spare wheel OPEL MOKKA X 2017 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2017, Model line: MOKKA X, Model: OPEL MOKKA X 2017Pages: 247, PDF Size: 6.59 MB

Page 208 of 247

206Vehicle careNote

The driving characteristics of the repaired tyre are severely affected,therefore have this tyre replaced.

If unusual noise is heard or the

compressor becomes hot, turn

compressor off for at least

30 minutes.

The built-in safety valve opens at a

pressure of 7 bar.

Note the expiry date of the kit. After

this date its sealing capability is no

longer guaranteed. Pay attention to

storage information on sealant

bottle.

Replace the used sealant bottle. Dispose of the bottle as prescribed

by applicable laws.

The compressor and sealant can be used from approx. -30 °C.

The adapters supplied can be used

to pump up other items e.g.

footballs, air mattresses, inflatable

dinghies etc. They are located on the underside of the compressor. To

remove, screw on compressor air hose and withdraw adapter.Wheel changing

Some vehicles are equipped with a

tyre repair kit instead of a spare wheel

3 203.

Make the following preparations and

observe the following information:

● Park the vehicle on a level, firm and non-skid surface. The front

wheels must be in the straight- ahead position.

● Apply the parking brake and engage first gear, reverse gear or

P .

● Remove the spare wheel 3 208.

● Never change more than one wheel at a time.

● Use the jack only to change wheels in case of puncture, not

for seasonal winter or summer

tyre change.

● The jack is maintenance-free.

● If the ground on which the vehicle

is standing is soft, a solid board

(max. 1 cm thick) should be

placed under the jack.

● Take heavy objects out of the vehicle before jacking up.● No people or animals may be in the vehicle when it is jacked-up.

● Never crawl under a jacked-up vehicle.

● Do not start the vehicle when it is

raised on the jack.

● Clean wheel nuts and thread with

a clean cloth before mounting the

wheel.9 Warning

Do not grease wheel bolt, wheel

nut and wheel nut cone.

1. Disengage wheel nut caps with a screwdriver and remove. Pull off

the wheel cover.

Page 209 of 247

Vehicle care207

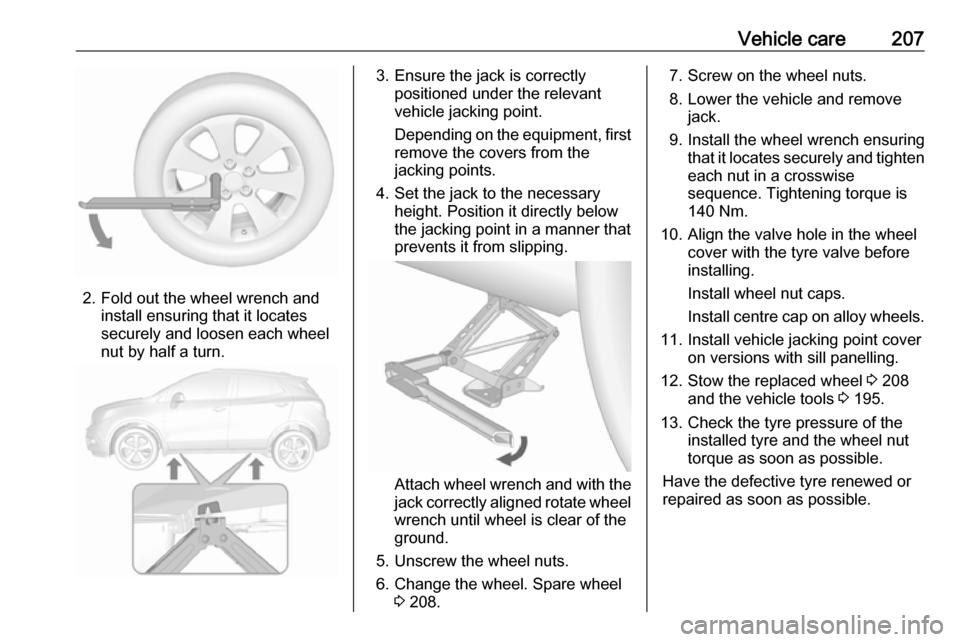

2. Fold out the wheel wrench andinstall ensuring that it locates

securely and loosen each wheel

nut by half a turn.

3. Ensure the jack is correctly positioned under the relevant

vehicle jacking point.

Depending on the equipment, first

remove the covers from the

jacking points.

4. Set the jack to the necessary height. Position it directly below

the jacking point in a manner that prevents it from slipping.

Attach wheel wrench and with the

jack correctly aligned rotate wheel wrench until wheel is clear of the

ground.

5. Unscrew the wheel nuts. 6. Change the wheel. Spare wheel 3 208.

7. Screw on the wheel nuts.

8. Lower the vehicle and remove jack.

9. Install the wheel wrench ensuring that it locates securely and tighten

each nut in a crosswise

sequence. Tightening torque is

140 Nm.

10. Align the valve hole in the wheel cover with the tyre valve before

installing.

Install wheel nut caps.

Install centre cap on alloy wheels.

