suspension OPEL VECTRA 1988 Service Repair Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1988, Model line: VECTRA, Model: OPEL VECTRA 1988Pages: 525, PDF Size: 58.26 MB

Page 2 of 525

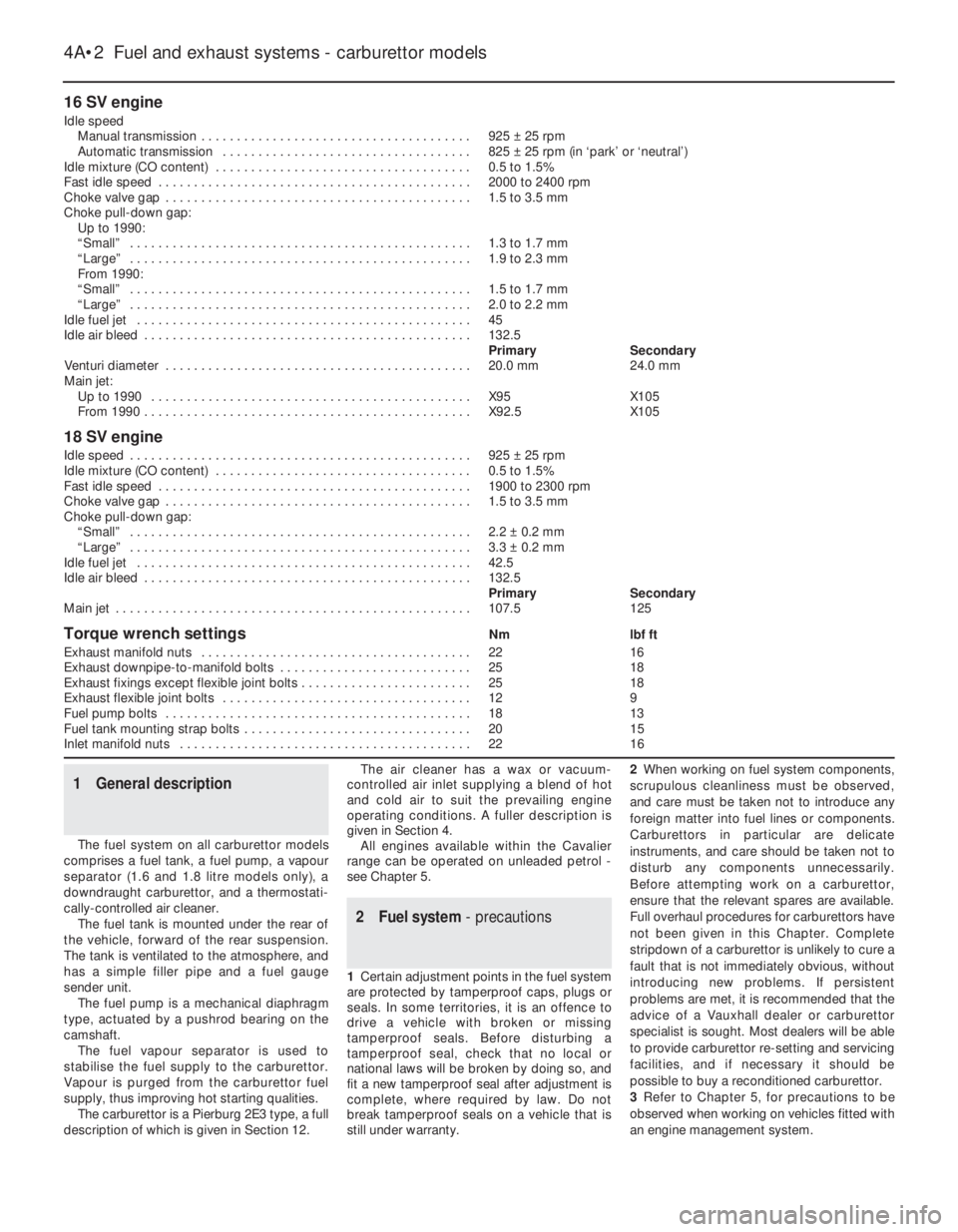

16 SV engine

Idle speed

Manual transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .925 ±25 rpm

Automatic transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .825 ±25 rpm (in ‘park’ or ‘neutral’)

Idle mixture (CO content) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.5 to 1.5%

Fast idle speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2000 to 2400 rpm

Choke valve gap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.5 to 3.5 mm

Choke pull-down gap:

Up to 1990:

“Small” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.3 to 1.7 mm

“Large” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.9 to 2.3 mm

From 1990:

“Small” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.5 to 1.7 mm

“Large” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.0 to 2.2 mm

Idle fuel jet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Idle air bleed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .132.5

PrimarySecondary

Venturi diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20.0 mm24.0 mm

Main jet:

Up to 1990 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .X95X105

From 1990 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .X92.5X105

18 SV engine

Idle speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .925 ±25 rpm

Idle mixture (CO content) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.5 to 1.5%

Fast idle speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1900 to 2300 rpm

Choke valve gap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.5 to 3.5 mm

Choke pull-down gap:

“Small” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.2 ±0.2 mm

“Large” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.3 ±0.2 mm

Idle fuel jet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42.5

Idle air bleed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .132.5

PrimarySecondary

Main jet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .107.5125

Torque wrench settingsNmlbf ft

Exhaust manifold nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2216

Exhaust downpipe-to-manifold bolts . . . . . . . . . . . . . . . . . . . . . . . . . . .2518

Exhaust fixings except flexible joint bolts . . . . . . . . . . . . . . . . . . . . . . . .2518

Exhaust flexible joint bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .129

Fuel pump bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1813

Fuel tank mounting strap bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2015

Inlet manifold nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2216

1General description

The fuel system on all carburettor models

comprises a fuel tank, a fuel pump, a vapour

separator (1.6 and 1.8 litre models only), a

downdraught carburettor, and a thermostati-

cally-controlled air cleaner.

The fuel tank is mounted under the rear of

the vehicle, forward of the rear suspension.

The tank is ventilated to the atmosphere, and

has a simple filler pipe and a fuel gauge

sender unit.

The fuel pump is a mechanical diaphragm

type, actuated by a pushrod bearing on the

camshaft.

The fuel vapour separator is used to

stabilise the fuel supply to the carburettor.

Vapour is purged from the carburettor fuel

supply, thus improving hot starting qualities.

The carburettor is a Pierburg 2E3 type, a full

description of which is given in Section 12.The air cleaner has a wax or vacuum-

controlled air inlet supplying a blend of hot

and cold air to suit the prevailing engine

operating conditions. A fuller description is

given in Section 4.

All engines available within the Cavalier

range can be operated on unleaded petrol -

see Chapter 5.

2Fuel system - precautions

1Certain adjustment points in the fuel system

are protected by tamperproof caps, plugs or

seals. In some territories, it is an offence to

drive a vehicle with broken or missing

tamperproof seals. Before disturbing a

tamperproof seal, check that no local or

national laws will be broken by doing so, and

fit a new tamperproof seal after adjustment is

complete, where required by law. Do not

break tamperproof seals on a vehicle that is

still under warranty.2When working on fuel system components,

scrupulous cleanliness must be observed,

and care must be taken not to introduce any

foreign matter into fuel lines or components.

