engine OPEL MOVANO_B 2019 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2019, Model line: MOVANO_B, Model: OPEL MOVANO_B 2019Pages: 251, PDF Size: 6.46 MB

Page 203 of 251

Vehicle care201

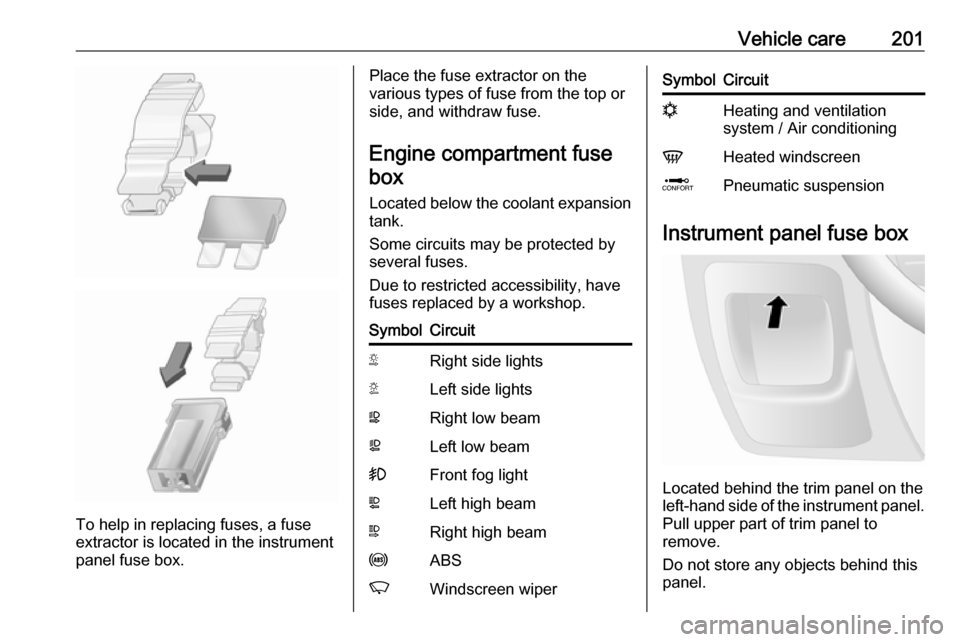

To help in replacing fuses, a fuse

extractor is located in the instrument

panel fuse box.

Place the fuse extractor on the

various types of fuse from the top or

side, and withdraw fuse.

Engine compartment fusebox

Located below the coolant expansion tank.

Some circuits may be protected by

several fuses.

Due to restricted accessibility, have

fuses replaced by a workshop.SymbolCircuitSRight side lightsTLeft side lightsWRight low beamaLeft low beam>Front fog lightLLeft high beamNRight high beamuABSKWindscreen wiperSymbolCircuitnHeating and ventilation

system / Air conditioningVHeated windscreenQPneumatic suspension

Instrument panel fuse box

Located behind the trim panel on the

left-hand side of the instrument panel.

Pull upper part of trim panel to

remove.

Do not store any objects behind this

panel.

Page 210 of 251

208Vehicle careLow tyre pressure condition

A detected low tyre pressure

condition is indicated by illumination

of control indicator w 3 104 and a

corresponding message appears in

the Driver Information Centre.

If w illuminates, stop as soon as

possible and inflate the tyres as

recommended 3 233.

After inflating, some driving may be

required to update the tyre pressure

values in the system. During this time

w may illuminate.

If w illuminates at lower temperatures

and extinguishes after some driving,

this could be an indicator for

approaching a low tyre pressure

condition. Check tyre pressure of all

four tyres.

If the tyre pressure must be reduced

or increased, switch off ignition.

Only mount wheels with pressure

sensors, otherwise w flashes for

several seconds then illuminates

continuously together with control

indicator A 3 101 and a

corresponding message appears in

the Driver Information Centre.

A spare wheel or temporary spare

wheel is not equipped with pressure

sensors. The tyre pressure

monitoring system is not operational

for these wheels. For the further three wheels, the tyre pressure monitoring

system remains operational.

Control indicator w and the

corresponding message appears at

each ignition cycle until the tyres are

inflated to the correct tyre pressure.

Driver Information Centre 3 106.

Vehicle messages 3 107.Puncture

A puncture or severely under-inflated

tyre is indicated by illumination of

control indicator w together with C

3 102 and a corresponding message

appears in the Driver Information

Centre. Stop vehicle and switch off

engine.

Tyre pressure 3 233.

Tyre repair kit 3 211.

Spare wheel 3 216.

Wheel changing 3 214.

