check engine OPEL MERIVA 2009 User Guide

[x] Cancel search | Manufacturer: OPEL, Model Year: 2009, Model line: MERIVA, Model: OPEL MERIVA 2009Pages: 248, PDF Size: 4.46 MB

Page 158 of 248

152 Driving and operationFor vehicles with manual transmission

automated 3, the control indicator flashes

for a few seconds when the ignition is

turned off when the hand brake is not

applied. Anti-lock brake system (ABS

u)

ABS prevents the wheels from locking.

ABS starts to regulate brake pressure as

soon as a wheel shows a tendency to lock.

The vehicle remains steerable, even during

hard braking.

ABS control is made apparent though a

pulse in the brake pedal and the noise of

the regulation process.

For optimum braking, keep the brake

pedal fully depresse d throughout the

braking process, despite the fact that the

pedal is pulsating. Do not reduce the

pressure on the pedal.

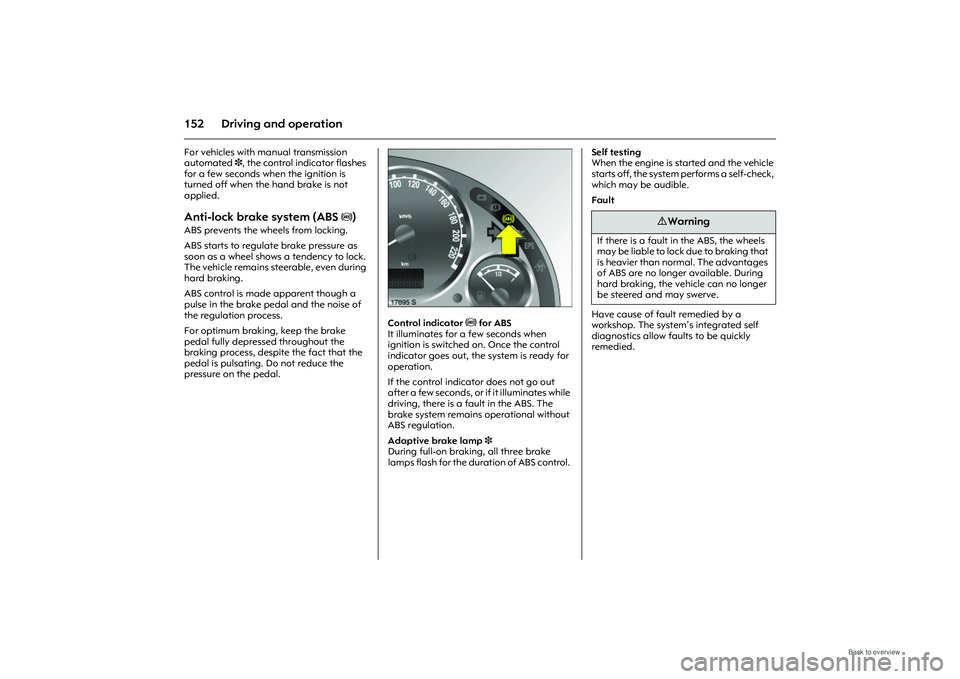

Picture no: 17895s.tif

Control indicator u for ABS

It illuminates for a few seconds when

ignition is switched on. Once the control

indicator goes out, the system is ready for

operation.

If the control indica tor does not go out

after a few seconds, or if it illuminates while

driving, there is a fault in the ABS. The

brake system remains operational without

ABS regulation.

Adaptive brake lamp 3

During full-on braking, all three brake

lamps flash for the duration of ABS control. Self testing

When the engine is started and the vehicle

starts off, the system performs a self-check,

which may be audible.

Fault

Have cause of fault remedied by a

workshop. The system’s integrated self

diagnostics allow faults to be quickly

remedied.

9 Warning

If there is a fault in the ABS, the wheels

may be liable to lock due to braking that

is heavier than normal. The advantages

of ABS are no longer available. During

hard braking, the vehicle can no longer

be steered and may swerve.