Carburettors in particular are delicate

instruments, and care should be taken not to

disturb any components unnecessarily.

Before attempting work on a carburettor,

ensure that the relevant spares are available.

Full overhaul procedures for carburettors have

not been given in this Chapter. Complete

stripdown of a carburettor is unlikely to cure a

fault that is not immediately obvious, without

introducing new problems. If persistent

problems are met, it is recommended that the

advice of a Vauxhall dealer or carburettor

specialist is sought. Most dealers will be able

to provide carburettor re-setting and servicing

facilities, and if necessary it should be

possible to buy a reconditioned carburettor.

3Refer to Chapter 5, for precautions to be

observed when working on vehicles fitted with

an engine management system.

4A•2Fuel and exhaust systems - carburettor models

Page 4 of 525

4Unscrew the two securing bolts, and

withdraw the pump from the camshaft

housing (see illustration).

5Recover the plastic insulating block.

Refitting

6Refitting is a reversal of removal, but ensure

that the fuel hoses are reconnected to their

correct locations as noted during removal,

and tighten the securing bolts to the specified

torque.

7Run the engine and check for leaks on

completion. If leakage is evident, stop the

engine immediately and rectify the problem

without delay. Note that the engine may take

a longer time than usual to start when the

pump has been removed, as the pump refills

with fuel.

7Fuel tank - removal,

examination and refitting

4

Note: Refer to Section 2 before proceeding

Removal

1Disconnect the battery negative lead.

2Siphon out any remaining fuel in the tank

through the filler pipe. Siphon the fuel into a

clean metal container that can be sealed.

3Chock the front wheels, then jack up the

rear of the vehicle, and support securely on

axle stands (see “Jacking and Vehicle

Support”) placed under the body side

members.

4Disconnect the exhaust system front

flexible joint. Suspend the front section of the

exhaust system with wire or string from the

underbody.

5Disconnect the rear section of the exhaust

system from its rubber mountings, and allow it

to rest on the rear suspension torsion beam. It

is advisable to support the rear section of the

exhaust at its front end, with wire or string

from the underbody, to avoid straining the

system.

6Unclip the handbrake cable from the

bracket on the left-hand fuel tank securing

strap.

7Disconnect the fuel hoses from the fuel

level sender unit located in the right-hand side

of the fuel tank. Make a note of the hosepositions for use when refitting. Be prepared

for fuel spillage, and take adequate fire

precautions. Plug the open ends of the hoses,

to prevent dirt ingress and further fuel loss.

8Disconnect the wiring plug from the fuel

level sender unit.

9Disconnect the filler and vent hoses from

the rear of the fuel tank.

10Support the weight of the fuel tank on a

jack with an interposed block of wood.

11Unscrew the securing bolts from the tank

mounting straps, then remove the straps and

lower the tank sufficiently to enable the

disconnection of the remaining vent hose.

12With the aid of an assistant, withdraw the

tank sideways from the right-hand side of the

vehicle. Note that as the tank is withdrawn,

some residual fuel may be released.

Examination

13If the tank contains sediment or water, it

may be cleaned out using two or three rinses

with clean fuel. Shake vigorously using

several changes of fuel, but before doing so,

remove the fuel level sender unit, as

described in Section 8. This procedure should

be carried out in a well-ventilated area, and it

is vital to take adequate fire precautions -

refer to the “Safety first!” Section at the

beginning of this manual for further details.

14Any repairs to the fuel tank should be

carried out by a professional. Do not under

any circumstances attempt to weld or solder a

fuel tank. Removal of all residual fuel vapour

requires several hours of specialist cleaning.

Refitting

15Refitting is a reversal of removal, ensuring

that all hoses are reconnected to their correct

locations as noted during removal.

16On completion, fill the fuel tank, then run

the engine and check for leaks. If leakage is

evident, stop the engine immediately and

rectify the problem without delay. Note that

the engine may take a longer time than usual

to start when the fuel tank has been removed,

as the pump refills with fuel.

8Fuel level sender unit -

removal and refitting

3

Note: Refer to Section 2 before proceeding

Removal

1Disconnect the battery negative lead.

2Siphon out any remaining fuel in the tank

through the filler pipe. Siphon the fuel into a

clear metal container that can be sealed.

3Chock the front wheels, then jack up the rear

of the vehicle, and support securely on axle

stands (see “Jacking and Vehicle Support”)

placed under the body side members.

4The sender unit is located in the right-hand

side at the fuel tank.

5Make alignment marks on the sender unit

and the fuel tank, so that the sender unit can

be refitted in its original position.6Disconnect the fuel hoses from the sender

unit. Be prepared for fuel spillage, and take

adequate fire precautions. Plug the open ends

of the hoses, to prevent dirt ingress and

further fuel loss.

7Disconnect the wiring plug from the fuel

level sender unit.

8To remove the sender unit, engage a flat

piece of metal as a lever between two of the

slots on the sender unit rim, and turn it anti-

clockwise.

9Withdraw the unit carefully, to avoid

bending the float arm.

10Recover the sealing ring.

Refitting

11Refitting is a reversal of removal,

remembering the following points.

12Examine the condition of the sealing ring,

and renew if necessary.

13Ensure that the marks made on the

sender unit and fuel tank before removal are

aligned.

14Ensure that the hoses are reconnected to

their correct locations as noted during

removal.

15On completion, fill the fuel tank, then run

the engine and check for leaks. Also check

that the fuel gauge reads correctly. If leakage

is evident, stop the engine immediately and

rectify the problem without delay. Note that

the engine may take a longer time than usual

to start when the sender unit has been

removed, as the fuel pump refills with fuel.

9Fuel vapour separator (1.6

and 1.8 litre models) -

removal and refitting

3

Note: Refer to Section 2 before proceeding

Removal

1The fuel vapour separator is located on a

bracket attached to the side of the

carburettor.

2Note the locations of the three fuel hoses,

labelling them if necessary for use when

refitting, then disconnect the hoses from the

vapour separator. Be prepared for fuel

spillage, and take adequate fire precautions.

Plug the open ends of the hoses, to prevent

dirt ingress and further fuel spillage.

3Remove the two securing screws, and lift

the vapour separator from its bracket.

4Check the body of the separator for cracks

or leaks before refitting, and renew if

necessary.

Refitting

5Refitting is a reversal of removal, but ensure

that the three fuel hoses are connected to

their correct locations as noted during

removal.

6Run the engine and check the hose

connections for leaks on completion. If

leakage is evident, stop the engine

immediately and rectify the problem without

delay.