Relearn function

Page 214 of 251

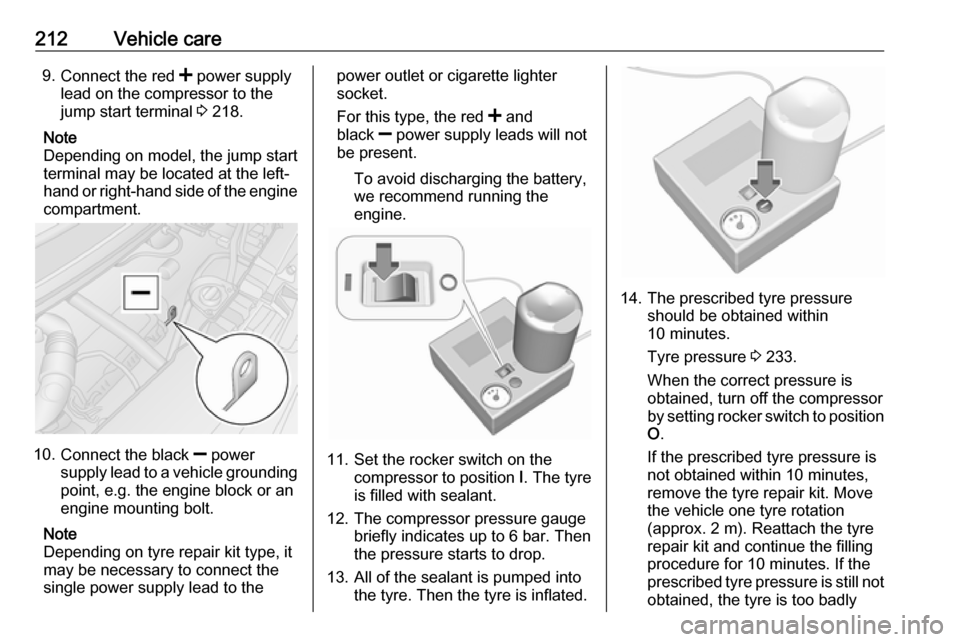

212Vehicle care9.Connect the red < power supply

lead on the compressor to the

jump start terminal 3 218.

Note

Depending on model, the jump start

terminal may be located at the left-

hand or right-hand side of the engine compartment.

10. Connect the black ] power

supply lead to a vehicle grounding

point, e.g. the engine block or an

engine mounting bolt.

Note

Depending on tyre repair kit type, it

may be necessary to connect the

single power supply lead to the

power outlet or cigarette lighter

socket.

For this type, the red < and

black ] power supply leads will not

be present.

To avoid discharging the battery,

we recommend running the

engine.

11. Set the rocker switch on the compressor to position I. The tyre

is filled with sealant.

12. The compressor pressure gauge briefly indicates up to 6 bar. Then

the pressure starts to drop.

13. All of the sealant is pumped into the tyre. Then the tyre is inflated.

14. The prescribed tyre pressureshould be obtained within

10 minutes.

Tyre pressure 3 233.

When the correct pressure is

obtained, turn off the compressor

by setting rocker switch to position O .

If the prescribed tyre pressure is

not obtained within 10 minutes,

remove the tyre repair kit. Move

the vehicle one tyre rotation

(approx. 2 m). Reattach the tyre

repair kit and continue the filling

procedure for 10 minutes. If the

prescribed tyre pressure is still not

obtained, the tyre is too badly

Page 216 of 251

214Vehicle careWheel changingMake the following preparations and

observe the following information:

● Park the vehicle on a level, firm and non-slippery surface. The

front wheels must be in the

straight-ahead position.

● Apply the parking brake and engage first gear or reverse gear(manual transmission) or N

(manual transmission

automated).

● Switch off the air suspension system 3 144.

● Remove the spare wheel 3 216.

● Never change more than one wheel at a time.

● Use the jack only to change wheels in case of puncture, not

for seasonal winter or summer

tyre change.

● The jack is maintenance-free.

● If the ground on which the vehicle

is standing is soft, a solid board

(max. 1 cm thick) should be

placed under the jack.● No people or animals may be in the vehicle when it is jacked-up.

● Never crawl under a jacked-up vehicle.

● Do not start the engine when the vehicle is raised on the jack.

● Clean wheel bolts / nuts and their

threads before mounting the

wheel.9 Warning

Do not grease wheel bolt, wheel

nut and wheel nut cone.

