battery OPEL MOVANO_B 2019 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2019, Model line: MOVANO_B, Model: OPEL MOVANO_B 2019Pages: 251, PDF Size: 6.46 MB

Page 214 of 251

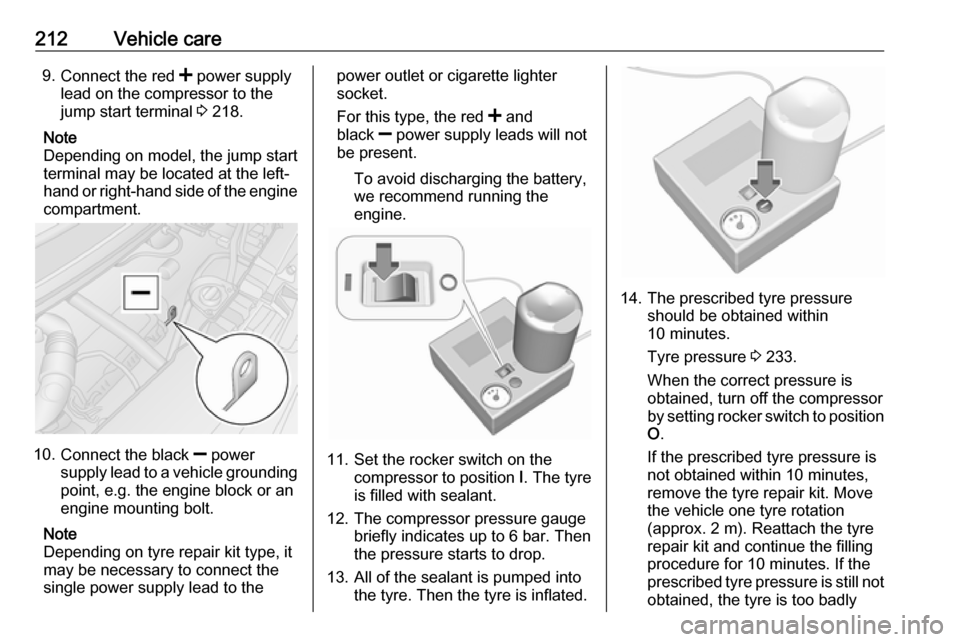

212Vehicle care9.Connect the red < power supply

lead on the compressor to the

jump start terminal 3 218.

Note

Depending on model, the jump start

terminal may be located at the left-

hand or right-hand side of the engine compartment.

10. Connect the black ] power

supply lead to a vehicle grounding

point, e.g. the engine block or an

engine mounting bolt.

Note

Depending on tyre repair kit type, it

may be necessary to connect the

single power supply lead to the

power outlet or cigarette lighter

socket.

For this type, the red < and

black ] power supply leads will not

be present.

To avoid discharging the battery,

we recommend running the

engine.

11. Set the rocker switch on the compressor to position I. The tyre

is filled with sealant.

12. The compressor pressure gauge briefly indicates up to 6 bar. Then

the pressure starts to drop.

13. All of the sealant is pumped into the tyre. Then the tyre is inflated.

14. The prescribed tyre pressureshould be obtained within

10 minutes.

Tyre pressure 3 233.

When the correct pressure is

obtained, turn off the compressor

by setting rocker switch to position O .

If the prescribed tyre pressure is

not obtained within 10 minutes,

remove the tyre repair kit. Move

the vehicle one tyre rotation

(approx. 2 m). Reattach the tyre

repair kit and continue the filling

procedure for 10 minutes. If the

prescribed tyre pressure is still not

obtained, the tyre is too badly

Page 220 of 251

218Vehicle careThen tighten cable using the wheel

wrench and adapters by connecting

to the slot position illustrated above

and turning wrench anticlockwise

until the wheel is secured in the fully

raised position.9 Warning

Ensure the front of the wheel (side

with tyre valve) is facing upwards

when the spare wheel is

reinstalled below the vehicle

frame.

Temporary spare wheel

Caution

The use of a spare wheel that is smaller than the other wheels or in combination with winter tyres

could affect driveability. Have the defective tyre replaced as soon as

possible.

Only mount one temporary spare

wheel. Do not drive faster than

80 km/h. Take curves slowly. Do not use for a long period of time.

Tyre chains 3 210.

Summer and winter tyres

If you use winter tyres, the spare

wheel may still be fitted with a

summer tyre.

If you use the spare wheel when it is

fitted with a summer tyre the vehicle's driveability may be affected,

especially on slippery road surfaces.

Directional tyres Fit directional tyres such that they rollin the direction of travel. The rolling

direction is indicated by a symbol

(e.g. an arrow) on the sidewall.

The following applies to tyres fitted

opposing the rolling direction:

● Driveability may be affected. Have the defective tyre renewed

or repaired as soon as possible

and fit it instead of the spare

wheel.