4A•4Fuel and exhaust systems - carburettor models

6.4 Withdrawing the fuel pump and plastic

insulating block - 1.6 litre model

Page 36 of 525

12•22Body electrical systems

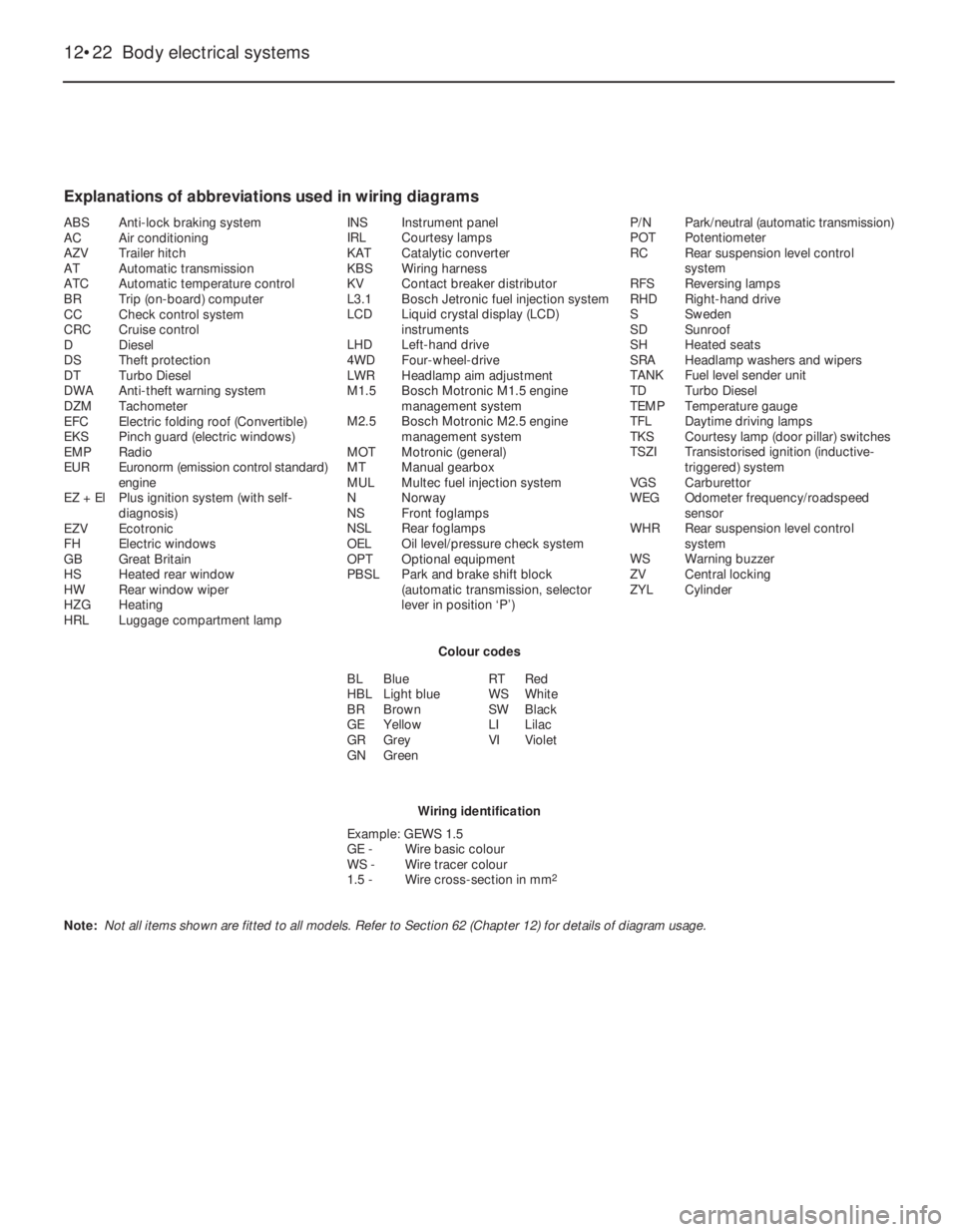

Explanations of abbreviations used in wiring diagrams

ABSAnti-lock braking system

ACAir conditioning

AZVTrailer hitch

ATAutomatic transmission

ATCAutomatic temperature control

BRTrip (on-board) computer

CCCheck control system

CRCCruise control

DDiesel

DSTheft protection

DTTurbo Diesel

DWAAnti-theft warning system

DZMTachometer

EFCElectric folding roof (Convertible)

EKSPinch guard (electric windows)

EMPRadio

EUREuronorm (emission control standard)

engine

EZ + ElPlus ignition system (with self-

diagnosis)

EZVEcotronic

FHElectric windows

GBGreat Britain

HSHeated rear window

HWRear window wiper

HZGHeating

HRLLuggage compartment lampINSInstrument panel

IRLCourtesy lamps

KATCatalytic converter

KBSWiring harness

KVContact breaker distributor

L3.1Bosch Jetronic fuel injection system

LCDLiquid crystal display (LCD)

instruments

LHDLeft-hand drive

4WDFour-wheel-drive

LWRHeadlamp aim adjustment

M1.5Bosch Motronic M1.5 engine

management system

M2.5Bosch Motronic M2.5 engine

management system

MOTMotronic (general)

MTManual gearbox

MULMultec fuel injection system

NNorway

NSFront foglamps

NSLRear foglamps

OELOil level/pressure check system

OPTOptional equipment

PBSLPark and brake shift block

(automatic transmission, selector

lever in position ‘P’)P/NPark/neutral (automatic transmission)

POTPotentiometer

RCRear suspension level control

system

RFSReversing lamps

RHDRight-hand drive

SSweden

SDSunroof

SHHeated seats

SRAHeadlamp washers and wipers

TANKFuel level sender unit

TDTurbo Diesel

TEMPTemperature gauge

TFLDaytime driving lamps

TKSCourtesy lamp (door pillar) switches

TSZITransistorised ignition (inductive-

triggered) system

VGSCarburettor

WEGOdometer frequency/roadspeed

sensor

WHRRear suspension level control

system

WSWarning buzzer

ZVCentral locking

ZYLCylinder

Colour codes

BLBlue

HBLLight blue

BRBrown

GEYellow

GRGrey

GNGreenRTRed

WSWhite

SWBlack

LILilac

VIViolet

Wiring identification

Example: GEWS 1.5

GE -Wire basic colour

WS -Wire tracer colour

1.5 -Wire cross-section in mm

2

Note: Not all items shown are fitted to all models. Refer to Section 62 (Chapter 12) for details of diagram usage.

Page 96 of 525

2When the starter switch is operated, current

flows from the battery to the solenoid that is

mounted on the starter body. The plunger in

the solenoid moves inwards, so causing a

centrally pivoted lever to push the drive pinion

into mesh with the starter ring gear. When the

solenoid plunger reaches the end of its travel,

it closes an internal contact and full starting

current flows to the starter field coils. The

armature is then able to rotate the crankshaft,

so starting the engine.

3A special freewheel clutch is fitted to the

starter driven pinion, so that when the engine

fires and starts to operate on its own it does

not drive the starter motor.

4When the starter switch is released, the

solenoid is de-energised, and a spring moves

the plunger back to its rest position. This

operates the pivoted lever to the withdraw the

drive pinion from engagement with the starter

ring.