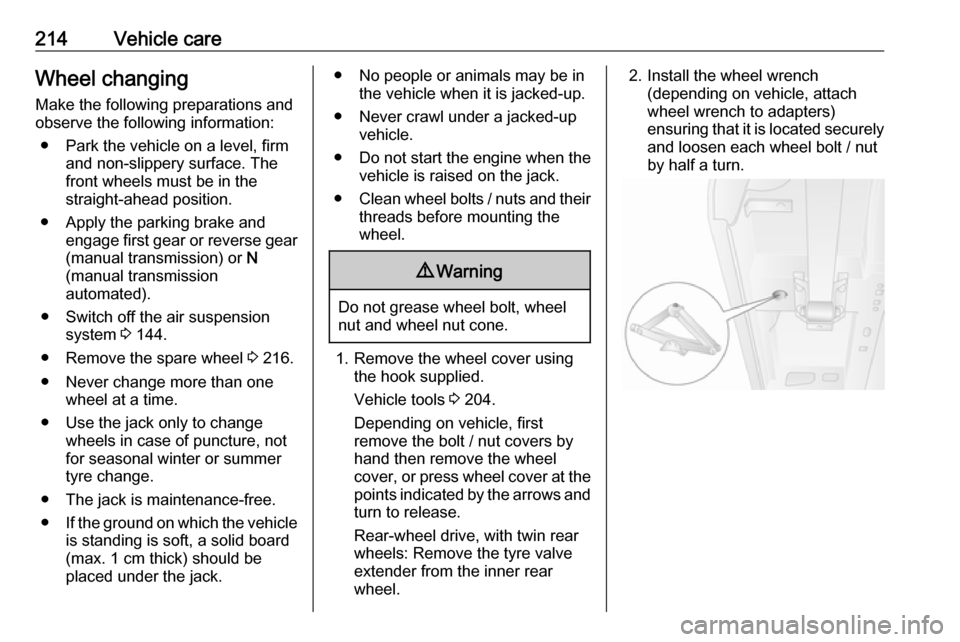

1. Remove the wheel cover using the hook supplied.

Vehicle tools 3 204.

Depending on vehicle, first

remove the bolt / nut covers by

hand then remove the wheel

cover, or press wheel cover at the points indicated by the arrows and

turn to release.

Rear-wheel drive, with twin rear

wheels: Remove the tyre valve

extender from the inner rear

wheel.

2. Install the wheel wrench (depending on vehicle, attach

wheel wrench to adapters)

ensuring that it is located securely and loosen each wheel bolt / nutby half a turn.

Page 220 of 251

218Vehicle careThen tighten cable using the wheel

wrench and adapters by connecting

to the slot position illustrated above

and turning wrench anticlockwise

until the wheel is secured in the fully

raised position.9 Warning

Ensure the front of the wheel (side

with tyre valve) is facing upwards

when the spare wheel is

reinstalled below the vehicle

frame.

Temporary spare wheel

Caution

The use of a spare wheel that is smaller than the other wheels or in combination with winter tyres

could affect driveability. Have the defective tyre replaced as soon as

possible.

Only mount one temporary spare

wheel. Do not drive faster than

80 km/h. Take curves slowly. Do not use for a long period of time.

Tyre chains 3 210.

Summer and winter tyres

If you use winter tyres, the spare

wheel may still be fitted with a

summer tyre.

If you use the spare wheel when it is

fitted with a summer tyre the vehicle's driveability may be affected,

especially on slippery road surfaces.

Directional tyres Fit directional tyres such that they rollin the direction of travel. The rolling

direction is indicated by a symbol

(e.g. an arrow) on the sidewall.

The following applies to tyres fitted

opposing the rolling direction:

● Driveability may be affected. Have the defective tyre renewed

or repaired as soon as possible

and fit it instead of the spare

wheel.

● Do not drive faster than 80 km/h.

● Drive particularly carefully on wet

and snow-covered road

surfaces.Jump starting

The jump start terminal is located in

the engine compartment.

A vehicle with a discharged vehicle

battery can be started using jump

leads and the vehicle battery of

another vehicle.

Do not start with a quick charger.9 Warning

Be extremely careful when starting

with jump leads. Any deviation

from the following instructions can

lead to injuries or damage caused

by battery explosion or damage to the electrical systems of both

vehicles.

9 Warning

Avoid contact of the battery with

eyes, skin, fabrics and painted

surfaces. The fluid contains

sulphuric acid which can cause

injuries and damage in the event

of direct contact.

Page 221 of 251

Vehicle care219Caution

The air suspension system must

be switched off prior to jump

starting.

Air suspension 3 144.

● Never expose the vehicle battery

to naked flames or sparks.

