trip computer OPEL VECTRA 1988 Service User Guide

[x] Cancel search | Manufacturer: OPEL, Model Year: 1988, Model line: VECTRA, Model: OPEL VECTRA 1988Pages: 525, PDF Size: 58.26 MB

Page 120 of 525

Refitting

11Refitting is a reversal of removal, but

make sure that the column switch gaiters

engage in the cut-outs in the upper shroud.

Instrument panel lower trim

panel

Removal

12Remove the steering column shrouds, as

described previously in this Section.

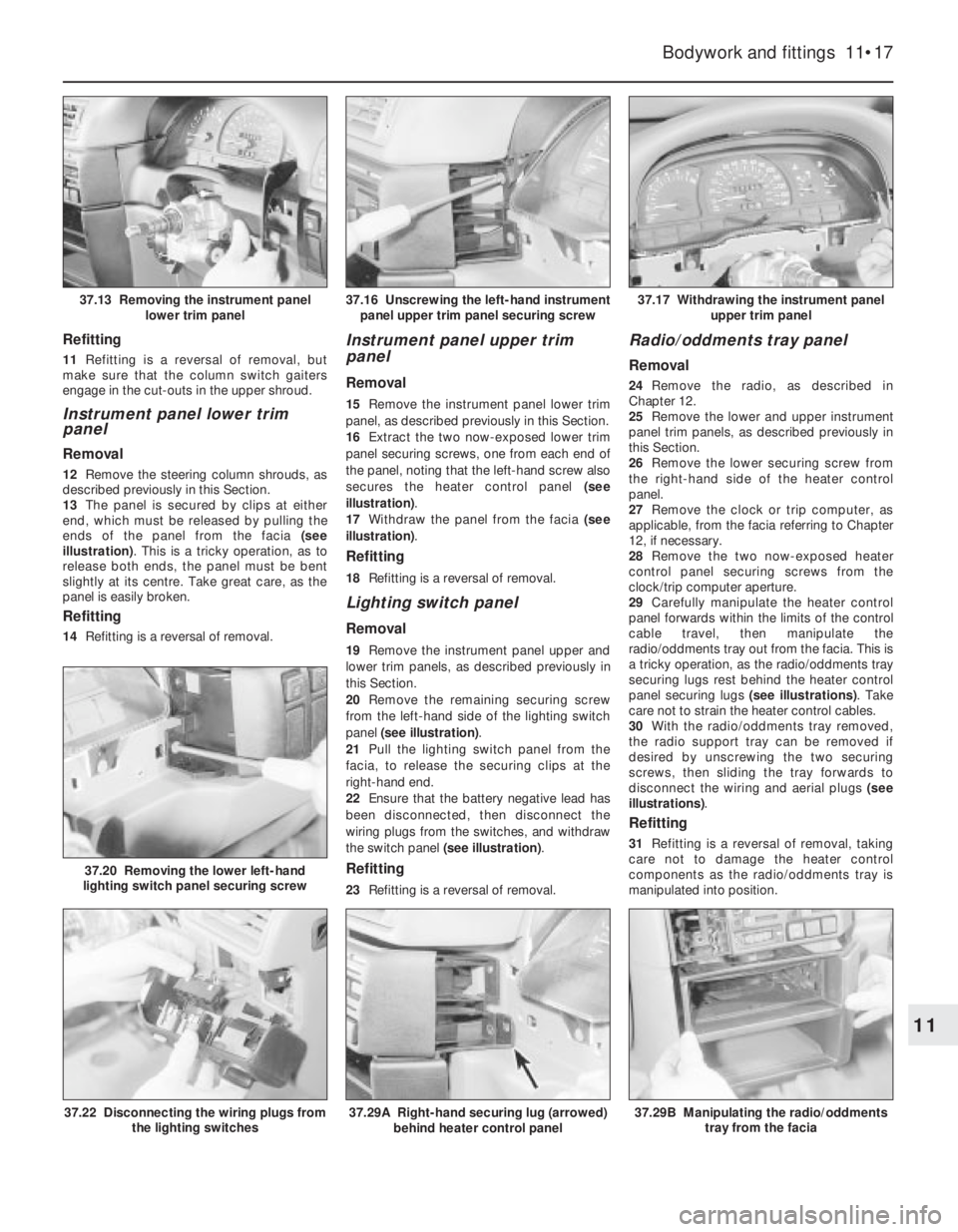

13The panel is secured by clips at either

end, which must be released by pulling the

ends of the panel from the facia (see

illustration). This is a tricky operation, as to

release both ends, the panel must be bent

slightly at its centre. Take great care, as the

panel is easily broken.

