brake OPEL MOKKA X 2019 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2019, Model line: MOKKA X, Model: OPEL MOKKA X 2019Pages: 253, PDF Size: 6.86 MB

Page 206 of 253

204Vehicle care●Light for comfort pressure up to

three people.

● Eco for Eco pressure up to three

people.

● Max for full loading.

Tyre pressure sensor matching process

Each tyre pressure sensor has a

unique identification code. The

identification code must be matched

to a new wheel position after rotating

the wheels or exchanging the

complete wheel set and if one or more tyre pressure sensors were replaced.The tyre pressure sensor matching

process should also be performed

after replacing a spare wheel with a

road wheel containing a tyre pressure

sensor.

The malfunction light w and the

warning message should extinguish

at the next ignition cycle. The sensors

are matched to the wheel positions,

using a relearn tool, in the following

order: left side front wheel, right side

front wheel, right side rear wheel andleft side rear wheel. The turn signal

light at the current active position is

illuminated until sensor is matched.

Consult a workshop for service. There are two minutes to match the first

wheel position, and five minutes

overall to match all four wheel

positions. If it takes longer, the

matching process stops and must be

restarted.

The tyre pressure sensor matching

process is:

1. Apply the parking brake.

2. Turn the ignition on.

3. On vehicles with automatic transmission: set the selector

lever to P.

On vehicles with manual

transmission: select neutral.

4. Press MENU on the turn signal

lever to select the Vehicle

Information Menu in the Driver

Information Centre.

5. Turn the adjuster wheel to scroll to

the tyre pressure menu.

Midlevel display:

Uplevel display:

Page 208 of 253

206Vehicle careChanging tyre and wheel

size

If tyres of a different size than thosefitted at the factory are used, it may be necessary to reprogramme the

nominal tyre pressure and make

other vehicle modifications.

After converting to a different tyre

size, have the label with tyre

pressures replaced and the tyre

pressure monitoring system

reinitialised. 3 2019 Warning

The use of unsuitable tyres or

wheels may lead to accidents and will invalidate the vehicle

operating permit.

Wheel covers

Wheel covers and tyres that are

factory-approved for the respective

vehicle and comply with all of the

relevant wheel and tyre combination requirements must be used.

If the wheel covers and tyres used are

not factory-approved, the tyres must

not have a rim protection ridge.

Wheel covers must not impair brake

cooling.9 Warning

Use of unsuitable tyres or wheel

covers could lead to sudden

pressure loss and thereby

accidents.

Vehicles with alloy wheels: When

mounting steel wheels with alloy

wheel nuts, e.g. when changing to

winter tyres, the wheel covers cannot

be attached to the steel wheels.

Tyre chains

Use tyre chains only on front wheels.

9 Warning

Damage may lead to tyre blowout.

Tyre chains are permitted on tyres of

size 215/65 R16, 215/60 R17 and

215/55 R18.

On tyres of size 215/65 R16 and

215/60 R17 always use fine mesh

chains suitable for sport utility

vehicles that add no more than

9 mm to the tyre tread and the inboard sides (including chain lock).

Page 209 of 253

Vehicle care207On tyres of size 215/55 R18 only usespecial snow chains which are

permitted for Opel Mokka and tyres of

these sizes. For further information

contact a workshop.

The use of tyre chains is not permitted on the temporary spare wheel.