● A discharged vehicle battery can already freeze at a temperature

of 0 °C. Defrost the frozen vehicle

battery before connecting jump leads.

● Wear eye protection and protective clothing when

handling a vehicle battery.

● Use a booster battery with the same voltage (12 V). Its capacity(Ah) must not be much less than

that of the discharged vehicle

battery.

● Use jump leads with insulated terminals and a cross section of

at least 25 mm 2

.

● Do not disconnect the discharged

battery from the vehicle.

● Switch off all unnecessary electrical consumers.

● Switch off the air suspension system 3 144.

● Do not lean over the vehicle battery during jump starting.

● Do not allow the terminals of one

lead to touch those of the other

lead.

● The vehicles must not come into contact with each other during

the jump starting process.

● Apply the parking brake and engage neutral (manual

transmission) or N (manual

transmission automated).Jump start terminal

In the event of a discharged vehicle

battery, the jump start terminal

enables the vehicle to be started

without the need to access the battery inside the vehicle.

The jump start terminal is located in

the engine compartment and

identified by a " <" sign on the red

insulating cover. Lift the red insulating

cover to access the terminal

connector.

Ensure the red insulating cover is

latched back into position when not in

use.

Page 222 of 251

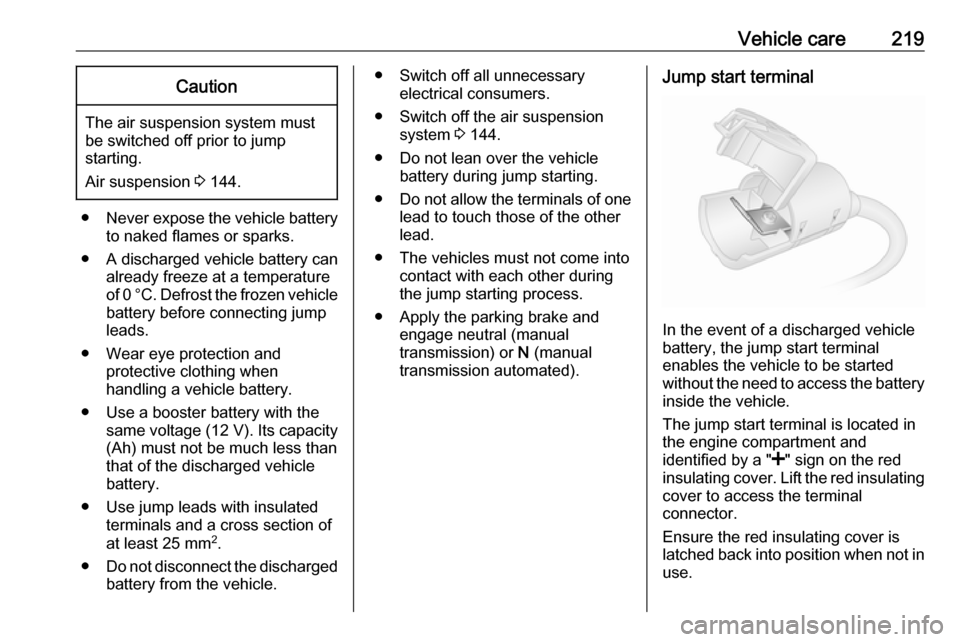

220Vehicle careJump starting procedure

Depending on model, the jump start

terminal may be located at the left-

hand or right-hand side of the engine

compartment.

Lead connection order:

1. Connect the red lead to the positive terminal (1) of the booster

battery.

2. Connect the other end of the red lead to the jump start terminal (2)

of the vehicle with the discharged

vehicle battery.

3. Connect the black lead to the negative terminal (3) of the

booster battery.

4. Connect the other end of the black

lead to a vehicle grounding point

(4), such as the engine block or an

engine mounting bolt. Connect as

far away from the discharged

vehicle battery as possible,

however at least 60 cm.

Route the leads so that they cannot

catch on rotating parts in the engine

compartment.

To start the engine: 1. Start the engine of the vehicle providing the jump start.

2. After 5 minutes, start the other engine. Start attempts should be

made for no longer than

15 seconds at an interval of

1 minute.

3. Allow both engines to idle for approx. 3 minutes with the leads

connected.

4. Switch on electrical consumers (e.g. headlights, heated rear

window) of the vehicle receiving

the jump start.

5. Reverse above sequence exactly when removing leads.

Page 223 of 251

Vehicle care221Towing

Towing the vehicle The towing eye and wheel wrench are stowed with the vehicle tools 3 204.

Disengage the cover using a suitable

tool and remove.

Screw the towing eye clockwise into

the front towing point and tighten fully using the wheel wrench.

