tow OPEL MOKKA X 2019 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2019, Model line: MOKKA X, Model: OPEL MOKKA X 2019Pages: 253, PDF Size: 6.86 MB

Page 153 of 253

Driving and operating151Brakes

The brake system comprises two

independent brake circuits.

If a brake circuit fails, the vehicle can

still be braked using the other brake

circuit. However, braking effect is

achieved only when the brake pedal

is depressed firmly. Considerably

more force is needed for this. The

braking distance is extended. Seek the assistance of a workshop before

continuing the journey.

When the engine is not running, the

support of the brake servo unit

disappears once the brake pedal has

been depressed once or twice.

Braking effect is not reduced, but

braking requires significantly greater

force. It is especially important to bear this in mind when being towed.

Control indicator R 3 93.

Antilock brake system

Antilock brake system (ABS)

prevents the wheels from locking.ABS starts to regulate brake pressure as soon as a wheel shows a tendency to lock. The vehicle remains

steerable, even during hard braking.

ABS control is made apparent

through a pulse in the brake pedal

and the noise of the regulation

process.

For optimum braking, keep the brake

pedal fully depressed throughout the

braking process, despite the fact that

the pedal is pulsating. Do not reduce

the pressure on the pedal.

After starting-off the system performs

a self-test which may be audible.

Control indicator u 3 94.

Adaptive brake light

During full braking, all three brake

lights flash for the duration of ABS

control.Fault9 Warning

If there is a fault in the ABS, the

wheels may be liable to lock due

to braking that is heavier than

normal. The advantages of ABS are no longer available. During

hard braking, the vehicle can no longer be steered and may

swerve.

Have the cause of the fault remedied

by a workshop.

Parking brake

Page 164 of 253

162Driving and operatingIf r is pressed once within an

ignition cycle, the front parking assist

is reactivated if the vehicle speed

goes below a certain value and if the

vehicle speed has not exceeded 25 km/h beforehand.

Deactivation

Deactivate the system by pressing r .

The LED in the button will go out and

a message will be displayed in the

Driver Information Centre.

If the parking assist is deactivated manually, it will be reactivated

automatically the next time the

ignition is switched on.

The system is deactivated

automatically at a certain speed.

Fault

In the event of a fault in the system, a vehicle message is displayed in the

Driver Information Centre.

Additionally, a vehicle message is

displayed in the Driver Information

Centre if a malfunction of the system

due to temporary conditions, e.g.

snow covered sensors is detected.Vehicle messages 3 104.

Important hints for using the

parking assist systems9 Warning

Under certain circumstances,

various reflective surfaces on

objects or clothing as well as

external noise sources may cause the system to fail to detect

obstacles.

Special attention has to be paid to

low obstacles which can damage

the lower part of the bumper. If

such obstacles leave the detection area of the sensors during

approach of the vehicle, a

continuous warning tone will

sound.

Caution

Performance of the system can be reduced when sensors are

covered, e.g. by ice or snow.

Performance of the parking assist

system can be reduced due to

heavy loading.

Special conditions apply if there

are taller vehicles in the vicinity

(e.g. off-road vehicles, mini vans,

vans). Object identification and correct distance indication in the

upper part of these vehicles

cannot be guaranteed.

Objects with a very small reflection

cross-section, e.g. objects of

narrow size or soft materials, may

not be detected by the system.

Parking assist systems do not

detect objects outside the

detection range.

Note

The parking assist system

automatically detects factory-fitted

towing equipment. It is deactivated

when the connector is plugged in.

The sensor may detect a non-

existent object (echo disturbance)

caused by external acoustic or

mechanical disturbances.

