remove seats OPEL VECTRA 1988 Service User Guide

[x] Cancel search | Manufacturer: OPEL, Model Year: 1988, Model line: VECTRA, Model: OPEL VECTRA 1988Pages: 525, PDF Size: 58.26 MB

Page 226 of 525

Inspection

3Check the clearance between the inner and

outer gear teeth (backlash) using a feeler

blade (see illustration).

4Check the clearance between the edges of

the gears and the housing (endfloat) using a

straight edge and a feeler blade (see

illustration).

5If any of the clearances are outside the

specified limits, renew the components as

necessary.

6Ensure that the gears and the interior of the

pump body are scrupulously clean before

reassembly, and note that the outer gear is

marked with a punch dot to indicate the gear

outer face.

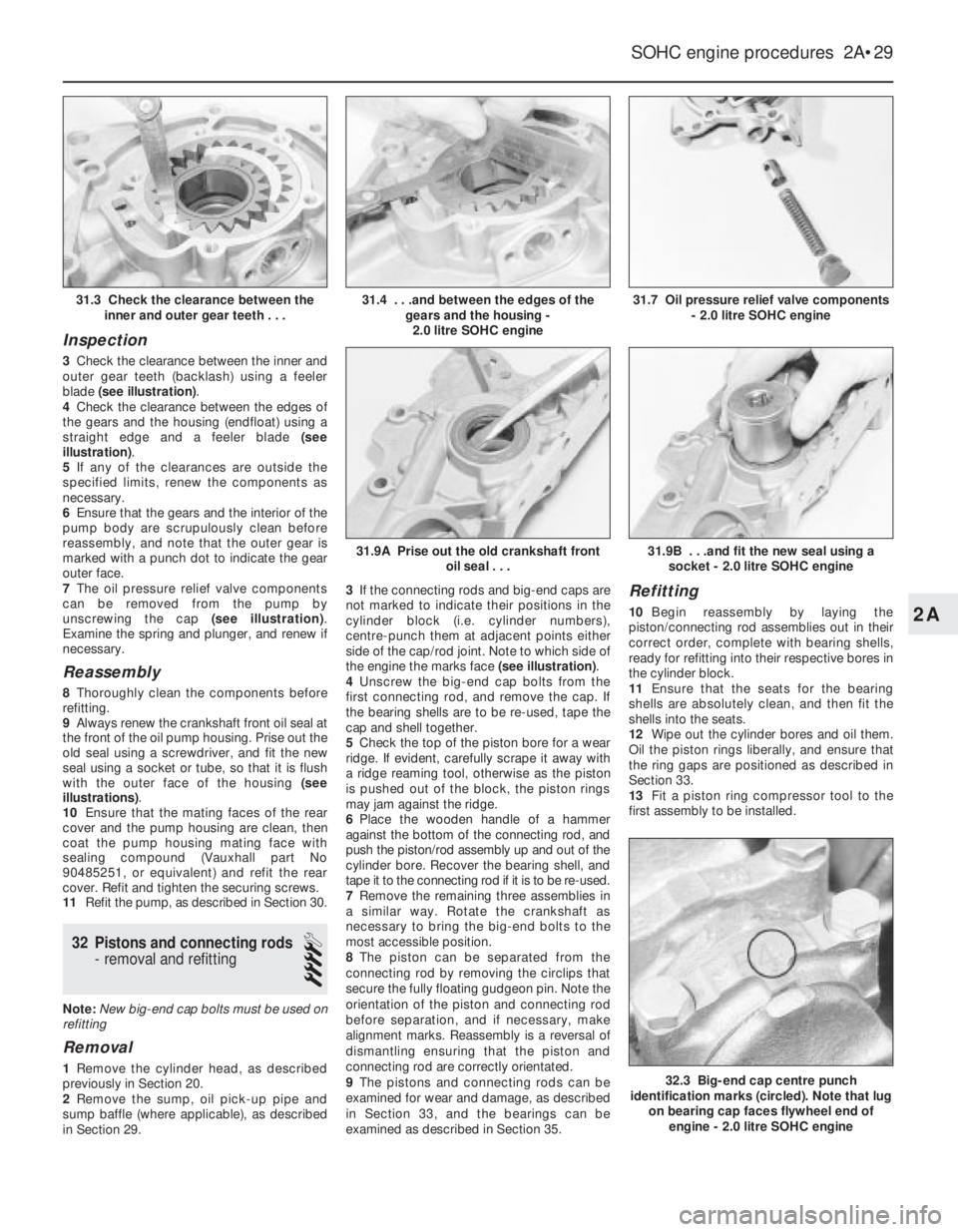

7The oil pressure relief valve components

can be removed from the pump by

unscrewing the cap (see illustration).

Examine the spring and plunger, and renew if

necessary.

Reassembly

8Thoroughly clean the components before

refitting.

9Always renew the crankshaft front oil seal at

the front of the oil pump housing. Prise out the

old seal using a screwdriver, and fit the new

seal using a socket or tube, so that it is flush

with the outer face of the housing (see

illustrations).

10Ensure that the mating faces of the rear

cover and the pump housing are clean, then

coat the pump housing mating face with

sealing compound (Vauxhall part No

90485251, or equivalent) and refit the rear

cover. Refit and tighten the securing screws.

11Refit the pump, as described in Section 30.

32Pistons and connecting rods

- removal and refitting

4

Note: New big-end cap bolts must be used on

refitting

Removal

1Remove the cylinder head, as described

previously in Section 20.

2Remove the sump, oil pick-up pipe and

sump baffle (where applicable), as described

in Section 29.3If the connecting rods and big-end caps are

not marked to indicate their positions in the

cylinder block (i.e. cylinder numbers),

centre-punch them at adjacent points either

side of the cap/rod joint. Note to which side of

the engine the marks face (see illustration).

4Unscrew the big-end cap bolts from the

first connecting rod, and remove the cap. If