Attach a tow rope – or better still a tow

rod – to the towing eye, never to the

bumper or front suspension units.

Caution

Do not tow the vehicle from the

rear. The front towing eye must

only be used for towing and not

recovering a vehicle.

Switch on ignition to permit operation

of brake lights, horn and windscreen

wipers, and move the steering wheel

slightly to release the steering wheel

lock.

Switch off the air suspension system 3 144.

Caution

Deactivate the driver assistance

systems like active emergency

braking 3 167, otherwise the

vehicle may automatically brake during towing.

Move the selector lever to neutral.

Release the parking brake.

Caution

Vehicles with manual

transmission automated: If neutral cannot be selected, the vehiclemust only be towed with the drive

wheels raised off the ground.

The vehicle should always be

towed with the ignition switched

off.

Manual transmission automated

3 154.

Caution

Drive slowly. Do not drive jerkily.

Excessive tractive force can

damage the vehicle.

When the engine is not running,

considerably more force is needed to

brake and steer.

To prevent the entry of exhaust fumes

from the towing vehicle, switch on the air recirculation system 3 121 and

close the windows.

Seek the assistance of a workshop.

Page 225 of 251

Vehicle care223If using a vehicle wash, comply with

the vehicle wash manufacturer's

instructions. The windscreen wipers must be switched off and the exterior

mirrors must be folded in. Remove

antenna and external accessories

such as roof racks etc.

If you wash your vehicle by hand,

make sure that the insides of the

wheel housings are also thoroughly

rinsed out.

Clean edges and folds on opened

doors and the bonnet as well as the

areas they cover.

Clean bright metal mouldings with a

cleaning solution approved for

aluminium to avoid damages.Caution

Always use a cleaning agent with

a pH value of four to nine.

Do not use cleaning agents on hot surfaces.

Have the door hinges of all doors

greased by a workshop.

Do not clean the engine compartment with a steam-jet or high-pressure jet

cleaner.

Thoroughly rinse and leather-off the vehicle. Rinse leather frequently. Use

separate leathers for painted and

glass surfaces: remnants of wax on

the windows will impair vision.

Do not use hard objects to remove

spots of tar. Use tar removal spray on

painted surfaces.

Exterior lights

Headlight and other light covers are

made of plastic. Do not use any

abrasive or caustic agents, do not use an ice scraper, and do not clean them

dry.

Polishing and waxing

Wax the vehicle regularly (at the

latest when water no longer beads).

Otherwise, the paintwork will dry out.

Polishing is necessary only if the paint

has become dull or if solid deposits

have become attached to it.Paintwork polish with silicone forms a

protective film, making waxing

unnecessary.

Unpainted plastic body parts must not be treated with wax or polishing

agents.

Matt filmed body parts or decor tapes must not be polished, to avoid

gleaming. Do not use hot wax

programmes in automatic car washes if the vehicle is equipped with theseparts.

Matt painted decor parts, e.g. mirror

housing cover, must not be polished.

Otherwise these parts would become

agleam or the colour would be

dissolved.

Windows and windscreen wiper

blades

Switch off wipers before handling in

their areas.

Use a soft lint-free cloth or chamois leather together with window cleaner

and insect remover.

When cleaning the rear window from

inside, always wipe in parallel to the

heating element to prevent damage.

Page 228 of 251

226Service and maintenanceService and

maintenanceGeneral information ...................226

Service information ..................226

Recommended fluids, lubricants

and parts .................................... 228

Recommended fluids and lubricants ................................ 228General information

Service information In order to ensure economical and

safe vehicle operation and to

maintain the value of your vehicle, it

is of vital importance that all

maintenance work is carried out at the proper intervals as specified.

The detailed, up-to-date service

schedule for the vehicle is available at

the workshop.

Service display 3 96.

Engine identification 3 231.

European service intervals -

except Bus

Maintenance of your vehicle is

required every 40,000 km or after

two years, whichever occurs first, unless otherwise indicated by the

service display.

A shorter service interval can be valid for severe driving behaviour, e.g. for

taxis and police vehicles.European service intervals - Bus

only

Maintenance of your vehicle is

required every 30,000 km or after

one year, whichever occurs first, unless otherwise indicated by the

service display.

The European service intervals are

valid for the following countries:

Andorra, Austria, Belgium, Croatia,

Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece,

Hungary, Iceland, Ireland, Italy,

Latvia, Liechtenstein, Lithuania,

Luxembourg, Netherlands, Norway,

Poland, Portugal, Slovakia, Slovenia,

Spain, Sweden, Switzerland, United

Kingdom.