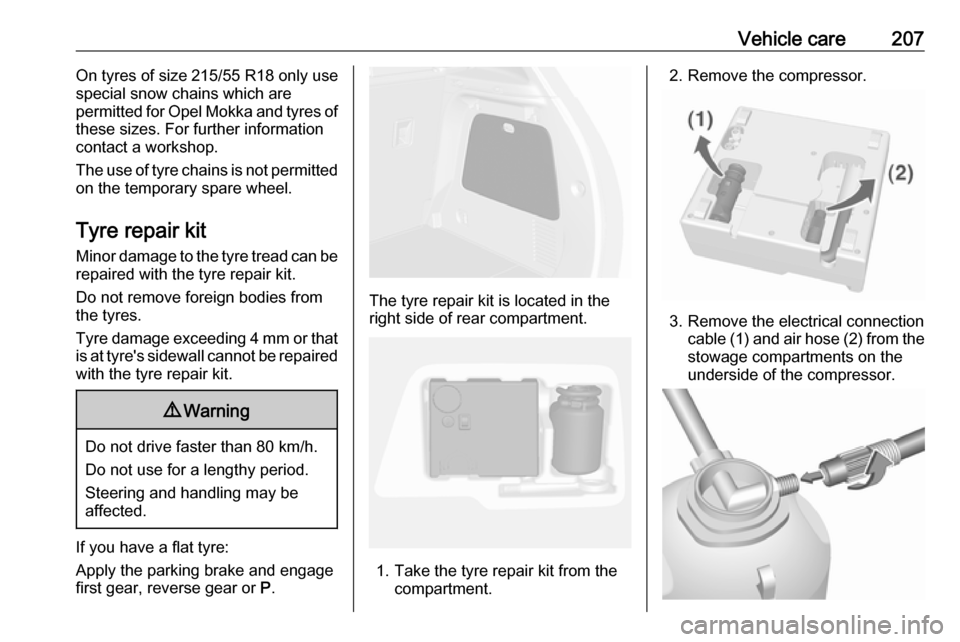

Tyre repair kit Minor damage to the tyre tread can be

repaired with the tyre repair kit.

Do not remove foreign bodies from

the tyres.

Tyre damage exceeding 4 mm or that is at tyre's sidewall cannot be repairedwith the tyre repair kit.9 Warning

Do not drive faster than 80 km/h.

Do not use for a lengthy period.

Steering and handling may be

affected.

If you have a flat tyre:

Apply the parking brake and engage

first gear, reverse gear or P.

The tyre repair kit is located in the

right side of rear compartment.

1. Take the tyre repair kit from the compartment.

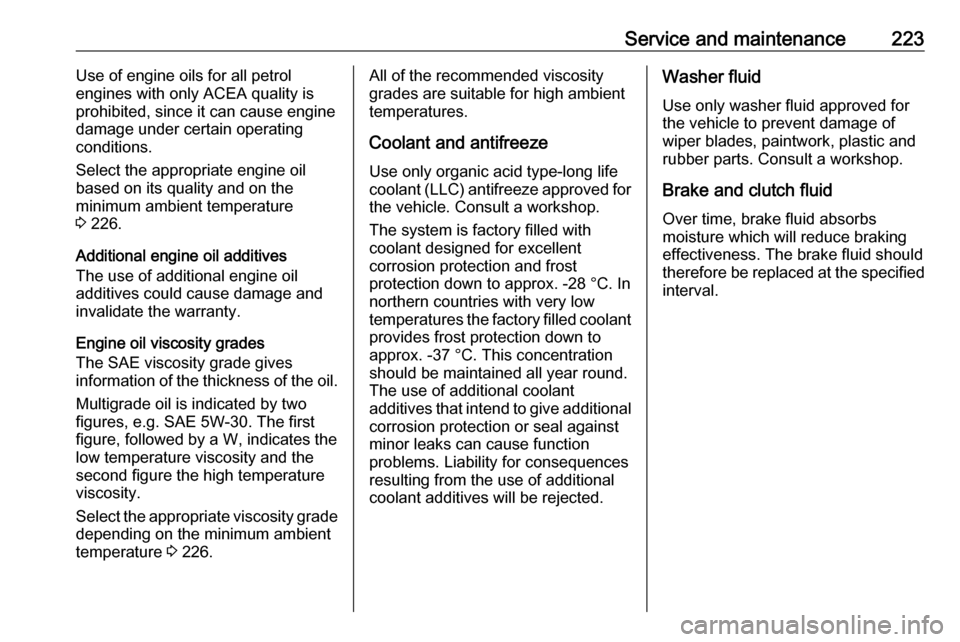

2. Remove the compressor.

3. Remove the electrical connection cable (1) and air hose (2) from the

stowage compartments on the

underside of the compressor.

Page 212 of 253

210Vehicle caredinghies etc. They can be located onthe underside of the compressor. To

remove, screw on compressor air

hose and withdraw adapter.