● Do not drive faster than 80 km/h.

● Drive particularly carefully on wet

and snow-covered road

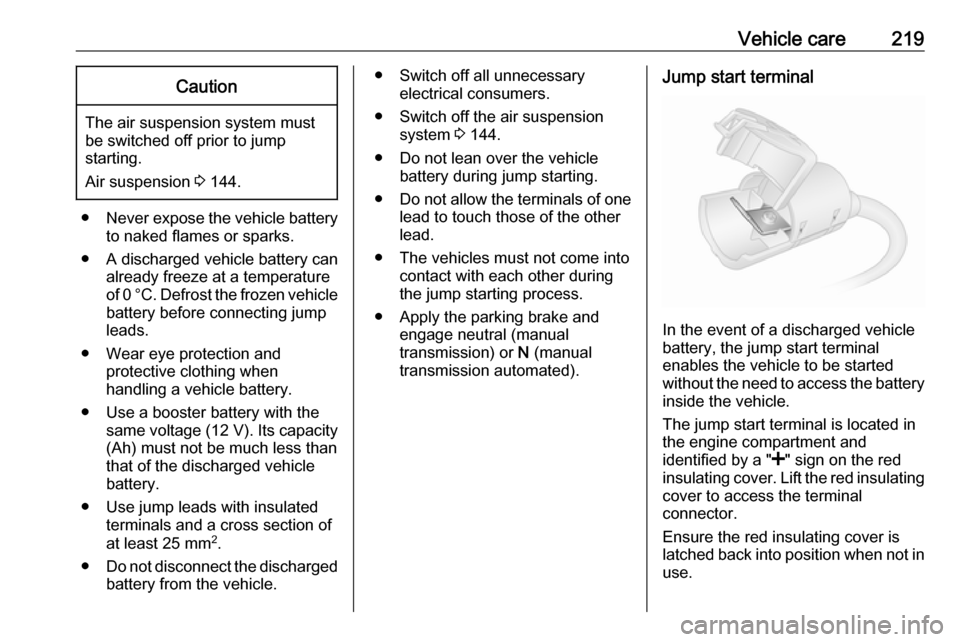

surfaces.Jump starting

The jump start terminal is located in

the engine compartment.

A vehicle with a discharged vehicle

battery can be started using jump

leads and the vehicle battery of

another vehicle.

Do not start with a quick charger.9 Warning

Be extremely careful when starting

with jump leads. Any deviation

from the following instructions can

lead to injuries or damage caused

by battery explosion or damage to the electrical systems of both

vehicles.

9 Warning

Avoid contact of the battery with

eyes, skin, fabrics and painted

surfaces. The fluid contains

sulphuric acid which can cause

injuries and damage in the event

of direct contact.

Page 221 of 251

Vehicle care219Caution

The air suspension system must

be switched off prior to jump

starting.

Air suspension 3 144.

● Never expose the vehicle battery

to naked flames or sparks.

● A discharged vehicle battery can already freeze at a temperature

of 0 °C. Defrost the frozen vehicle

battery before connecting jump leads.

● Wear eye protection and protective clothing when

handling a vehicle battery.

● Use a booster battery with the same voltage (12 V). Its capacity(Ah) must not be much less than

that of the discharged vehicle

battery.

● Use jump leads with insulated terminals and a cross section of

at least 25 mm 2

.

● Do not disconnect the discharged

battery from the vehicle.

● Switch off all unnecessary electrical consumers.

● Switch off the air suspension system 3 144.

● Do not lean over the vehicle battery during jump starting.

● Do not allow the terminals of one

lead to touch those of the other

lead.

● The vehicles must not come into contact with each other during

the jump starting process.