13Starter motor - testing

3

Note: Refer to Section 3 before proceeding

Testing

1If the starter motor fails to turn the engine

when the switch is operated, and engine

seizure is not the problem, there are several

other possible reasons:

a)The battery is faulty

b)The electrical connections between the

switch, solenoid battery and starter motor

are somewhere failing to pass the

necessary current from the battery

through the starter to earth

c)The solenoid switch is faulty

d)The starter motor is mechanically or

electrically defective

e)The starter motor pinion and/or flywheel

ring gear is badly worn, and in need of

replacement

2To check the battery, switch on the

headlamps. If they dim after a few seconds,

then the battery is in a discharged state. If the

lamps glow brightly, operate the starter switch

and see what happens to the lamps. If theydim, then power is reaching the motor, but

failing to turn it. If the starter turns slowly, go

on to the next check.

3If, when the starter switch is operated, the

lamps stay bright, then insufficient power is

reaching the motor. Disconnect the battery

and the starter/solenoid power connections,

and the engine earth strap, then thoroughly

clean them and refit them. Smear petroleum

jelly around the battery connections to

prevent corrosion. Corroded connections are

the most frequent cause of electrical system

malfunctions.

4If the preceding checks and cleaning tasks

have been carried out without success, a

clicking noise will probably have been heard

each time the starter switch was operated.

This indicates that the solenoid switch was

operating, but it does not necessarily follow

that the main contacts were closing properly

(if no clicking has been heard from the

solenoid, it is certainly defective). The

solenoid can be checked by connecting a

voltmeter across the main cable connection

on the solenoid and earth. When the switch is

operated, these should be a reading on the

voltmeter. If there is no reading, the solenoid

unit is faulty, and should be renewed.

5If the starter motor operates, but does not

turn the engine, then it is likely that the starter

pinion and/or flywheel ring gear are badly

worn. If this is the case, the starter motor will

normally be noisy in operation.

6Finally, if it is established that the solenoid

is not faulty, and 12 volts are reaching the

starter, then the motor itself is faulty, and

should be removed for inspection.

14Starter motor - removal and

refitting

3

Note: Refer to Section 3 before proceeding

Removal

1Disconnect the battery negative lead.

2Apply the handbrake, then jack up the front

of the vehicle, and support securely on axle

stands (see “Jacking and Vehicle Support”)

positioned under the body side members.3On DOHC models, remove the engine

undershield, as described in Chapter 11.

4Note the wiring connections on the

solenoid, then disconnect them (see

illustration).

5Where applicable, unscrew the bolt

securing the exhaust bracket and the starter

motor mounting bracket to the cylinder block

(see illustration).

6Unscrew the two starter motor mounting

bolts. Note that the top bolt on some models

are fitted from the transmission side, and

secures a wiring harness bracket (see

illustration).

7Withdraw the starter motor.

Refitting

8Refitting is a reversal of removal, but where

applicable, ensure that the wiring harness

bracket is in place on the top mounting bolt,

and tighten all bolts to the specified torque.

15Starter motor - overhaul

5

If the starter motor is thought to be suspect,

it should be removed from the vehicle and

taken to an auto-electrician for testing. Most

auto-electricians will be able to supply and fit

brushes at a reasonable cost. However, check

on the cost of repairs before continuing as it

may prove more economical to obtain a new

or exchange motor.

16Ignition coil - removal, testing

and refitting

3

Note: Refer to Section 3 before proceeding.

An ohmmeter will be required to test the coil

Removal

1The ignition coil is either a cylindrical metal

canister or a moulded plastic unit. It is

clamped or bolted to the left-hand inner wing

panel, near the suspension strut top mounting

(under the power steering fluid reservoir, on

Engine electrical systems 5•9

14.6 Starter motor securing bolts

(arrowed) - 1.6 litre model

(engine removed)14.5 Starter motor mounting

bracket/exhaust bracket securing bolt

(arrowed) - 1.6 litre model14.4 Starter motor and solenoid viewed

from underneath the vehicle. Solenoid

wiring connections arrowed

5

Page 104 of 525

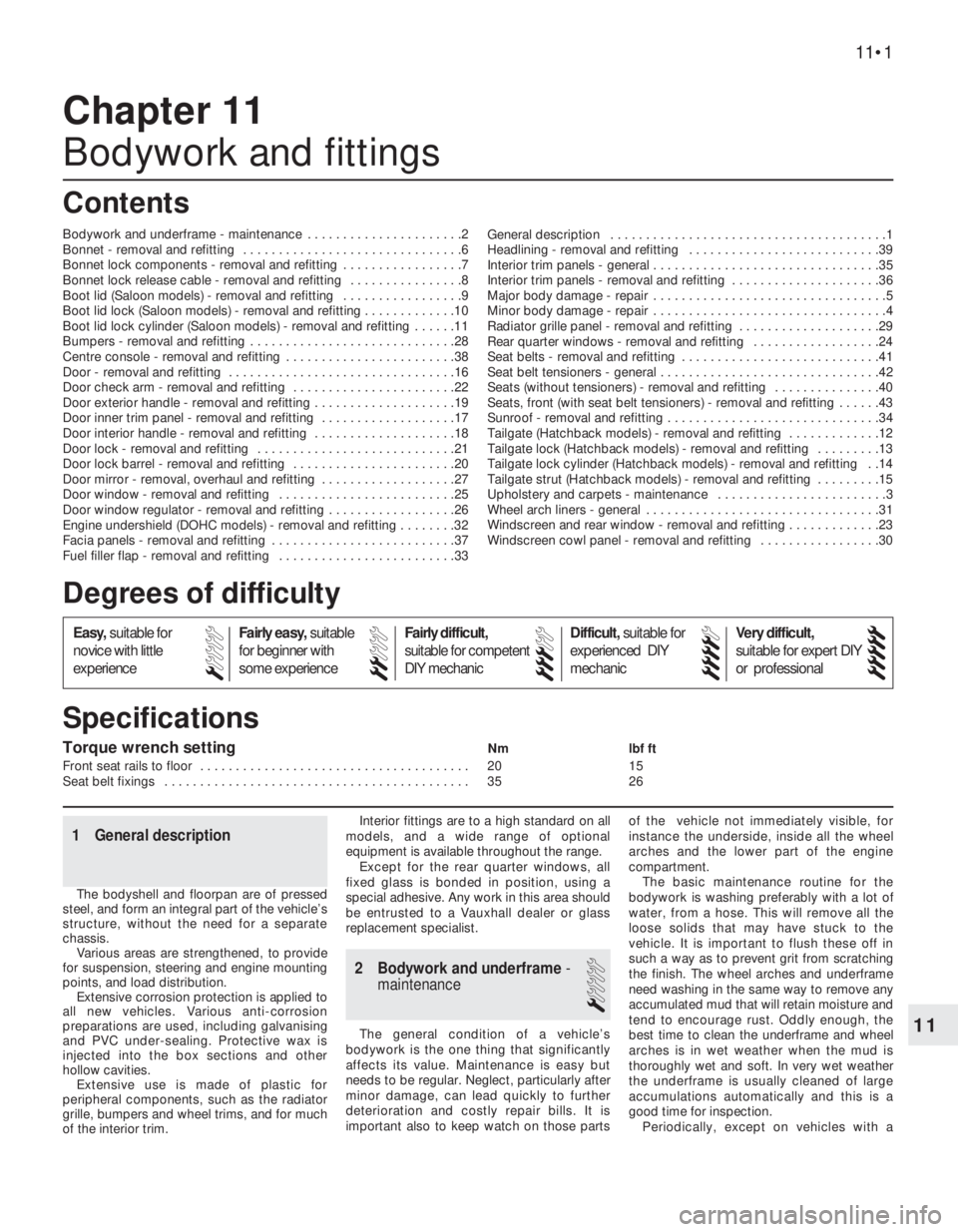

11

Torque wrench settingNm lbf ft

Front seat rails to floor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 15