Refitting

14Refitting is a reversal of removal.

Instrument panel upper trim

panel

Removal

15Remove the instrument panel lower trim

panel, as described previously in this Section.

16Extract the two now-exposed lower trim

panel securing screws, one from each end of

the panel, noting that the left-hand screw also

secures the heater control panel (see

illustration).

17Withdraw the panel from the facia (see

illustration).

Refitting

18Refitting is a reversal of removal.

Lighting switch panel

Removal

19Remove the instrument panel upper and

lower trim panels, as described previously in

this Section.

20Remove the remaining securing screw

from the left-hand side of the lighting switch

panel (see illustration).

21Pull the lighting switch panel from the

facia, to release the securing clips at the

right-hand end.

22Ensure that the battery negative lead has

been disconnected, then disconnect the

wiring plugs from the switches, and withdraw

the switch panel (see illustration).

Refitting

23Refitting is a reversal of removal.

Radio/oddments tray panel

Removal

24Remove the radio, as described in

Chapter 12.

25Remove the lower and upper instrument

panel trim panels, as described previously in

this Section.

26Remove the lower securing screw from

the right-hand side of the heater control

panel.

27Remove the clock or trip computer, as

applicable, from the facia referring to Chapter

12, if necessary.

28Remove the two now-exposed heater

control panel securing screws from the

clock/trip computer aperture.

29Carefully manipulate the heater control

panel forwards within the limits of the control

cable travel, then manipulate the

radio/oddments tray out from the facia. This is

a tricky operation, as the radio/oddments tray

securing lugs rest behind the heater control

panel securing lugs (see illustrations). Take

care not to strain the heater control cables.

30With the radio/oddments tray removed,

the radio support tray can be removed if

desired by unscrewing the two securing

screws, then sliding the tray forwards to

disconnect the wiring and aerial plugs (see

illustrations).

Refitting

31Refitting is a reversal of removal, taking

care not to damage the heater control

components as the radio/oddments tray is

manipulated into position.

Bodywork and fittings 11•17

37.17 Withdrawing the instrument panel

upper trim panel

37.29B Manipulating the radio/oddments

tray from the facia37.29A Right-hand securing lug (arrowed)

