alternator belt OPEL MANTA 1973 Service Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: MANTA, Model: OPEL MANTA 1973Pages: 625, PDF Size: 17.22 MB

Page 18 of 625

LUBRICATION AND MAINTENANCE OC-9

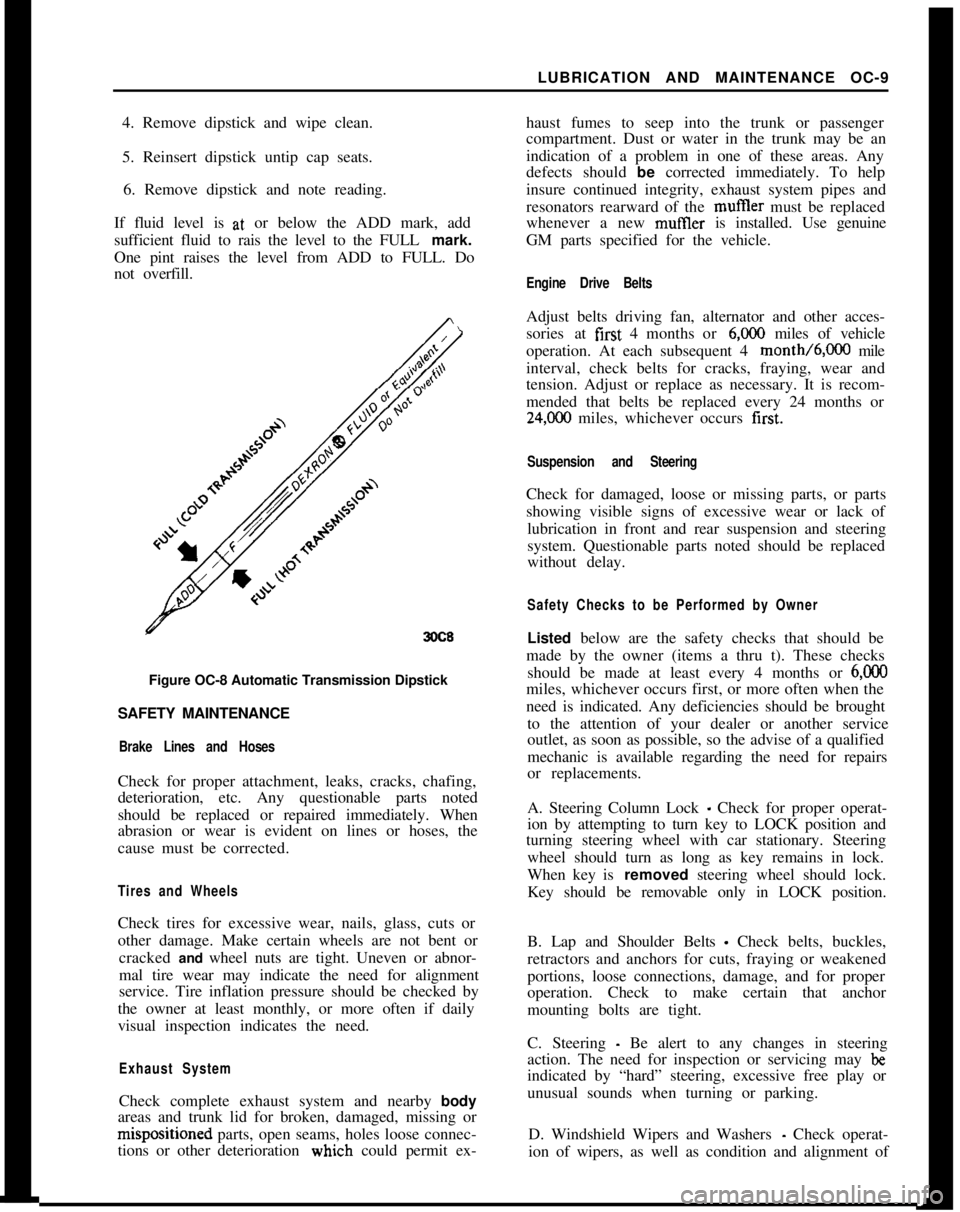

4. Remove dipstick and wipe clean.

5. Reinsert dipstick untip cap seats.

6. Remove dipstick and note reading.

If fluid level is at, or below the ADD mark, add

sufficient fluid to rais the level to the FULL mark.

One pint raises the level from ADD to FULL. Do

not overfill.

3OC8Figure OC-8 Automatic Transmission Dipstick

SAFETY MAINTENANCE

Brake Lines and HosesCheck for proper attachment, leaks, cracks, chafing,

deterioration, etc. Any questionable parts noted

should be replaced or repaired immediately. When

abrasion or wear is evident on lines or hoses, the

cause must be corrected.

Tires and WheelsCheck tires for excessive wear, nails, glass, cuts or

other damage. Make certain wheels are not bent or

cracked and wheel nuts are tight. Uneven or abnor-

mal tire wear may indicate the need for alignment

service. Tire inflation pressure should be checked by

the owner at least monthly, or more often if daily

visual inspection indicates the need.

Exhaust SystemCheck complete exhaust system and nearby body

areas and trunk lid for broken, damaged, missing orm&positioned parts, open seams, holes loose connec-

tions or other deterioration wiuch could permit ex-haust fumes to seep into the trunk or passenger

compartment. Dust or water in the trunk may be an

indication of a problem in one of these areas. Any

defects should be corrected immediately. To help

insure continued integrity, exhaust system pipes and

resonators rearward of the muftler must be replaced

whenever a new mufIler is installed. Use genuine

GM parts specified for the vehicle.

