tow OPEL MOVANO_B 2018 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2018, Model line: MOVANO_B, Model: OPEL MOVANO_B 2018Pages: 265, PDF Size: 6.39 MB

Page 157 of 265

Driving and operating155Interruption of power supplyThe clutch is not disengaged if there

is an interruption of the power supply

when a gear is engaged. The vehicle

cannot move.

If the vehicle battery is discharged,

start the vehicle using jump leads

3 213.

If the cause of the fault is not a

discharged vehicle battery, seek the

assistance of a workshop.

If neutral cannot be selected, the

vehicle must only be towed with the

drive wheels raised off the ground

3 216.

Towing the vehicle 3 216.Brakes

The brake system comprises two

independent brake circuits.

If a brake circuit fails, the vehicle can

still be braked using the other brake

circuit. However, braking effect is

achieved only when you depress the

brake pedal firmly. You need to use

considerably more force for this. The

braking distance is extended. Seek

the assistance of a workshop before

continuing your journey.

When the engine is not running, the

support of the brake servo unit

disappears once the brake pedal has been depressed once or twice.

Braking effect is not reduced, but

braking requires significantly greater

force. It is especially important to bear this in mind when being towed.

Control indicator R 3 99.

Antilock brake system

Antilock brake system (ABS)

prevents the wheels from locking.ABS starts to regulate brake pressure as soon as a wheel shows a tendency

to lock. The vehicle remains

steerable, even during hard braking.

ABS control is made apparent

through a pulse in the brake pedal

and the noise of the regulation

process.

For optimum braking, keep the brake

pedal fully depressed throughout the

braking process, despite the fact that the pedal is pulsating. Do not reduce

the pressure on the pedal.

Control indicator u 3 99.

Fault

If control indicators u and A

illuminate with the messages CHECK

ABS and CHECK ESP in the Driver

Information Centre, there is a fault in

the ABS. The brake system remains

operational but without ABS

regulation.

Page 174 of 265

172Driving and operatingTrailer hitch

General information

Only use towing equipment that has

been approved for your vehicle.

Entrust fitting of towing equipment at

a later date to a workshop. It may be

necessary to make changes that

affect the cooling system, heat

shields or other equipment.

Driving characteristics and towing tips

In the case of trailers with brakes,

attach the breakaway stopping cable.

Before attaching a trailer, lubricate

the coupling ball. However, do not do so if a stabiliser, which acts on thecoupling ball, is being used to reduce

snaking movements. For trailers with

low driving stability the use of a

stabiliser is recommended.

A maximum speed of 80 km/h must

not be exceeded, even in countries

where higher speeds are permitted.If the trailer starts snaking, drive more slowly, do not attempt to correct the

steering and brake sharply if

necessary.

When driving downhill, drive in the

same gear as if driving uphill and

drive at a similar speed.

Adjust tyre pressure to the value

specified for full load 3 247.

Trailer towing

Trailer loads The permissible trailer loads are

vehicle-dependent and engine-

dependent maximum values which

must not be exceeded. The actual

trailer load is the difference between

the actual gross weight of the trailer

and the actual coupling socket load

with the trailer coupled.

The permissible trailer loads are

specified in the vehicle documents. In

general, they are valid for gradients

up to max. 12%.

The permitted trailer load applies up to the specified incline and up to an

altitude of 1000 metres above sealevel. Since engine power decreases

as altitude increases due to the air

becoming thinner, therefore reducing

climbing ability, the permissible gross

train weight also decreases by 10%

for every 1000 metres of additional

altitude. The gross train weight does

not have to be reduced when driving

on roads with slight inclines (less than 8%, e.g. motorways).

The permissible gross train weight

must not be exceeded. This weight is

specified on the identification plate

3 226.

Vertical coupling load

The vertical coupling load is the load

exerted by the trailer on the coupling

ball. It can be varied by changing the

weight distribution when loading the

trailer.

The maximum permissible vertical

coupling load is specified on the

towing equipment identification plate

and in the vehicle documents. Always aim for the maximum load, especially in the case of heavy trailers. The

vertical coupling load should never

fall below 25 kg.

Page 175 of 265

Driving and operating173In the case of trailer loads of

1200 kg or more, the vertical coupling

load should not be less than 50 kg.

Rear axle loadWhen the trailer is coupled and the

towing vehicle fully loaded (including all occupants), the permissible rear

axle load (see identification plate or

vehicle documents) must not be

exceeded.

