brake OPEL MOVANO_B 2017 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2017, Model line: MOVANO_B, Model: OPEL MOVANO_B 2017Pages: 255, PDF Size: 6.12 MB

Page 171 of 255

Vehicle care169Vehicle careGeneral Information...................170

Accessories and vehicle modifications .......................... 170

Vehicle storage ........................170

End-of-life vehicle recovery .....171

Vehicle checks ........................... 171

Performing work ......................171

Bonnet ..................................... 171

Engine oil ................................. 172

Engine coolant ......................... 173

Power steering fluid .................174

Washer fluid ............................ 175

Brakes ..................................... 175

Brake fluid ............................... 175

Vehicle battery ......................... 175

Diesel fuel filter ........................178

Diesel fuel system bleeding .....178

Wiper blade replacement ........179

Bulb replacement .......................179

Headlights ............................... 179

Adaptive forward lighting .........182

Fog lights ................................. 182

Front turn signal lights .............182

Tail lights ................................. 183

Side turn signal lights ..............184Centre high-mounted brake

light ......................................... 185

Number plate light ...................185

Interior lights ............................ 186

Instrument panel illumination ...187

Electrical system ........................187

Fuses ....................................... 187

Engine compartment fuse box . 188

Instrument panel fuse box .......189

Load compartment fuse box ....190

Vehicle tools .............................. 192

Tools ........................................ 192

Wheels and tyres .......................193

Tyres ....................................... 193

Winter tyres ............................. 193

Tyre designations ....................193

Tyre pressure .......................... 193

Tyre pressure monitoring system .................................... 194

Tread depth ............................. 196

Changing tyre and wheel size . 197 Wheel covers ........................... 197

Tyre chains .............................. 197

Tyre repair kit .......................... 198

Wheel changing .......................201

Spare wheel ............................ 203

Jump starting ............................. 206Towing....................................... 208

Towing the vehicle ...................208

Towing another vehicle ...........209

Appearance care .......................209

Exterior care ............................ 209

Interior care ............................. 211

Page 172 of 255

170Vehicle careGeneral Information

Accessories and vehicle modifications

We recommend the use of genuine

parts and accessories and factory

approved parts specific for your

vehicle type. We cannot assess or guarantee reliability of other products

- even if they have a regulatory or

otherwise granted approval.

Any modification, conversion or other changes made to standard vehicle

specifications (including, without

limitation, software modifications,

modifications of the electronic control units) may invalidate the warranty

offered by Opel. Furthermore, such

changes may impact fuel

consumption, CO 2 emissions and

other emissions of the vehicle and

cause the vehicle to no longer

conform to the type approval,

impacting the validity of your vehicle

registration.Caution

When transporting the vehicle on

a train or on a recovery vehicle, the

mud flaps might be damaged.

Vehicle storage

Storage for a long period of time

If the vehicle is to be stored for several months:

● Wash and wax the vehicle.

● Have the wax in the engine compartment and underbody

checked.

● Clean and preserve rubber seals.

● Change engine oil.

● Drain washer fluid reservoir. ● Check coolant antifreeze and corrosion protection.

● Adjust tyre pressure to the value specified for full load.

● Park vehicle in a dry, well ventilated place. Engage first or

reverse gear. Prevent the vehicle

from rolling.

● Do not apply parking brake.

● Open bonnet, close all doors and

lock the vehicle.

● Disconnect the clamp from the negative terminal of the vehicle

battery. Beware that all systems

are not functional, e.g. anti-theft

alarm system.

Putting back into operation When the vehicle is to be put back into

operation:

● Connect the clamp to the negative terminal of the vehicle

battery. Activate the electronics

of the power windows.

● Check tyre pressure.

● Fill up the washer fluid reservoir. ● Check the engine oil level.

● Check the coolant level.

● Fit the number plate, if necessary.

Page 177 of 255

Vehicle care175Washer fluid

Fill with clean water mixed with a

suitable quantity of windscreen

washer fluid which contains

antifreeze.

Caution

Only washer fluid with a sufficient

antifreeze concentration provides

protection at low temperatures or

a sudden drop in temperature.

Use of washer fluid containing

isopropanol can damage exterior

lamps.

Brakes

In the event of minimum thickness ofthe brake lining, a squealing noise

sounds during braking.