Seat belt fixings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35 26

1 General description

The bodyshell and floorpan are of pressed

steel, and form an integral part of the vehicle’s

structure, without the need for a separate

chassis.

Various areas are strengthened, to provide

for suspension, steering and engine mounting

points, and load distribution.

Extensive corrosion protection is applied to

all new vehicles. Various anti-corrosion

preparations are used, including galvanising

and PVC under-sealing. Protective wax is

injected into the box sections and other

hollow cavities.

Extensive use is made of plastic for

peripheral components, such as the radiator

grille, bumpers and wheel trims, and for much

of the interior trim.Interior fittings are to a high standard on all

models, and a wide range of optional

equipment is available throughout the range.

Except for the rear quarter windows, all

fixed glass is bonded in position, using a

special adhesive. Any work in this area should

be entrusted to a Vauxhall dealer or glass

replacement specialist.

2 Bodywork and underframe -

maintenance

1

The general condition of a vehicle’s

bodywork is the one thing that significantly

affects its value. Maintenance is easy but

needs to be regular. Neglect, particularly after

minor damage, can lead quickly to further

deterioration and costly repair bills. It is

important also to keep watch on those partsof the vehicle not immediately visible, for

instance the underside, inside all the wheel

arches and the lower part of the engine

compartment.

The basic maintenance routine for the

bodywork is washing preferably with a lot of

water, from a hose. This will remove all the

loose solids that may have stuck to the

vehicle. It is important to flush these off in

such a way as to prevent grit from scratching

the finish. The wheel arches and underframe

need washing in the same way to remove any

accumulated mud that will retain moisture and

tend to encourage rust. Oddly enough, the

best time to clean the underframe and wheel

arches is in wet weather when the mud is

thoroughly wet and soft. In very wet weather

the underframe is usually cleaned of large

accumulations automatically and this is a

good time for inspection.

Periodically, except on vehicles with a

Chapter 11

Bodywork and fittings

Bodywork and underframe - maintenance . . . . . . . . . . . . . . . . . . . . . .2

Bonnet - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Bonnet lock components - removal and refitting . . . . . . . . . . . . . . . . .7

Bonnet lock release cable - removal and refitting . . . . . . . . . . . . . . . .8

Boot lid (Saloon models) - removal and refitting . . . . . . . . . . . . . . . . .9

Boot lid lock (Saloon models) - removal and refitting . . . . . . . . . . . . .10

Boot lid lock cylinder (Saloon models) - removal and refitting . . . . . .11

Bumpers - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Centre console - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . .38

Door - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Door check arm - removal and refitting . . . . . . . . . . . . . . . . . . . . . . .22

Door exterior handle - removal and refitting . . . . . . . . . . . . . . . . . . . .19

Door inner trim panel - removal and refitting . . . . . . . . . . . . . . . . . . .17

Door interior handle - removal and refitting . . . . . . . . . . . . . . . . . . . .18

Door lock - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Door lock barrel - removal and refitting . . . . . . . . . . . . . . . . . . . . . . .20

Door mirror - removal, overhaul and refitting . . . . . . . . . . . . . . . . . . .27

Door window - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . .25

Door window regulator - removal and refitting . . . . . . . . . . . . . . . . . .26

Engine undershield (DOHC models) - removal and refitting . . . . . . . .32

Facia panels - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . .37

Fuel filler flap - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . .33General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Headlining - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Interior trim panels - general . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Interior trim panels - removal and refitting . . . . . . . . . . . . . . . . . . . . .36

Major body damage - repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Minor body damage - repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Radiator grille panel - removal and refitting . . . . . . . . . . . . . . . . . . . .29

Rear quarter windows - removal and refitting . . . . . . . . . . . . . . . . . .24

Seat belts - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Seat belt tensioners - general . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Seats (without tensioners) - removal and refitting . . . . . . . . . . . . . . .40

Seats, front (with seat belt tensioners) - removal and refitting . . . . . .43

Sunroof - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Tailgate (Hatchback models) - removal and refitting . . . . . . . . . . . . .12

Tailgate lock (Hatchback models) - removal and refitting . . . . . . . . .13

Tailgate lock cylinder (Hatchback models) - removal and refitting . .14

Tailgate strut (Hatchback models) - removal and refitting . . . . . . . . .15

Upholstery and carpets - maintenance . . . . . . . . . . . . . . . . . . . . . . . .3

Wheel arch liners - general . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Windscreen and rear window - removal and refitting . . . . . . . . . . . . .23

Windscreen cowl panel - removal and refitting . . . . . . . . . . . . . . . . .30

