fuel OPEL MOVANO_B 2019 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2019, Model line: MOVANO_B, Model: OPEL MOVANO_B 2019Pages: 251, PDF Size: 6.46 MB

Page 154 of 251

152Driving and operatingNote

If AdBlue must be refilled at very low temperatures, the refilling of AdBlue

may not be detected by the system.

In this case, park the vehicle in a

space with a higher ambient

temperature until AdBlue is

liquefied.

Note

If engine starting is prohibited due to low AdBlue level, we recommend

refilling the tank completely or with a volume of at least 10 l of AdBlue

(depending on AdBlue

consumption).

Avoid minor top-ups (e.g. less than

10 l), otherwise the system may not

detect a refill.

Note

When unscrewing the protective cap from the filler neck, ammonia fumes

may emerge. Do not inhale as the fumes have a pungent smell. The

fumes are not harmful by inhalation.

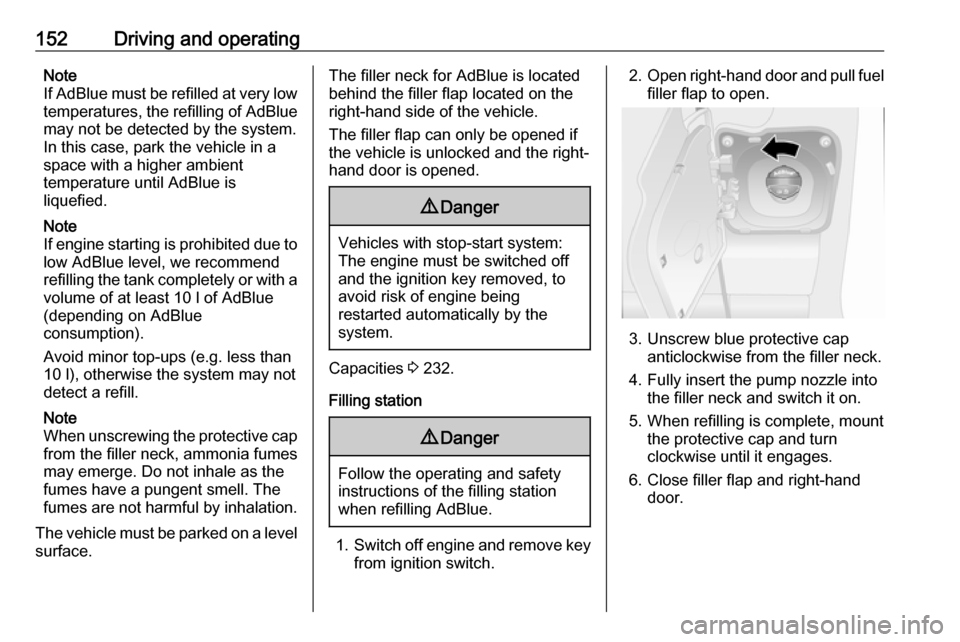

The vehicle must be parked on a level surface.The filler neck for AdBlue is located

behind the filler flap located on the

right-hand side of the vehicle.

The filler flap can only be opened if

the vehicle is unlocked and the right-

hand door is opened.9 Danger

Vehicles with stop-start system:

The engine must be switched off

and the ignition key removed, to

avoid risk of engine being

restarted automatically by the

system.

Capacities 3 232.

Filling station

9 Danger

Follow the operating and safety

instructions of the filling station

when refilling AdBlue.

1. Switch off engine and remove key

from ignition switch.

2. Open right-hand door and pull fuel

filler flap to open.

3. Unscrew blue protective cap anticlockwise from the filler neck.

4. Fully insert the pump nozzle into the filler neck and switch it on.

5. When refilling is complete, mount the protective cap and turn

clockwise until it engages.

6. Close filler flap and right-hand door.

Page 155 of 251

Driving and operating153AdBlue canisterNote

Only use the designated AdBlue

canisters for refilling, to prevent a

topping-up of too much AdBlue.

Additionally, the fumes in the tank

are captured in the canister and do

not emerge.

Note

Since AdBlue has a limited

durability, check the date of expiry

before refilling.