Engine Drive BeltsAdjust belts driving fan, alternator and other acces-

sories at first 4 months or

6,ooO miles of vehicle

operation. At each subsequent 4 month/6,000 mile

interval, check belts for cracks, fraying, wear and

tension. Adjust or replace as necessary. It is recom-

mended that belts be replaced every 24 months or

24,C00 miles, whichever occurs first.

Suspension and SteeringCheck for damaged, loose or missing parts, or parts

showing visible signs of excessive wear or lack of

lubrication in front and rear suspension and steering

system. Questionable parts noted should be replaced

without delay.

Safety Checks to be Performed by OwnerListed below are the safety checks that should be

made by the owner (items a thru t). These checks

should be made at least every 4 months or

6,ooOmiles, whichever occurs first, or more often when the

need is indicated. Any deficiencies should be brought

to the attention of your dealer or another service

outlet, as soon as possible, so the advise of a qualified

mechanic is available regarding the need for repairs

or replacements.

A. Steering Column Lock

_ Check for proper operat-

ion by attempting to turn key to LOCK position and

turning steering wheel with car stationary. Steering

wheel should turn as long as key remains in lock.

When key is removed steering wheel should lock.

Key should be removable only in LOCK position.

B. Lap and Shoulder Belts

- Check belts, buckles,

retractors and anchors for cuts, fraying or weakened

portions, loose connections, damage, and for proper

operation. Check to make certain that anchor

mounting bolts are tight.

C. Steering

- Be alert to any changes in steering

action. The need for inspection or servicing may

beindicated by “hard” steering, excessive free play or

unusual sounds when turning or parking.

D. Windshield Wipers and Washers

- Check operat-

ion of wipers, as well as condition and alignment of

Page 50 of 625

CHARGING SYSTEMlD- 29

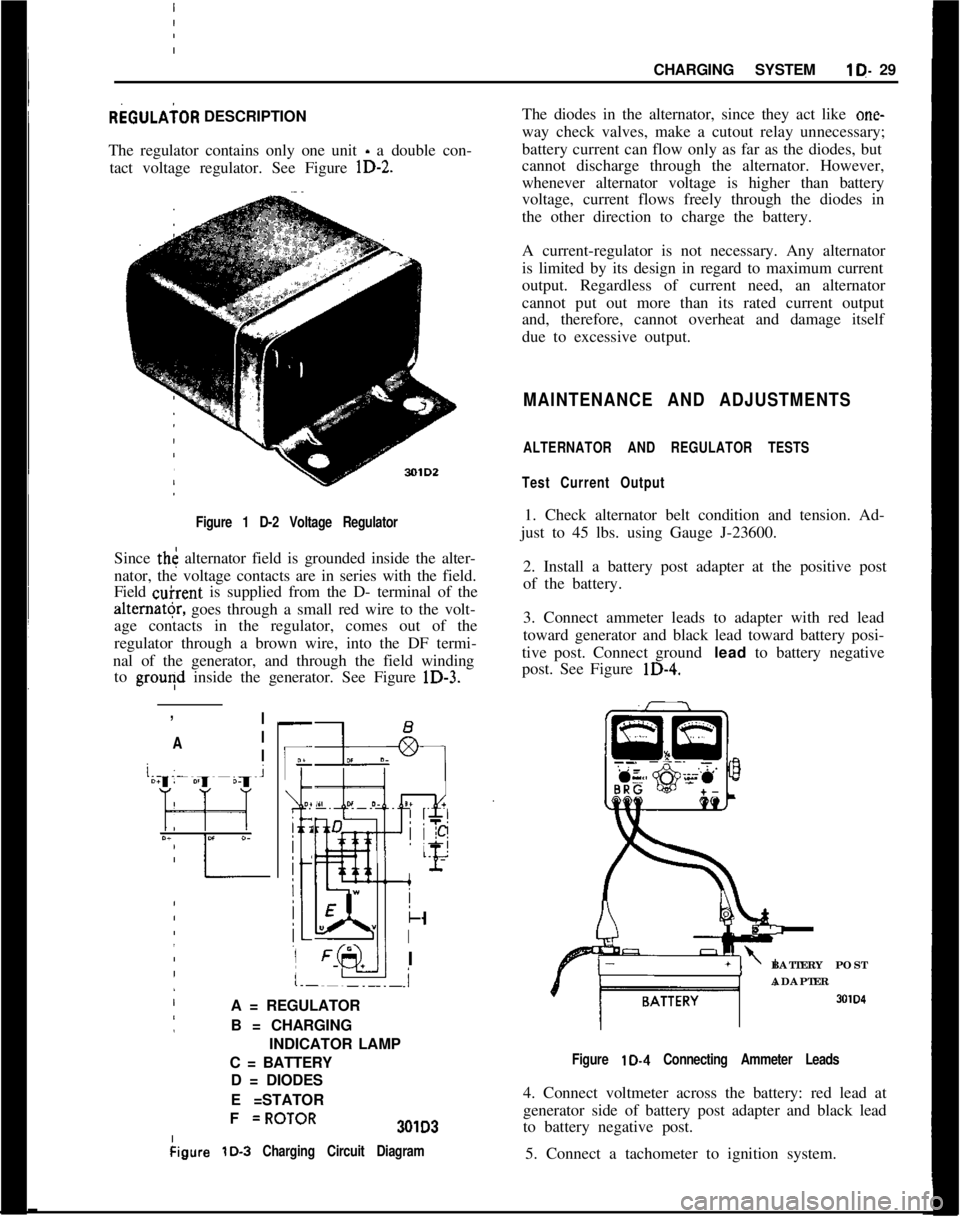

REGULAiOR DESCRIPTION

The regulator contains only one unit - a double con-

tact voltage regulator. See Figure

lD-2.