Page 166 of 253

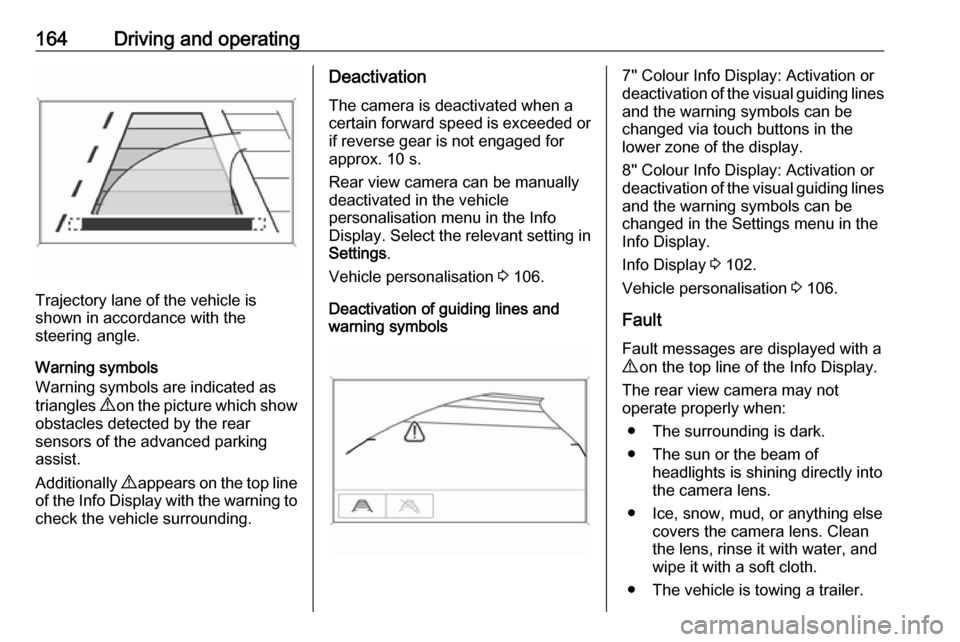

164Driving and operating

Trajectory lane of the vehicle is

shown in accordance with the

steering angle.

Warning symbols

Warning symbols are indicated as

triangles 9 on the picture which show

obstacles detected by the rear

sensors of the advanced parking

assist.

Additionally 9 appears on the top line

of the Info Display with the warning to

check the vehicle surrounding.

Deactivation

The camera is deactivated when acertain forward speed is exceeded or

if reverse gear is not engaged for

approx. 10 s.

Rear view camera can be manually

deactivated in the vehicle

personalisation menu in the Info

Display. Select the relevant setting in

Settings .

Vehicle personalisation 3 106.

Deactivation of guiding lines and

warning symbols7'' Colour Info Display: Activation or

deactivation of the visual guiding lines and the warning symbols can be

changed via touch buttons in the

lower zone of the display.

8'' Colour Info Display: Activation or

deactivation of the visual guiding lines

and the warning symbols can be

changed in the Settings menu in the

Info Display.

Info Display 3 102.

Vehicle personalisation 3 106.

Fault

Fault messages are displayed with a 9 on the top line of the Info Display.

The rear view camera may not

operate properly when:

● The surrounding is dark.

● The sun or the beam of headlights is shining directly into

the camera lens.

● Ice, snow, mud, or anything else covers the camera lens. Clean

the lens, rinse it with water, and

wipe it with a soft cloth.

● The vehicle is towing a trailer.

Page 167 of 253

Driving and operating165● The vehicle had a rear endaccident.

● There are extreme temperature changes.