Continued driving is possible but

have the brake linings replaced as

soon as possible.

Once new brake linings are installed,

do not brake unnecessarily hard for

the first few journeys.

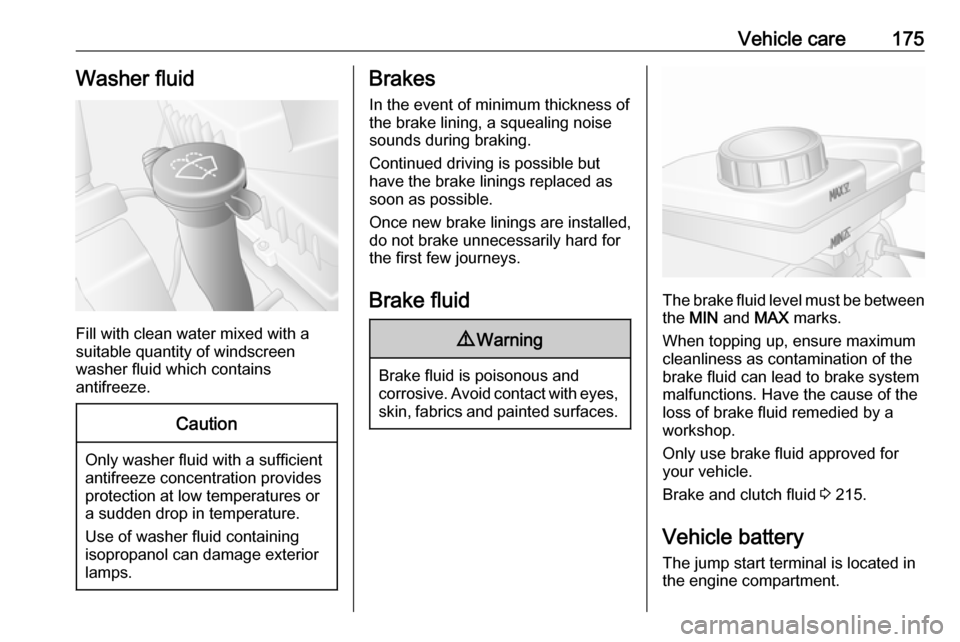

Brake fluid9 Warning

Brake fluid is poisonous and

corrosive. Avoid contact with eyes, skin, fabrics and painted surfaces.

The brake fluid level must be betweenthe MIN and MAX marks.

When topping up, ensure maximum cleanliness as contamination of the

brake fluid can lead to brake system

malfunctions. Have the cause of the

loss of brake fluid remedied by a

workshop.

Only use brake fluid approved for

your vehicle.

Brake and clutch fluid 3 215.

Vehicle battery

The jump start terminal is located in

the engine compartment.

Page 185 of 255

Vehicle care183

5. Detach bulb from bulb holder andrenew the bulb.

6. Insert the bulb holder, engaging the two lugs in the reflectorhousing and rotate clockwise to

secure.

