tow bar OPEL MERIVA 2009 Owners Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 2009, Model line: MERIVA, Model: OPEL MERIVA 2009Pages: 248, PDF Size: 4.46 MB

Page 131 of 248

125

Climate control

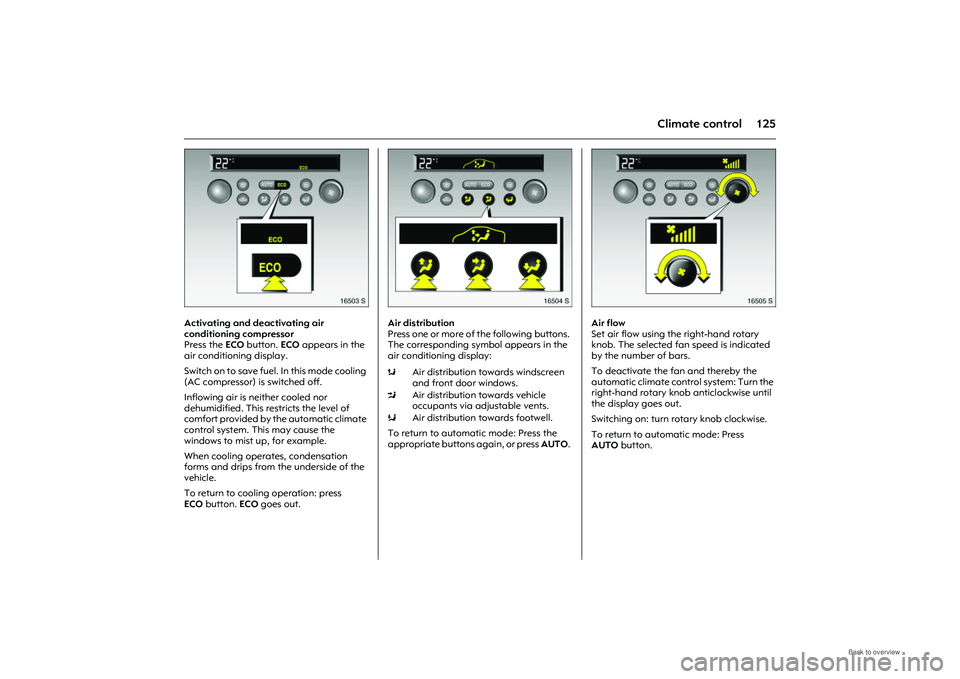

Picture no: 16503s.tif

Activating and deactivating air

conditioning compressor

Press the ECO button. ECO appears in the

air conditioning display.

Switch on to sa ve fuel. In this m ode cooling

(AC compressor) is switched off.

Inflowing air is neither cooled nor

dehumidified. This restricts the level of

comfort provided by the automatic climate

control system. This may cause the

windows to mist up, for example.

When cooling operates, condensation

forms and drips from the underside of the

vehicle.

To return to cooling operation: press

ECO button. ECO goes out.

Picture no: 16504s.tif

Air distribution

Press one or more of the following buttons.

The corresponding symbol appears in the

air conditioning display:

To return to automatic mode: Press the

appropriate buttons again, or press AUTO.

Picture no: 16505s.tif

Air flow

Set air flow using the right-hand rotary

knob. The selected fan speed is indicated

by the number of bars.

To deactivate the fan and thereby the

automatic climate control system: Turn the

right-hand rotary knob anticlockwise until

the display goes out.

Switching on: turn rota ry knob clockwise.

To return to automatic mode: Press

AUTO button.

sAir distribution towards windscreen

and front door windows.

M Air distribution towards vehicle

occupants via adjustable vents.

K Air distribution towards footwell.

Page 135 of 248

129

Driving and operation

Driving and operation

Manual transmission

automated

3

The manual transmission automated

transmission 3 permits manual ( manual

mode ) or automatic gear shifting

(automatic mode ), both with automatic

clutch control.