Page 172 of 248

166 Self-help, vehicle care

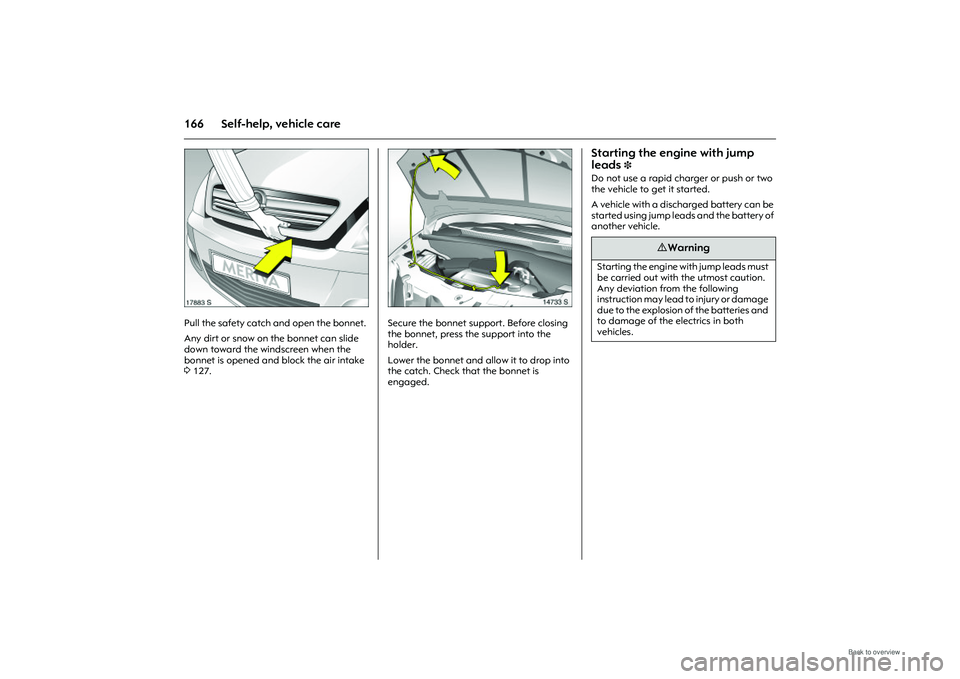

Picture no: 17883s.tif

Pull the safety catch and open the bonnet.

Any dirt or snow on the bonnet can slide

down toward the windscreen when the

bonnet is opened and block the air intake

3127.

Picture no: 14733s.tif

Secure the bonnet support. Before closing

the bonnet, press the support into the

holder.

Lower the bonnet and allow it to drop into

the catch. Check that the bonnet is

engaged.

Starting the engine with jump

leads

3

Do not use a rapid charger or push or two

the vehicle to get it started.

A vehicle with a discha rged battery can be

started using jump leads and the battery of

another vehicle.

9 Warning

Starting the engine with jump leads must

be carried out with the utmost caution.

Any deviation from the following

instruction may lead to injury or damage

due to the explosion of the batteries and

to damage of the electrics in both

vehicles.