I Figure 1 D-2 Voltage Regulator

Since th< alternator field is grounded inside the alter-

nator, the voltage contacts are in series with the field.

Field

&rent is supplied from the D- terminal of the

alter”@, goes through a small red wire to the volt-

age contacts in the regulator, comes out of the

regulator through a brown wire, into the DF termi-

nal of the generator, and through the field winding to

grouqd inside the generator. See Figure lD-3.

:

,

!

/ I

’ A I

j

/ I

-

IF

O?

i 2

j

:

:

k

I

I

.i

A = REGULATOR

B = CHARGING

INDICATOR LAMP

C = BATTERY D = DIODES

E =STATOR

I

I F

=ROTOR301D3

kigure

lD-3 Charging Circuit Diagram

The diodes in the alternator, since they act like one-

way check valves, make a cutout relay unnecessary;

battery current can flow only as far as the diodes, but

cannot discharge through the alternator. However,

whenever alternator voltage is higher than battery

voltage, current flows freely through the diodes in

the other direction to charge the battery.

A current-regulator is not necessary. Any alternator

is limited by its design in regard to maximum current

output. Regardless of current need, an alternator

cannot put out more than its rated current output

and, therefore, cannot overheat and damage itself

due to excessive output.

MAINTENANCE AND ADJUSTMENTS

ALTERNATOR AND REGULATOR TESTS

Test Current Output

1. Check alternator belt condition and tension. Ad-

just to 45 lbs. using Gauge J-23600.

2. Install a battery post adapter at the positive post

of the battery.

3. Connect ammeter leads to adapter with red lead

toward generator and black lead toward battery posi-

tive post. Connect ground

lead to battery negative

post. See Figure

lD-4.

BATTERY POST

ADAPTER

SOID

Figure lD-4 Connecting Ammeter Leads

4. Connect voltmeter across the battery: red lead at

generator side of battery post adapter and black lead

to battery negative post.

5. Connect a tachometer to ignition system.

Page 51 of 625

i

1 D- 301973 OPEL SERVICE MANUAL

6. Make sure all electrical accessories are turned (lff.

Start engine with battery post adapter switch closed;

open switch as soon as engine

iS: started.