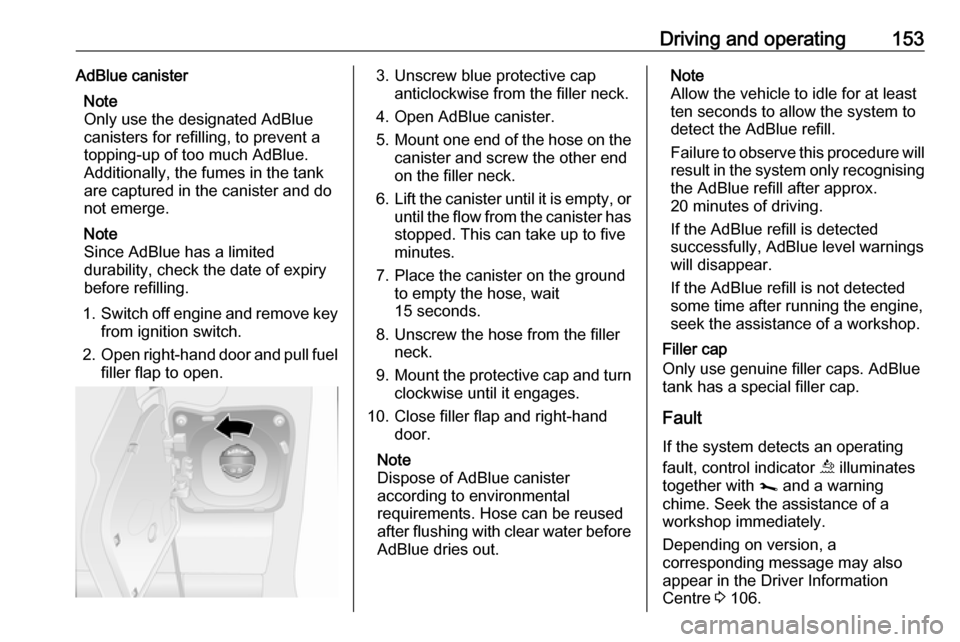

1. Switch off engine and remove key

from ignition switch.

2. Open right-hand door and pull fuel

filler flap to open.3. Unscrew blue protective cap anticlockwise from the filler neck.

4. Open AdBlue canister.

5. Mount one end of the hose on the

canister and screw the other end

on the filler neck.

6. Lift the canister until it is empty, or

until the flow from the canister has stopped. This can take up to five

minutes.

7. Place the canister on the ground to empty the hose, wait

15 seconds.

8. Unscrew the hose from the filler neck.

9. Mount the protective cap and turn

clockwise until it engages.

10. Close filler flap and right-hand door.

Note

Dispose of AdBlue canister

according to environmental

requirements. Hose can be reused

after flushing with clear water before

AdBlue dries out.Note

Allow the vehicle to idle for at least

ten seconds to allow the system to

detect the AdBlue refill.

Failure to observe this procedure will

result in the system only recognising the AdBlue refill after approx.

20 minutes of driving.

If the AdBlue refill is detected

successfully, AdBlue level warnings

will disappear.

If the AdBlue refill is not detected

some time after running the engine,

seek the assistance of a workshop.

Filler cap

Only use genuine filler caps. AdBlue tank has a special filler cap.

Fault

If the system detects an operating

fault, control indicator ú illuminates

together with j and a warning

chime. Seek the assistance of a

workshop immediately.

Depending on version, a

corresponding message may also

appear in the Driver Information

Centre 3 106.

Page 176 of 251

174Driving and operatingcontrol indicator ì flashes together

with a warning chime to alert the

driver.

Deactivation

The system is deactivated by

pressing ì; LED in the button

illuminates. A corresponding

message also appears in the Driver

Information Centre.

At speeds below 60 km/h the system is inoperable.

Operation hints The lane departure warning systemmay not operate properly when:

● The windscreen is not clean.

● There are adverse environmental

conditions like heavy rain, snow,

direct sunlight or shadows.

The system cannot operate when no

lane marking is detected.Fault

In the event of a fault in the system, a warning message appears in the

Driver Information Centre (possibly in combination with control indicator j)

and the LED in the button illuminates.

Seek the assistance of a workshop.

