tyre pressure OPEL MOKKA X 2018 Infotainment system

[x] Cancel search | Manufacturer: OPEL, Model Year: 2018, Model line: MOKKA X, Model: OPEL MOKKA X 2018Pages: 251, PDF Size: 6.61 MB

Page 207 of 251

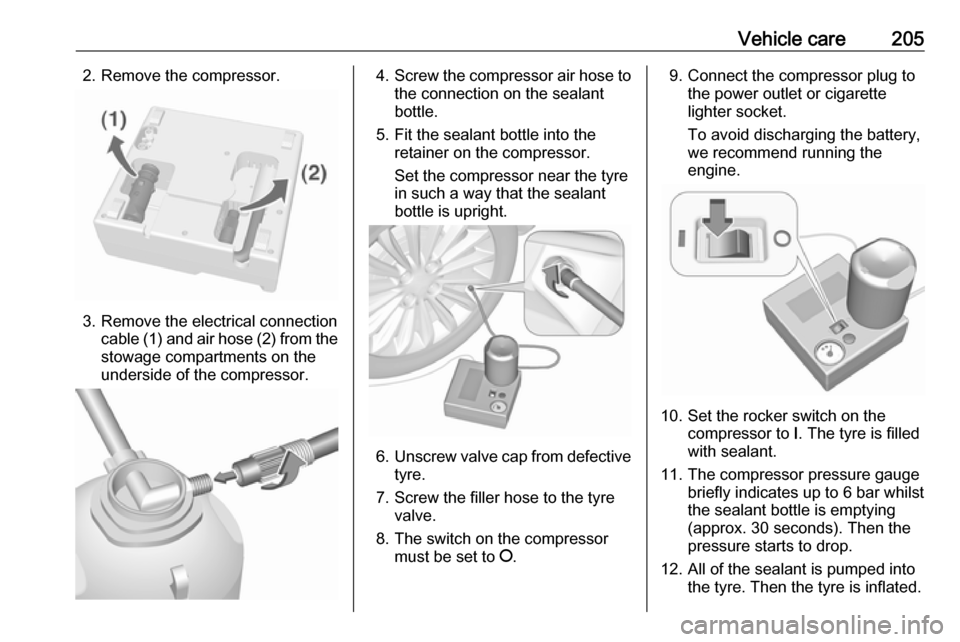

Vehicle care2052. Remove the compressor.

3. Remove the electrical connectioncable (1) and air hose (2) from the

stowage compartments on the

underside of the compressor.

4. Screw the compressor air hose to

the connection on the sealant

bottle.

5. Fit the sealant bottle into the retainer on the compressor.

Set the compressor near the tyre

in such a way that the sealant

bottle is upright.

6. Unscrew valve cap from defective

tyre.

7. Screw the filler hose to the tyre valve.

8. The switch on the compressor must be set to J.

9. Connect the compressor plug to

the power outlet or cigarette

lighter socket.

To avoid discharging the battery,

we recommend running the

engine.

10. Set the rocker switch on the compressor to I. The tyre is filled

with sealant.

11. The compressor pressure gauge briefly indicates up to 6 bar whilstthe sealant bottle is emptying

(approx. 30 seconds). Then the

pressure starts to drop.

12. All of the sealant is pumped into the tyre. Then the tyre is inflated.

Page 208 of 251

206Vehicle care13. The prescribed tyre pressureshould be obtained within

ten minutes. Tyre pressure

3 233 . When the correct pressure

is obtained, switch off the

compressor.

If the prescribed tyre pressure is

not obtained within ten minutes,

remove the tyre repair kit. Move

the vehicle one tyre rotation.

Reattach the tyre repair kit and

continue the filling procedure for

10 minutes. If the prescribed tyre

pressure is still not obtained, the

tyre is too badly damaged. Seek

the assistance of a workshop.

Drain excess tyre pressure with

the button over the pressure indicator.

Do not run the compressor longer

than 10 minutes.

14. Detach the tyre repair kit. Push catch on bracket to remove

sealant bottle from bracket. Screw the tyre inflation hose to the freeconnection of the sealant bottle.

This prevents sealant from

escaping. Stow tyre repair kit in

load compartment.