Wheel changing

Some vehicles are equipped with a

tyre repair kit instead of a spare wheel 3 207.

Make the following preparations and

observe the following information:

● Park the vehicle on a level, firm and non-skid surface. The front

wheels must be in the straight- ahead position.

● Apply the parking brake and engage first gear, reverse gear or

P .

● Remove the spare wheel 3 211.

● Never change more than one wheel at a time.

● Use the jack only to change wheels in case of puncture, not

for seasonal winter or summer

tyre change.

● The jack is maintenance-free.● If the ground on which the vehicle

is standing is soft, a solid board

(max. 1 cm thick) should be

placed under the jack.

● Take heavy objects out of the vehicle before jacking up.

● No people or animals may be in the vehicle when it is jacked-up.

● Never crawl under a jacked-up vehicle.

● Do not start the vehicle when it is

raised on the jack.

● Clean wheel nuts and thread with

a clean cloth before mounting the wheel.9 Warning

Do not grease wheel bolt, wheel

nut and wheel nut cone.

Have the defective tyre renewed or

repaired as soon as possible.

Jacking position for lifting platform

Rear arm position of the lifting

platform centrically under the recess

of the sill.

Page 213 of 253

Vehicle care211Front arm position of the lifting

platform at the underbody.

Spare wheelCaution

The use of a spare wheel that is smaller than the other wheels or in

combination with winter tyres

could affect driveability. Have the defective tyre replaced as soon as

possible.

Caution

The use of a spare wheel that is smaller than the other wheels or in

combination with winter tyres

could affect driveability. Have the defective tyre replaced as soon as

possible.

The spare wheel is located in the load

compartment beneath the floor

covering. It is secured with a wing nut.

Spare wheel with directional tyre If possible, fit directional tyres such

that they roll in the direction of travel.

The rolling direction is indicated by a

symbol (e.g. an arrow) on the

sidewall.

The following applies to tyres fitted

opposing the rolling direction:

● Driveability may be affected. Have the defective tyre renewed

or repaired as soon as possible

and fit it instead of the spare

wheel.

● Drive particularly carefully on wet

and snow-covered road

surfaces.

Fitting the spare wheel

Make the following preparations and

observe the following information:

● Park the vehicle on a level, firm and non-skid surface. The front

wheels must be in the straight-

ahead position.

● Apply the parking brake and engage first gear, reverse gear or

P .

● Remove the spare wheel 3 211.

● Never change more than one wheel at a time.

● Use the jack only to change wheels in case of puncture, not

for seasonal winter or summer

tyre change.

Page 217 of 253

Vehicle care215● Apply the parking brake,transmission in neutral,

automatic transmission in P.

● Open the positive terminal protection caps of both batteries.

Lead connection order:

1. Connect the red lead to the positive terminal of the booster

battery.

2. Connect the other end of the red lead to the positive terminal of the

discharged battery.

3. Connect the black lead to the negative terminal of the booster

battery.

4. Connect the other end of the black

lead to a vehicle grounding point,

such as the engine block or an

engine mounting bolt. Connect as far away from the discharged

battery as possible, however at

least 60 cm.

Route the leads so that they cannot

catch on rotating parts in the engine

compartment.

To start the engine: 1. Start the engine of the vehicle providing the jump.

2. After 5 min, start the other engine.

Start attempts should be made for

no longer than 15 s at an interval

of 1 min.

3. Allow both engines to idle for approx. three minutes with the

leads connected.4. Switch on electrical consumers (e.g. headlights, heated rear

window) of the vehicle receiving

the jump start.

5. Reverse above sequence exactly when removing leads.

Page 218 of 253

216Vehicle careTowingTowing the vehicle

Wrap a cloth around the tip of a flat

screwdriver to prevent paint damage.

Insert the screwdriver in the slot at the

lower part of the cap. Release the cap by carefully moving the screwdriver

downwards.

The towing eye is stowed with the

vehicle tools 3 199.

Screw in the towing eye as far as it will

go until it stops in a horizontal

position.

Attach a tow rope – or better still a tow

rod – to the towing eye.