Driver Information Centre 3 106.Fuel

Fuel for diesel engines The Diesel engines are compatible

with bio-fuels that conform to current and future European standards and

can be obtained from filling stations:

Diesel fuel that meets standard

EN590 mixed with a biofuel that

meets standard EN14214 (possibly

containing up to 7% Fatty Acid Methyl

Ester).

Page 177 of 251

Driving and operating175Diesel fuel that meets standard

EN16734 mixed with a biofuel that

meets standard EN14214 (possibly

containing up to 10% Fatty Acid

Methyl Ester).

If travelling in countries outside the

European Union, occasional use of

Euro-Diesel fuel with a sulphur

concentration below 50 ppm is

possible.Caution

Frequent usage of diesel fuel containing more than 15 ppm

sulphur will cause severe engine

damage.

Caution

Use of fuel that does not comply to EN 590 or similar can lead to

engine powerloss, increased wear

or engine damage and may affect

your warranty.

Do not use marine diesel oils, heating

oils, Aquazole and similar diesel-

water emulsions. Diesel fuels must

not be diluted with fuels for petrol

engines. Do not use additives.

The flow and filterability of diesel fuels are temperature-dependent. When

temperatures are low, refuel with

diesel fuel with guaranteed winter

properties.

Diesel fuel filter 3 189.

Diesel fuel system bleeding 3 189.

Low temperature operation

At temperatures below 0 °C, some

diesel products with biodiesel blends

may clog, freeze or gel, which may

affect the fuel supply system. Starting

and engine operation may not work

properly. Make sure to fill winter

grade diesel fuel at ambient

temperatures below 0 °C.

Arctic grade diesel fuel can be used

in extreme cold temperatures below

-20 °C. Using this fuel grade in warm

or hot climates is not recommended

and may cause engine stalling, poor starting or damage to the fuel

injection system.Refuelling9 Danger

Before refuelling, switch off engine

and any external heaters with

combustion chambers. Switch off

any mobile phones.

Follow the operating and safety

instructions of the filling station

when refuelling.

9 Danger

Fuel is flammable and explosive.

No smoking. No naked flames or

sparks.

If you can smell fuel in your

vehicle, have the cause of this

remedied immediately by a

workshop.

A label with symbols at the fuel filler

flap is indicating the allowed fuel

types. In Europe the pump nozzles of

the filling stations are marked with

these symbols. Refuel only the

allowed fuel type.

Page 178 of 251

176Driving and operatingCaution

In case of misfuelling, do not

switch on ignition.

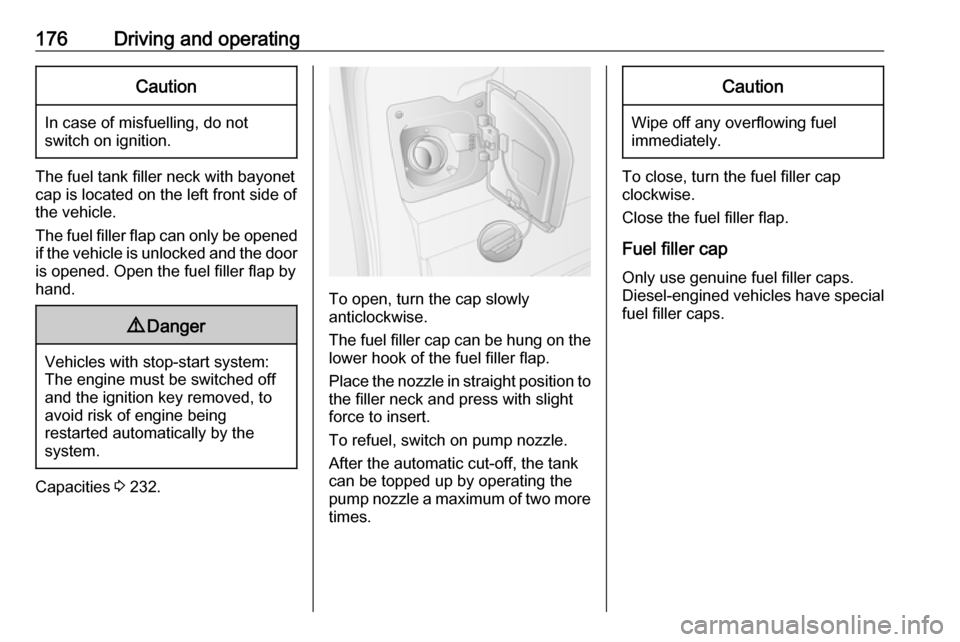

The fuel tank filler neck with bayonet

cap is located on the left front side of

the vehicle.