Towing equipmentCaution

When operating without a trailer,

remove the coupling ball bar.

Towing equipment audible

warning

For vehicles fitted with towing

equipment, when connected to a

trailer the pitch of the audible warning

changes upon operation of the turn

signals.

The pitch of the audible warning will

change if a turn signal light on the

trailer or the towing vehicle fails.

Trailer stability assist

If the system detects snaking

movements, engine power is reduced

and the vehicle/trailer combination is

selectively braked until the snaking ceases. While the system is working,keep steering wheel as still as

possible.

Trailer stability assist (TSA) is a

function of the Electronic Stability

Program (ESP) 3 158.Auxiliary features

Power take-off

Activation

To activate the power take-off, with

the vehicle stationary and the engine

idling:

● Set the gearshift lever to neutral (vehicles with manual

transmission automated:

selector lever in position N).

● Depress the clutch pedal.

Page 177 of 265

Vehicle care175Vehicle careGeneral Information...................176

Accessories and vehicle modifications .......................... 176

Vehicle storage ........................176

End-of-life vehicle recovery .....177

Vehicle checks ........................... 177

Performing work ......................177

Bonnet ..................................... 177

Engine oil ................................. 178

Engine coolant ......................... 179

Power steering fluid .................180

Washer fluid ............................ 181

Brakes ..................................... 181

Brake fluid ............................... 181

Vehicle battery ......................... 182

Diesel fuel filter ........................184

Diesel fuel system bleeding .....184

Wiper blade replacement ........185

Bulb replacement .......................185

Headlights ............................... 186

Adaptive forward lighting .........188

Fog lights ................................. 188

Front turn signal lights .............189

Tail lights ................................. 189

Side turn signal lights ..............191Centre high-mounted brake

light ......................................... 192

Number plate light ...................192

Interior lights ............................ 193

Instrument panel illumination ...194

Electrical system ........................194

Fuses ....................................... 194

Engine compartment fuse box . 196

Instrument panel fuse box .......196

Load compartment fuse box ....197

Vehicle tools .............................. 199

Tools ........................................ 199

Wheels and tyres .......................200

Tyres ....................................... 200

Winter tyres ............................. 200

Tyre designations ....................200

Tyre pressure .......................... 201

Tyre pressure monitoring system .................................... 202

Tread depth ............................. 204

Changing tyre and wheel size . 204 Wheel covers ........................... 204

Tyre chains .............................. 205

Tyre repair kit .......................... 205

Wheel changing .......................208

Spare wheel ............................ 210

Jump starting ............................. 213Towing....................................... 216

Towing the vehicle ...................216

Towing another vehicle ...........217

Appearance care .......................217

Exterior care ............................ 217

Interior care ............................. 219

Page 187 of 265

Vehicle care1851.Turn ignition key to position 2 and

hold for five seconds.

2. Turn key back to position 1 and

wait for three seconds.

3. Repeat Step 1 and 2 multiple times.

4. Turn key to position 3, then return

to 0.

If the engine cannot be started after

several attempts to bleed the diesel

fuel system, seek the assistance of a

workshop.