15. Remove any excess sealant using a cloth.

16. Take the label indicating maximum permitted speed from

the sealant bottle and affix in the

driver's field of view.

17. Continue driving immediately so that sealant is evenly distributedin the tyre. After driving approx.

10 km (but no more than

ten minutes), stop and check tyre

pressure. Screw compressor air

hose directly onto tyre valve and

compressor when doing this.

If tyre pressure is more than 1.3 bar , set it to the correct value.

Repeat the procedure until there

is no more loss of pressure.

If the tyre pressure has fallen

below 1.3 bar, the vehicle must

not be used. Seek the assistance

of a workshop.

18. Stow away tyre repair kit in load compartment.

Page 209 of 251

Vehicle care207Note

The driving characteristics of the

repaired tyre are severely affected, therefore have this tyre replaced.

If unusual noise is heard or the

compressor becomes hot, turn

compressor off for at least

30 minutes.

The built-in safety valve opens at a

pressure of 7 bar.

Note the expiry date of the kit. After

this date its sealing capability is no

longer guaranteed. Pay attention to

storage information on sealant

bottle.

Replace the used sealant bottle. Dispose of the bottle as prescribed

by applicable laws.

The compressor and sealant can be

used from approx. -30 °C.

The adapters supplied can be used

to pump up other items e.g.

footballs, air mattresses, inflatable

dinghies etc. They are located on the underside of the compressor. To

remove, screw on compressor air

hose and withdraw adapter.Wheel changing

Some vehicles are equipped with a

tyre repair kit instead of a spare wheel

3 204.

Make the following preparations and

observe the following information:

● Park the vehicle on a level, firm and non-skid surface. The front

wheels must be in the straight-

ahead position.

● Apply the parking brake and engage first gear, reverse gear or

P .

● Remove the spare wheel 3 209.

● Never change more than one wheel at a time.

● Use the jack only to change wheels in case of puncture, not

for seasonal winter or summer

tyre change.

● The jack is maintenance-free. ● If the ground on which the vehicle

is standing is soft, a solid board

(max. 1 cm thick) should be

placed under the jack.

● Take heavy objects out of the vehicle before jacking up.● No people or animals may be in the vehicle when it is jacked-up.

● Never crawl under a jacked-up vehicle.

● Do not start the vehicle when it is

raised on the jack.

● Clean wheel nuts and thread with

a clean cloth before mounting the wheel.9 Warning

Do not grease wheel bolt, wheel

nut and wheel nut cone.

1. Disengage wheel nut caps with a screwdriver and remove. Pull off

the wheel cover.

Page 210 of 251

208Vehicle care

2. Fold out the wheel wrench andinstall ensuring that it is located

securely and loosen each wheel

nut by half a turn.

3. Ensure the jack is correctly positioned under the relevant

vehicle jacking point.

Depending on the equipment, first

remove the covers from the

jacking points.

4. Set the jack to the necessary height. Position it directly below

the jacking point in a manner that prevents it from slipping.

Attach wheel wrench and with the

jack correctly aligned rotate wheel wrench until wheel is clear of the

ground.

5. Unscrew the wheel nuts. 6. Change the wheel. Spare wheel 3 209.

7. Screw on the wheel nuts.

8. Lower the vehicle and remove jack.

9. Install the wheel wrench ensuring that it locates securely and tighten

each nut in a crosswise

sequence. Tightening torque is

140 Nm.

10. Align the valve hole in the wheel cover with the tyre valve before

installing.

Install wheel nut caps.

Install centre cap on alloy wheels.

11. Install vehicle jacking point cover on versions with sill panelling.

12. Stow the replaced wheel 3 209

and the vehicle tools 3 196.

13. Check the tyre pressure of the installed tyre and the wheel nut

torque as soon as possible.

Have the defective tyre renewed or

repaired as soon as possible.

Page 218 of 251

216Vehicle careThoroughly rinse and leather-off the

vehicle. Rinse leather frequently. Use

separate leathers for painted and

glass surfaces: remnants of wax on

the windows will impair vision.

Do not use hard objects to remove spots of tar. Use tar removal spray on painted surfaces.

Exterior lights

Headlight and other light covers are made of plastic. Do not use any

abrasive or caustic agents, do not use

an ice scraper, and do not clean them

dry.