7. Adjust engine speed to 2500 RPM.

8. Turn tester control knob to “LOAD” position

aid

adjust knob to obtain highest possible ammeter r&d-

ing. Output must be 30 amperes minimum. If

outcut

is okay, proceed to voltage regulator test below. j

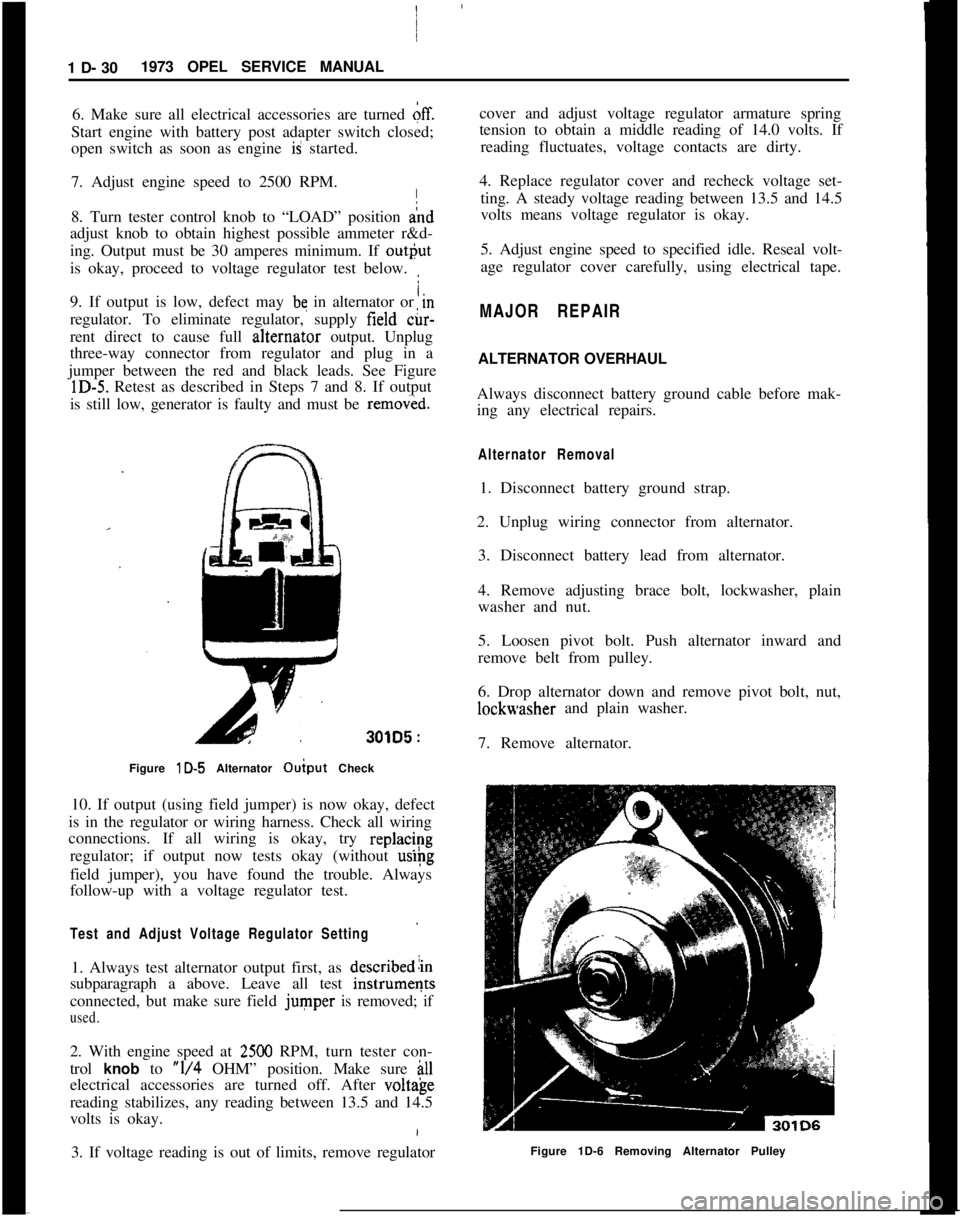

/.9. If output is low, defect may be in alternator or m

regulator. To eliminate regulator, supply field &-

rent direct to cause full alternat,or output. Unplug

three-way connector from regulator and plug in a

jumper between the red and black leads. See Figure

lD-5. Retest as described in Steps 7 and 8. If output

is still low, generator is faulty and must be

remov&d.

301D5 :

Figure lD-5 Alternator Ouiput Check I

10. If output (using field jumper) is now okay, defect

is in the regulator or wiring harness. Check all wiring

connections. If all wiring is okay, try

replac/~g

regulator; if output now tests okay (without

uslpg

field jumper), you have found the trouble. Always

follow-up with a voltage regulator test.

Test and Adjust Voltage Regulator Setting

1. Always test alternator output first, as describedlin

subparagraph a above. Leave all test

instrumeqts

connected, but make sure field

jumper is removed; if

used.

2. With engine speed at 2500 RPM, turn tester con-

trol

knob to “l/4 OHM” position. Make sure ill

electrical accessories are turned off. After volt&e

reading stabilizes, any reading between 13.5 and 14.5

volts is okay.

3. If voltage reading is out of limits, remove regulator cover and adjust voltage regulator armature spring

tension to obtain a middle reading of 14.0 volts. If

reading fluctuates, voltage contacts are dirty.

4. Replace regulator cover and recheck voltage set- ting. A steady voltage reading between 13.5 and 14.5

volts means voltage regulator is okay.

5. Adjust engine speed to specified idle. Reseal volt-

age regulator cover carefully, using electrical tape.

MAJOR REPAIR

ALTERNATOR OVERHAUL

Always disconnect battery ground cable before mak-

ing any electrical repairs.

Alternator Removal

1. Disconnect battery ground strap.

2. Unplug wiring connector from alternator. 3. Disconnect battery lead from alternator.

4. Remove adjusting brace bolt, lockwasher, plain

washer and nut.

5. Loosen pivot bolt. Push alternator inward and

remove belt from pulley.

6. Drop alternator down and remove pivot bolt, nut,

lockwasher and plain washer.

7. Remove alternator.

Figure 1D-6 Removing Alternator Pulley

Page 56 of 625

CHARGING SYSTEMlD- 35

’Figure lD-25 Installing Diode

I

7. Instail rotor together with drive end frame intostator and assemble generator in reverse order ofdisasse+bly. Make sure marks made during disas-

sembly

+-ire aligned.

8. Insta!l pulley and fan. Tighten nut to 30 lb.ft.

9. Test benerator on test bench, if available. If not,

install alternator on car and test.