behind heater control panel37.22 Disconnecting the wiring plugs from

the lighting switches

37.20 Removing the lower left-hand

lighting switch panel securing screw

37.16 Unscrewing the left-hand instrument

panel upper trim panel securing screw37.13 Removing the instrument panel

lower trim panel

11

Page 122 of 525

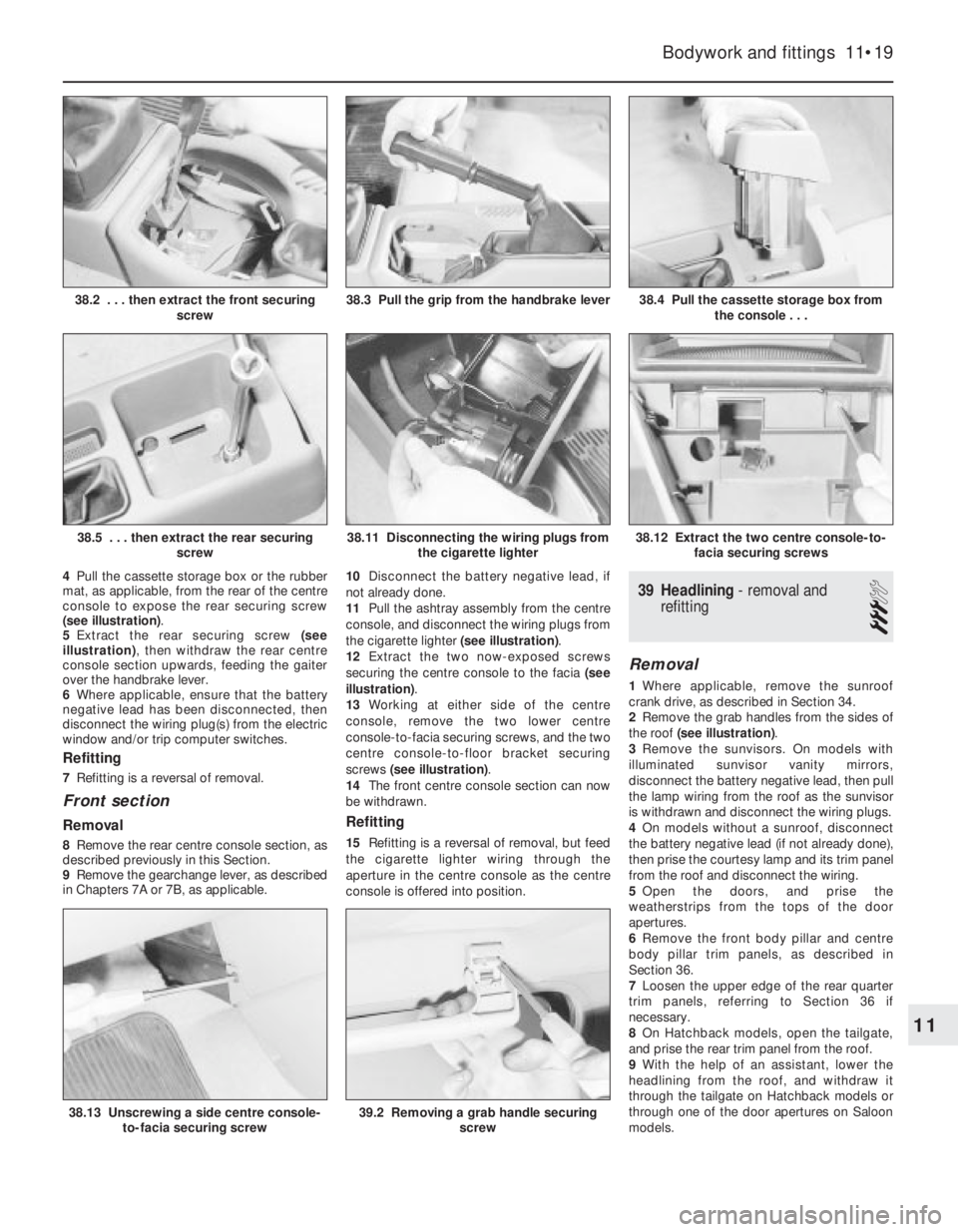

4Pull the cassette storage box or the rubber

mat, as applicable, from the rear of the centre

console to expose the rear securing screw

(see illustration).

5Extract the rear securing screw (see

illustration), then withdraw the rear centre

console section upwards, feeding the gaiter

over the handbrake lever.

6Where applicable, ensure that the battery

negative lead has been disconnected, then

disconnect the wiring plug(s) from the electric

window and/or trip computer switches.

Refitting

7Refitting is a reversal of removal.

Front section

Removal

8Remove the rear centre console section, as

described previously in this Section.

9Remove the gearchange lever, as described

in Chapters 7A or 7B, as applicable. 10Disconnect the battery negative lead, if

not already done.

11Pull the ashtray assembly from the centre

console, and disconnect the wiring plugs from

the cigarette lighter (see illustration).

12Extract the two now-exposed screws

securing the centre console to the facia (see

illustration).

13Working at either side of the centre

console, remove the two lower centre

console-to-facia securing screws, and the two

centre console-to-floor bracket securing

screws (see illustration).

14The front centre console section can now

be withdrawn.

Refitting

15Refitting is a reversal of removal, but feed

the cigarette lighter wiring through the

aperture in the centre console as the centre

console is offered into position.

39Headlining -removal and

refitting

3

Removal

1Where applicable, remove the sunroof

crank drive, as described in Section 34.

2Remove the grab handles from the sides of

the roof (see illustration).

3Remove the sunvisors. On models with

illuminated sunvisor vanity mirrors,

disconnect the battery negative lead, then pull

the lamp wiring from the roof as the sunvisor

is withdrawn and disconnect the wiring plugs.