The towing eye must only be used for

towing and not for recovering the

vehicle.

Switch on ignition to release steering wheel lock and to permit operation of

brake lights, horn and windscreen

wiper.

Switch the selector lever to neutral.

Release the parking brake.

Caution

Never tow a vehicle equipped with All Wheel Drive (AWD) with the

front or rear tyres on the road. If

you tow a vehicle equipped with

AWD while the front or rear tyres

are rolling on the road, the drive

system in the vehicle could be

severely damaged. When towing

vehicles equipped with AWD, all

four tyres must not be in contact

with the road.

Caution

Drive slowly. Do not drive jerkily.

Excessive tractive force can

damage the vehicle.

When the engine is not running,

considerably more force is needed to

brake and steer.

To prevent the entry of exhaust gases from the towing vehicle, switch on the

air recirculation system 3 128 and

close the windows.

Page 225 of 253

Service and maintenance223Use of engine oils for all petrol

engines with only ACEA quality is

prohibited, since it can cause engine

damage under certain operating

conditions.

Select the appropriate engine oil based on its quality and on the

minimum ambient temperature

3 226.

Additional engine oil additives

The use of additional engine oil

additives could cause damage and

invalidate the warranty.

Engine oil viscosity grades

The SAE viscosity grade gives

information of the thickness of the oil.

Multigrade oil is indicated by two

figures, e.g. SAE 5W-30. The first

figure, followed by a W, indicates the

low temperature viscosity and the

second figure the high temperature viscosity.

Select the appropriate viscosity grade depending on the minimum ambient

temperature 3 226.All of the recommended viscosity

grades are suitable for high ambient

temperatures.

Coolant and antifreeze

Use only organic acid type-long life

coolant (LLC) antifreeze approved for

the vehicle. Consult a workshop.

The system is factory filled with

coolant designed for excellent

corrosion protection and frost

protection down to approx. -28 °C. In

northern countries with very low

temperatures the factory filled coolant provides frost protection down to

approx. -37 °C. This concentration

should be maintained all year round.

The use of additional coolant

additives that intend to give additional

corrosion protection or seal against

minor leaks can cause function

problems. Liability for consequences

resulting from the use of additional

coolant additives will be rejected.Washer fluid

Use only washer fluid approved for

the vehicle to prevent damage of

wiper blades, paintwork, plastic and

rubber parts. Consult a workshop.

Brake and clutch fluidOver time, brake fluid absorbs

moisture which will reduce braking

effectiveness. The brake fluid should therefore be replaced at the specified

interval.

Page 245 of 253

Customer information243Depending on technical equipment

level, the data stored is as follows:

● system component operating states (e.g. fill level, tyre

pressure, battery status)

● faults and defects in important system components (e.g. lights,

brakes)

● system reactions in special driving situations (e.g. triggeringof an airbag, actuation of the

stability control systems)

● information on events damaging the vehicle

● for electric vehicles the amount of

charge in the high-voltage

battery, estimated range

In special cases (e.g. if the vehicle

has detected a malfunction), it may be

necessary to save data that would

otherwise just be volatile.

When you use services (e.g. repairs,

maintenance), the operating data

saved can be read together with the

vehicle identification number and

used where necessary. Staff working

for the service network ( e.g. garages,

manufacturers) or third parties (e.g.breakdown services) can read the

data from the vehicle. The same

applies to warranty work and quality

assurance measures.

Data is generally read via the OBD

(On-Board Diagnostics) port

prescribed by law in the vehicle. The operating data which is read out,

documents the technical condition of

the vehicle or individual components

and assists with fault diagnosis,

compliance with warranty obligations

and quality improvement. This data,

in particular information on

component stress, technical events,

operator errors and other faults, is

transmitted to the manufacturer

where appropriate, together with the vehicle identification number. The

manufacturer is also subject to

product liability. The manufacturer

potentially also uses operating data

from vehicles for product recalls. This

data can also be used to check

customer warranty and guarantee

claims.

Fault memories in the vehicle can be

reset by a service company when

carrying out servicing or repairs or at

your request.Comfort and infotainment

functions

Comfort settings and custom settings can be stored in the vehicle and

changed or reset at any time.