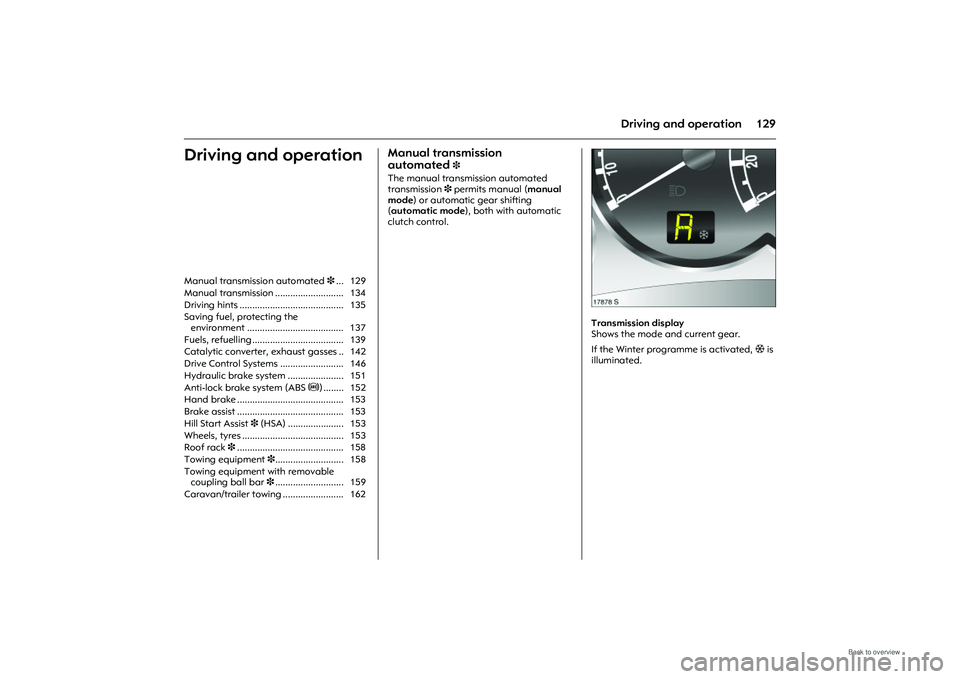

Picture no: 17878s.tif

Transmission display

Shows the mode and current gear.

If the Winter programme is activated, T is

illuminated.

Manual transmission automated

3... 129

Manual transmission ........................... 134

Driving hints ......................................... 135

Saving fuel, protecting the environment ...................................... 137

Fuels, refuelling .................................... 139

Catalytic converter, exhaust gasses .. 142

Drive Control Systems ......................... 146

Hydraulic brake system ...................... 151

Anti-lock brake system (ABS u ) ........ 152

Hand brake .......................................... 153

Brake assist .......................................... 153

Hill Start Assist 3 (HSA) ...................... 153

Wheels, tyres ........................................ 153

Roof rack 3.......................................... 158

Towing equipment 3........................... 158

Towing equipment with removable coupling ball bar 3........................... 159

Caravan/trailer towing ........................ 162

Page 156 of 248

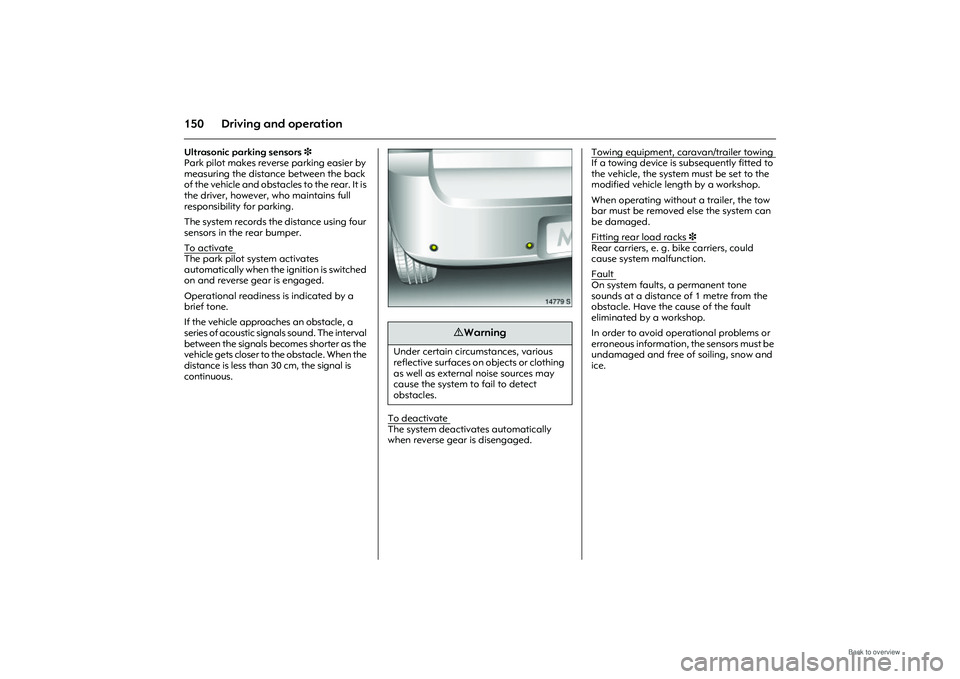

150 Driving and operationUltrasonic parking sensors 3

Park pilot makes reverse parking easier by

measuring the distance between the back

of the vehicle and obstacles to the rear. It is

the driver, however, who maintains full

responsibility for parking.