Polishing and waxing

Wax the vehicle regularly (at the

latest when water no longer beads).

Otherwise, the paintwork will dry out.

Polishing is necessary only if the paint

has become dull or if solid deposits

have become attached to it.

Paintwork polish with silicone forms a

protective film, making waxing

unnecessary.

Plastic body parts must not be treated with wax or polishing agents.Windows and windscreen wiper

blades

Use a soft lint-free cloth or chamois

leather together with window cleaner and insect remover.

When cleaning the rear window from

inside, always wipe in parallel to the

heating element to prevent damage.

For mechanical removal of ice, use a

sharp-edged ice scraper. Press the

scraper firmly against the glass so

that no dirt can get under it and

scratch the glass.

Clean smearing wiper blades with a

soft cloth and window cleaner.

Remove dirt residues from smearing

wiper blades by using a soft cloth and window cleaner. Also make sure to

remove any residues such as wax,

insect residues and similar from the

window.

Ice residues, pollution and continuous

wiping on dry windows will damage or

even destroy the wiper blades.Wheels and tyres

Do not use high-pressure jet

cleaners.

Clean rims with a pH-neutral wheel

cleaner.

Rims are painted and can be treated

with the same agents as the body.

Paintwork damageRectify minor paintwork damage with

a touch-up pen before rust forms.

Have more extensive damage or rust

areas repaired by a workshop.

Underbody Some areas of the vehicle underbody

have a PVC undercoating while other

critical areas have a durable

protective wax coating.

After the underbody is washed, check

the underbody and have it waxed if

necessary.

Bitumen/rubber materials could

damage the PVC coating. Have

underbody work carried out by a

workshop.

Page 224 of 251

222Technical dataTechnical dataVehicle identification..................222

Vehicle Identification Number ..222

Identification plate ...................222

Engine identification ................223

Vehicle data ............................... 224

Recommended fluids and lubricants ................................ 224

Engine data ............................. 227

Performance ............................ 229

Vehicle weight ......................... 230

Vehicle dimensions .................231

Capacities ................................ 232

Tyre pressures ........................ 233Vehicle identification

Vehicle IdentificationNumber

The Vehicle Identification Number is

located in the engine compartment.

The Vehicle Identification Number

may be embossed on the instrument

panel, visible through the windscreen.

Identification plate

The identification plate is located on

the front left or right door frame.

Page 235 of 251

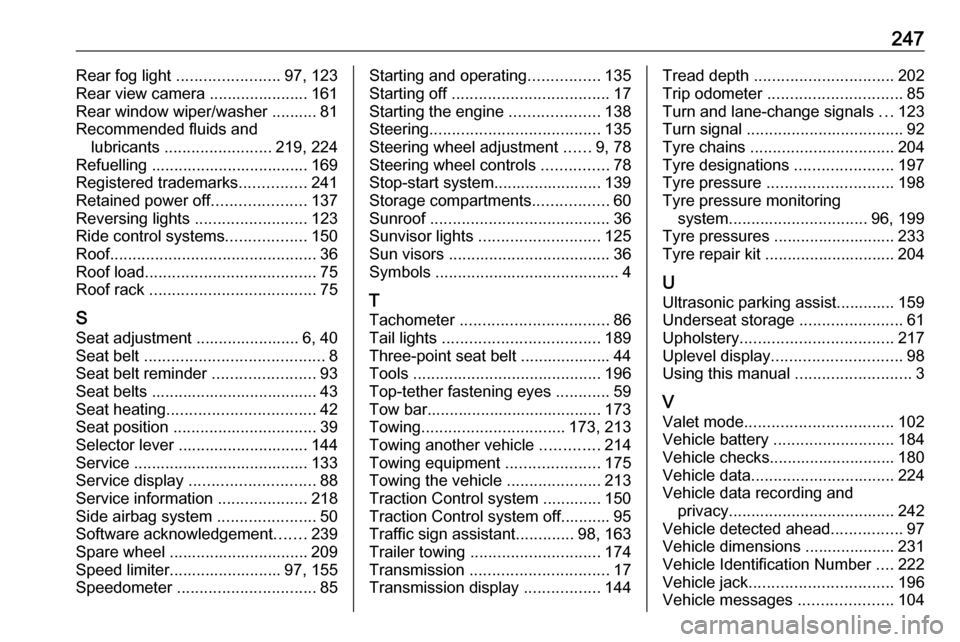

![OPEL MOKKA X 2018 Infotainment system Technical data233Tyre pressuresComfort with up to 3 peopleECO with up to 3 peopleWith full loadEngineTyresfrontrearfrontrearfrontrear[kPa/bar]