Page 191 of 248

185

Self-help, vehicle care

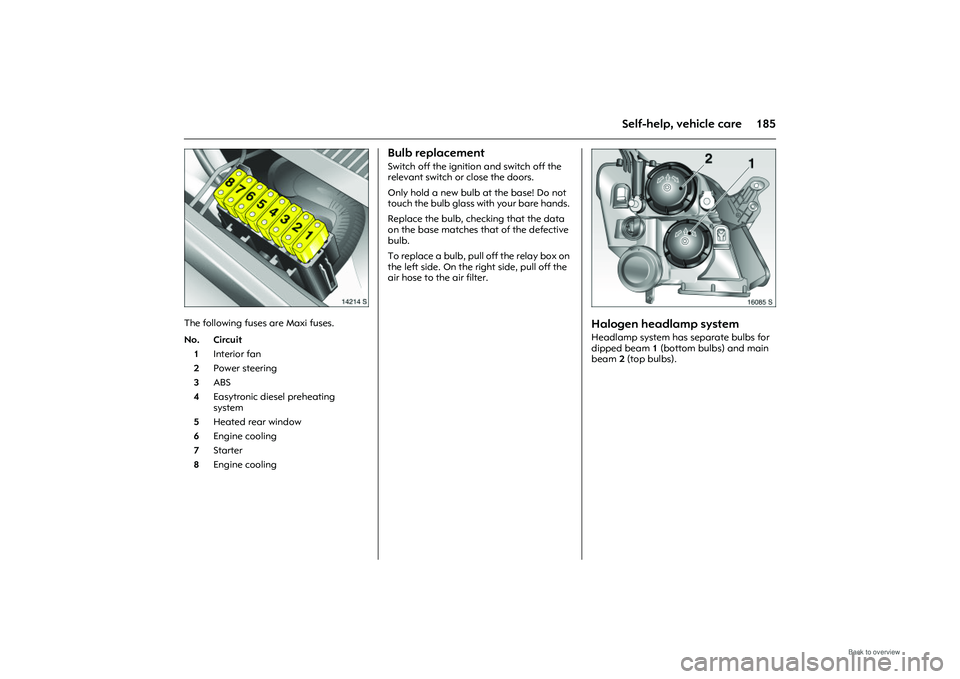

Picture no: 14214s.tif

The following fuses are Maxi fuses.

Bulb replacement Switch off the ignition and switch off the

relevant switch or close the doors.

Only hold a new bulb at the base! Do not

touch the bulb glass with your bare hands.

Replace the bulb, checking that the data

on the base matches that of the defective

bulb.

To replace a bulb, pull off the relay box on

the left side. On the right side, pull off the

air hose to the air filter.

Picture no: 16085s.tif

Halogen headlamp systemHeadlamp system has separate bulbs for

dipped beam 1 (bottom bulbs) and main

beam 2 (top bulbs).

No. Circuit

1 Interior fan

2 Power steering

3 ABS

4 Easytronic diesel preheating

system

5 Heated rear window

6 Engine cooling

7 Starter

8 Engine cooling

Page 204 of 248

198 Self-help, vehicle careWindows and windscreen wiper blades

Use a soft lint-free cloth or chamois leather

together with window cleaner and insect

remover.

When cleaning the rear window, make sure

the heating element inside the window is

not damaged.

For mechanical removal of ice, use a sharp-

edged ice scraper. Pre ss the scraper firmly

against the glass so that no dirt can get

under it and scratch the glass.

Clean smearing wiper blades with a soft

cloth and window cleaner. Locks

The locks are lubricated with a high-quality

locking cylinder grease

in the factory. Only

use de-icer in urgent cases, since it has a

de-greasing effect and affects the

operation of the locks. Have the locks re-

greased in a workshop after using de-icer.

Engine compartment

Look after areas in the engine

compartment that are painted in the same

colour as the vehicle like any other

paintwork.

It is advisable to wash the engine

compartment before and after winter and

preserve it with wax. Cover alternator and

brake fluid reservoir with plastic sheets

before washing the engine.

When washing the engine with a steam-jet

cleaner, do not direct the steam jet at

components of the Anti-lock Braking

System 3, the automatic air conditioning

system 3 or the belt drive and its

components.

After an engine wash, have all engine room

components preserved thoroughly by a

workshop using protective wax.

Do not use high-pressure jet cleaners. Underbody

Some areas of the vehicle underbody have

a PVC undercoating while other critical

areas have a durable protective wax

coating.

After the underbody is washed, check the

underbody and have more protective wax

applied if necessary.

Bitumen/rubber materials could damage

the PVC coating. Have underbody work

carried out by a workshop.

Before and after winter, wash the

underbody and have the protective wax

coating checked.

Towing equipment

Do not clean the coupling ball bar with a

steam-jet or high-pressure jet cleaner.