The system records the distance using four

sensors in the rear bumper.

To activate The park pilot system activates

automatically when the ignition is switched

on and reverse gear is engaged.

Operational readiness is indicated by a

brief tone.

If the vehicle approaches an obstacle, a

series of acoustic signals sound. The interval

between the signals be comes shorter as the

vehicle gets closer to the obstacle. When the

distance is less than 30 cm, the signal is

continuous.

Picture no: 14779s.tif

To deactivate The system deactivates automatically

when reverse gear is disengaged. Towing equipment, caravan/trailer towing

If a towing device is subsequently fitted to

the vehicle, the system must be set to the

modified vehicle length by a workshop.

When operating without a trailer, the tow

bar must be removed else the system can

be damaged.

Fitting rear load racks

3

Rear carriers, e. g. bike carriers, could

cause system malfunction.

Fault

On system faults, a permanent tone

sounds at a distance of 1 metre from the

obstacle. Have the cause of the fault

eliminated by a workshop.

In order to avoid operational problems or

erroneous information, the sensors must be

undamaged and free of soiling, snow and

ice.

9 Warning

Under certain circumstances, various

reflective surfaces on objects or clothing

as well as external noise sources may

cause the system to fail to detect

obstacles.

Page 165 of 248

159

Driving and operation

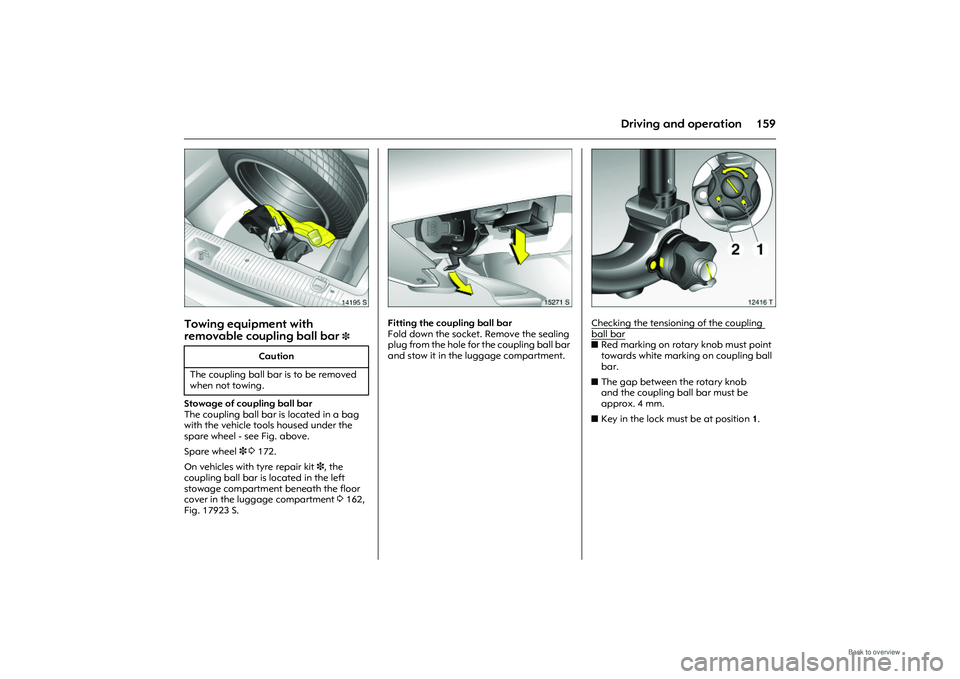

Picture no: 14195s.tif

Towing equipment with

removable coupling ball bar

3

Stowage of coupling ball bar

The coupling ball bar is located in a bag

with the vehicle tools housed under the

spare wheel - see Fig. above.

Spare wheel 3 3172.

On vehicles with tyre repair kit 3, the

coupling ball bar is located in the left

stowage compartment beneath the floor

cover in the luggage compartment 3162,

Fig. 17923 S.