The fuel filler flap can only be opened

if the vehicle is unlocked and the door is opened. Open the fuel filler flap by

hand.

9 Danger

Vehicles with stop-start system:

The engine must be switched off

and the ignition key removed, to

avoid risk of engine being

restarted automatically by the

system.

Capacities 3 232.

To open, turn the cap slowly

anticlockwise.

The fuel filler cap can be hung on the lower hook of the fuel filler flap.

Place the nozzle in straight position to

the filler neck and press with slight

force to insert.

To refuel, switch on pump nozzle.

After the automatic cut-off, the tank can be topped up by operating the

pump nozzle a maximum of two more times.

Caution

Wipe off any overflowing fuel

immediately.

To close, turn the fuel filler cap

clockwise.

Close the fuel filler flap.

Fuel filler cap Only use genuine fuel filler caps.Diesel-engined vehicles have special

fuel filler caps.

Page 182 of 251

180Vehicle careVehicle careGeneral Information...................181

Accessories and vehicle modifications .......................... 181

Vehicle storage ........................181

End-of-life vehicle recovery .....182

Vehicle checks ........................... 182

Performing work ......................182

Bonnet ..................................... 182

Engine oil ................................. 183

Engine coolant ......................... 185

Power steering fluid .................185

Washer fluid ............................ 186

Brakes ..................................... 187

Brake fluid ............................... 187

Vehicle battery ......................... 187

Diesel fuel filter ........................189

Diesel fuel system bleeding .....189

Wiper blade replacement ........190

Bulb replacement .......................191

Headlights ............................... 191

Front fog lights ......................... 194

Front turn lights .......................194

Tail lights ................................. 195

Side turn lights ......................... 196Centre high-mounted brake

light ......................................... 197

Number plate light ...................198

Interior lights ............................ 198

Instrument panel illumination ...199

Electrical system ........................200

Fuses ....................................... 200

Engine compartment fuse box . 201

Instrument panel fuse box .......201

Load compartment fuse box ....202

Vehicle tools .............................. 204

Tools ........................................ 204

Wheels and tyres .......................205

Tyres ....................................... 205

Winter tyres ............................. 206

Tyre designations ....................206

Tyre pressure .......................... 206

Tyre pressure monitoring system .................................... 207

Tread depth ............................. 209

Changing tyre and wheel size . 210 Wheel covers ........................... 210

Tyre chains .............................. 210

Tyre repair kit .......................... 211

Wheel changing .......................214

Spare wheel ............................ 216

Jump starting ............................. 218Towing....................................... 221

Towing the vehicle ...................221

Towing another vehicle ...........222

Appearance care .......................222

Exterior care ............................ 222

Interior care ............................. 224

Page 183 of 251

Vehicle care181General Information

Accessories and vehicle modifications

We recommend the use of genuine

parts and accessories and factory

approved parts specific for your

vehicle type. We cannot assess or guarantee reliability of other products

- even if they have a regulatory or

otherwise granted approval.

Any modification, conversion or other changes made to standard vehicle

specifications (including, without

limitation, software modifications,

modifications of the electronic control

units) may invalidate the warranty

offered by Opel. Furthermore, such

changes may affect driver assistance systems, fuel consumption, CO 2

emissions and other emissions of the

vehicle. They may also invalidate the

vehicle operating permit.Caution

When transporting the vehicle on

a train or on a recovery vehicle, the

mud flaps might be damaged.

Vehicle storage

Storage for a long period of time

If the vehicle is to be stored for several months:

● Wash and wax the vehicle.

● Have the wax in the engine compartment and underbody

checked.

● Clean and preserve rubber seals.

● Change engine oil.

● Drain washer fluid reservoir. ● Check coolant antifreeze and corrosion protection.