Page 207 of 248

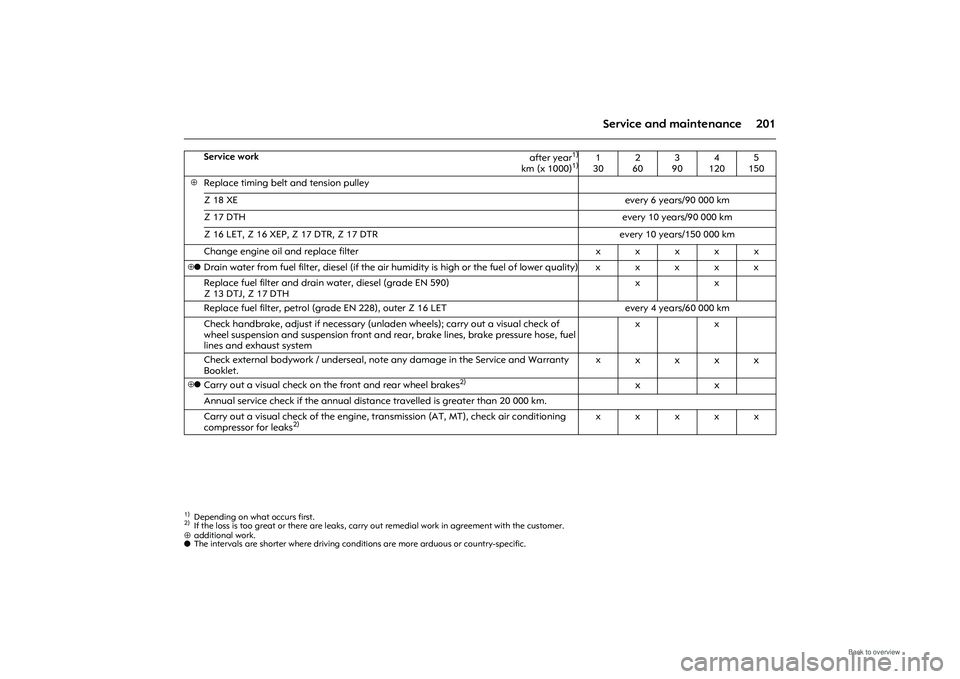

201

Service and maintenance

⊕ additional work.

o The intervals are shorter where driving conditions are more arduous or country-specific.

Service work

after year

1)

km (x 1000)

1)

1)Depending on what occurs first.

1

30 2

60 3

90 4

120 5

150

⊕

Replace timing belt and tension pulley

Z 18 XE every 6 years/90 000 km

Z 17 DTH every 10 years/90 000 km

Z 16 LET, Z 16 XEP, Z 17 DTR, Z 17 DTR every 10 years/150 000 km

Change engine oil and replace filter xxxxx

⊕o

Drain water from fuel filter, diesel (if the air humidity is high or the fuel of lower quality)xxxxx

Replace fuel filter and drain water, diesel (grade EN 590)

Z 13 DTJ, Z 17 DTH xx

Replace fuel filter, petrol (grade EN 228), outer Z 16 LET every 4 years/60 000 km

Check handbrake, adjust if necessary (unl aden wheels); carry out a visual check of

wheel suspension and suspension front and re ar, brake lines, brake pressure hose, fuel

lines and exhaust system xx

Check external bodywork / underseal, note any damage in the Service and Warranty

Booklet. x

xxxx

⊕o

Carry out a visual check on the front and rear wheel brakes

2)

2)If the loss is too great or there are leaks, carry out remedial work in agr

eement with the customer.

xx

Annual service check if the annual distance travelled is greater than 20 000 km.