Picture no: 15271s.tif

Fitting the coupling ball bar

Fold down the socket. Remove the sealing

plug from the hole for the coupling ball bar

and stow it in the luggage compartment.

Picture no: 12416t.tif

Checking the tensioning of the coupling ball bar

z Red marking on rotary knob must point

towards white marking on coupling ball

bar.

z The gap between the rotary knob

and the coupling ball bar must be

approx. 4 mm.

z Key in the lock must be at position 1.

Caution

The coupling ball bar is to be removed

when not towing.

Page 167 of 248

161

Driving and operation

Check that the coupling ball bar is correctly installedzGreen marking on rotary knob must

point towards white ma rking on coupling

ball bar

z There must be no gap between the

rotary handle and the coupling ball bar

z The coupling ball bar must be firmly

engaged in the opening

z The coupling ball bar must be locked

and the key removed

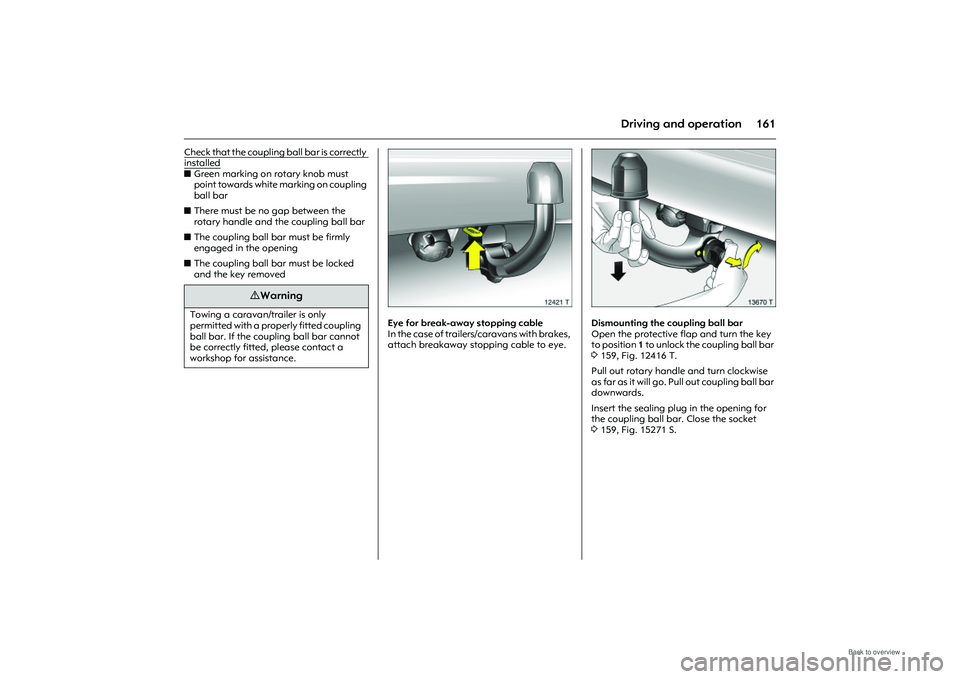

Picture no: 12421t.tif

Eye for break-away stopping cable

In the case of trailers/caravans with brakes,

attach breakaway stopping cable to eye.

Picture no: 13670t.tif

Dismounting the coupling ball bar

Open the protective flap and turn the key

to position 1 to unlock the coupling ball bar

3 159, Fig. 12416 T.

Pull out rotary handle and turn clockwise

as far as it will go. Pull out coupling ball bar

downwards.

Insert the sealing plug in the opening for

the coupling ball bar. Close the socket

3 159, Fig. 15271 S.

9 Warning

Towing a caravan/trailer is only

permitted with a properly fitted coupling

ball bar. If the coupling ball bar cannot

be correctly fitted, please contact a

workshop for assistance.