● Adjust tyre pressure to the value specified for full load.

● Park vehicle in a dry, well ventilated place. Engage first or

reverse gear. Prevent the vehicle

from rolling.

● Do not apply parking brake.

● Close all doors except front left- hand door and lock the vehicle.

● Disconnect the clamp from the negative terminal of the vehicle

battery. Beware that all systems

are not functional, e.g. anti-theft

alarm system.

● Close and lock front left-hand door.

Putting back into operation When the vehicle is to be put back into

operation:

● Connect the clamp to the negative terminal of the vehicle

battery. Activate the electronics

of the power windows.

● Check tyre pressure.

● Fill up the washer fluid reservoir.

● Check the engine oil level.

● Check the coolant level.

● Fit the number plate, if necessary.

Page 191 of 251

Vehicle care189● See the Owner's Manual forfurther information.

● Explosive gas may be present in the vicinity of the battery.

Additional battery

Depending on the vehicle's auxiliary

equipment, certain models may have

an additional battery mounted under

the right-hand front seat.

Note

The additional battery is

automatically connected to the main vehicle battery only when the engine

is running. It does not need to be

manually disconnected before

disconnecting the main vehicle

battery or before jump starting the vehicle.

The terminals are designed for

additional electrical consumers up to

a maximum of 50 A.

Jump starting 3 218.

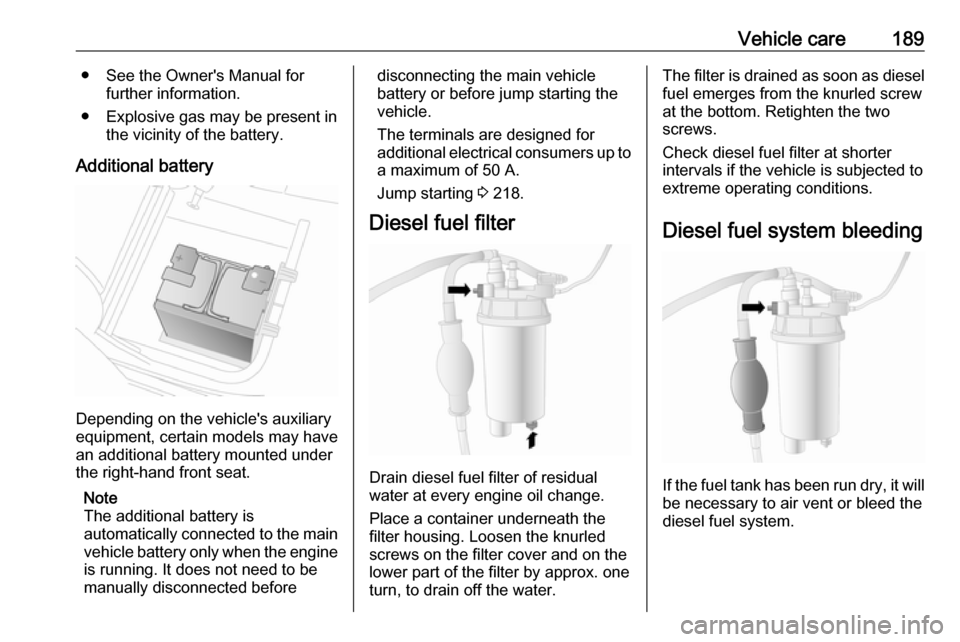

Diesel fuel filter

Drain diesel fuel filter of residual

water at every engine oil change.

Place a container underneath the

filter housing. Loosen the knurled

screws on the filter cover and on the

lower part of the filter by approx. one

turn, to drain off the water.

The filter is drained as soon as diesel fuel emerges from the knurled screw

at the bottom. Retighten the two

screws.

Check diesel fuel filter at shorter

intervals if the vehicle is subjected to

extreme operating conditions.

Diesel fuel system bleeding

If the fuel tank has been run dry, it will be necessary to air vent or bleed the

diesel fuel system.

Page 192 of 251

190Vehicle careFill the tank with fuel and proceed asfollows:

1. Place a suitable container underneath the fuel filter vent

screw to collect fuel.