Carry out a visual check of the engine, tran smission (AT, MT), check air conditioning

compressor for leaks

2)

xxxxx

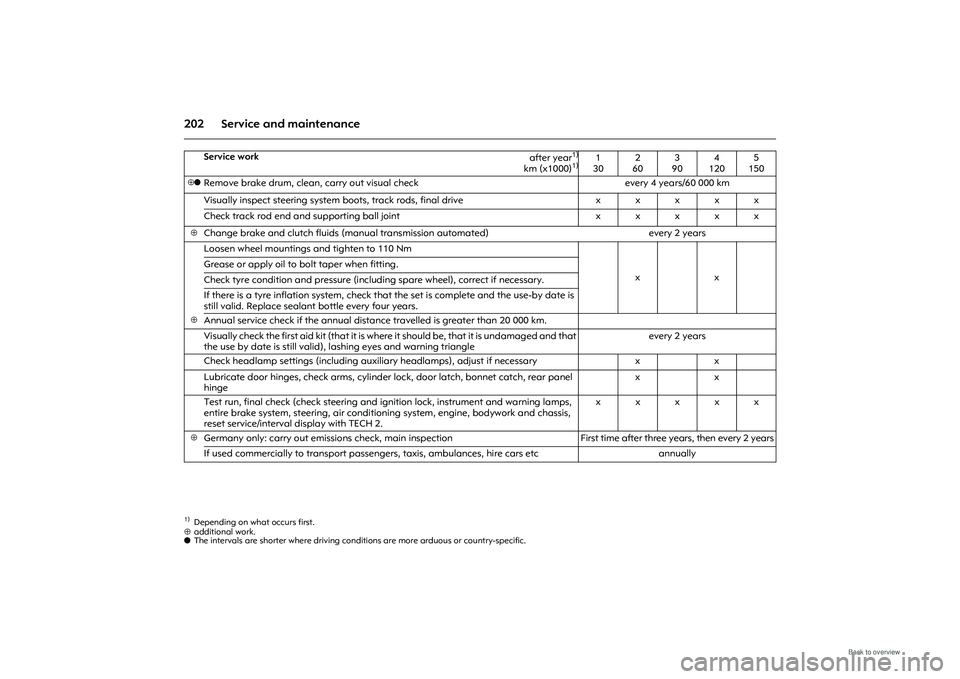

Page 208 of 248

202 Service and maintenance⊕additional work.

o The intervals are shorter where driving conditions are more arduous or country-specific.

Service work

after year

1)

km (x1000)

1)

1)Depending on what occurs first.

1

30 2

60 3

90 4

120 5

150

⊕o

Remove brake drum, clean, carry out visual check every 4 years/60 000 km

Visually inspect steering system boots, track rods, final drive xxxxx

Check track rod end and supporting ball joint xxxxx

⊕

Change brake and clutch fluids (manual transmission automated) every 2 years

Loosen wheel mountings and tighten to 110 Nm

xx

Grease or apply oil to

bolt taper when fitting.

Check tyre condition and pressure (inclu ding spare wheel), correct if necessary.

If there is a tyre inflation system, check that the set is complete and the use-by date is

still valid. Replace sealant bottle every four years.

⊕

Annual service check if the annual distance travelled is greater than 20 000 km.

Visually check the first aid kit (that it is wher e it should be, that it is undamaged and that

the use by date is still valid), lashing eyes and warning triangle every 2 years

Check headlamp settings (including auxi liary headlamps), adjust if necessary xx

Lubricate door hinges, check arms, cylinder lo ck, door latch, bonnet catch, rear panel

hinge xx

Test run, final check (check steering and ig nition lock, instrument and warning lamps,

entire brake system, steering, air conditioni ng system, engine, bodywork and chassis,

reset service/interval display with TECH 2. xxxxx

⊕

Germany only: carry out emissions check, main inspection

First time after three years, then every 2 years

If used commercially to tran sport passengers, taxis, ambulances, hire cars etc annually