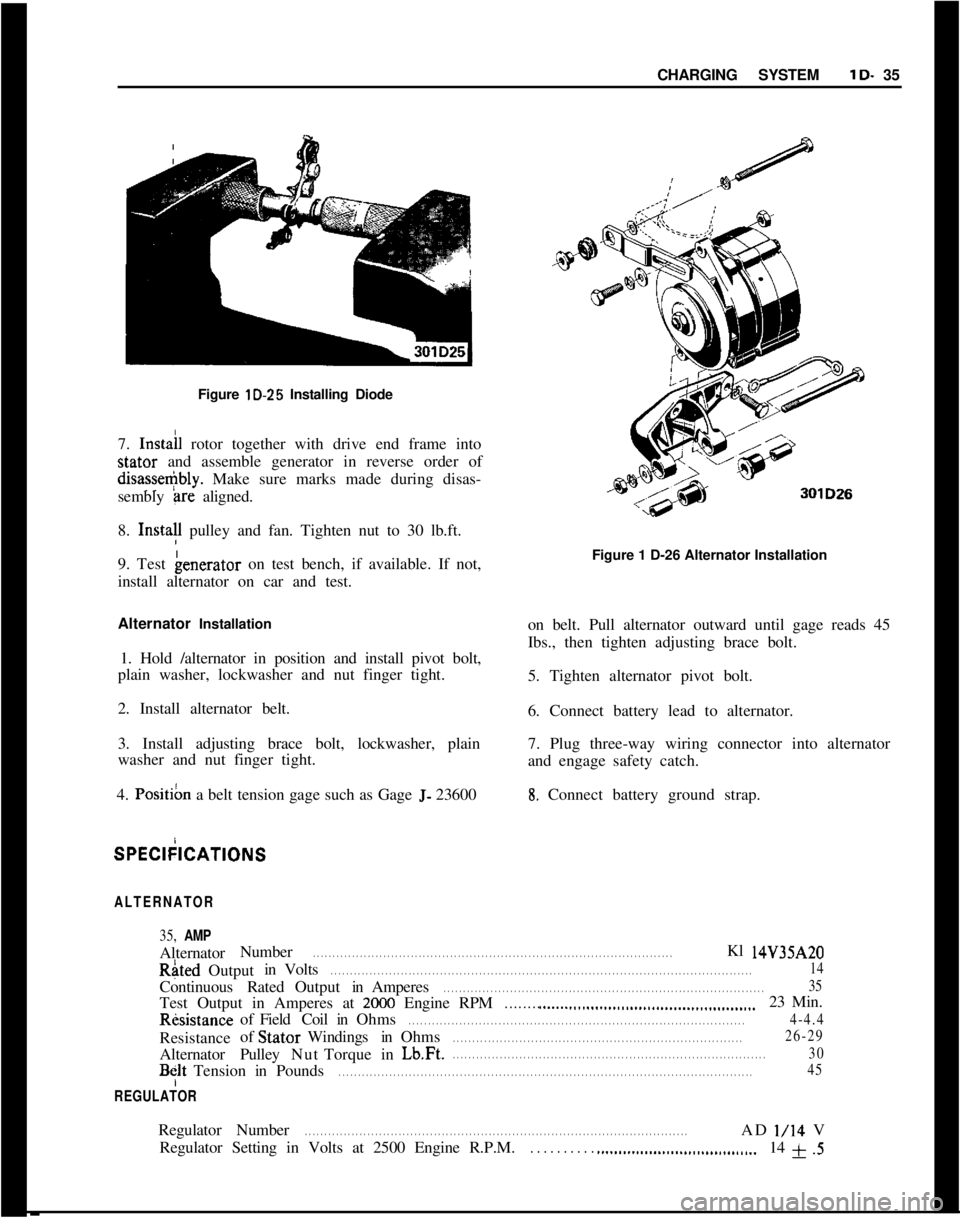

Alternator Installation

1. Hold /alternator in position and install pivot bolt,

plain washer, lockwasher and nut finger tight.

2. Install alternator belt.

3. Install adjusting brace bolt, lockwasher, plain

washer and nut finger tight.

4.

Posit& a belt tension gage such as Gage J- 23600Figure 1 D-26 Alternator Installation

on belt. Pull alternator outward until gage reads 45

Ibs., then tighten adjusting brace bolt.

5. Tighten alternator pivot bolt.

6. Connect battery lead to alternator.

7. Plug three-way wiring connector into alternator

and engage safety catch.8. Connect battery ground strap.SPECkICATIONS

ALTERNATOR

35, AMPAlternatorNumberRated

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Kl 14V35AZOOutputinVolts

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14ContinuousRatedOutputinAmperes

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35Test Output in Amperes at

2000 Engine RPM. . . . . . . . ..__.._...........................................23 Min.RksistanceofFieldCoilinOhms

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4.4Resistanceof StatorWindingsinOhms

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26-29AlternatorPulleyNutTorqueinLb.Ft.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

BfltTensioninPounds. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

REGULATORRegulatorNumber

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ADl/14V

Regulator Setting in Volts at 2500 Engine R.P.M.