11. Install vehicle jacking point cover on versions with sill panelling.

12. Stow the replaced wheel 3 208

and the vehicle tools 3 195.

13. Check the tyre pressure of the installed tyre and the wheel nut

torque as soon as possible.

Have the defective tyre renewed or

repaired as soon as possible.

Page 210 of 247

208Vehicle careJacking position for lifting platform

Rear arm position of the lifting

platform centrically under the recess

of the sill.

Front arm position of the lifting

platform at the underbody.

Spare wheel Some vehicles are equipped with a

tyre repair kit instead of a spare wheel

3 203.

If mounting a spare wheel, which is

different from the other wheels, this

wheel might be classified as a

temporary spare wheel and the

corresponding speed limits apply,

even though no label indicates this.

Seek the assistance of a workshop to

check the applicable speed limit.

The spare wheel has a steel rim.Caution

The use of a spare wheel that is smaller than the other wheels or in combination with winter tyres

could affect driveability. Have the defective tyre replaced as soon as

possible.

The spare wheel is located in the load

compartment beneath the floor

covering. It is secured with a wing nut.

Stowing a damaged full size

wheel in the load compartment

The spare wheel well is not designed for other tyre sizes than the spare

wheel.

Page 211 of 247

Vehicle care209

A damaged full size wheel must be

stowed in the load compartment and

secured with a strap. Vehicle tools

3 195.

To secure the wheel: 1. Position the wheel in the middle of

the load compartment.

2. Place the loop end of the strap through the lashing eye on one

side.

3. Place the hook end of the strap through the loop and pull it until

the strap is fastened securely to

the lashing eye.4. Insert the strap through the spokes of the wheel as shown in

the illustration.

5. Mount the hook to the opposite lashing eye.

6. Tighten the strap and secure it using the buckle.

9 Danger

Always drive with folded up and

engaged rear seat backrests when stowing a damaged full size wheel

in the load compartment.

Temporary spare wheelCaution

The use of the temporary spare

wheel could affect driveability.

Have the defective tyre renewed

or repaired as soon as possible.

Only mount one temporary spare

wheel. Do not drive faster than

80 km/h. Take curves slowly. Do not

use for a long period of time.

If your vehicle gets a flat tyre on the

rear while towing another vehicle,

mount the temporary spare wheel at

the front and the full size tyre at the

rear.

Tyre chains 3 202.

Spare wheel with directional tyre If possible, fit directional tyres such

that they roll in the direction of travel.

The rolling direction is indicated by a

symbol (e.g. an arrow) on the

sidewall.

Page 212 of 247

210Vehicle careThe following applies to tyres fitted

opposing the rolling direction:

● Driveability may be affected. Have the defective tyre renewed

or repaired as soon as possible

and fit it instead of the spare

wheel.

● Drive particularly carefully on wet

and snow-covered road

surfaces.Jump starting

Do not start with a quick charger.

A vehicle with a discharged battery

can be started using jump leads and

the battery of another vehicle.9 Warning

Be extremely careful when starting

with jump leads. Any deviation

from the following instructions can

lead to injuries or damage caused

by battery explosion or damage to the electrical systems of both

vehicles.

9 Warning

Avoid contact of the battery with

eyes, skin, fabrics and painted

surfaces. The fluid contains

sulphuric acid which can cause

injuries and damage in the event

of direct contact.

● Never expose the battery to naked flames or sparks.

●A discharged battery can already

freeze at a temperature of 0 °C.

Defrost the frozen battery before

connecting jump leads.

● Wear eye protection and protective clothing when

handling a battery.

● Use a booster battery with the same voltage (12 Volts). Its

capacity (Ah) must not be much less than that of the discharged

battery.

● Use jump leads with insulated terminals and a cross section of

at least 16 mm 2

(25 mm 2

for

diesel engines).

● Do not disconnect the discharged

battery from the vehicle.

● Switch off all unnecessary electrical consumers.

● Do not lean over the battery during jump starting.

● Do not allow the terminals of one

lead to touch those of the other

lead.

● The vehicles must not come into contact with each other during

the jump starting process.

Page 234 of 247

![OPEL MOKKA X 2017 Manual user 232Technical dataComfort with up to 3 peopleECO with up to 3 peopleWith full loadEngineTyresfrontrearfrontrearfrontrear[kPa/bar]

([psi])[kPa/bar]

([psi])[kPa/bar]

([psi])[kPa/bar]

([psi])[kPa/bar]

([p OPEL MOKKA X 2017 Manual user 232Technical dataComfort with up to 3 peopleECO with up to 3 peopleWith full loadEngineTyresfrontrearfrontrearfrontrear[kPa/bar]

([psi])[kPa/bar]

([psi])[kPa/bar]

([psi])[kPa/bar]

([psi])[kPa/bar]

([p](/img/37/18892/w960_18892-233.png)

232Technical dataComfort with up to 3 peopleECO with up to 3 peopleWith full loadEngineTyresfrontrearfrontrearfrontrear[kPa/bar]

([psi])[kPa/bar]

([psi])[kPa/bar]

([psi])[kPa/bar]