● Apply the parking brake and engage neutral (manual

transmission) or N (manual

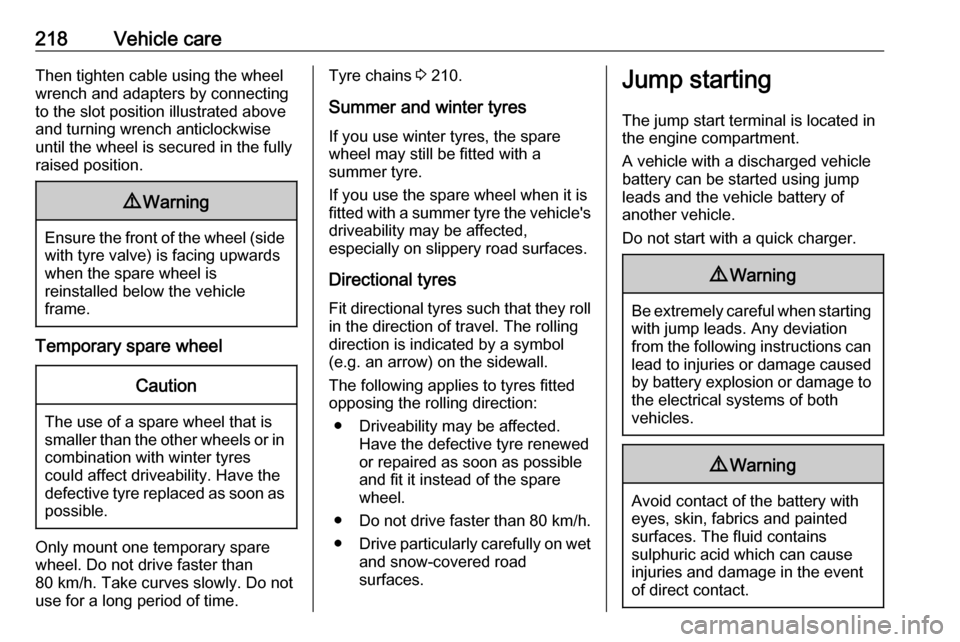

transmission automated).Jump start terminal

In the event of a discharged vehicle

battery, the jump start terminal

enables the vehicle to be started

without the need to access the battery inside the vehicle.

The jump start terminal is located in

the engine compartment and

identified by a " <" sign on the red

insulating cover. Lift the red insulating

cover to access the terminal

connector.

Ensure the red insulating cover is

latched back into position when not in

use.

Page 222 of 251

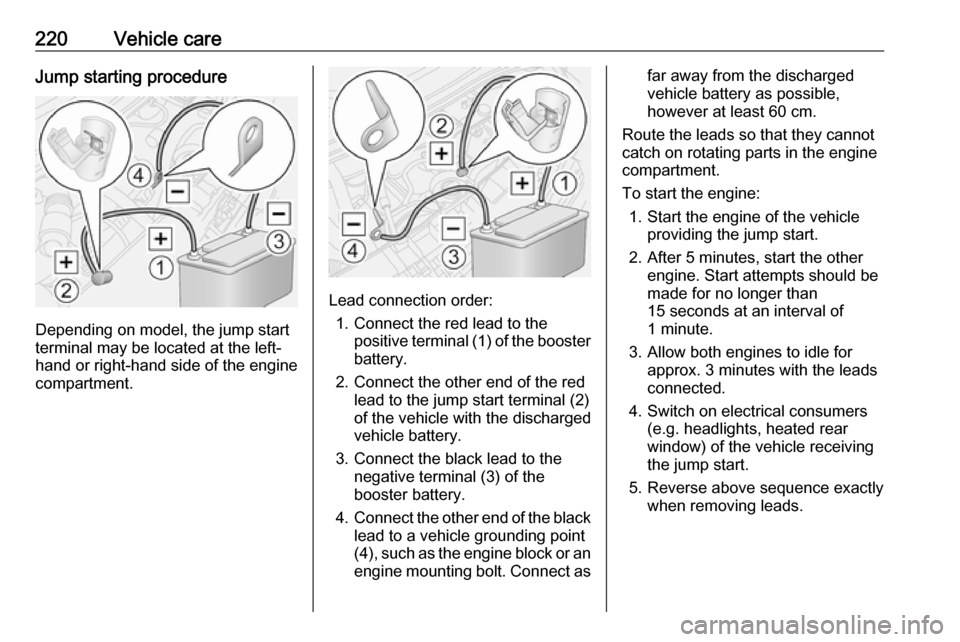

220Vehicle careJump starting procedure

Depending on model, the jump start

terminal may be located at the left-

hand or right-hand side of the engine

compartment.

Lead connection order:

1. Connect the red lead to the positive terminal (1) of the booster

battery.

2. Connect the other end of the red lead to the jump start terminal (2)

of the vehicle with the discharged

vehicle battery.

3. Connect the black lead to the negative terminal (3) of the

booster battery.

4. Connect the other end of the black

lead to a vehicle grounding point

(4), such as the engine block or an

engine mounting bolt. Connect as

far away from the discharged

vehicle battery as possible,

however at least 60 cm.

Route the leads so that they cannot

catch on rotating parts in the engine

compartment.

To start the engine: 1. Start the engine of the vehicle providing the jump start.

2. After 5 minutes, start the other engine. Start attempts should be

made for no longer than

15 seconds at an interval of

1 minute.

3. Allow both engines to idle for approx. 3 minutes with the leads

connected.

4. Switch on electrical consumers (e.g. headlights, heated rear

window) of the vehicle receiving

the jump start.

5. Reverse above sequence exactly when removing leads.

Page 241 of 251

Customer information239Operating data in the vehicleControl units process data for

operation of the vehicle.