7. Reattach wiring connector to bulb.

8. Replace protective cover.

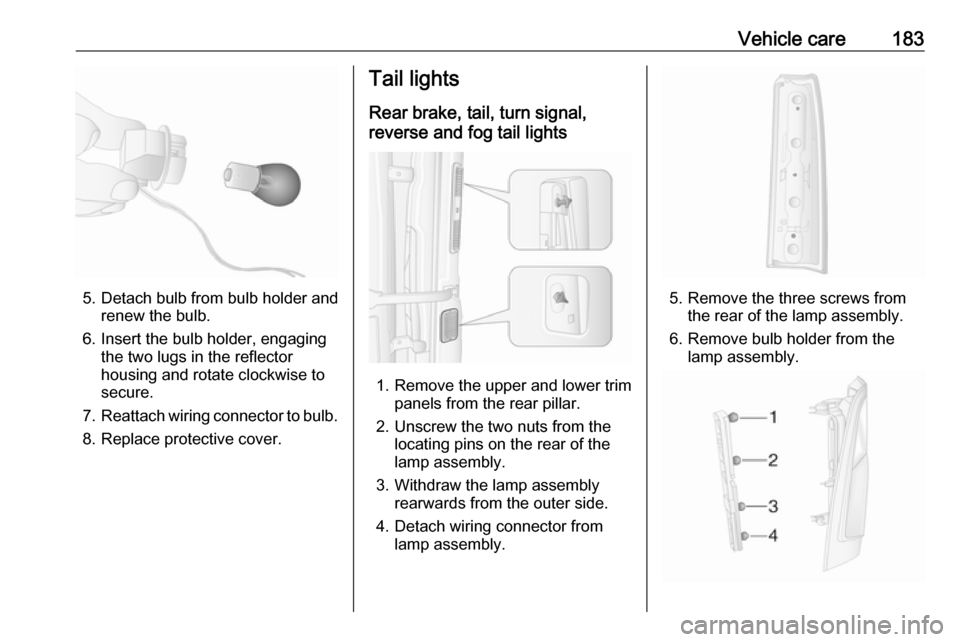

Tail lights

Rear brake, tail, turn signal,

reverse and fog tail lights

1. Remove the upper and lower trim panels from the rear pillar.

2. Unscrew the two nuts from the locating pins on the rear of the

lamp assembly.

3. Withdraw the lamp assembly rearwards from the outer side.

4. Detach wiring connector from lamp assembly.

5. Remove the three screws from the rear of the lamp assembly.

6. Remove bulb holder from the lamp assembly.

Page 186 of 255

184Vehicle care7. Push bulb into socket slightly,rotate anti-clockwise, remove andrenew bulb.

Turn signal light ( 1)

Tail and brake light ( 2)

Reverse light ( 3)

Rear fog light, may be on one side

only ( 4)

8. Replace bulb holder in lamp assembly.

9. Replace the three screws on the rear of the lamp assembly.

10. Reattach wiring connector to lamp

assembly.

11. Replace lamp assembly from the outer side into original position,

ensuring that it is seated correctly.

12. Replace the two nuts onto the locating pins on the rear of the

lamp assembly.

13. Install the upper and lower trim panels to the rear pillar.Side turn signal lights

1. Push the lamp assembly to the right and pull at the left-hand side

of the lamp assembly to release

from the aperture.

2. Detach wiring connector from lamp assembly.

3. Remove bulb holder from lamp assembly by rotating 90° and

renew bulb.

4. Install bulb holder in lamp assembly.

5. Reattach wiring connector.

6. Install lamp assembly into aperture and push to the left to

secure.

Mirror turn signal lights 1. Move the lower mirror assembly from the front to access the screw.

2. Remove the screw using a torx screwdriver.

3. Remove bulb holder from the rear

of the lower mirror assembly.

4. Renew bulb.

5. Replace bulb holder.

6. Replace the screw.

Page 187 of 255

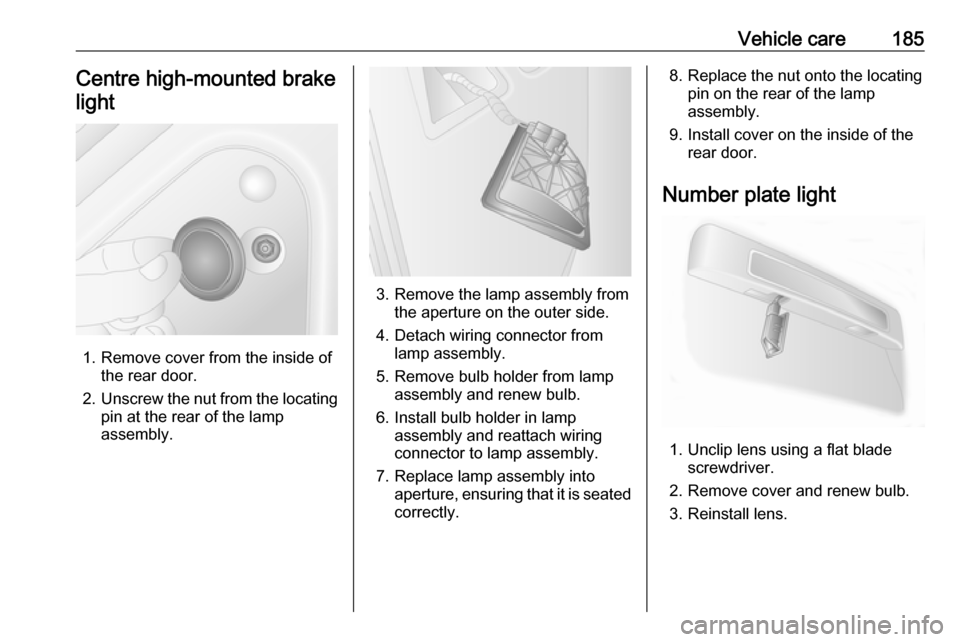

Vehicle care185Centre high-mounted brakelight

1. Remove cover from the inside of the rear door.

2. Unscrew the nut from the locating

pin at the rear of the lamp

assembly.