4On models without a sunroof, disconnect

the battery negative lead (if not already done),

then prise the courtesy lamp and its trim panel

from the roof and disconnect the wiring.

5Open the doors, and prise the

weatherstrips from the tops of the door

apertures.

6Remove the front body pillar and centre

body pillar trim panels, as described in

Section 36.

7Loosen the upper edge of the rear quarter

trim panels, referring to Section 36 if

necessary.

8On Hatchback models, open the tailgate,

and prise the rear trim panel from the roof.

9With the help of an assistant, lower the

headlining from the roof, and withdraw it

through the tailgate on Hatchback models or

through one of the door apertures on Saloon

models.

Bodywork and fittings 11•19

38.4 Pull the cassette storage box from

the console . . .

38.12 Extract the two centre console-to-

facia securing screws38.11 Disconnecting the wiring plugs from

the cigarette lighter

38.3 Pull the grip from the handbrake lever38.2 . . . then extract the front securing

screw

11

38.5 . . . then extract the rear securing

screw

38.13 Unscrewing a side centre console-

to-facia securing screw39.2 Removing a grab handle securing

screw

Page 237 of 525

4Position a container beneath the tank, then

disconnect the bottom hose and allow the

contents of the tank to drain into the

container. Suspend the bottom hose as high

as possible above the engine to prevent

coolant loss.

Refitting

5Refitting is a reversal of removal, but on

completion check and if necessary top-up the

coolant level, as described in Section 4. The

coolant drained from the expansion tank

during removal can be re-used, provided it

has not been contaminated.

Coolant level sensor

6The coolant level sensor, where fitted, is an

integral part of the expansion tank cap. If the

level sensor is faulty, the complete cap

assembly must be renewed.