2. Loosen the vent screw (arrowed) by one turn.

3. Manually operate the in-line supply pump slowly and steadily

until fuel discharging from the

loosened vent screw is free of air

bubbles.

4. Retighten the vent screw.

In vehicles without an in-line supply

pump, fill the tank with fuel and

proceed as follows:Caution

Do not turn ignition key to position 3 before beginning the bleeding

procedure.

Ignition switch positions 3 138.

1. Turn ignition key to position 2 and

hold for 5 seconds.

2. Turn key back to position 1 and

wait for 3 seconds.

3. Repeat Step 1 and 2 multiple times.

4. Turn key to position 3, then return

to 0.

If the engine cannot be started after

several attempts to bleed the diesel

fuel system, seek the assistance of a

workshop.

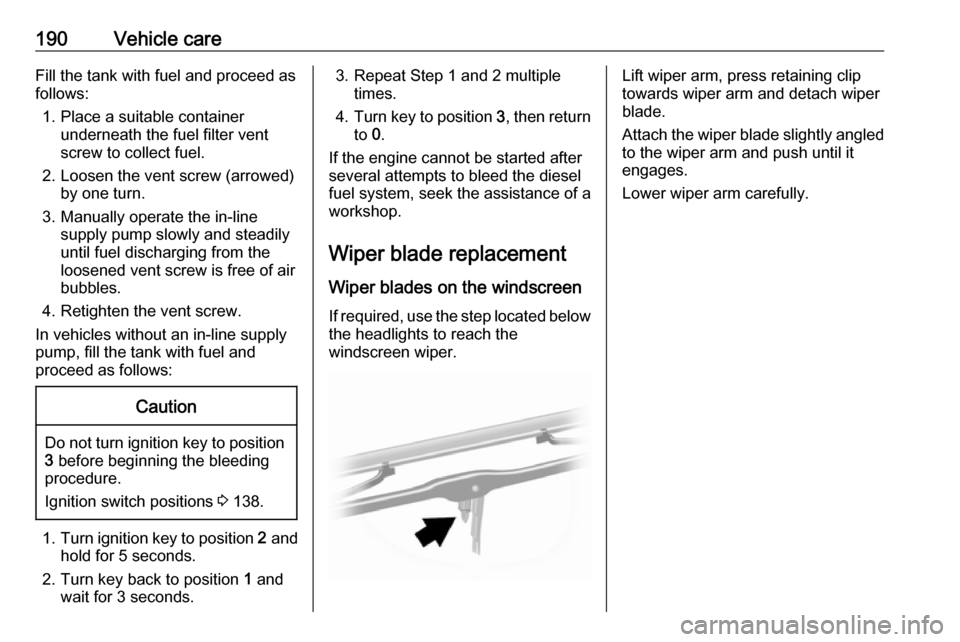

Wiper blade replacement

Wiper blades on the windscreen If required, use the step located below

the headlights to reach the

windscreen wiper.Lift wiper arm, press retaining clip

towards wiper arm and detach wiper

blade.

Attach the wiper blade slightly angled

to the wiper arm and push until it

engages.

Lower wiper arm carefully.

Page 204 of 251

202Vehicle careSome circuits may be protected by

several fuses.SymbolCircuitZInfotainment system / Seat

heating / Driver Information

Centre / Audio connec‐

tions / Alarm?Power outletÌCigarette lightereInstrument panelUCentral locking0Interior lightsOTurn lights / Rear fog lights / Body control moduleDIAGDiagnostic connectoruABS / Electronic Stability

ControldInterior lights / Brake lightsZBody control moduleSTOPBrake lightSymbolCircuitIBody control module /

Power windows / Heating

and ventilation system / Air

conditioningmLeft heated rear windownRight heated rear windowRWindscreen washerMElectronic immobiliserUHeated seatsFBLCornering lightlHands-free connection&TachographPTOPower take-offjHornÍPreheating / Diesel fuel filterxClimate control fandHeated exterior mirrorsTLeft-hand side lightSRight-hand side lightSymbolCircuitONavigation systemADPAdditional adaptations,Power windows / Body

control module

Load compartment fuse box

Combi

Located behind the trim panel on the

right-hand side of the load

compartment, beside the rear door.