11•1

Specifications Contents

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert DIY

or professional

Degrees of difficulty

54321

Page 106 of 525

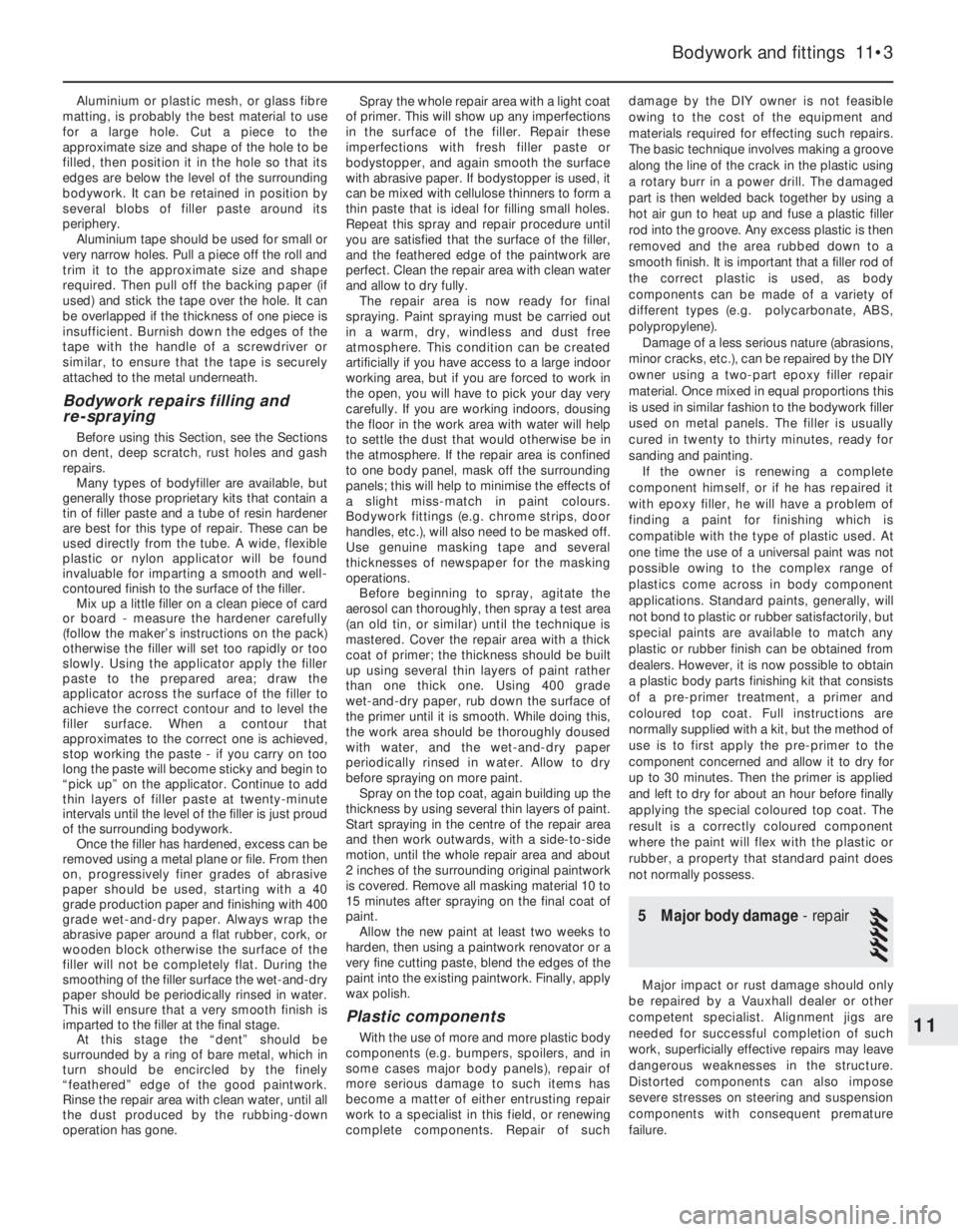

Aluminium or plastic mesh, or glass fibre

matting, is probably the best material to use

for a large hole. Cut a piece to the

approximate size and shape of the hole to be

filled, then position it in the hole so that its

edges are below the level of the surrounding

bodywork. It can be retained in position by

several blobs of filler paste around its

periphery.

Aluminium tape should be used for small or

very narrow holes. Pull a piece off the roll and

trim it to the approximate size and shape

required. Then pull off the backing paper (if

used) and stick the tape over the hole. It can

be overlapped if the thickness of one piece is

insufficient. Burnish down the edges of the

tape with the handle of a screwdriver or

similar, to ensure that the tape is securely

attached to the metal underneath.

Bodywork repairs filling and

re-spraying

Before using this Section, see the Sections

on dent, deep scratch, rust holes and gash

repairs.

Many types of bodyfiller are available, but

generally those proprietary kits that contain a

tin of filler paste and a tube of resin hardener

are best for this type of repair. These can be

used directly from the tube. A wide, flexible

plastic or nylon applicator will be found

invaluable for imparting a smooth and well-

contoured finish to the surface of the filler.

Mix up a little filler on a clean piece of card

or board - measure the hardener carefully

(follow the maker’s instructions on the pack)

otherwise the filler will set too rapidly or too

slowly. Using the applicator apply the filler

paste to the prepared area; draw the

applicator across the surface of the filler to

achieve the correct contour and to level the

filler surface. When a contour that

approximates to the correct one is achieved,

stop working the paste - if you carry on too

long the paste will become sticky and begin to

“pick up” on the applicator. Continue to add

thin layers of filler paste at twenty-minute

intervals until the level of the filler is just proud

of the surrounding bodywork.

Once the filler has hardened, excess can be

removed using a metal plane or file. From then

on, progressively finer grades of abrasive

paper should be used, starting with a 40

grade production paper and finishing with 400

grade wet-and-dry paper. Always wrap the

abrasive paper around a flat rubber, cork, or

wooden block otherwise the surface of the

filler will not be completely flat. During the

smoothing of the filler surface the wet-and-dry

paper should be periodically rinsed in water.

This will ensure that a very smooth finish is

imparted to the filler at the final stage.

At this stage the “dent” should be

surrounded by a ring of bare metal, which in

turn should be encircled by the finely

“feathered” edge of the good paintwork.

Rinse the repair area with clean water, until all

the dust produced by the rubbing-down

operation has gone.Spray the whole repair area with a light coat

of primer. This will show up any imperfections

in the surface of the filler. Repair these

imperfections with fresh filler paste or

bodystopper, and again smooth the surface

with abrasive paper. If bodystopper is used, it

can be mixed with cellulose thinners to form a

thin paste that is ideal for filling small holes.

Repeat this spray and repair procedure until

you are satisfied that the surface of the filler,

and the feathered edge of the paintwork are

perfect. Clean the repair area with clean water

and allow to dry fully.

The repair area is now ready for final

spraying. Paint spraying must be carried out

in a warm, dry, windless and dust free

atmosphere. This condition can be created

artificially if you have access to a large indoor

working area, but if you are forced to work in

the open, you will have to pick your day very

carefully. If you are working indoors, dousing

the floor in the work area with water will help

to settle the dust that would otherwise be in

the atmosphere. If the repair area is confined

to one body panel, mask off the surrounding

panels; this will help to minimise the effects of

a slight miss-match in paint colours.

Bodywork fittings (e.g. chrome strips, door

handles, etc.), will also need to be masked off.

Use genuine masking tape and several

thicknesses of newspaper for the masking

operations.

Before beginning to spray, agitate the

aerosol can thoroughly, then spray a test area

(an old tin, or similar) until the technique is

mastered. Cover the repair area with a thick

coat of primer; the thickness should be built

up using several thin layers of paint rather

than one thick one. Using 400 grade

wet-and-dry paper, rub down the surface of

the primer until it is smooth. While doing this,

the work area should be thoroughly doused

with water, and the wet-and-dry paper

periodically rinsed in water. Allow to dry

before spraying on more paint.

Spray on the top coat, again building up the

thickness by using several thin layers of paint.

Start spraying in the centre of the repair area

and then work outwards, with a side-to-side

motion, until the whole repair area and about

2 inches of the surrounding original paintwork

is covered. Remove all masking material 10 to

15 minutes after spraying on the final coat of

paint.

Allow the new paint at least two weeks to

harden, then using a paintwork renovator or a

very fine cutting paste, blend the edges of the

paint into the existing paintwork. Finally, apply

wax polish.