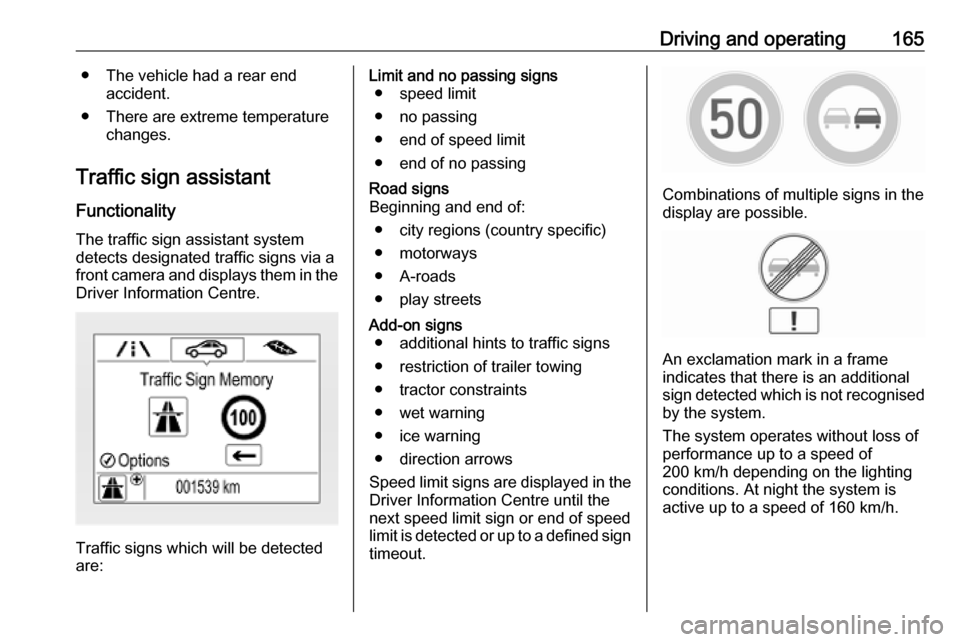

Traffic sign assistant Functionality

The traffic sign assistant system

detects designated traffic signs via a

front camera and displays them in the

Driver Information Centre.

Traffic signs which will be detected

are:

Limit and no passing signs ● speed limit

● no passing

● end of speed limit

● end of no passingRoad signs

Beginning and end of:

● city regions (country specific)

● motorways

● A-roads

● play streetsAdd-on signs ● additional hints to traffic signs

● restriction of trailer towing

● tractor constraints

● wet warning

● ice warning

● direction arrows

Speed limit signs are displayed in the

Driver Information Centre until the

next speed limit sign or end of speed

limit is detected or up to a defined sign timeout.

Combinations of multiple signs in the

display are possible.

An exclamation mark in a frame

indicates that there is an additional

sign detected which is not recognised

by the system.

The system operates without loss of

performance up to a speed of

200 km/h depending on the lighting

conditions. At night the system is

active up to a speed of 160 km/h.

Page 176 of 253

174Driving and operating

The funnel is stowed in the load

compartment.

Place the funnel in storage bin and

store into polybag.

Use the funnel to fill in the fuel into the

filler neck.

After topping-up, stow the funnel into

polybag in the load compartment.

Liquid gas refuelling

Follow the operating and safety

instructions of the filling station when

refuelling.

Filling adapter

As filling systems are not

standardised, different adapters are

required which are available from

Opel Distributors and from Opel

Service Partners.

ACME adapter: Belgium, Germany,

Ireland, Luxembourg, Switzerland

DISH adapter: Austria, Bosnia-

Herzegovina, Bulgaria, Czech

Republic, Croatia, Denmark, Estonia, France, Greece, Hungary, Italy,

Latvia, Lithuania, Macedonia,

Poland, Portugal, Romania, Serbia,

Slovakia, Slovenia, Sweden,

Switzerland, Turkey, Ukraine

Page 177 of 253

Driving and operating175

Bayonet adapter: Netherlands,

Norway, Spain, United Kingdom

EURO adapter: Spain

The filling valve for the liquid gas is

behind the fuel filler cap.

Unscrew protective cap from the filler

neck.

Screw the required adapter hand-

tight onto the filler neck.

ACME adapter: Screw the nut of the

filling nozzle onto the adapter.

Engage the locking lever of the filler

nozzle.

DISH adapter: Place the filler nozzle

into the adapter. Engage the locking

lever of the filler nozzle.

Bayonet adapter: Place filler nozzle

on the adapter and turn one quarter

turn. Engage the locking lever of the

filler nozzle.

EURO adapter: Press the filler nozzle

onto the adapter. Engage the locking

lever of the filler nozzle.

Press the button at the liquid gas supply point. The filling system stops

or begins to run slowly when 80% of

the tank volume is reached

(maximum fill level).

Release button on filling system and

the filling process stops. Release the

locking lever and remove the filler

nozzle. A small quantity of liquid gas

may escape.

Remove adapter and stow in vehicle.

Page 178 of 253

176Driving and operatingFit protective cap to prevent the

penetration of foreign bodies into the

filler opening and the system.9 Warning

Due to the system design, an

escape of liquid gas after

releasing the locking lever is

unavoidable. Avoid inhaling.

9 Warning

The liquid gas tank should only be

filled to 80% capacity, for safety

reasons.

The multivalve on the liquid gas tank

automatically limits the fill quantity. If

a larger quantity is added, we

recommend not exposing the vehicle

to the sun until the excess amount

has been used up.

Fuel filler cap

Only use genuine fuel filler caps. Diesel-engined vehicles have special fuel filler caps.

Trailer hitch

General information

Only use towing equipment that has

been approved for your vehicle.