This data includes, e.g.: ● vehicle status information (e.g. speed, movement delay, lateral

acceleration, wheel rotation rate,

"seat belts fastened" display)

● ambient conditions (e.g. temperature, rain sensor,

distance sensor)

As a rule such data is transient, not

stored for longer than an operational

cycle, and only processed on board

the vehicle itself. Control units often

include data storage (including the

vehicle key). This is used to allow

information to be documented

temporarily or permanently on vehicle

condition, component stress,

maintenance requirements and

technical events and errors.Depending on technical equipment

level, the data stored is as follows:

● system component operating states (e.g. fill level, tyre

pressure, battery status)

● faults and defects in important system components (e.g. lights,brakes)

● system reactions in special driving situations (e.g. triggering

of an airbag, actuation of the

stability control systems)

● information on events damaging the vehicle

● for electric vehicles the amount of

charge in the high-voltage

battery, estimated range

In special cases (e.g. if the vehicle

has detected a malfunction), it may be

necessary to save data that would

otherwise just be volatile.

When you use services (e.g. repairs,

maintenance), the operating data

saved can be read together with the

vehicle identification number and

used when necessary. Staff working

for the service network ( e.g. garages,

manufacturers) or third parties (e.g.breakdown services) can read the

data from the vehicle. The same

applies to warranty work and quality

assurance measures.

Data is generally read via the OBD

(On-Board Diagnostics) port

prescribed by law in the vehicle. The operating data which is read out,

documents the technical condition of

the vehicle or individual components

and assists with fault diagnosis,

compliance with warranty obligations

and quality improvement. This data,

in particular information on

component stress, technical events,

operator errors and other faults, is

transmitted to the manufacturer

where appropriate, together with the

vehicle identification number. The

manufacturer is also subject to

product liability. The manufacturer

potentially also uses operating data

from vehicles for product recalls. This

data can also be used to check

customer warranty and guarantee

claims.

Fault memories in the vehicle can be

reset by a service company when

carrying out servicing or repairs or at

your request.

Page 244 of 251

242IndexAAbsorptive Glass Mat battery .....187

Accessories and vehicle modifications .......................... 181

Active emergency braking ..105, 167

AdBlue ........................ 103, 147, 228

AdBlue gauge ............................... 95

AdBlue tank ................................ 232

Adjustable air vents ...................133

Airbag and belt tensioners .........100

Airbag deactivation ..............65, 100

Airbag label................................... 61 Airbag system .............................. 61

Air conditioning regular operation ................................ 134

Air conditioning system .............. 121

Air intake .................................... 134

Air suspension ........................... 144

Air suspension system................ 221

Air vents...................................... 133

Antifreeze ................................... 185

Antilock brake system ................ 158

Antilock brake system (ABS) .....102

Anti-theft alarm system ................38

Anti-theft bolts............................. 214

Anti-theft locking system .............. 37

Anti-theft security lock ..................25

Appearance care ........................222

Armrest ........................................ 53

Ashtrays ....................................... 93Automatic light control ...............112

Automatic locking ...................26, 31

Autostop ....................... 19, 139, 140

Auxiliary heater ........................... 127

B Battery .................... 23, 24, 127, 187

Battery discharge protection ......119

Battery, jump starting.................. 218

Belts.............................................. 57 Bonnet ....................................... 182

Bottle holders................................ 77

Brake assist ............................... 160

Brake fluid .......................... 187, 228

Brakes ............................... 158, 187

Brake system ............................. 102

Breakdown.................................. 221

Bulb replacement ....................... 191

Bus Rear seats ................................. 54

C Cabin bulkhead grille ....................83

Capacities .................................. 232

Cargo management system ........80

Car Pass ...................................... 23

Catalytic converter .....................146

Central locking system ................26

Centre high-mounted brake light 197

Changing tyre and wheel size ...210

Charging system ........................ 101

Page 249 of 251

247Upholstery.................................. 224

USB socket ................................... 91

Using this manual ..........................3

V Vehicle battery ...................187, 218

Vehicle checks............................ 182

Vehicle data ................................ 232

Vehicle data recording and privacy ..................................... 238

Vehicle Identification Number ....230

Vehicle jack ................................ 204

Vehicle messages .....................107

Vehicle security ............................ 37

Vehicle specific data ......................3

Vehicle storage ........................... 181

Vehicle tools ............................... 204

Vehicle unlocking ........................... 6

Ventilation ................................... 120

W

Warning chimes .........................108

Warning lights ............................... 93

Warning triangle .......................... 83

Washer and wiper systems .........17

Washer fluid ............................... 186

Washing the vehicle ...................222

Wheel changing .........................214

Wheel covers ............................. 210

Wheels and tyres .......................205

Wheel wrench ............................. 204Wide view mirror.....................42, 45

Window guard............................... 83

Windows ....................................... 43

Windscreen................................... 43

Windscreen wiper and washer ....89

Winter tyres ............................... 206

Wiper blade replacement ..........190