14Temperature gauge sender -

removal and refitting

2

Removal

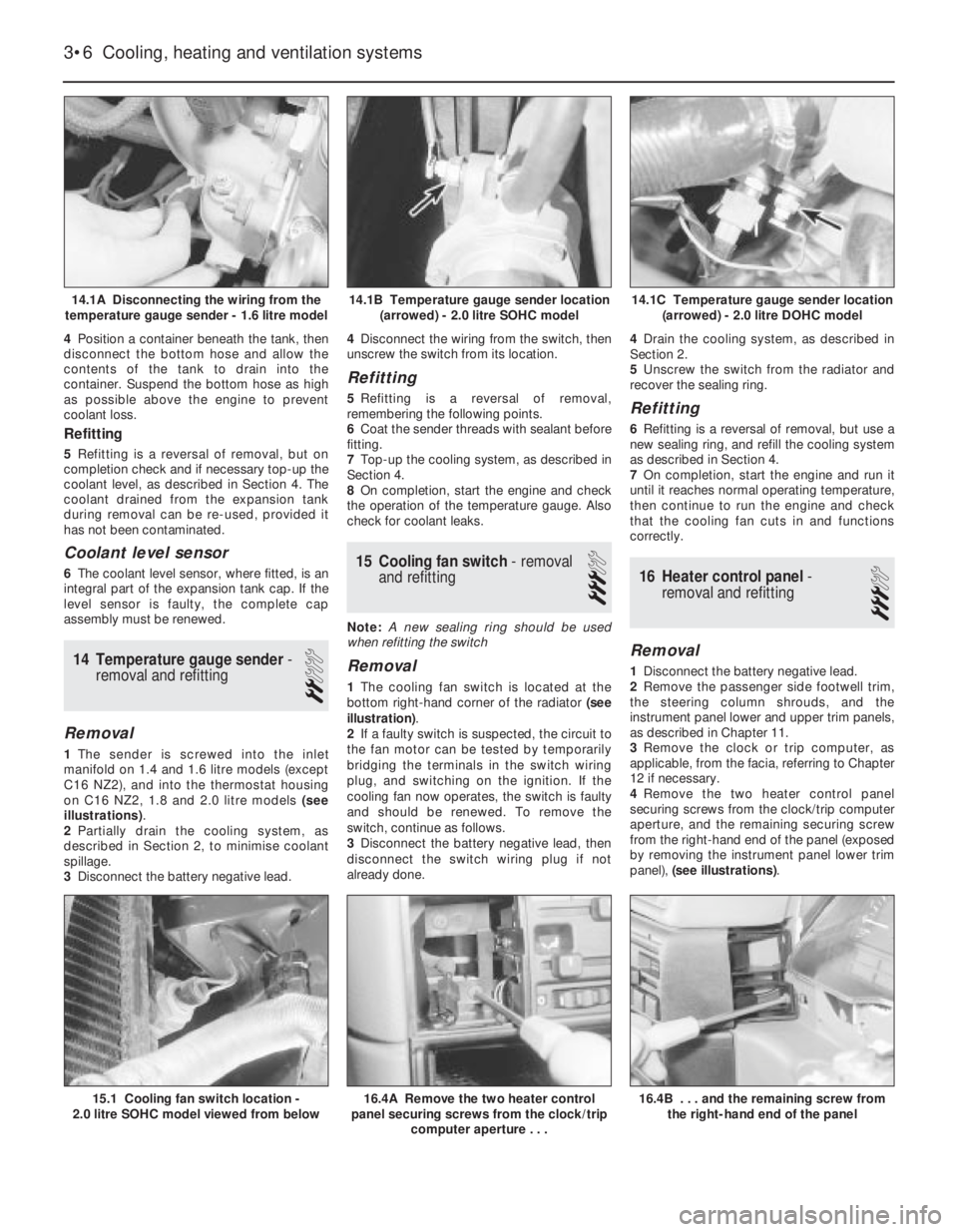

1The sender is screwed into the inlet

manifold on 1.4 and 1.6 litre models (except

C16 NZ2), and into the thermostat housing

on C16 NZ2, 1.8 and 2.0 litre models (see

illustrations).

2Partially drain the cooling system, as

described in Section 2, to minimise coolant

spillage.

3Disconnect the battery negative lead.4Disconnect the wiring from the switch, then

unscrew the switch from its location.

Refitting

5Refitting is a reversal of removal,

remembering the following points.

6Coat the sender threads with sealant before

fitting.

7Top-up the cooling system, as described in

Section 4.

8On completion, start the engine and check

the operation of the temperature gauge. Also

check for coolant leaks.

15Cooling fan switch -removal

and refitting

3

Note: A new sealing ring should be used

when refitting the switch

Removal

1The cooling fan switch is located at the

bottom right-hand corner of the radiator (see

illustration).

2If a faulty switch is suspected, the circuit to

the fan motor can be tested by temporarily

bridging the terminals in the switch wiring

plug, and switching on the ignition. If the

cooling fan now operates, the switch is faulty

and should be renewed. To remove the

switch, continue as follows.

3Disconnect the battery negative lead, then

disconnect the switch wiring plug if not

already done.4Drain the cooling system, as described in

Section 2.

5Unscrew the switch from the radiator and

recover the sealing ring.

Refitting

6Refitting is a reversal of removal, but use a

new sealing ring, and refill the cooling system

as described in Section 4.

7On completion, start the engine and run it

until it reaches normal operating temperature,

then continue to run the engine and check

that the cooling fan cuts in and functions

correctly.

16Heater control panel -

removal and refitting

3

Removal

1Disconnect the battery negative lead.

2Remove the passenger side footwell trim,

the steering column shrouds, and the

instrument panel lower and upper trim panels,

as described in Chapter 11.

3Remove the clock or trip computer, as

applicable, from the facia, referring to Chapter

12 if necessary.

4Remove the two heater control panel

securing screws from the clock/trip computer

aperture, and the remaining securing screw

from the right-hand end of the panel (exposed

by removing the instrument panel lower trim

panel), (see illustrations).

3•6Cooling, heating and ventilation systems

14.1A Disconnecting the wiring from the

temperature gauge sender - 1.6 litre model14.1C Temperature gauge sender location

(arrowed) - 2.0 litre DOHC model

16.4B . . . and the remaining screw from

the right-hand end of the panel16.4A Remove the two heater control

panel securing screws from the clock/trip

computer aperture . . .15.1 Cooling fan switch location -

2.0 litre SOHC model viewed from below

14.1B Temperature gauge sender location

(arrowed) - 2.0 litre SOHC model

Page 261 of 525

REF•22Glossary of Technical Terms

EEGR valveA valve used to introduce exhaust

gases into the intake air stream.