3. Remove the lamp assembly from the aperture on the outer side.

4. Detach wiring connector from lamp assembly.

5. Remove bulb holder from lamp assembly and renew bulb.

6. Install bulb holder in lamp assembly and reattach wiring

connector to lamp assembly.

7. Replace lamp assembly into aperture, ensuring that it is seated

correctly.

8. Replace the nut onto the locating pin on the rear of the lamp

assembly.

9. Install cover on the inside of the rear door.

Number plate light

1. Unclip lens using a flat blade screwdriver.

2. Remove cover and renew bulb.

3. Reinstall lens.

Page 191 of 255

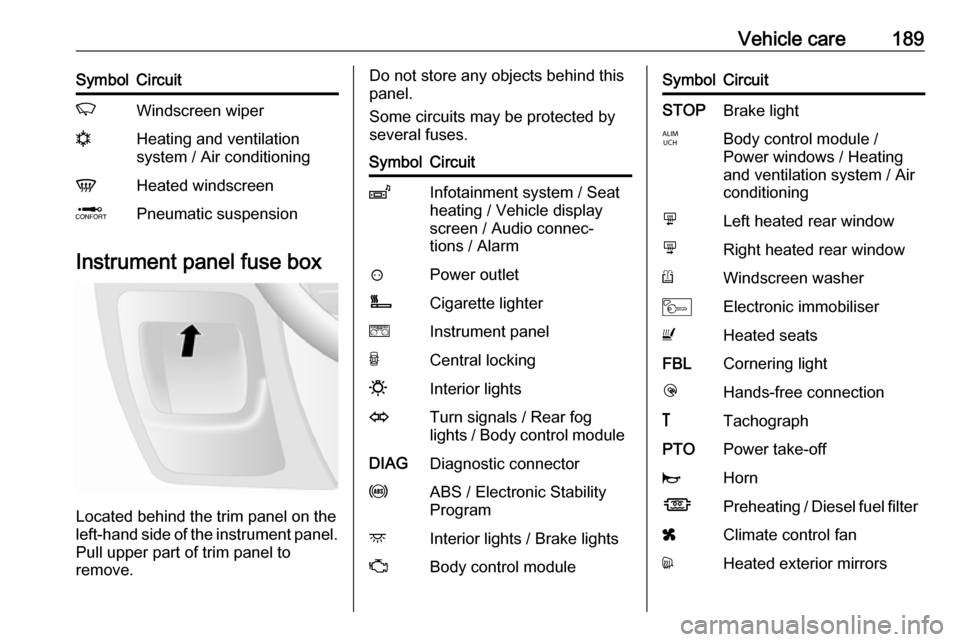

Vehicle care189SymbolCircuitKWindscreen wipernHeating and ventilation

system / Air conditioningVHeated windscreenQPneumatic suspension

Instrument panel fuse box

Located behind the trim panel on the

left-hand side of the instrument panel. Pull upper part of trim panel to

remove.

Do not store any objects behind this

panel.

Some circuits may be protected by

several fuses.SymbolCircuitZInfotainment system / Seat

heating / Vehicle display

screen / Audio connec‐

tions / Alarm?Power outletÌCigarette lightereInstrument panelUCentral locking0Interior lightsOTurn signals / Rear fog

lights / Body control moduleDIAGDiagnostic connectoruABS / Electronic Stability

ProgramdInterior lights / Brake lightsZBody control moduleSymbolCircuitSTOPBrake lightIBody control module /

Power windows / Heating

and ventilation system / Air

conditioningmLeft heated rear windownRight heated rear windowRWindscreen washerMElectronic immobiliserUHeated seatsFBLCornering lightlHands-free connection&TachographPTOPower take-offjHornÍPreheating / Diesel fuel filterxClimate control fandHeated exterior mirrors

Page 199 of 255

Vehicle care197indicators (TWI). Their position is

indicated by markings on the

sidewall.

