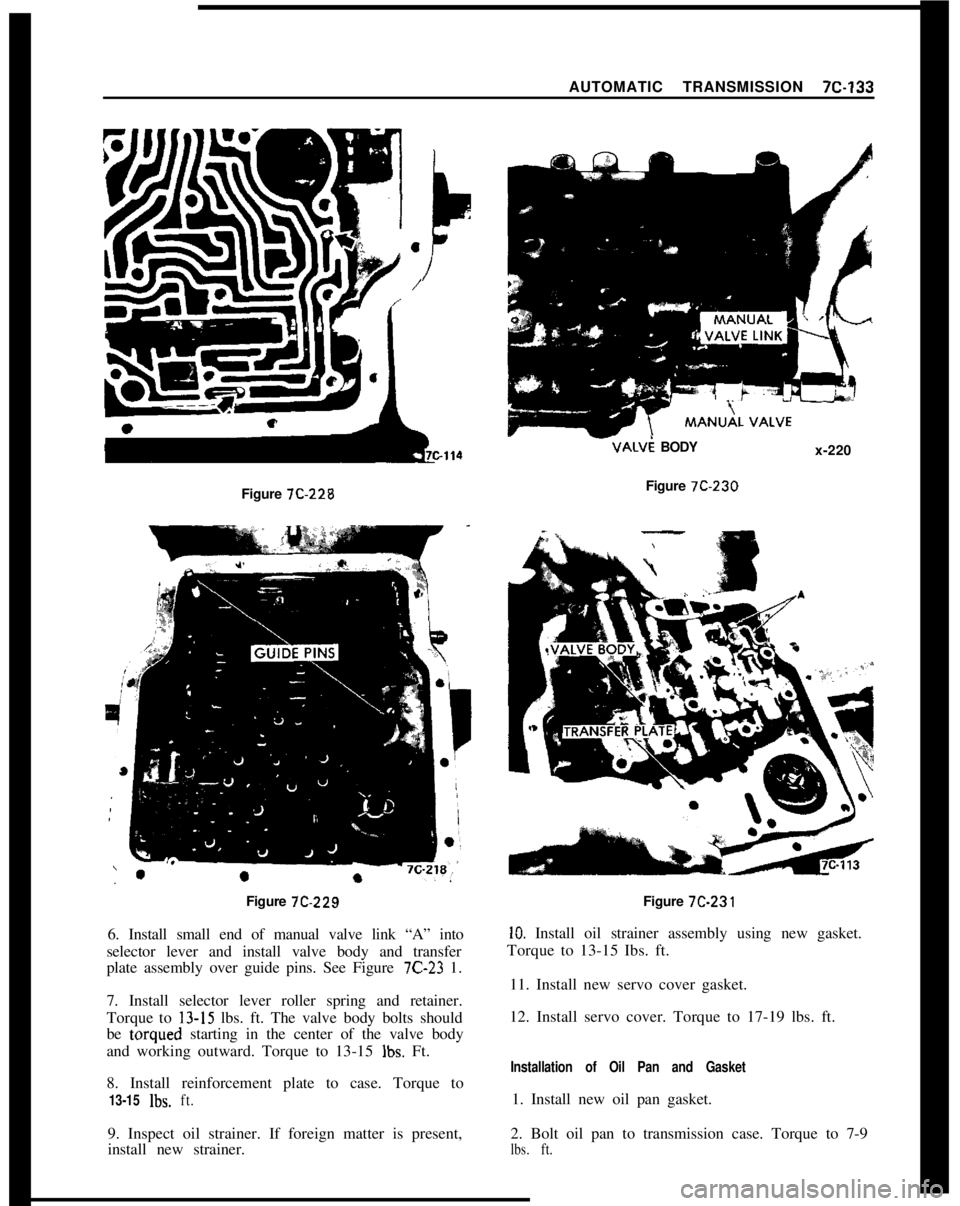

AUTOMATIC TRANSMISSION 7C-1338/Figure 7C-228

Figure 7C-229

6. Install small end of manual valve link “A” into

selector lever and install valve body and transfer

plate assembly over guide pins. See Figure

7C-23 1.

7. Install selector lever roller spring and retainer.

Torque to

13-15 lbs. ft. The valve body bolts should

be torqued starting in the center of the valve body

and working outward. Torque to 13-15

lbs. Ft.

8. Install reinforcement plate to case. Torque to

13-15 lbs. ft.9. Inspect oil strainer. If foreign matter is present,

install new strainer.

-VALV; BODY

x-220

Figure 7C-230

Figure

7C-231

10. Install oil strainer assembly using new gasket.

Torque to 13-15 Ibs. ft.

11. Install new servo cover gasket.

12. Install servo cover. Torque to 17-19 lbs. ft.

Installation of Oil Pan and Gasket1. Install new oil pan gasket.

2. Bolt oil pan to transmission case. Torque to 7-9

lbs. ft.