the bearing shells are to be re-used, tape the

cap and shell together.

5Check the top of the piston bore for a wear

ridge. If evident, carefully scrape it away with

a ridge reaming tool, otherwise as the piston

is pushed out of the block, the piston rings

may jam against the ridge.

6Place the wooden handle of a hammer

against the bottom of the connecting rod, and

push the piston/rod assembly up and out of the

cylinder bore. Recover the bearing shell, and

tape it to the connecting rod if it is to be re-used.

7Remove the remaining three assemblies in

a similar way. Rotate the crankshaft as

necessary to bring the big-end bolts to the

most accessible position.

8The piston can be separated from the

connecting rod by removing the circlips that

secure the fully floating gudgeon pin. Note the

orientation of the piston and connecting rod

before separation, and if necessary, make

alignment marks. Reassembly is a reversal of

dismantling ensuring that the piston and

connecting rod are correctly orientated.

9The pistons and connecting rods can be

examined for wear and damage, as described

in Section 33, and the bearings can be

examined as described in Section 35.

Refitting

10Begin reassembly by laying the

piston/connecting rod assemblies out in their

correct order, complete with bearing shells,

ready for refitting into their respective bores in

the cylinder block.

11Ensure that the seats for the bearing

shells are absolutely clean, and then fit the

shells into the seats.

12Wipe out the cylinder bores and oil them.

Oil the piston rings liberally, and ensure that

the ring gaps are positioned as described in

Section 33.

13Fit a piston ring compressor tool to the

first assembly to be installed.

SOHC engine procedures 2A•29

31.7 Oil pressure relief valve components

- 2.0 litre SOHC engine

32.3 Big-end cap centre punch

identification marks (circled). Note that lug

on bearing cap faces flywheel end of

engine - 2.0 litre SOHC engine

31.9B . . .and fit the new seal using a

socket - 2.0 litre SOHC engine31.9A Prise out the old crankshaft front

oil seal . . .

31.4 . . .and between the edges of the

gears and the housing -

2.0 litre SOHC engine31.3 Check the clearance between the

inner and outer gear teeth . . .