. . . . . . . . . . ..___................................14 f .5

Page 314 of 625

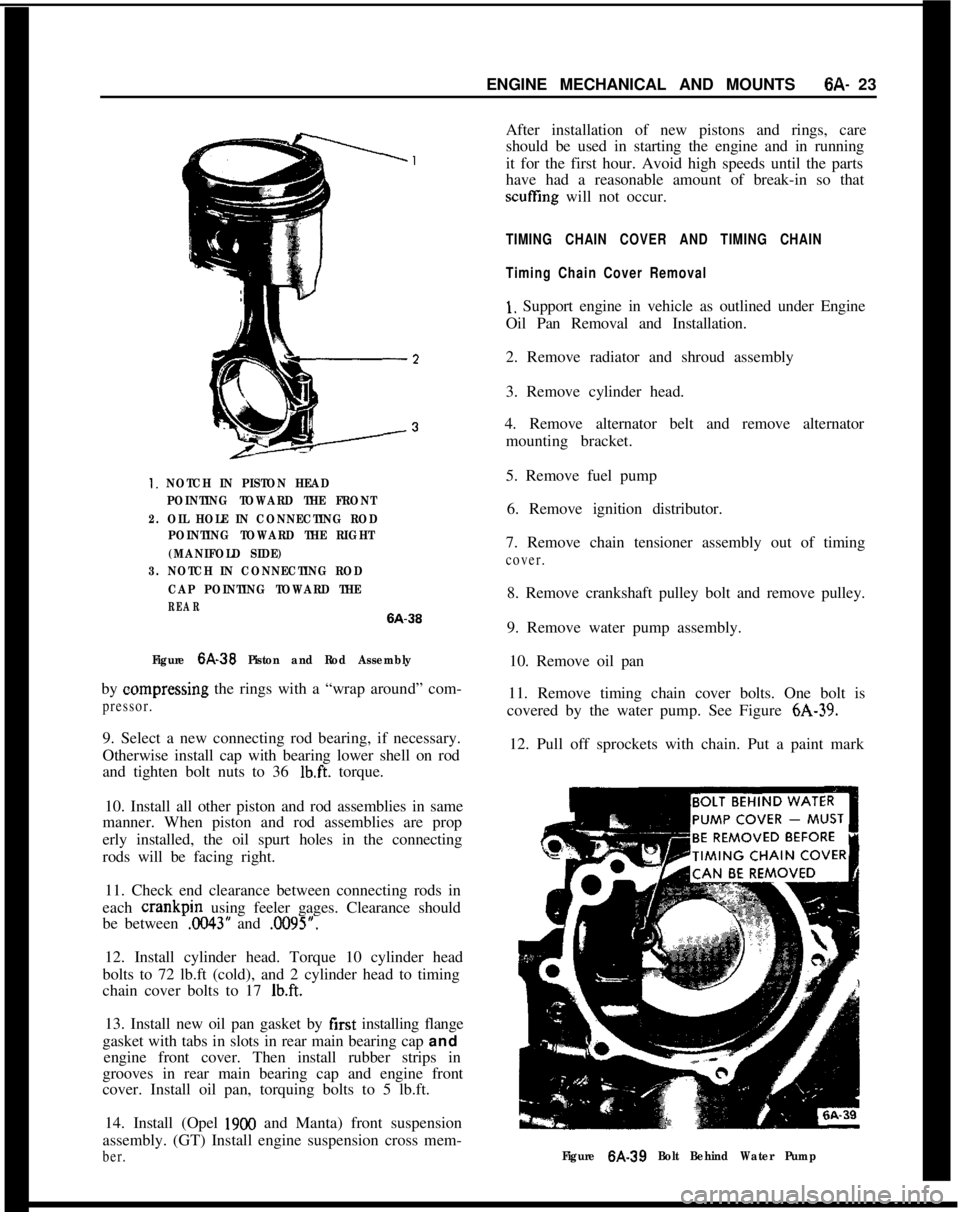

ENGINE MECHANICAL AND MOUNTS6A- 231. NOTCH IN PISTON HEAD

POINTING TOWARD THE FRONT

2. OIL HOLE IN CONNECTING ROD

POINTING TOWARD THE RIGHT

(MANIFOLD SIDE)

3. NOTCH IN CONNECTING ROD

CAP POINTING TOWARD THE

REAR6A-36

Figure

6A-39 Piston and Rod Assemblyby oompressing the rings with a “wrap around” com-

pressor.9. Select a new connecting rod bearing, if necessary.

Otherwise install cap with bearing lower shell on rod

and tighten bolt nuts to 36

lb.ft. torque.

10. Install all other piston and rod assemblies in same

manner. When piston and rod assemblies are prop

erly installed, the oil spurt holes in the connecting

rods will be facing right.

11. Check end clearance between connecting rods in

each crankpin using feeler gages. Clearance should

be between

.0043” and .0095”.

12. Install cylinder head. Torque 10 cylinder head

bolts to 72 lb.ft (cold), and 2 cylinder head to timing

chain cover bolts to 17

lb.ft.13. Install new oil pan gasket by first installing flange

gasket with tabs in slots in rear main bearing cap and

engine front cover. Then install rubber strips in

grooves in rear main bearing cap and engine front

cover. Install oil pan, torquing bolts to 5 lb.ft.

14. Install (Opel

1900 and Manta) front suspension

assembly. (GT) Install engine suspension cross mem-

ber.After installation of new pistons and rings, care

should be used in starting the engine and in running

it for the first hour. Avoid high speeds until the parts

have had a reasonable amount of break-in so that

scuffling will not occur.

TIMING CHAIN COVER AND TIMING CHAIN

Timing Chain Cover Removal

1, Support engine in vehicle as outlined under Engine

Oil Pan Removal and Installation.

2. Remove radiator and shroud assembly

3. Remove cylinder head.

4. Remove alternator belt and remove alternator

mounting bracket.

5. Remove fuel pump

6. Remove ignition distributor.

7. Remove chain tensioner assembly out of timing

cover.8. Remove crankshaft pulley bolt and remove pulley.