Page 495 of 625

7C-1341973 OPEL SERVICE MANUAL

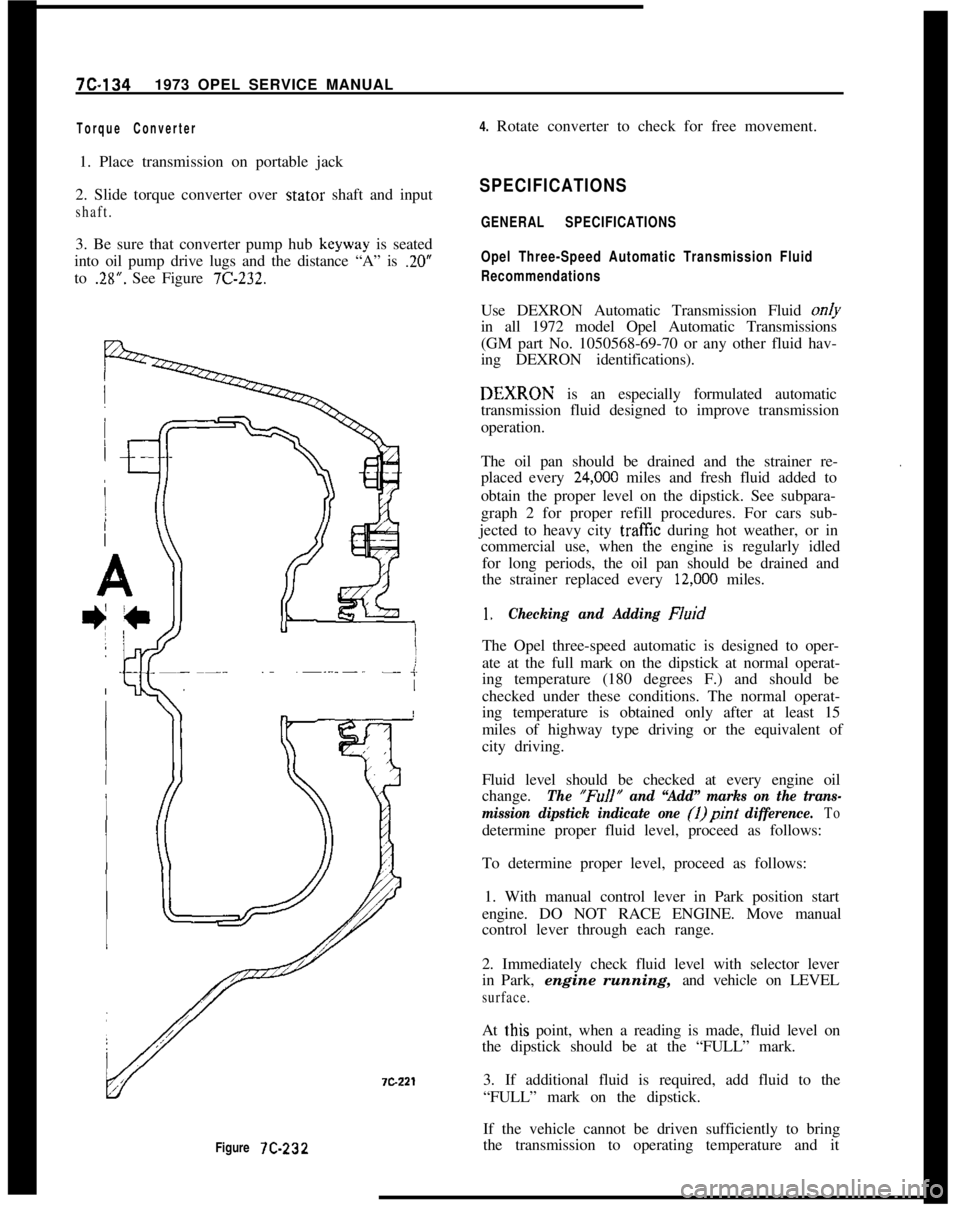

Figure 7C-232

Torque Converter4. Rotate converter to check for free movement.

1. Place transmission on portable jack

2. Slide torque converter over stator shaft and input

shaft.3. Be sure that converter pump hub keyway is seated

into oil pump drive lugs and the distance “A” is

.20”to

.28”. See Figure 7C-232.

SPECIFICATIONS

GENERAL SPECIFICATIONS

Opel Three-Speed Automatic Transmission Fluid

RecommendationsUse DEXRON Automatic Transmission Fluid on/y

in all 1972 model Opel Automatic Transmissions

(GM part No. 1050568-69-70 or any other fluid hav-

ing DEXRON identifications).DEXIRON is an especially formulated automatic

transmission fluid designed to improve transmission

operation.

The oil pan should be drained and the strainer re-

placed every

24,ooO miles and fresh fluid added to

obtain the proper level on the dipstick. See subpara-

graph 2 for proper refill procedures. For cars sub-

jected to heavy city

traff%z during hot weather, or in

commercial use, when the engine is regularly idled

for long periods, the oil pan should be drained and

the strainer replaced every

12,ooO miles.

.

1.Checking and Adding FluidThe Opel three-speed automatic is designed to oper-

ate at the full mark on the dipstick at normal operat-

ing temperature (180 degrees F.) and should be

checked under these conditions. The normal operat-

ing temperature is obtained only after at least 15

miles of highway type driving or the equivalent of

city driving.

Fluid level should be checked at every engine oil

change.

The “FuIl” and “Add” marks on the trans-

mission dipstick indicate one (1)pint

difference. Todetermine proper fluid level, proceed as follows:

To determine proper level, proceed as follows:

1. With manual control lever in Park position start

engine. DO NOT RACE ENGINE. Move manual

control lever through each range.

2. Immediately check fluid level with selector lever

in Park, engine running, and vehicle on LEVEL

surface.At

t,his point, when a reading is made, fluid level on

the dipstick should be at the “FULL” mark.

3. If additional fluid is required, add fluid to the

“FULL” mark on the dipstick.

If the vehicle cannot be driven sufficiently to bring

the transmission to operating temperature and it