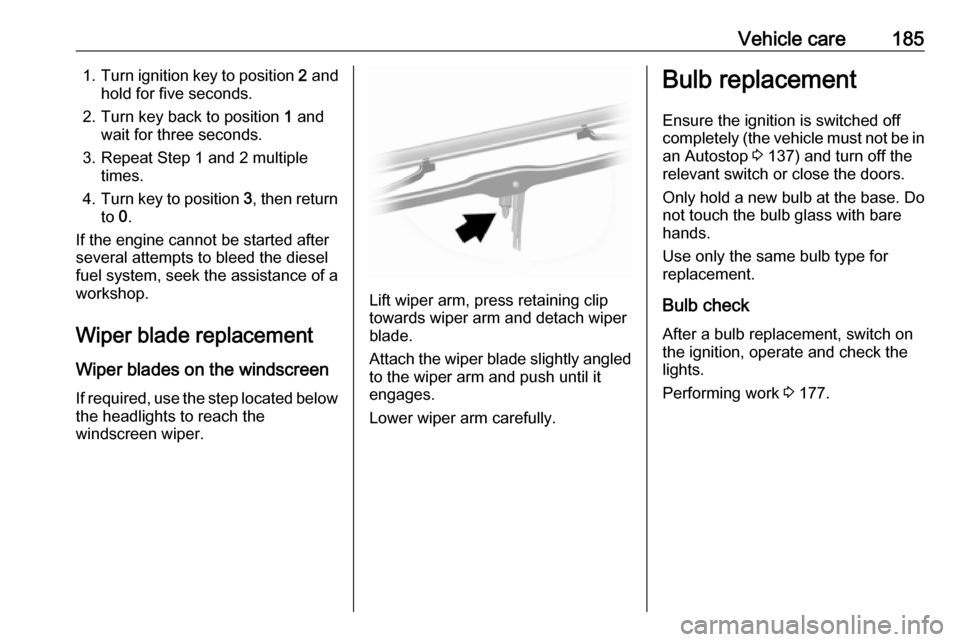

Wiper blade replacement Wiper blades on the windscreen

If required, use the step located below

the headlights to reach the

windscreen wiper.

Lift wiper arm, press retaining clip

towards wiper arm and detach wiper

blade.

Attach the wiper blade slightly angled

to the wiper arm and push until it engages.

Lower wiper arm carefully.

Bulb replacement

Ensure the ignition is switched off

completely (the vehicle must not be in

an Autostop 3 137) and turn off the

relevant switch or close the doors.

Only hold a new bulb at the base. Do not touch the bulb glass with bare

hands.

Use only the same bulb type for

replacement.

Bulb check After a bulb replacement, switch on

the ignition, operate and check the

lights.

Performing work 3 177.

Page 201 of 265

Vehicle care199No.Circuit14Foot panel15Child safety warning buzzer16Speed 1: right-hand evaporator

fan

Some circuits may be protected by

several fuses.

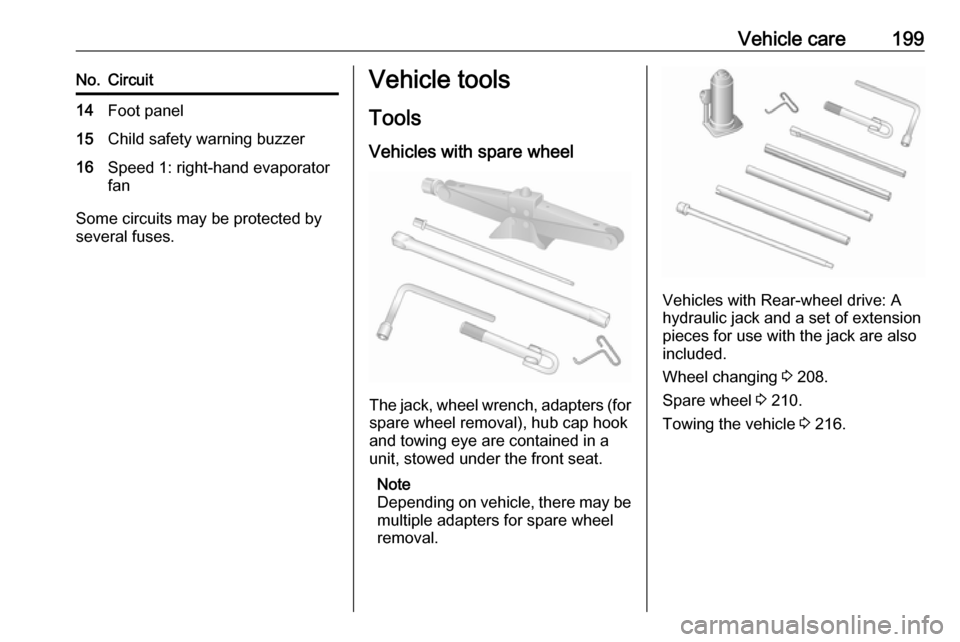

Vehicle tools

Tools

Vehicles with spare wheel

The jack, wheel wrench, adapters (for

spare wheel removal), hub cap hook

and towing eye are contained in a

unit, stowed under the front seat.

Note

Depending on vehicle, there may be

multiple adapters for spare wheel

removal.

Vehicles with Rear-wheel drive: A hydraulic jack and a set of extension

pieces for use with the jack are also

included.

Wheel changing 3 208.

Spare wheel 3 210.

Towing the vehicle 3 216.

Page 204 of 265

202Vehicle carefor a 10 °C temperature increase.

This must be considered when warm

tyres are checked.

Trailer towing When towing a trailer with a fullyladen vehicle, the tyre pressure must

be increased by 20 kPa/0.2 bar

(3.0 psi) and the maximum speed

limited to 100 km/h.