9. Remove water pump assembly.

10. Remove oil pan

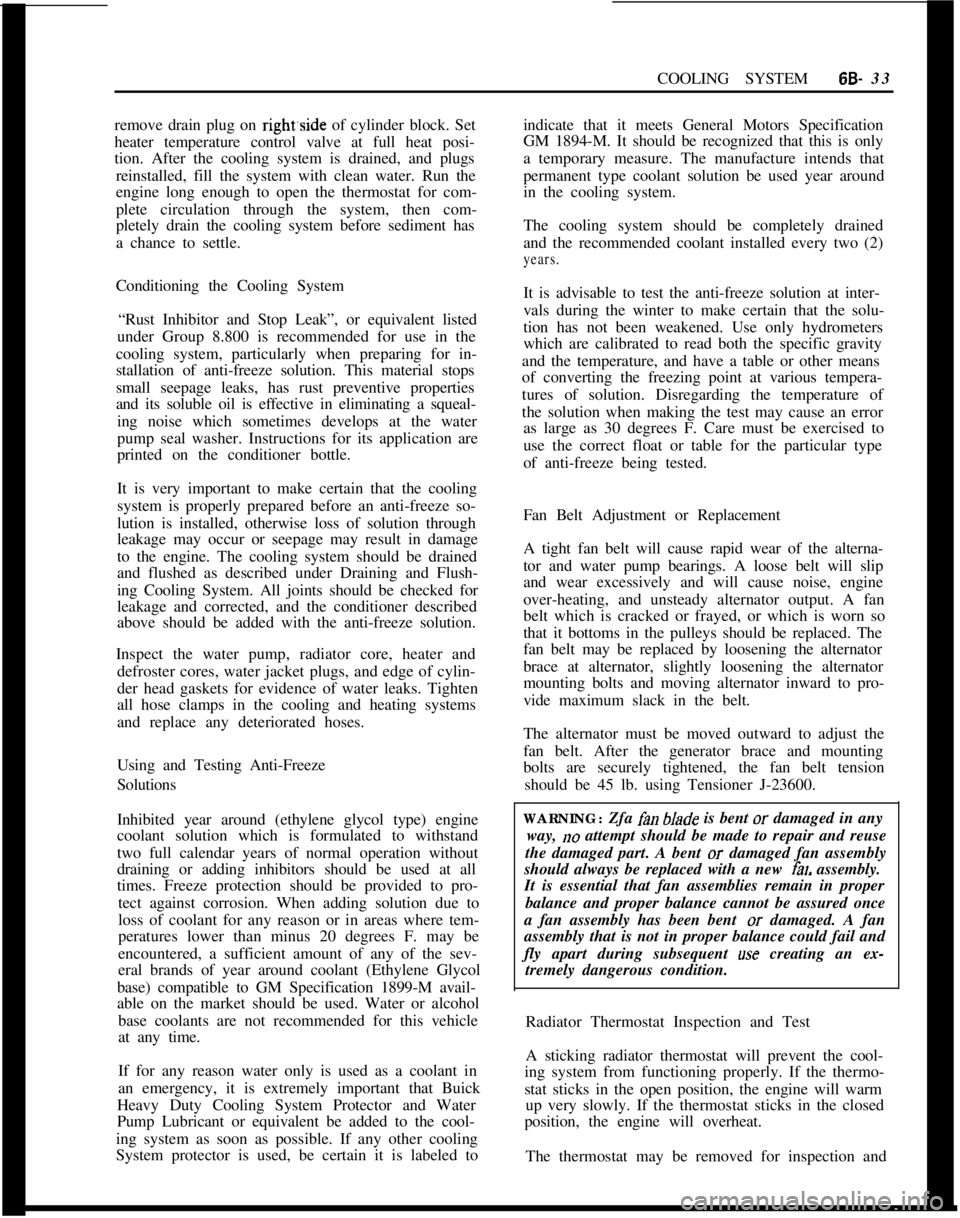

11. Remove timing chain cover bolts. One bolt is

covered by the water pump. See Figure 6A-39.

12. Pull off sprockets with chain. Put a paint mark

Figure 6A-39 Bolt Behind Water Pump

Page 324 of 625

COOLING SYSTEM6B- 33

remove drain plug on right.side of cylinder block. Set

heater temperature control valve at full heat posi-

tion. After the cooling system is drained, and plugs

reinstalled, fill the system with clean water. Run the

engine long enough to open the thermostat for com-

plete circulation through the system, then com-

pletely drain the cooling system before sediment has

a chance to settle.

Conditioning the Cooling System

“Rust Inhibitor and Stop Leak”, or equivalent listed

under Group 8.800 is recommended for use in the

cooling system, particularly when preparing for in-

stallation of anti-freeze solution. This material stops

small seepage leaks, has rust preventive properties

and its soluble oil is effective in eliminating a squeal-

ing noise which sometimes develops at the water

pump seal washer. Instructions for its application are

printed on the conditioner bottle.

It is very important to make certain that the cooling

system is properly prepared before an anti-freeze so-

lution is installed, otherwise loss of solution through

leakage may occur or seepage may result in damage

to the engine. The cooling system should be drained

and flushed as described under Draining and Flush-

ing Cooling System. All joints should be checked for

leakage and corrected, and the conditioner described

above should be added with the anti-freeze solution.

Inspect the water pump, radiator core, heater and

defroster cores, water jacket plugs, and edge of cylin-

der head gaskets for evidence of water leaks. Tighten

all hose clamps in the cooling and heating systems

and replace any deteriorated hoses.

Using and Testing Anti-Freeze

Solutions

Inhibited year around (ethylene glycol type) engine

coolant solution which is formulated to withstand

two full calendar years of normal operation without

draining or adding inhibitors should be used at all

times. Freeze protection should be provided to pro-

tect against corrosion. When adding solution due to

loss of coolant for any reason or in areas where tem-

peratures lower than minus 20 degrees F. may be

encountered, a sufficient amount of any of the sev-

eral brands of year around coolant (Ethylene Glycol

base) compatible to GM Specification 1899-M avail-

able on the market should be used. Water or alcohol

base coolants are not recommended for this vehicle

at any time.

If for any reason water only is used as a coolant in

an emergency, it is extremely important that Buick

Heavy Duty Cooling System Protector and Water

Pump Lubricant or equivalent be added to the cool-

ing system as soon as possible. If any other cooling

System protector is used, be certain it is labeled toindicate that it meets General Motors Specification

GM 1894-M. It should be recognized that this is only

a temporary measure. The manufacture intends that

permanent type coolant solution be used year around

in the cooling system.