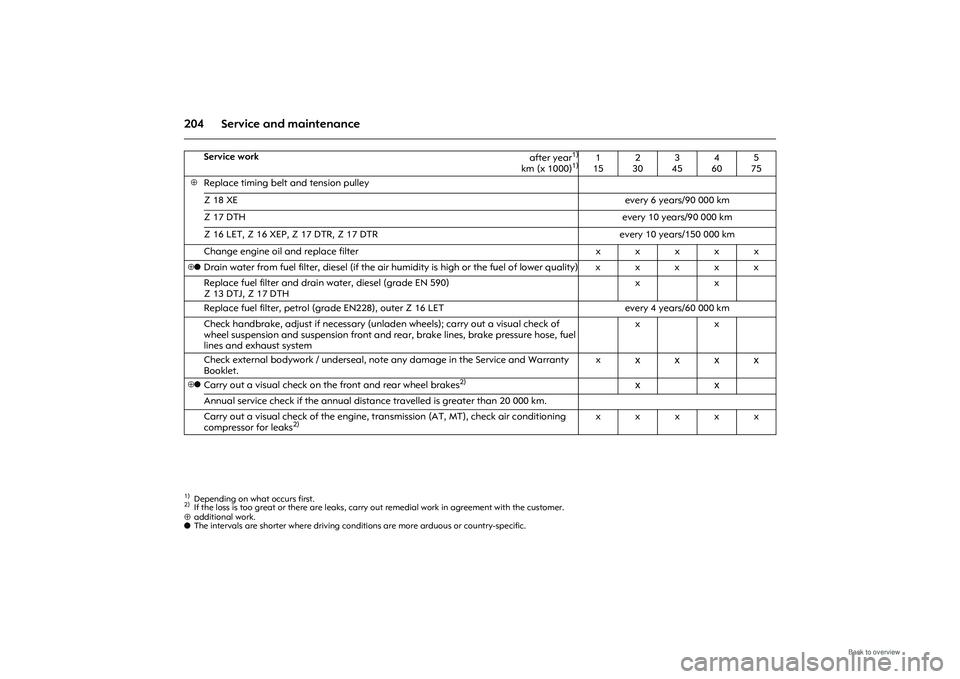

Page 210 of 248

204 Service and maintenance⊕additional work.

o The intervals are shorter where driving conditions are more arduous or country-specific.

Service work

after year

1)

km (x 1000)

1)

1)Depending on what occurs first.

1

15 2

30 3

45 4

60 5

75

⊕

Replace timing belt and tension pulley

Z 18 XE every 6 years/90 000 km

Z 17 DTH every 10 years/90 000 km

Z 16 LET, Z 16 XEP, Z 17 DTR, Z 17 DTR every 10 years/150 000 km

Change engine oil and replace filter xxxxx

⊕o

Drain water from fuel filter, diesel (if the air humidity is high or the fuel of lower quality)xxxxx

Replace fuel filter and drain water, diesel (grade EN 590)

Z 13 DTJ, Z 17 DTH xx

Replace fuel filter, petrol (grade EN228), outer Z 16 LET every 4 years/60 000 km

Check handbrake, adjust if necessary (unl aden wheels); carry out a visual check of

wheel suspension and suspension front and re ar, brake lines, brake pressure hose, fuel

lines and exhaust system xx

Check external bodywork / underseal, note any damage in the Service and Warranty

Booklet. x

xxxx

⊕o

Carry out a visual check on the front and rear wheel brakes

2)

2)If the loss is too great or there are leaks, carry out remedial work in agr

eement with the customer.

xx

Annual service check if the annual distance travelled is greater than 20 000 km.

Carry out a visual check of the engine, tran smission (AT, MT), check air conditioning

compressor for leaks

2)