Page 168 of 248

162 Driving and operation

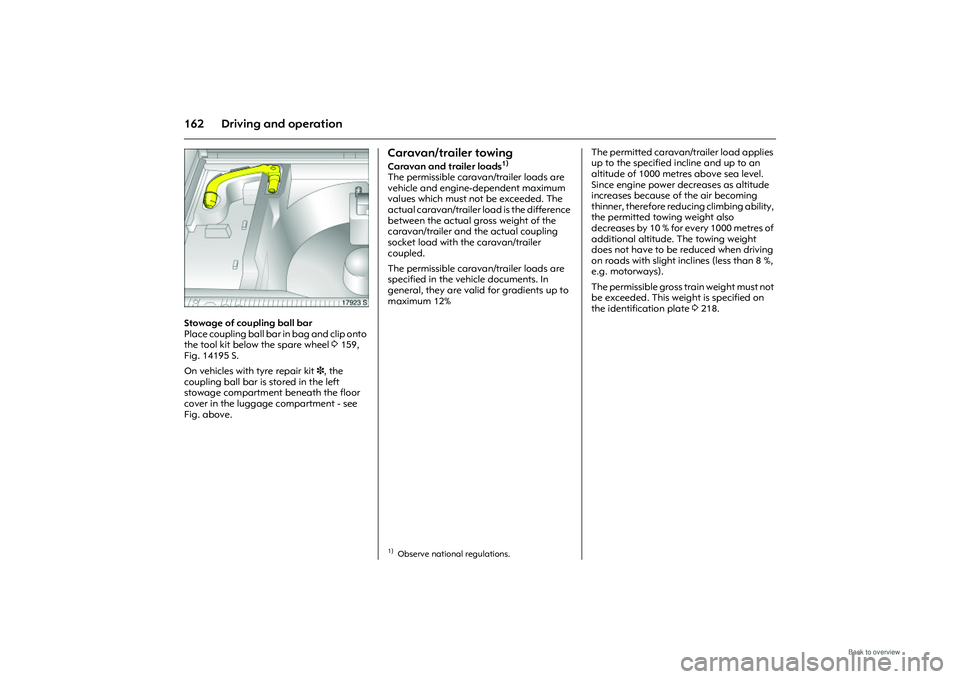

Picture no: 17923s.tif

Stowage of coupling ball bar

Place coupling ball bar in bag and clip onto

the tool kit below the spare wheel 3159,

Fig. 14195 S.

On vehicles with tyre repair kit 3, the

coupling ball bar is stored in the left

stowage compartment beneath the floor

cover in the luggage compartment - see

Fig. above.

Caravan/trailer towingCaravan and trailer loads

1)

The permissible caravan/trailer loads are

vehicle and engine-dependent maximum

values which must not be exceeded. The

actual caravan/trailer load is the difference

between the actual gross weight of the

caravan/trailer and the actual coupling

socket load with the caravan/trailer

coupled.

The permissible caravan/trailer loads are

specified in the vehi cle documents. In

general, they are valid for gradients up to

maximum 12% The permitted caravan/trailer load applies

up to the specified incline and up to an

altitude of 1000 metres above sea level.

Since engine power decreases as altitude

increases because of the air becoming

thinner, therefore reducing climbing ability,

the permitted towing weight also

decreases by 10 % for

every 1000 metres of

additional altitude. The towing weight

does not have to be reduced when driving

on roads with slight inclines (less than 8 %,

e.g. motorways).

The permissible gross train weight must not

be exceeded. This weig ht is specified on

the identification plate 3218. 1)Observe national regulations.

Page 169 of 248

163

Driving and operation

Coupling socket load

The coupling socket load is the load

exerted by the trailer/caravan on the

coupling ball. It can be varied by changing

the weight distribution when loading the

trailer/caravan.

The maximum permissible coupling socket

load (55 kg) of the towing vehicle is

specified on the towing equipment

identification plate and in the vehicle

documents. This must always be complied

with, particularly in the case of heavy

caravans/trailers. The coupling socket load

should be no less than 25 kg.

When measuring the coupling socket load,

make sure that the drawbar of the loaded

trailer/caravan is at the same height as it

will be when the trailer/caravan is coupled

with the towing vehicle loaded. Particularly

important for trailers/caravans with

tandem axle. Rear axle load during towing

With the trailer connected and the towing

vehicle fully loaded including all

occupants, the permitted rear axle load

(specified on the identification plate and

vehicle documents) must be exceeded by

no more than 25 kg and the maximum

permitted gross vehicle weight by no more

than 30 kg. If the maximum permitted rear

axle load is exceeded, a maximum speed

of 100 km/h applies, and 80 km/h for

commercial vehicles.

Driving characteristics, towing tips

Before attaching th

e trailer/caravan,

lubricate the ball of the trailer/caravan

towing device. However, do not lubricate

the ball if a stabiliser, which acts on the

coupling ball, is being used to damp

hunting.