The cooling system should be completely drained

and the recommended coolant installed every two (2)years.It is advisable to test the anti-freeze solution at inter-

vals during the winter to make certain that the solu-

tion has not been weakened. Use only hydrometers

which are calibrated to read both the specific gravity

and the temperature, and have a table or other means

of converting the freezing point at various tempera-

tures of solution. Disregarding the temperature of

the solution when making the test may cause an error

as large as 30 degrees F. Care must be exercised to

use the correct float or table for the particular type

of anti-freeze being tested.

Fan Belt Adjustment or Replacement

A tight fan belt will cause rapid wear of the alterna-

tor and water pump bearings. A loose belt will slip

and wear excessively and will cause noise, engine

over-heating, and unsteady alternator output. A fan

belt which is cracked or frayed, or which is worn so

that it bottoms in the pulleys should be replaced. The

fan belt may be replaced by loosening the alternator

brace at alternator, slightly loosening the alternator

mounting bolts and moving alternator inward to pro-

vide maximum slack in the belt.

The alternator must be moved outward to adjust the

fan belt. After the generator brace and mounting

bolts are securely tightened, the fan belt tension

should be 45 lb. using Tensioner J-23600.

WARNING: Zfa

fan blade is bent or damaged in any

way, no attempt should be made to repair and reuse

the damaged part. A bent or damaged fan assembly

should always be replaced with a new

fal. assembly.

It is essential that fan assemblies remain in proper

balance and proper balance cannot be assured once

a fan assembly has been bent or damaged. A fan

assembly that is not in proper balance could fail and

fly apart during subsequent

we creating an ex-

tremely dangerous condition.

Radiator Thermostat Inspection and Test

A sticking radiator thermostat will prevent the cool-

ing system from functioning properly. If the thermo-

stat sticks in the open position, the engine will warm

up very slowly. If the thermostat sticks in the closed

position, the engine will overheat.

The thermostat may be removed for inspection and

Page 621 of 625

SubjectPage Number

Subject Page Number

A

Air Conditioning Refrigerant Components .................

98.17

Opel 1900

& Manta-In Car Components .....9B-90

GT.ln Car Components..................98-97

Alignment Opel 1900

& Manta .....................3C-22

GT-Opel ..............................

3C-22

Alternator Description ...........................

lD-28

Specifications. .........................1 D-35

Overhaul K-l..........................lD-30

Removal & Installation ..................lD-30

Testing...............................lD-29

Wiring Diagrams

Manta .............................

1 J-105

Opel 1900

..........................lJ-103

GT ................................

lJ-107

AM

Radio-GT............................9C-105

AM Radio-Opel 1900 &Manta ...............

9C-109

Antenna, Installation .......................

9C-111

Antenna Trimmer .........................

9C-110

Assembly of Transmission from Major Units Manual ...............................

78-23

3 Speed Automatic .....................

7C-103

Axle,

R&r, Disassembly ....................48~11

Bolt Torque Specifications

Engine ...............................

6A-27

Transmission. Manual ....................

78-33

3 Speed Automatic .....................

7C-136

Clutch ...............................

7A-7

Body ................................

2A-4

Brakes

Brake Drum, Shoes & Linings .............5C-28

Hydraulic Wheel Cylinder ................

5C-30

Hydraulic Master Cylinder ................

5A-2

Parking Brake Cables .....................

5C-33

Standard Brakes ........................

X-22

Disc Brakes...........................5B-10

Brake Booster and Vacuum

Coritrol Valve ....5A-5

Bumpers, Front and Rear ...................

ZH-33

C

B

Balance,,Wheel and Tire....................3G-62

Ball

J&tUpper .........................3A-7

Lower ...............................

3A-7

Battery

Specifications ..........................

lA-9

Testing...............................lA-6

Charging ..............................lA-9

Trouble Diagnosis ......................lA-4

Battery Test 421.........................l A-6

Belt Tensions ............................

68.33

Blower and Air Inlet Assembly, Removal and Installation

Owl 1900&Manta.....................9A-15

GT

.: ................................9A-5

Body Name Plate ............................

OA-1

Style’Numbers ......................... OA-2

Windows and Weatherstrips ...............

ZC-9

Doors ................................

ZD-13

Interior Trim and Headlining ..............

26-33

Seatsi................................26-33

Roof&d Sunroof-Opel 1900

& Manta ......2F.24 Camshaft,

1.9L

Engine .....................6A-25

Car Model Identification .......

.,............OA-1

Carburetor..............................6E-44

Trouble Diagnosis ......................

6E-49

Description ...........................

6E-44

Overhaul .............................

6E-53

Adjust ...............................

6E-50

Removal

& Installation ......,............6E-52

Specifications ..........................

6E-58

Charging

System

Description ..............

:............ 1 D-28

Specifications. ............

.,............lD-35

Testing..................:............lD-29

Wiring Diagrams

Manta .............................

lJ-105

Opel 1900 ..........................

lJ.103

GT ................................

lJ-107

Chart Lubrication ........................ OC-5

Chassis Springs, Front. ........

!............3A-15

Clutch, Second-Automatic Transmission .......

7C-103

Clutch Adjustment .........................

7A-4

Control Arm Front Upper ...................

:............3A-10

Lower ...............................

3A-11

Converter Checking Procedure ................

7C-125

Coolant Flow ............................

68-32

4 Speed Manual Transmission ...

!,...........7B-12

Cranking System. See Starting

SyStem

Crankshaft..............................6A-16

Cylinder Head ...............

:............6A-12

D

Description

3.Speed Automatic.....................7C-37