2A

Page 228 of 525

7If any of the ring end gaps exceed the

specified tolerance, the relevant rings will have

to be renewed, and if the ring grooves in the

pistons are worn, new pistons may be required.

8Clean out the piston ring grooves using a

piece of old piston ring as a scraper. Take

care not to scratch the surface of the pistons.

Protect your fingers, piston ring edges are

sharp. Also probe the groove oil return holes,

to ensure that they are not blocked.

9Check the cylinder bores for signs of wear

ridges towards the top of the bores. If wear

ridges are evident, and new piston rings are

being fitted, the top ring must be stepped to

clear the wear ridge, or the bore must be

de-ridged using a scraper.

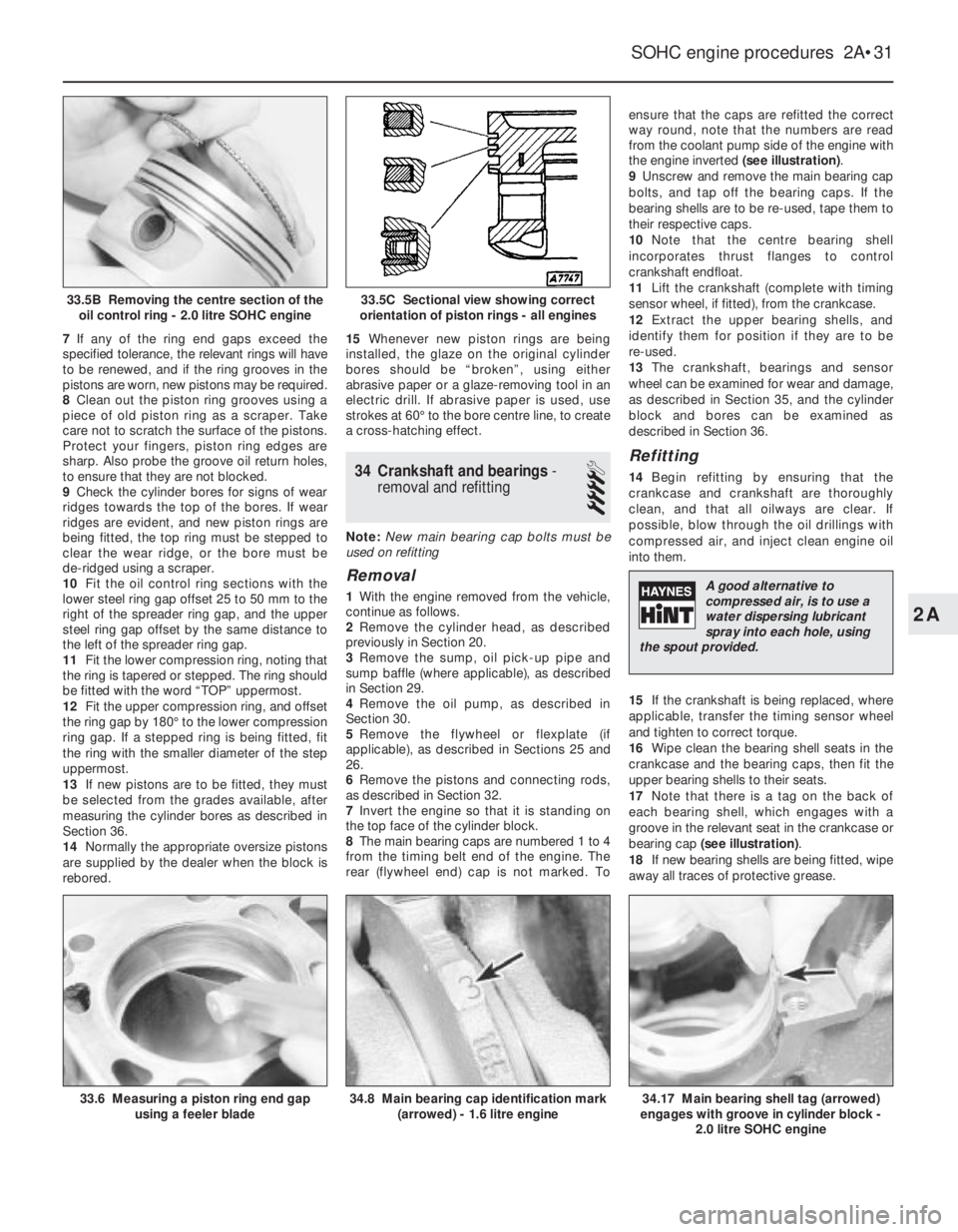

10Fit the oil control ring sections with the

lower steel ring gap offset 25 to 50 mm to the

right of the spreader ring gap, and the upper

steel ring gap offset by the same distance to

the left of the spreader ring gap.

11Fit the lower compression ring, noting that

the ring is tapered or stepped. The ring should

be fitted with the word “TOP” uppermost.

12Fit the upper compression ring, and offset

the ring gap by 180°to the lower compression

ring gap. If a stepped ring is being fitted, fit

the ring with the smaller diameter of the step

uppermost.

13If new pistons are to be fitted, they must

be selected from the grades available, after

measuring the cylinder bores as described in

Section 36.

14Normally the appropriate oversize pistons

are supplied by the dealer when the block is

rebored.15Whenever new piston rings are being

installed, the glaze on the original cylinder

bores should be “broken”, using either

abrasive paper or a glaze-removing tool in an

electric drill. If abrasive paper is used, use

strokes at 60°to the bore centre line, to create

a cross-hatching effect.

34Crankshaft and bearings -

removal and refitting

4

Note: New main bearing cap bolts must be

used on refitting

Removal

1With the engine removed from the vehicle,

continue as follows.

2Remove the cylinder head, as described

previously in Section 20.

3Remove the sump, oil pick-up pipe and

sump baffle (where applicable), as described

in Section 29.

4Remove the oil pump, as described in

Section 30.

5Remove the flywheel or flexplate (if

applicable), as described in Sections 25 and

26.