Tyres age, even if they are not used.

We recommend tyre replacement

every six years.

Changing tyre and wheel

size

If tyres of a different size than those

fitted at the factory are used, it may be

necessary to reprogramme the

speedometer as well as the nominal

tyre pressure and make other vehicle modifications.

After converting to a different tyre

size, have the label with tyre

pressures replaced.9 Warning

Use of unsuitable tyres or wheels

may lead to accidents and will

invalidate the vehicle type

approval.

Wheel covers

Wheel covers and tyres that are

factory approved for the respective

vehicle and comply with all of the

relevant wheel and tyre combination requirements must be used.

If the wheel covers and tyres used are

not factory approved, the tyres must

not have a rim protection ridge.

Wheel covers must not impair brake

cooling.9 Warning

Use of unsuitable tyres or wheel

covers could lead to sudden

pressure loss and thereby

accidents.

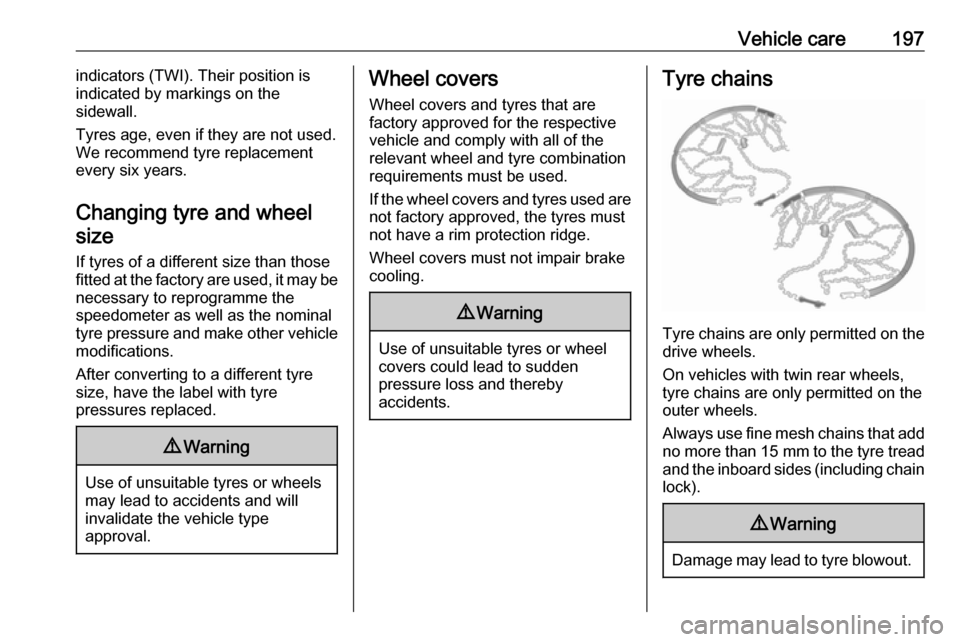

Tyre chains

Tyre chains are only permitted on the

drive wheels.

On vehicles with twin rear wheels,

tyre chains are only permitted on the

outer wheels.

Always use fine mesh chains that add no more than 15 mm to the tyre tread

and the inboard sides (including chain lock).

9 Warning

Damage may lead to tyre blowout.

Page 200 of 255

198Vehicle careWheel covers on steel wheels maycome into contact with parts of the

chains. In such cases, remove the

wheel covers.

Tyre chains may only be used at

speeds up to 50 km/h and, when

travelling on roads that are free of

snow, they may only be used for brief

periods since they are subject to rapid wear on a hard road and may snap.

The use of tyre chains is not permitted on the temporary spare wheel.