Check caravan/traile r lighting before

starting to drive. The fog tail lamps on the

vehicle are deactivated when towing a

caravan or trailer.

Trailers with LED turn signals must have a

provision enables lamp monitoring for

commercial bulbs.

Handling is greatly influenced by the

loading of the trailer/caravan. Loads

should therefore be secured so that they

cannot slip and be placed in the centre of

the trailer/caravan if possible, i.e. above

the axle.

In the case of trailers with low driving

stability, do not exceed a speed of 80 km/h;

the use of a friction-type stabiliser is

strongly recommended.

Page 186 of 248

180 Self-help, vehicle care

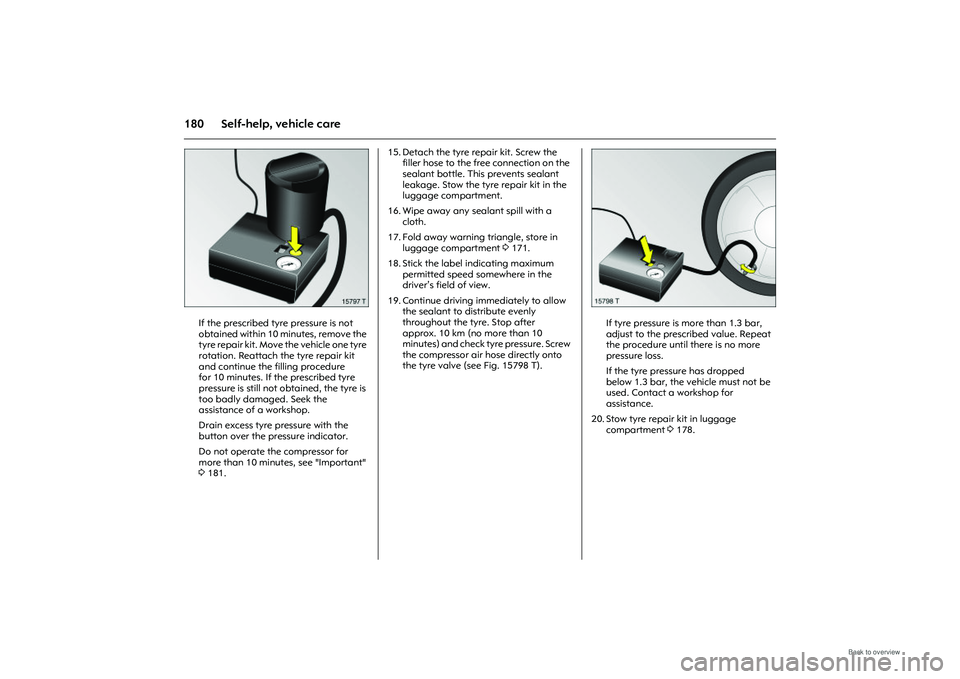

Picture no: 15797t.tif

If the prescribed tyre pressure is not

obtained within 10 minutes, remove the

tyre repair kit. Move the vehicle one tyre

rotation. Reattach the tyre repair kit

and continue the filling procedure

for 10 minutes. If the prescribed tyre

pressure is still not obtained, the tyre is

too badly damaged. Seek the

assistance of a workshop.

Drain excess tyre pressure with the

button over the pressure indicator.

Do not operate the compressor for

more than 10 minutes, see "Important"

3181. 15. Detach the tyre repair kit. Screw the

filler hose to the free connection on the

sealant bottle. This prevents sealant

leakage. Stow the tyre repair kit in the

luggage compartment.

16. Wipe away any sealant spill with a cloth.

17. Fold away warning triangle, store in luggage compartment 3171.

18. Stick the label indicating maximum permitted speed somewhere in the

driver’s field of view.

19. Continue driving immediately to allow the sealant to distribute evenly

throughout the tyre. Stop after

approx. 10 km (no more than 10

minutes) and check tyre pressure. Screw

the compressor air hose directly onto

the tyre valve (see Fig. 15798 T).

Picture no: 15798t.tif

If tyre pressure is more than 1.3 bar,

adjust to the prescribed value. Repeat

the procedure until there is no more

pressure loss.

If the tyre pressure has dropped

below 1.3 bar, the vehicle must not be

used. Contact a workshop for

assistance.

20. Stow tyre repair kit in luggage compartment 3178.

Page 204 of 248

198 Self-help, vehicle careWindows and windscreen wiper blades

Use a soft lint-free cloth or chamois leather

together with window cleaner and insect

remover.