6Remove the pistons and connecting rods,

as described in Section 32.

7Invert the engine so that it is standing on

the top face of the cylinder block.

8The main bearing caps are numbered 1 to 4

from the timing belt end of the engine. The

rear (flywheel end) cap is not marked. Toensure that the caps are refitted the correct

way round, note that the numbers are read

from the coolant pump side of the engine with

the engine inverted (see illustration).

9Unscrew and remove the main bearing cap

bolts, and tap off the bearing caps. If the

bearing shells are to be re-used, tape them to

their respective caps.

10Note that the centre bearing shell

incorporates thrust flanges to control

crankshaft endfloat.

11Lift the crankshaft (complete with timing

sensor wheel, if fitted), from the crankcase.

12Extract the upper bearing shells, and

identify them for position if they are to be

re-used.

13The crankshaft, bearings and sensor

wheel can be examined for wear and damage,

as described in Section 35, and the cylinder

block and bores can be examined as

described in Section 36.

Refitting

14Begin refitting by ensuring that the

crankcase and crankshaft are thoroughly

clean, and that all oilways are clear. If

possible, blow through the oil drillings with

compressed air, and inject clean engine oil

into them.

15If the crankshaft is being replaced, where

applicable, transfer the timing sensor wheel

and tighten to correct torque.

16Wipe clean the bearing shell seats in the

crankcase and the bearing caps, then fit the

upper bearing shells to their seats.

17Note that there is a tag on the back of

each bearing shell, which engages with a

groove in the relevant seat in the crankcase or

bearing cap (see illustration).

18If new bearing shells are being fitted, wipe

away all traces of protective grease.

SOHC engine procedures 2A•31

33.6 Measuring a piston ring end gap

using a feeler blade34.8 Main bearing cap identification mark

(arrowed) - 1.6 litre engine34.17 Main bearing shell tag (arrowed)

engages with groove in cylinder block -

2.0 litre SOHC engine

33.5C Sectional view showing correct

orientation of piston rings - all engines33.5B Removing the centre section of the

oil control ring - 2.0 litre SOHC engine

2A

A good alternative to

compressed air, is to use a

water dispersing lubricant

spray into each hole, using

the spout provided.