Trailer towing 3 172.

Rear-wheel drive, with twin rear

wheels

When inflating the outer tyre, the

inflation tube should be passed

between the two wheels.

Tyre pressure monitoringsystem

The tyre pressure monitoring system

uses radio and sensor technology to

check tyre pressure levels.Caution

Tyre pressure monitoring system

warns only about low tyre pressure condition and does not replace

regular tyre maintenance by the

driver.

All wheels must be equipped with pressure sensors and the tyres must

have the prescribed pressure.

Note

In countries where the tyre pressure

monitoring system is legally

required, the use of wheels without

pressure sensors will invalidate the

vehicle operating permit.

The tyre pressure monitoring system

sensors monitor the air pressure in

the tyres and transmit tyre pressure

readings to a receiver located in the

vehicle.

Tyre pressure chart 3 247.

Low tyre pressure condition

A detected low tyre pressure

condition is indicated by illumination

of control indicator w 3 100 and a

corresponding message appears in

the Driver Information Centre.

If w illuminates, stop as soon as

possible and inflate the tyres as

recommended 3 247.

After inflating, some driving may be

required to update the tyre pressure

values in the system. During this time

w may illuminate.

If w illuminates at lower temperatures

and extinguishes after some driving,

this could be an indicator for

Page 207 of 265

Vehicle care2059Warning

Use of unsuitable tyres or wheel

covers could lead to sudden

pressure loss and thereby

accidents.

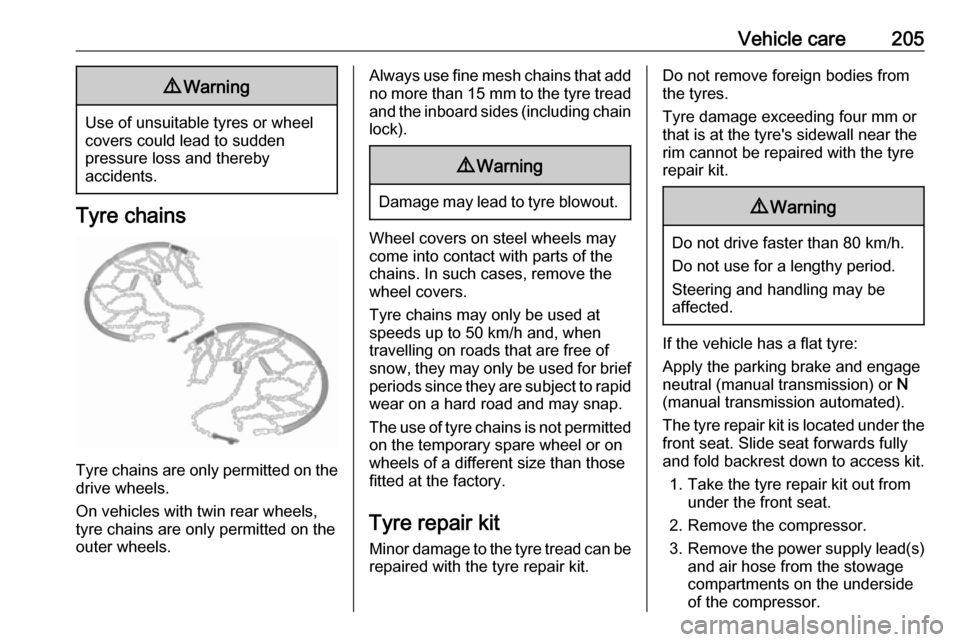

Tyre chains

Tyre chains are only permitted on the

drive wheels.

On vehicles with twin rear wheels,

tyre chains are only permitted on the

outer wheels.

Always use fine mesh chains that add no more than 15 mm to the tyre tread

and the inboard sides (including chain lock).9 Warning

Damage may lead to tyre blowout.

Wheel covers on steel wheels may

come into contact with parts of the

chains. In such cases, remove the

wheel covers.

Tyre chains may only be used at

speeds up to 50 km/h and, when

travelling on roads that are free of

snow, they may only be used for brief

periods since they are subject to rapid wear on a hard road and may snap.

The use of tyre chains is not permitted on the temporary spare wheel or on

wheels of a different size than those

fitted at the factory.

Tyre repair kit Minor damage to the tyre tread can be

repaired with the tyre repair kit.

Do not remove foreign bodies from

the tyres.