Plastic components

With the use of more and more plastic body

components (e.g. bumpers, spoilers, and in

some cases major body panels), repair of

more serious damage to such items has

become a matter of either entrusting repair

work to a specialist in this field, or renewing

complete components. Repair of suchdamage by the DIY owner is not feasible

owing to the cost of the equipment and

materials required for effecting such repairs.

The basic technique involves making a groove

along the line of the crack in the plastic using

a rotary burr in a power drill. The damaged

part is then welded back together by using a

hot air gun to heat up and fuse a plastic filler

rod into the groove. Any excess plastic is then

removed and the area rubbed down to a

smooth finish. It is important that a filler rod of

the correct plastic is used, as body

components can be made of a variety of

different types (e.g. polycarbonate, ABS,

polypropylene).

Damage of a less serious nature (abrasions,

minor cracks, etc.), can be repaired by the DIY

owner using a two-part epoxy filler repair

material. Once mixed in equal proportions this

is used in similar fashion to the bodywork filler

used on metal panels. The filler is usually

cured in twenty to thirty minutes, ready for

sanding and painting.

If the owner is renewing a complete

component himself, or if he has repaired it

with epoxy filler, he will have a problem of

finding a paint for finishing which is

compatible with the type of plastic used. At

one time the use of a universal paint was not

possible owing to the complex range of

plastics come across in body component

applications. Standard paints, generally, will

not bond to plastic or rubber satisfactorily, but

special paints are available to match any

plastic or rubber finish can be obtained from

dealers. However, it is now possible to obtain

a plastic body parts finishing kit that consists

of a pre-primer treatment, a primer and

coloured top coat. Full instructions are

normally supplied with a kit, but the method of

use is to first apply the pre-primer to the

component concerned and allow it to dry for

up to 30 minutes. Then the primer is applied

and left to dry for about an hour before finally

applying the special coloured top coat. The

result is a correctly coloured component

where the paint will flex with the plastic or

rubber, a property that standard paint does

not normally possess.

5Major body damage - repair

5

Major impact or rust damage should only

be repaired by a Vauxhall dealer or other

competent specialist. Alignment jigs are

needed for successful completion of such

work, superficially effective repairs may leave

dangerous weaknesses in the structure.

Distorted components can also impose

severe stresses on steering and suspension

components with consequent premature

failure.

Bodywork and fittings 11•3

11

Page 135 of 525

4Front disc pads - inspection,

removal and refitting

3

Note: When working on the brake

components, take care not to disperse brake

dust into the air, or to inhale it, since it may

contain asbestos, which can damage your

health.

Inspection

1Where applicable, remove the wheel trims,

then loosen the front roadwheel bolts and

apply the handbrake. Jack up the front of the

vehicle, and support on axle stands (see

“Jacking and Vehicle Support”) positioned

under the body side members.

2Remove the roadwheels. Turn the steering to

full right-hand lock, and check the wear of the

friction material on the right-hand brake pads.

Check that the thickness of the friction material

(including the backing plate) is not less than the

minimum given in the Specifications.

3Turn the steering to full left-hand lock, and

check the left-hand brake pads in the same

way.

4If any brake pad is worn below the specified

minimum thickness, renew all the front pads

as a set.

5If the pads require renewal, continue as

follows according to model.

Removal

1.4, 1.6 and 1.8 litre models

6Note how the anti-rattle springs are located

(see illustration), then drive the upper and

lower pad retaining pins out from the inboard

side of the caliper, using a pin punch.

7Remove the anti-rattle springs (see

illustration).

8Push the pads away from the disc slightly,

then using a pair of pliers, withdraw the

outboard pad (see illustration).

9Withdraw the inboard pad, and the shim

that fits between the pad and the caliper

piston (see illustration).

Refitting

10Brush the dust and dirt from the caliper,

but take care not to inhale it. Carefully remove

any rust from the edge of the brake disc.11To accommodate the new thicker pads,

the caliper piston must be depressed fully into

its cylinder bore, using a flat bar of metal such

as a tyre lever. The action of depressing the

piston will cause the fluid level in the reservoir

to rise, so to avoid spillage, syphon out some

fluid using an old hydrometer or a teat pipette.

Refer to the note at the beginning of Section 3.

Do not lever between the piston and disc to

depress the piston.

12Check that the cutaway recesses in the

piston are positioned vertically. If necessary,

carefully turn the piston to its correct position.

13Apply a little brake grease to the top and

bottom edges of the backplates on the new

brake pads.

14Locate the new pads in the caliper,

ensuring that the shim is in place between the

inboard pad and the piston. Ensure that the

friction material faces the disc, and check that

the pads are free to move slightly.

15Locate the anti-rattle springs on the pads,

then insert the pad retaining pins from the

outboard side of the caliper, while depressing

the springs. Tap the pins firmly into the caliper

(see illustration).

16Repeat the operations on the remaining

side of the vehicle.

17Refit the roadwheels and lower the vehicle

to the ground. Do not fully tighten the

roadwheel bolts until the vehicle is resting on

its wheels.

18Apply the footbrake hard several times to

position the pads against the discs.

19Check and if necessary top-up the brake

fluid level.20New brake pads should be carefully

bedded in and, where possible, heavy braking

should be avoided during the first 100 miles

(160 km) or so after fitting new pads.

2.0 litre models

Removal

21Where applicable, pull the pad wear

sensor from the inboard pad, and disconnect

the wiring at the connector under the wheel

arch, next to the suspension strut (see

illustration). Note the wire routing.

22Using a screwdriver, prise the pad

retaining clip from the outboard edge of the

caliper, noting how it is located (see

illustration).

23Prise out the two guide bolt dust caps

from the inboard edge of the caliper, then

using a Allen key or hexagon bit, unscrew the

9•4Braking system

4.6 Front disc pad anti-rattle springs

(arrowed) - models with solid discs

4.8 Withdrawing the outboard disc pad -

models with solid discs

4.21 Withdrawing the pad wear sensor

from the inboard pad - DOHC model4.15 Fitting a disc pad retaining pin -

models with solid discs4.9 Withdrawing the inboard disc pad and

shim - models with solid discs

4.7 Removing an anti-rattle spring -

models with solid discs

Page 172 of 525

1

Chapter 1

Routine maintenance and servicing

Air cleaner element - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Air inlet temperature control check . . . . . . . . . . . . . . . . . . . . . . . . . .28

Alternator V-belt check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Automatic transmission check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Automatic transmission fluid level check . . . . . . . . . . . . . . . . . . . . . . .7

Automatic transmission fluid renewal . . . . . . . . . . . . . . . . . . . . . . . . .38

Bodywork check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Brake fluid renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Brake pad check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Brake shoe check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Clutch cable check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Coolant renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Distributor and HT lead check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Door lock key battery - replacement . . . . . . . . . . . . . . . . . . . . . . . . .24

Driveshaft gaiter check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Engine oil and filter - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Exhaust system check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Fuel filter renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Handbrake linkage check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16Headlamp alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Hose and fluid leak check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Idle speed and mixture - adjustment . . . . . . . . . . . . . . . . . . . . . . . . . .9