([psi])[kPa/bar]

([psi])[kPa/bar]

([psi])B14XFT,

B16DTH,

B16DTU,

B16DTN215/60R17,240/2.4 (35)240/2.4 (35)270/2.7 (39)280/2.8 (41)270/2.7

(39)300/3.0

(44)215/55 R18205/70 R16,

215/65 R16220/2.2 (32)220/2.2 (32)270/2.7 (39)280/2.8 (41)270/2.7

(39)300/3.0

(44)225/45 R19240/2.4 (35)240/2.4 (35)270/2.7 (39)280/2.8 (41)270/2.7

(39)280/2.8

(41)AllTemporary spare

wheel

125/70 R16420/4.2 (60)420/4.2 (60)––420/4.2

(60)420/4.2

(60)

Page 237 of 247

Customer information235Translation of the original declaration

of conformity

Declaration of conformity according

to EC Directive 2006/42/EC

We declare that the product:

Product designation: Jack

Type/GM part number: 13590195

is in compliance with the provisions of

Directive 2006/42/EC.

Applied technical standards:GMW 14337:Standard Equipment

Jack – Hardware

TestsGMW15005:Standard Equipment

Jack and Spare Tyre, Vehicle TestThe person authorised to compile thetechnical documentation is

Hans-Peter Metzger

Engineering Group Manager Chassis

& Structure

Adam Opel AG

D-65423 RüsselsheimSigned by

Daehyeok An

Engineering Group Manager Tyre

Wheel Systems

GM Korea

Bupyung, Incheon, 403-714, Korea

Incheon, Republic of Korea, 4th April

2014

Collision damage repair

Paint thickness Due to production techniques, the

thickness of the paint can vary

between 50 and 400 µm.

Therefore, different paint thickness is

no indicator for a collision damage

repair.Software acknowledgement

Certain OnStar components include

libcurl and unzip software and other

third party software. Below are the

notices and licenses associated with

libcurl and unzip and for other third

party software please see http://

www.lg.com/global/support/

opensource/index.

libcurl Copyright and permission notice

Copyright (c) 1996 - 2010, Daniel

Stenberg,

All rights reserved.

Permission to use, copy, modify, and

distribute this software for any

purpose with or without fee is hereby

granted, provided that the above

copyright notice and this permission

notice appear in all copies.

The software is provided "as is",

without warranty of any kind, express

or implied, including but not limited to the warranties of merchantability,

fitness for a particular purpose and

noninfringement of third party rights.

In no event shall the authors or

Page 245 of 247

243Rear view camera ...................... 160

Rear window wiper/washer .......... 80

Recommended fluids and lubricants ........................ 218, 222

Refuelling ................................... 169 Registered trademarks ...............237

Retained power off .....................136

Reversing lights .........................122

Ride control systems ..................149

Roof .............................................. 37

Roof load ...................................... 74

Roof rack ..................................... 74

S Seat adjustment ....................... 6, 41Seat belt ........................................ 8

Seat belt reminder .......................92

Seat belts ..................................... 44

Seat heating ................................. 43

Seat position ................................ 40

Selector lever ............................. 143

Service ....................................... 132

Service display ............................ 87

Service information ....................217

Side airbag system ......................50

Software acknowledgement .......235

Spare wheel ............................... 208

Speed limiter......................... 96, 154

Speedometer ............................... 84

Starting and operating ................134Starting off ................................... 17

Starting the engine ....................137

Steering ...................................... 134

Steering wheel adjustment ......9, 77

Steering wheel controls ...............77

Stop-start system........................ 138

Storage compartments .................59

Sunglasses storage .....................60

Sunroof ........................................ 37

Sunvisor lights ........................... 124

Sun visors .................................... 36

Symbols ......................................... 4

T

Tachometer ................................. 85

Tail lights ................................... 188

Three-point seat belt .................... 45

Tools .......................................... 195

Top-tether fastening eyes ............58

Tow bar....................................... 173

Towing ................................ 173, 212

Towing another vehicle .............213

Towing equipment .....................174

Towing the vehicle .....................212

Traction Control system ............. 149

Traction Control system off........... 94

Traffic sign assistant .............97, 161

Trailer towing ............................. 173

Transmission ............................... 17

Transmission display .................143Tread depth ............................... 201

Trip odometer .............................. 84

Turn and lane-change signals ...122

Turn signal ................................... 91

Tyre chains ................................ 202

Tyre designations ......................196

Tyre pressure ............................ 196

Tyre pressure monitoring system ............................... 95, 197

Tyre pressures ........................... 231

Tyre repair kit ............................. 203

U

Ultrasonic parking assist............. 158

Underseat storage .......................61

Upholstery .................................. 216

Uplevel display ............................. 97

Using this manual ..........................3

V Valet mode ................................. 101

Vehicle battery ........................... 183

Vehicle checks............................ 179

Vehicle data ................................ 222

Vehicle data recording and privacy ..................................... 237

Vehicle detected ahead ................96

Vehicle dimensions .................... 229

Vehicle Identification Number ....220

Vehicle jack ................................ 195

Vehicle messages .....................103