When cleaning the rear window, make sure

the heating element inside the window is

not damaged.

For mechanical removal of ice, use a sharp-

edged ice scraper. Pre ss the scraper firmly

against the glass so that no dirt can get

under it and scratch the glass.

Clean smearing wiper blades with a soft

cloth and window cleaner. Locks

The locks are lubricated with a high-quality

locking cylinder grease

in the factory. Only

use de-icer in urgent cases, since it has a

de-greasing effect and affects the

operation of the locks. Have the locks re-

greased in a workshop after using de-icer.

Engine compartment

Look after areas in the engine

compartment that are painted in the same

colour as the vehicle like any other

paintwork.

It is advisable to wash the engine

compartment before and after winter and

preserve it with wax. Cover alternator and

brake fluid reservoir with plastic sheets

before washing the engine.

When washing the engine with a steam-jet

cleaner, do not direct the steam jet at

components of the Anti-lock Braking

System 3, the automatic air conditioning

system 3 or the belt drive and its

components.

After an engine wash, have all engine room

components preserved thoroughly by a

workshop using protective wax.

Do not use high-pressure jet cleaners. Underbody

Some areas of the vehicle underbody have

a PVC undercoating while other critical

areas have a durable protective wax

coating.

After the underbody is washed, check the

underbody and have more protective wax

applied if necessary.

Bitumen/rubber materials could damage

the PVC coating. Have underbody work

carried out by a workshop.

Before and after winter, wash the

underbody and have the protective wax

coating checked.

Towing equipment

Do not clean the coupling ball bar with a

steam-jet or high-pressure jet cleaner.

Page 243 of 248

237

Index

KKeyextending .............................................. 26

ignition lock ..................................... 16, 27

Locking doors............................28, 30, 36

Starting .................................................. 27

Starting the engine ............................... 16

Keys ........................................................... 26LLanguage selection .................................. 95

Lashing eyes ............................................. 57

Leather trim ............................................ 197

Light switch ............................................... 11

Lighting ............................................. 11, 102 Driving abroad .................................... 110

Loading .....................................58, 162, 226

Loading the vehicle .................................. 58

Locking doors ...........................2, 28, 30, 36

Locking from the inside ............................ 30

Lubricants ............................................... 210

Luggage compartment Bulb replacement................................ 195

Cover...................................................... 55

Extension ......................................... 32, 53

Lighting ............................................... 109

Loading .................................58, 162, 226

Luggage compartment cover ................. 55

Lumbar support ........................................ 45

MMain beam ................................................ 11 Bulb replacement ....................... 187, 188

Control indicator ................................... 84

Maintenance Air conditioning system...................... 128

Antifreeze protection ......................... 212

Brake fluid ........................................... 214

Brakes .................................................. 213

Catalytic converter ............................. 145

Engine oil ............................................. 210

Fuel consumption ............................... 138

Tyre pressure............................... 154, 228

Tyres .................................................... 155

Manual transmission ........................ 14, 134

Mirrors ................................................... 4, 38

Misted windows ......................118, 121, 124

Mobile telephone.................................... 113

Muffler, see Exhaust system .................. 144NNumber plate lamps Bulb replacement ............................... 193

Number plate lighting............................ 193

Number plates ........................................ 217OOctane numbers ............................. 220, 221

Odometer .................................................. 87

Oil ............................................................ 207 Additives ............................................. 207

Top up ................................................. 207

Viscosity............................................... 207 Oil consumption ..................... 210, 220, 221

Oil level.................................................... 210

Oil pressure ............................................... 84

Opel Service ............................................ 199

Operating temperature ......................... 136

Outside temperature gauge ................... 91

Overrun ........................................... 136, 138

PPaintwork damage................................. 197

Park pilot ................................................. 150

Parking lamps........................................... 11

Bulb replacement ............................... 189

Pedals...................................................... 136

Performance ........................................... 222

Pollen filter .............................................. 127

Power assisted steering, see electronic power steering ................ 86

Power steering, see electronic power steering ........................................ 86

Preheating ................................................ 86

Pushing, towing .............................. 142, 166QQuickheat ............................................... 127RRadio ................................................. 24, 111

Radio equipment (CB) ........................... 113

Radio reception ...................................... 111

Radio remote control ............................... 28

Reading lamps ....................................... 109

Rear lamp cluster ................................... 102 Bulb replacement ............................... 191