Entrust retrofitting of towing

equipment to a workshop. It may be

necessary to make changes that

affect the cooling system, heat

shields or other equipment.

The bulb outage detection function for

trailer brake light cannot detect a

partial bulb outage. E.g. in case of

four bulbs with a power of 5 W each,

the function only detects lamp outage when only a single 5 W lamp remains

or none remain.

Fitting of towing equipment could

cover the opening of the towing eye.

If this is the case, use the coupling ball

bar for towing. Always keep the

coupling ball bar in the vehicle when

not in use.Driving characteristics and

towing tips

Before attaching a trailer, lubricate the coupling ball. However, do not do

so if a stabiliser, which acts on the

coupling ball, is being used to reduce snaking movements.

For trailers with low driving stability

and caravan trailers with a permitted

gross vehicle weight of more than

1000 kg, a speed of 80 km/h must not

be exceeded. The use of a stabiliser

is recommended.

If the trailer starts snaking, drive more slowly, do not attempt to correct the

steering and brake sharply if

necessary.

When driving downhill, drive in the

same gear as if driving uphill and

drive at a similar speed.

Adjust tyre pressure to the value

specified for full load 3 235.

Page 179 of 253

Driving and operating177Trailer towingTrailer loads

The permissible trailer loads are

vehicle and engine-dependent

maximum values which must not be

exceeded. The actual trailer load is

the difference between the actual

gross weight of the trailer and the

actual coupling socket load with the

trailer coupled.

The permissible trailer loads are

specified in the vehicle documents. In general, they are valid for gradients

up to max. 12%.

The permitted trailer loads apply up to the specified incline and up to an

altitude of 1000 m above sea level.

Since engine power decreases as

altitude increases due to the air

becoming thinner, therefore reducing

climbing ability, the permissible gross

train weight also decreases by 10%

for every 1000 m of additional

altitude. The gross train weight does

not have to be reduced when driving

on roads with slight inclines (less than

8%, e.g. motorways).The permissible gross train weight

must not be exceeded. This weight is specified on the identification plate

3 224.

Vertical coupling load

The vertical coupling load is the load

exerted by the trailer on the coupling

ball. It can be varied by changing the

weight distribution when loading the

trailer.

The maximum permissible vertical

coupling load (75 kg) is specified on

the towing equipment identification

plate and in the vehicle documents.

Always aim for the maximum load,

especially in the case of heavy

trailers. The vertical coupling load

should never fall below 25 kg.

Rear axle load

The permissible axle loads (see

identification plate or vehicle

documents) must not be exceeded.Towing equipmentCaution

When operating without a trailer,

remove the coupling ball bar.

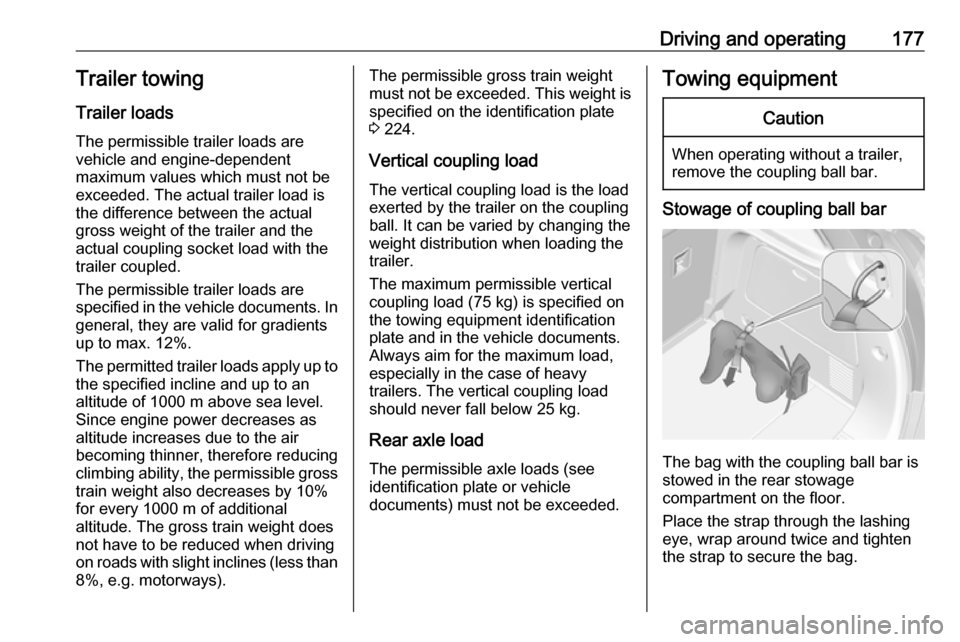

Stowage of coupling ball bar

The bag with the coupling ball bar is

stowed in the rear stowage

compartment on the floor.