xxxxx

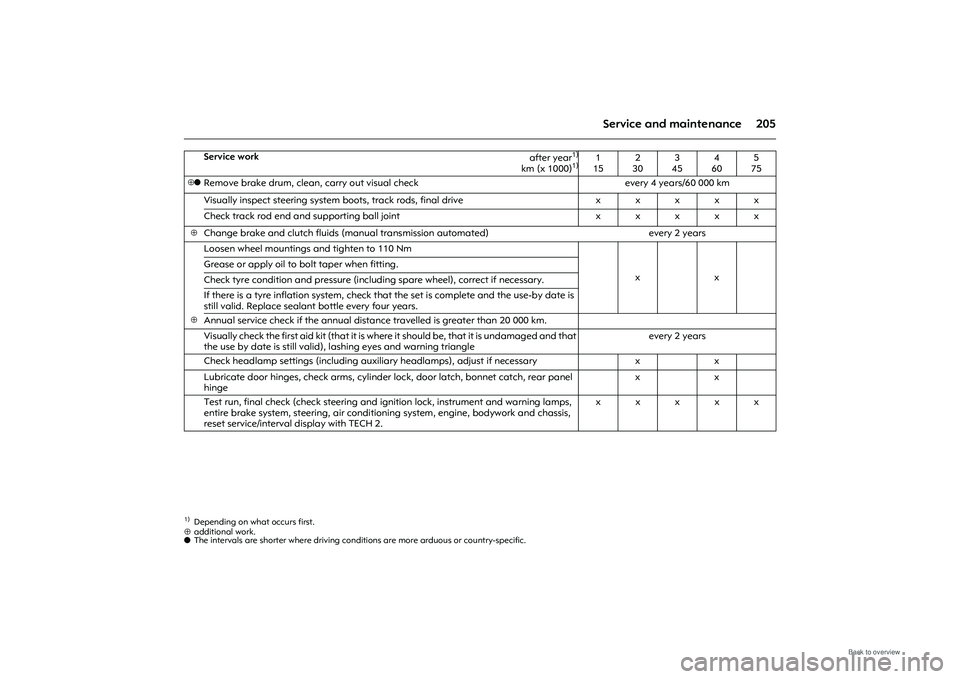

Page 211 of 248

205

Service and maintenance

⊕ additional work.

o The intervals are shorter where driving conditions are more arduous or country-specific.

Service work

after year

1)

km (x 1000)

1)

1)Depending on what occurs first.

1

15 2

30 3

45 4

60 5

75

⊕o

Remove brake drum, clean, carry out visual check every 4 years/60 000 km

Visually inspect steering system boots, track rods, final drive xxxxx

Check track rod end and supporting ball joint xxxxx

⊕

Change brake and clutch fluids (manual transmission automated) every 2 years

Loosen wheel mountings and tighten to 110 Nm

xx

Grease or apply oil to

bolt taper when fitting.

Check tyre condition and pressure (inclu ding spare wheel), correct if necessary.

If there is a tyre inflation system, check that the set is complete and the use-by date is

still valid. Replace sealant bottle every four years.

⊕

Annual service check if the annual distance travelled is greater than 20 000 km.

Visually check the first aid kit (that it is wher e it should be, that it is undamaged and that

the use by date is still valid), lashing eyes and warning triangle every 2 years

Check headlamp settings (including auxi liary headlamps), adjust if necessary xx

Lubricate door hinges, check arms, cylinder lo ck, door latch, bonnet catch, rear panel

hinge xx

Test run, final check (check steering and ig nition lock, instrument and warning lamps,

entire brake system, steering, air conditioni ng system, engine, bodywork and chassis,

reset service/interval display with TECH 2. xxxxx

Page 213 of 248

207

Service and maintenance

Engine oil

Engine oil is graded by quality and

viscosity. When choosing an engine oil, the

quality grade is more important than the

viscosity.

Engine oil for Service schedule Europe

Opel engine oil is GM-LL-A-025 and

GM-LL-B-025 grade and therefore suitable

for both petrol and diesel engines.

Engine oil for International service

scheduleEngine oil: top up

Oils from different manufacturers and

different brands of oil can be mixed as long

as the grades (quality and viscosity) are

the same.

Not all the engine oils available on the

market are of a suitable quality. Always

check that the required specification and

classification are given on the cans.

If engine oil of a suitable quality cannot be

obtained, use no more than 1 litre of

category ACEA A3/B4 or A3/B3 (once

between two oil changes). The viscosity

must be suitable for requirements.

It is forbidden to use engine oil of

grades ACEA A1/B1 and A5/B5. Under

certain circumstances, these oils can cause

long-term damage to the engine.

Engine oil additives

The use of motor oil additives can lead to

damage and will invalidate the guarantee.

Engine oil viscosity

Only use engine oils with viscosity

grades 0W-30, 0W-40, 5W-30 or 5W-40.