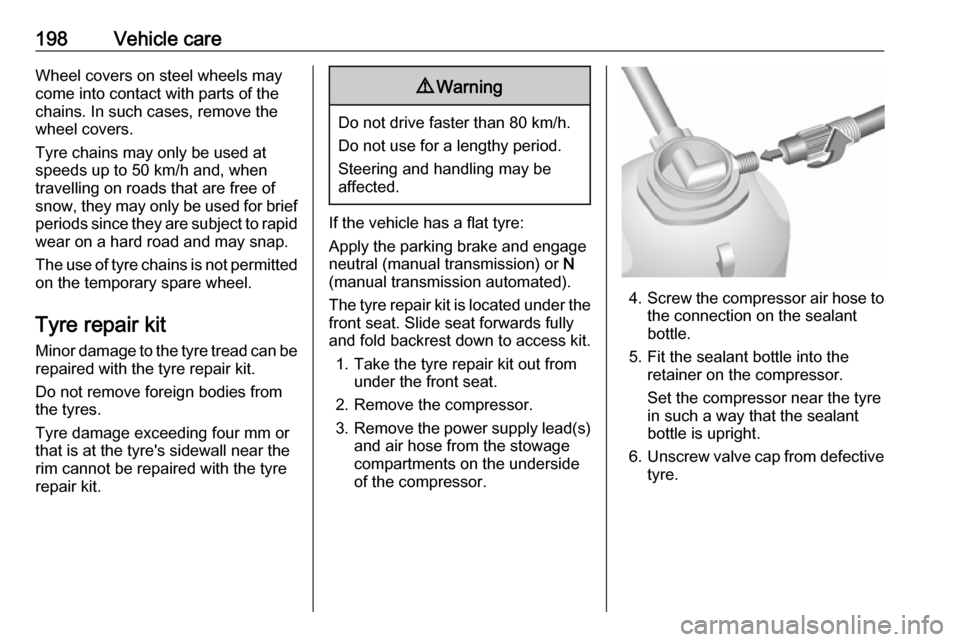

Tyre repair kit Minor damage to the tyre tread can be

repaired with the tyre repair kit.

Do not remove foreign bodies from

the tyres.

Tyre damage exceeding four mm or

that is at the tyre's sidewall near the rim cannot be repaired with the tyrerepair kit.9 Warning

Do not drive faster than 80 km/h.

Do not use for a lengthy period.

Steering and handling may be

affected.

If the vehicle has a flat tyre:

Apply the parking brake and engage

neutral (manual transmission) or N

(manual transmission automated).

The tyre repair kit is located under the

front seat. Slide seat forwards fully

and fold backrest down to access kit.

1. Take the tyre repair kit out from under the front seat.

2. Remove the compressor.

3. Remove the power supply lead(s)

and air hose from the stowage

compartments on the underside

of the compressor.

4. Screw the compressor air hose to

the connection on the sealant

bottle.

5. Fit the sealant bottle into the retainer on the compressor.

Set the compressor near the tyre

in such a way that the sealant

bottle is upright.

6. Unscrew valve cap from defective

tyre.

Page 203 of 255

Vehicle care201not be driven. Seek the

assistance of a workshop.

21. Stow tyre repair kit under the front

seat.

Note

The driving characteristics of the repaired tyre are severely affected,therefore have this tyre replaced.

If unusual noise is heard or the

compressor becomes hot, turn

compressor off for at least

30 minutes.

The built-in safety valve opens at a

pressure of seven bar.

Note the expiry date of the kit. After

this date its sealing capability is no

longer guaranteed. Pay attention to

storage information on sealant

bottle.

Replace the used sealant bottle. Dispose of the bottle as prescribed

by applicable laws.

The compressor and sealant can be used from approx. -30 °C.Wheel changing

Some vehicles are equipped with a

tyre repair kit instead of a spare wheel

3 198.

Make the following preparations and

observe the following information:

● Park the vehicle on a level, firm and non-slippery surface. The

front wheels must be in the

straight-ahead position.

● Apply the parking brake and engage first gear or reverse gear

(manual transmission) or N

(manual transmission

automated).

● Switch off the air suspension system 3 135.

● Remove the spare wheel 3 203.

● Never change more than one wheel at a time.

● Use the jack only to change wheels in case of puncture, not

for seasonal winter or summer

tyre change.

● The jack is maintenance-free.● If the ground on which the vehicle

is standing is soft, a solid board

(max. 1 cm thick) should be

placed under the jack.

● No people or animals may be in the vehicle when it is jacked-up.

● Never crawl under a jacked-up vehicle.

● Do not start the engine when the vehicle is raised on the jack.

● Clean wheel bolts/nuts and their threads before mounting the

wheel.9 Warning

Do not grease wheel bolt, wheel

nut and wheel nut cone.

1. Remove the wheel cover using the hook supplied. Vehicle tools

3 192.

2. Install the wheel wrench ensuring that it locates securely and loosen

each wheel bolt/nut by half a turn.