Place the strap through the lashing

eye, wrap around twice and tighten

the strap to secure the bag.

Page 180 of 253

178Driving and operatingFitting the coupling ball bar

Disengage and fold down the socket.Remove the sealing plug from the

opening for the coupling ball bar and

stow it.

Checking the tensioning of the

coupling ball bar

● Red marking on rotary knob must

point towards green marking on

coupling ball bar.

● The gap between the rotary knob

and the coupling ball bar must be approx. 6 mm.

● The key must be in position c.

Otherwise, the coupling ball bar must be tensioned before being inserted:

● Unlock coupling ball bar by turning key to position c.

● Pull out rotary knob and turn

clockwise as far as it will go.

Inserting the coupling ball bar

Page 181 of 253

Driving and operating179Insert the tensioned coupling ball bar

in the opening and push firmly

upwards until it audibly engages.

The rotary handle snaps back into its

original position resting against the

coupling ball bar without a gap.9 Warning

Do not touch rotary handle during

insertion.

Lock the coupling ball bar by turning

the key to position e. Remove the key

and close the protective flap.

Eye for break-away stopping cable

Attach breakaway stopping cable to

eye.

Check that the coupling ball bar is correctly installed

● Green marking on rotary knob must point towards green

marking on coupling ball bar.

● There must be no gap between the rotary handle and the

coupling ball bar.

● The coupling ball bar must be firmly engaged in the opening.

● The coupling ball bar must be locked and the key removed.9Warning

Towing a trailer is permitted only

when a coupling ball bar is fitted correctly. If the coupling ball bardoes not engage correctly, seekthe assistance of a workshop.

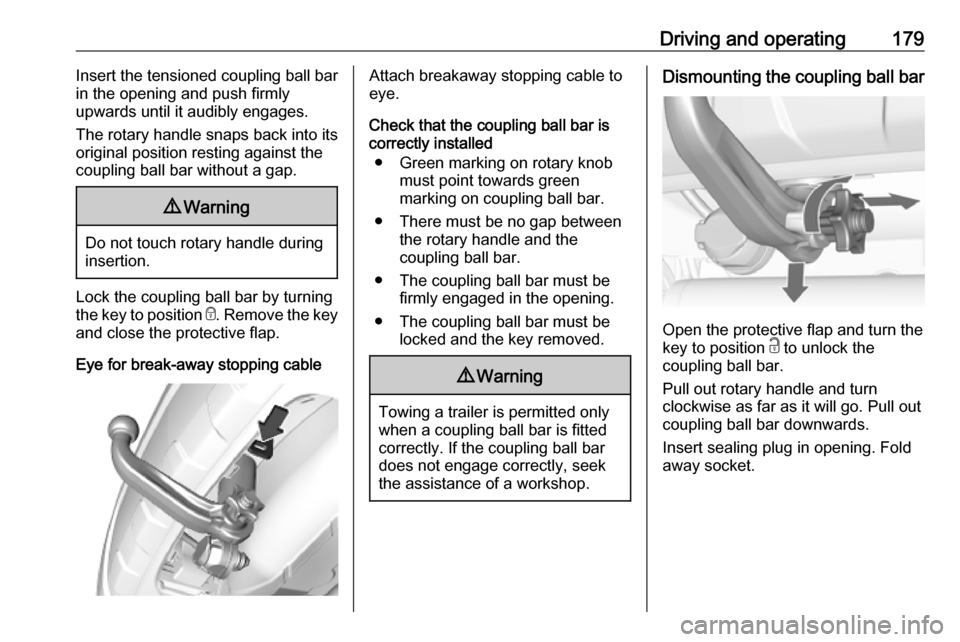

Dismounting the coupling ball bar

Open the protective flap and turn the

key to position c to unlock the

coupling ball bar.

Pull out rotary handle and turn

clockwise as far as it will go. Pull out coupling ball bar downwards.

Insert sealing plug in opening. Fold away socket.