The SAE viscosity grading system indicates

the oil’s flowability. Oil is more viscous

when cold than when warm.

Multigrade oil has two numbers. The first,

followed by a W, indicates the viscosity at

low temperatures and the second indicates

the viscosity at high temperatures.

GM-LL-A-025: Petrol engines

GM-LL-B-025: Diesel engines

GM General Motors Europe

LL Long life

A or B Details of engine oil grade

025 Validity code

ACEA-A3: Petrol engines

ACEA-B4: Diesel engines

without diesel

particulate filter

ACEA-C3 Diesel engines with diesel particulate

filter

Page 215 of 248

209

Service and maintenance

Genuine Opel Parts and

Accessories We recommend that you use "Genuine

Opel Parts and Accessories" and

conversion parts released expressly for

your vehicle type. These parts have

undergone special tests to establish their

reliability, safety and specific suitability for

Opel vehicles. Despit e continuous market

monitoring, we cannot assess or guarantee

these attributes for other products, even if

they have been granted approval by the

relevant authorities or in some other form.

"Genuine Opel Parts and Accessories" and

conversion parts approved by Opel can be

obtained from your Op el Partner, who can

provide expert advice on permitted

technical changes and ensure correct

installation.

Picture no: 17922S.tif

Performing work To avoid injury from moving parts and

cables conducting ignition voltage, only

carry out engine compartment checks

(e. g. checking brake fluid or engine oil

level) when the igniti on is switched off.

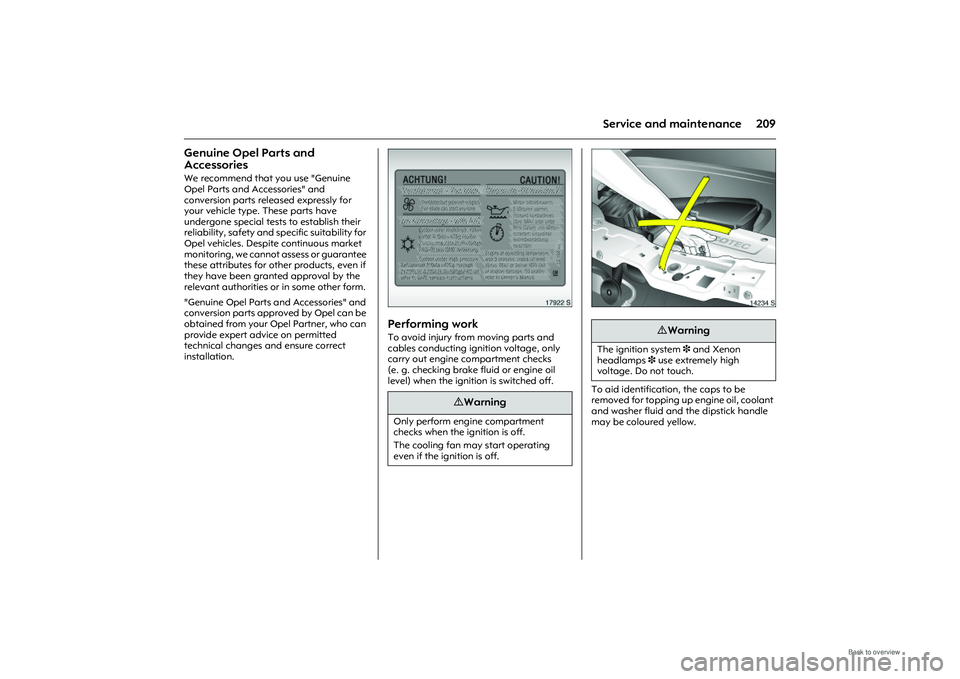

Picture no: 14234s.tif

To aid identification, the caps to be

removed for topping up engine oil, coolant

and washer fluid and the dipstick handle

may be coloured yellow.

9 Warning

Only perform engine compartment

checks when the ignition is off.

The cooling fan may start operating

even if the ignition is off.

9 Warning

The ignition system 3 and Xenon

headlamps 3 use extremely high

voltage. Do not touch.