Tyre damage exceeding four mm or

that is at the tyre's sidewall near the

rim cannot be repaired with the tyre repair kit.9 Warning

Do not drive faster than 80 km/h.

Do not use for a lengthy period.

Steering and handling may be

affected.

If the vehicle has a flat tyre:

Apply the parking brake and engage

neutral (manual transmission) or N

(manual transmission automated).

The tyre repair kit is located under the

front seat. Slide seat forwards fully

and fold backrest down to access kit.

1. Take the tyre repair kit out from under the front seat.

2. Remove the compressor.

3. Remove the power supply lead(s)

and air hose from the stowage

compartments on the underside

of the compressor.

Page 209 of 265

![OPEL MOVANO_B 2018 Manual user Vehicle care207power outlet or cigarette lighter

socket.

For this type, the red < and

black ] power supply leads will not

be present.

To avoid discharging the battery,we recommend running the

engine OPEL MOVANO_B 2018 Manual user Vehicle care207power outlet or cigarette lighter

socket.

For this type, the red < and

black ] power supply leads will not

be present.

To avoid discharging the battery,we recommend running the

engine](/img/37/18908/w960_18908-208.png)

Vehicle care207power outlet or cigarette lighter

socket.

For this type, the red < and

black ] power supply leads will not

be present.

To avoid discharging the battery,we recommend running the

engine.

11. Set the rocker switch on the compressor to position I. The tyre

is filled with sealant.

12. The compressor pressure gauge briefly indicates up to six bar.

Then the pressure starts to drop.

13. All of the sealant is pumped into the tyre. Then the tyre is inflated.

14. The prescribed tyre pressureshould be obtained within

ten minutes. Tyre pressure

3 247 . When the correct pressure

is obtained, turn off the

compressor by setting rocker

switch to position O.

If the prescribed tyre pressure is

not obtained within ten minutes,

remove the tyre repair kit. Move

the vehicle one tyre rotation

(approx. two metres). Reattach

the tyre repair kit and continue the

filling procedure for ten minutes. If the prescribed tyre pressure is still

not obtained, the tyre is too badly

damaged. Seek the assistance of

a workshop.

Drain excess tyre pressure with

the button beside the pressure

indicator.

Do not run the compressor for

longer than ten minutes.

15. Detach the tyre repair kit.

16. Remove any excess sealant using a cloth.

17. Take the label indicating maximum permitted speed from

the tyre repair kit and affix in the

driver's field of view.

18. Screw the sealant filler hose to the

free connection on the sealant

bottle. This prevents sealant from

escaping. Store the sealant bottle in the plastic bag. Stow tyre repair

kit under the front seat.

Page 210 of 265

208Vehicle care

19. Continue driving immediately sothat the sealant is evenlydistributed throughout the tyre.

After driving approx. ten km, but

no more than ten minutes, stop

and check tyre pressure using the

compressor. Screw compressor

air hose directly onto tyre valve

and compressor when doing this.

20. If the tyre pressure is more than 3.1 bar , set it to the correct value.

Repeat the procedure until there

is no more loss of pressure.

If the tyre pressure has fallen

below 3.1 bar, the vehicle must

not be driven. Seek the

assistance of a workshop.

21. Stow tyre repair kit under the front

seat.

Note

The driving characteristics of the repaired tyre are severely affected,

therefore have this tyre replaced.

If unusual noise is heard or the

compressor becomes hot, turn

compressor off for at least

30 minutes.

The built-in safety valve opens at a

pressure of seven bar.

Note the expiry date of the kit. After

this date its sealing capability is no

longer guaranteed. Pay attention to

storage information on sealant

bottle.

Replace the used sealant bottle. Dispose of the bottle as prescribed

by applicable laws.

The compressor and sealant can be

used from approx. -30 °C.Wheel changing

Some vehicles are equipped with a

tyre repair kit instead of a spare wheel

3 205.

Make the following preparations and

observe the following information:

● Park the vehicle on a level, firm and non-slippery surface. The

front wheels must be in the

straight-ahead position.

● Apply the parking brake and engage first gear or reverse gear

(manual transmission) or N

(manual transmission

automated).

● Switch off the air suspension system 3 141.

● Remove the spare wheel 3 210.

● Never change more than one wheel at a time.

● Use the jack only to change wheels in case of puncture, not

for seasonal winter or summer

tyre change.

● The jack is maintenance-free.