([psi])[kPa/bar]

([psi])[kPa/bar]

([psi])[kPa/bar]

([psi] OPEL MOKKA X 2018 Infotainment system Technical data233Tyre pressuresComfort with up to 3 peopleECO with up to 3 peopleWith full loadEngineTyresfrontrearfrontrearfrontrear[kPa/bar]

([psi])[kPa/bar]

([psi])[kPa/bar]

([psi])[kPa/bar]

([psi]](/img/37/18893/w960_18893-234.png)

Technical data233Tyre pressuresComfort with up to 3 peopleECO with up to 3 peopleWith full loadEngineTyresfrontrearfrontrearfrontrear[kPa/bar]

([psi])[kPa/bar]

([psi])[kPa/bar]

([psi])[kPa/bar]

([psi])[kPa/bar]

([psi])[kPa/bar]

([psi])B14NET,

B14NET LPG,

B16XER,

A18XER215/60 R17,220/2.2 (32)220/2.2 (32)270/2.7 (39)280/2.8 (41)270/2.7

(39)300/3.0

(44)215/55 R18205/70 R16,

215/65 R16200/2.0 (29)200/2.0 (29)270/2.7 (39)280/2.8 (41)270/2.7

(39)300/3.0

(44)225/45 R19240/2.4 (35)240/2.4 (35)270/2.7 (39)280/2.8 (41)270/2.7

(39)280/2.8

(41)

Page 238 of 251

236Customer information42367 Wuppertal, GermanyOperation

frequency (MHz)Maximum output

(mW)2400 - 2480102400 - 248020

Antenna module

Laird

8100 Industrial Park Drive, Grand

Blanc, MI, 48439, USA

Operation frequency: N/A

Maximum output: N/A

OnStar module

LG Electronics European Shared

Service Center B.V.

Krijgsman 1, 1186 DM Amstelveen,

The Netherlands

Operation

frequency (MHz)Maximum output

(dBm)2402 - 248042412 - 246218880 - 915331710 - 1785241850 - 1910241920 - 1980242500 - 257023

Electronic key module

Denso Coperation

Waldeckerstraße 11, 64546

Mörfelden-Walldorf, Germany

Operation frequency: 125 kHz

Maximum output: -0.14 dBm

Electronic key

Denso Coperation

Waldeckerstraße 11, 64546

Mörfelden-Walldorf, Germany

Operation frequency: 433.92 MHz

Maximum output: -5.88 dBm

Radio remote control transmitter

Continental Automotive GmbH

Siemensstraße 12, 93055

Regensburg, Germany

Operation frequency: 433.92 MHz

Maximum output: -5.7 dBm

Radio remote control transmitter

Robert Bosch GmbH

Robert Bosch Platz 1, 70839

Gerlingen, Germany

Operation frequency: 433.92 MHz

Maximum output: -4 dbm

Radio remote control receiver

Robert Bosch GmbH

Robert Bosch Platz 1, 70839

Gerlingen, Germany

Operation frequency: 433.92 MHz

Maximum output: N/A

Tyre pressure sensors

Schrader Electronics Ltd.

11 Technology Park, Belfast Road,

Antrim BT41 1QS, Northern Ireland,

United Kingdom

Operation frequency: 433.92 MHz

Maximum output: 10 mW

Parking heater remote control

receiver

Eberspaecher Climate Control

Systemse GmbH & Co. KG

Page 244 of 251

242Customer informationVehicle data recording

and privacy

Event data recorders Data storage modules in the

vehicle

A large number of electronic

components of your vehicle contain

data storage modules temporarily or

permanently storing technical data

about the condition of the vehicle,

events and errors. In general, this

technical information documents the

condition of parts, modules, systems

or the environment:

● Operating conditions of system components (e.g. filling levels)

● Status messages of the vehicle and its single components (e.g.

number of wheel revolutions / rotational speed, deceleration,

lateral acceleration)

● Dysfunctions and defects in important system components● Vehicle reactions in particular driving situations (e.g. inflation of

an airbag, activation of the

stability regulation system)

● Environmental conditions (e.g. temperature)

These data are exclusively technical and help identifying and correcting

errors as well as optimizing vehicle

functions.