Depending on the equipment level in

question, these include

● seat and steering wheel position settings

● chassis and air conditioning settings

● custom settings such as interior lighting

You can input your own data in the

infotainment functions for your

vehicle as part of the selected

features.

Depending on the equipment level in

question, these include

● multimedia data such as music, videos or photos for playback in

an integrated multimedia system

● address book data for use with an

integrated hands-free system or an integrated navigation system

Page 248 of 253

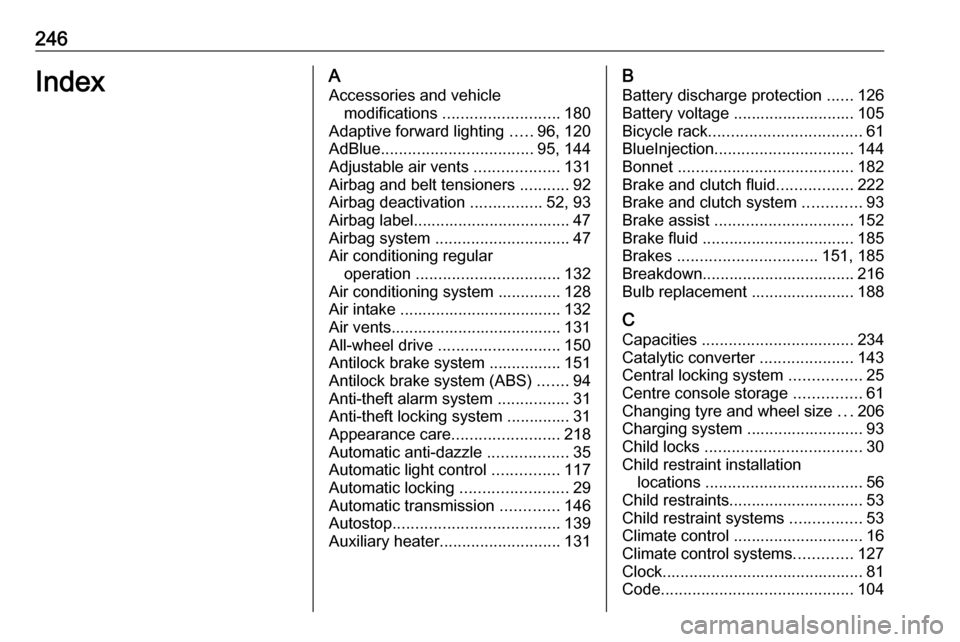

246IndexAAccessories and vehicle modifications .......................... 180

Adaptive forward lighting .....96, 120

AdBlue .................................. 95, 144

Adjustable air vents ...................131

Airbag and belt tensioners ...........92

Airbag deactivation ................52, 93

Airbag label................................... 47 Airbag system .............................. 47

Air conditioning regular operation ................................ 132

Air conditioning system .............. 128

Air intake .................................... 132

Air vents...................................... 131

All-wheel drive ........................... 150

Antilock brake system ................ 151

Antilock brake system (ABS) .......94

Anti-theft alarm system ................31

Anti-theft locking system .............. 31

Appearance care ........................218

Automatic anti-dazzle ..................35

Automatic light control ...............117

Automatic locking ........................29

Automatic transmission .............146

Autostop ..................................... 139

Auxiliary heater ........................... 131B

Battery discharge protection ......126

Battery voltage ........................... 105

Bicycle rack .................................. 61

BlueInjection ............................... 144

Bonnet ....................................... 182

Brake and clutch fluid .................222

Brake and clutch system .............93

Brake assist ............................... 152

Brake fluid .................................. 185

Brakes ............................... 151, 185

Breakdown.................................. 216

Bulb replacement ....................... 188

C Capacities .................................. 234

Catalytic converter .....................143

Central locking system ................25

Centre console storage ...............61

Changing tyre and wheel size ...206

Charging system .......................... 93

Child locks ................................... 30

Child restraint installation locations ................................... 56

Child restraints.............................. 53

Child restraint systems ................53

Climate control ............................. 16

Climate control systems .............127

Clock............................................. 81

Code ........................................... 104