Electronic control unit (ECU)A computer

which controls (for instance) ignition and fuel

injection systems, or an anti-lock braking

system. For more information refer to the

Haynes Automotive Electrical and Electronic

Systems Manual.

Electronic Fuel Injection (EFI)A computer

controlled fuel system that distributes fuel

through an injector located in each intake port

of the engine.

Emergency brakeA braking system,

independent of the main hydraulic system,

that can be used to slow or stop the vehicle if

the primary brakes fail, or to hold the vehicle

stationary even though the brake pedal isn’t

depressed. It usually consists of a hand lever

that actuates either front or rear brakes

mechanically through a series of cables and

linkages. Also known as a handbrake or

parking brake.

EndfloatThe amount of lengthwise

movement between two parts. As applied to a

crankshaft, the distance that the crankshaft

can move forward and back in the cylinder

block.

Engine management system (EMS)A

computer controlled system which manages

the fuel injection and the ignition systems in

an integrated fashion.

Exhaust manifoldA part with several

passages through which exhaust gases leave

the engine combustion chambers and enter

the exhaust pipe.

FFan clutchA viscous (fluid) drive coupling

device which permits variable engine fan

speeds in relation to engine speeds.Feeler bladeA thin strip or blade of hardened

steel, ground to an exact thickness, used to

check or measure clearances between parts.

Firing orderThe order in which the engine

cylinders fire, or deliver their power strokes,

beginning with the number one cylinder.

Flywheel A heavy spinning wheel in which

energy is absorbed and stored by means of

momentum. On cars, the flywheel is attached

to the crankshaft to smooth out firing

impulses.

Free playThe amount of travel before any

action takes place. The “looseness” in a

linkage, or an assembly of parts, between the

initial application of force and actual

movement. For example, the distance the

brake pedal moves before the pistons in the

master cylinder are actuated.

FuseAn electrical device which protects a

circuit against accidental overload. The typical

fuse contains a soft piece of metal which is

calibrated to melt at a predetermined current

flow (expressed as amps) and break the

circuit.

Fusible linkA circuit protection device

consisting of a conductor surrounded by

heat-resistant insulation. The conductor is

smaller than the wire it protects, so it acts as

the weakest link in the circuit. Unlike a blown

fuse, a failed fusible link must frequently be

cut from the wire for replacement.

GGapThe distance the spark must travel in

jumping from the centre electrode to the sideelectrode in a spark plug. Also refers to the

spacing between the points in a contact

breaker assembly in a conventional points-

type ignition, or to the distance between the

reluctor or rotor and the pickup coil in an

electronic ignition.

GasketAny thin, soft material - usually cork,

cardboard, asbestos or soft metal - installed

between two metal surfaces to ensure a good

seal. For instance, the cylinder head gasket

seals the joint between the block and the

cylinder head.

GaugeAn instrument panel display used to

monitor engine conditions. A gauge with a

movable pointer on a dial or a fixed scale is an

analogue gauge. A gauge with a numerical

readout is called a digital gauge.

HHalfshaftA rotating shaft that transmits

power from the final drive unit to a drive

wheel, usually when referring to a live rear

axle.

Harmonic balancerA device designed to

reduce torsion or twisting vibration in the

crankshaft. May be incorporated in the

crankshaft pulley. Also known as a vibration

damper.

HoneAn abrasive tool for correcting small

irregularities or differences in diameter in an

engine cylinder, brake cylinder, etc.

Hydraulic tappetA tappet that utilises

hydraulic pressure from the engine’s

lubrication system to maintain zero clearance

(constant contact with both camshaft and

valve stem). Automatically adjusts to variation

in valve stem length. Hydraulic tappets also

reduce valve noise.

IIgnition timingThe moment at which the

spark plug fires, usually expressed in the

number of crankshaft degrees before the

piston reaches the top of its stroke.

Inlet manifoldA tube or housing with

passages through which flows the air-fuel

mixture (carburettor vehicles and vehicles with

throttle body injection) or air only (port fuel-

injected vehicles) to the port openings in the

cylinder head.

Exhaust manifold

Feeler blade

Adjusting spark plug gap

Gasket

EGR valve