Motion profiles indicating travelled

routes cannot be created with these

data.

If services are used (e.g. repair

works, service processes, warranty cases, quality assurance),

employees of the service network

(manufacturer included) are able to

read out this technical information

from the event and error data storage

modules applying special diagnostic

devices. If required, you will receive

further information at these

workshops. After an error has been

corrected, the data are deleted from

the error storage module or they are

constantly overwritten.When using the vehicle, situations

may occur in which these technical

data related to other information

(accident report, damages on the

vehicle, witness statements etc.) may be associated with a specific person -

possibly, with the assistance of an

expert.

Additional functions contractually

agreed upon with the client (e.g.

vehicle location in emergency cases)

allow the transmission of particular vehicle data from the vehicle.

Radio Frequency

Identification (RFID)

RFID technology is used in some vehicles for functions such as tyre

pressure monitoring and ignition

system security. It is also used in

connection with conveniences such

as radio remote controls for door

locking/unlocking and starting, and in- vehicle transmitters for garage dooropeners. RFID technology in Opel

vehicles does not use or record

personal information or link with any

other Opel system containing

personal information.

Page 249 of 251

247Rear fog light ....................... 97, 123

Rear view camera ...................... 161

Rear window wiper/washer .......... 81 Recommended fluids and lubricants ........................ 219, 224

Refuelling ................................... 169 Registered trademarks ...............241

Retained power off .....................137

Reversing lights .........................123

Ride control systems ..................150

Roof .............................................. 36

Roof load ...................................... 75

Roof rack ..................................... 75

S

Seat adjustment ....................... 6, 40

Seat belt ........................................ 8

Seat belt reminder .......................93

Seat belts ..................................... 43

Seat heating ................................. 42

Seat position ................................ 39

Selector lever ............................. 144

Service ....................................... 133

Service display ............................ 88

Service information ....................218

Side airbag system ......................50

Software acknowledgement .......239

Spare wheel ............................... 209

Speed limiter......................... 97, 155

Speedometer ............................... 85Starting and operating ................135

Starting off ................................... 17

Starting the engine ....................138

Steering ...................................... 135

Steering wheel adjustment ......9, 78

Steering wheel controls ...............78

Stop-start system........................ 139

Storage compartments .................60

Sunroof ........................................ 36

Sunvisor lights ........................... 125

Sun visors .................................... 36

Symbols ......................................... 4

T

Tachometer ................................. 86

Tail lights ................................... 189

Three-point seat belt .................... 44

Tools .......................................... 196

Top-tether fastening eyes ............59

Tow bar....................................... 173

Towing ................................ 173, 213

Towing another vehicle .............214

Towing equipment .....................175

Towing the vehicle .....................213

Traction Control system ............. 150

Traction Control system off........... 95

Traffic sign assistant .............98, 163

Trailer towing ............................. 174

Transmission ............................... 17

Transmission display .................144Tread depth ............................... 202

Trip odometer .............................. 85

Turn and lane-change signals ...123

Turn signal ................................... 92

Tyre chains ................................ 204

Tyre designations ......................197

Tyre pressure ............................ 198

Tyre pressure monitoring system ............................... 96, 199

Tyre pressures ........................... 233

Tyre repair kit ............................. 204

U Ultrasonic parking assist............. 159

Underseat storage .......................61

Upholstery .................................. 217

Uplevel display ............................. 98

Using this manual ..........................3

V Valet mode ................................. 102

Vehicle battery ........................... 184

Vehicle checks............................ 180

Vehicle data ................................ 224

Vehicle data recording and privacy ..................................... 242

Vehicle detected ahead ................97

Vehicle dimensions .................... 231 Vehicle Identification Number ....222

Vehicle jack ................................ 196

Vehicle messages .....................104