Ignition timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Intensive maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Lock and hinge check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Manual transmission fluid check . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Power steering fluid check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Power steering pump drivebelt check . . . . . . . . . . . . . . . . . . . . . . . .18

Radiator inspection and cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Rear suspension level control system check . . . . . . . . . . . . . . . . . . .19

Road test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Spark plug renewal (SOHC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Spark plug renewal (DOHC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Steering and suspension check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Throttle linkage maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Timing belt renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Wiring check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

1•1

Contents

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert DIY

or professional

Degrees of difficulty

54321

Page 175 of 525

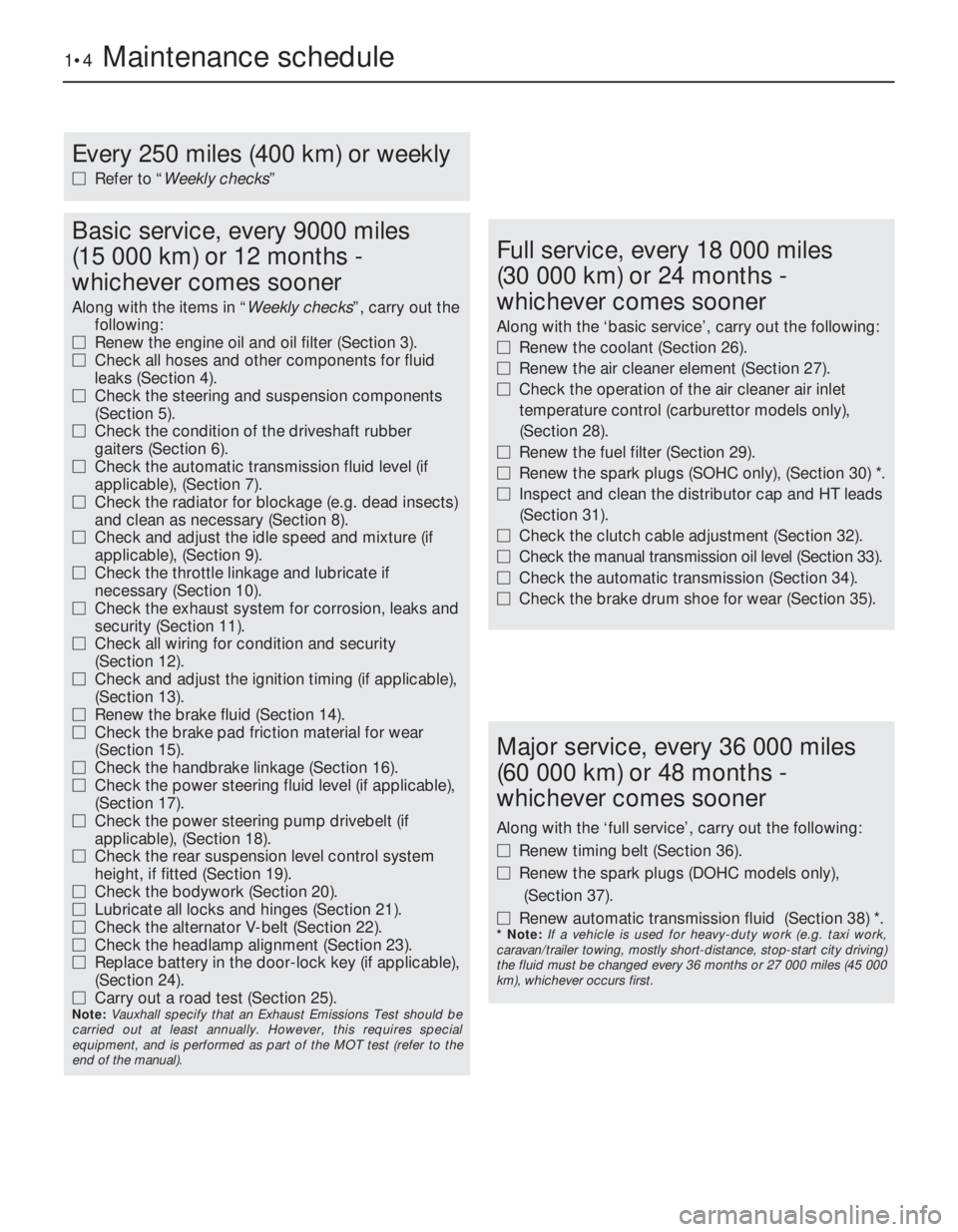

1•4Maintenance schedule

Every 250 miles (400 km) or weekly

MRefer to “Weekly checks”

Basic service, every 9000 miles

(15 000 km) or 12 months -

whichever comes sooner

Along with the items in “Weekly checks”, carry out the

following:

MRenew the engine oil and oil filter (Section 3).

MCheck all hoses and other components for fluid

leaks (Section 4).

MCheck the steering and suspension components

(Section 5).

MCheck the condition of the driveshaft rubber

gaiters (Section 6).

MCheck the automatic transmission fluid level (if

applicable), (Section 7).

MCheck the radiator for blockage (e.g. dead insects)

and clean as necessary (Section 8).

MCheck and adjust the idle speed and mixture (if

applicable), (Section 9).

MCheck the throttle linkage and lubricate if

necessary (Section 10).

MCheck the exhaust system for corrosion, leaks and

security (Section 11).

MCheck all wiring for condition and security

(Section 12).

MCheck and adjust the ignition timing (if applicable),

(Section 13).

MRenew the brake fluid (Section 14).

MCheck the brake pad friction material for wear

(Section 15).

MCheck the handbrake linkage (Section 16).

MCheck the power steering fluid level (if applicable),

(Section 17).

MCheck the power steering pump drivebelt (if

applicable), (Section 18).

MCheck the rear suspension level control system

height, if fitted (Section 19).

MCheck the bodywork (Section 20).

MLubricate all locks and hinges (Section 21).

MCheck the alternator V-belt (Section 22).

MCheck the headlamp alignment (Section 23).

MReplace battery in the door-lock key (if applicable),

(Section 24).

MCarry out a road test (Section 25).

Note: Vauxhall specify that an Exhaust Emissions Test should be

carried out at least annually. However, this requires special

equipment, and is performed as part of the MOT test (refer to the

end of the manual).

Full service, every 18 000 miles

(30 000 km) or 24 months -

whichever comes sooner

Along with the ‘basic service’, carry out the following:

MRenew the coolant (Section 26).

MRenew the air cleaner element (Section 27).

MCheck the operation of the air cleaner air inlet

temperature control (carburettor models only),

(Section 28).

MRenew the fuel filter (Section 29).

MRenew the spark plugs (SOHC only), (Section 30) *.

MInspect and clean the distributor cap and HT leads

(Section 31).

MCheck the clutch cable adjustment (Section 32).

MCheck the manual transmission oil level (Section 33).

MCheck the automatic transmission (Section 34).

MCheck the brake drum shoe for wear (Section 35).

Major service, every 36 000 miles

(60 000 km) or 48 months -

whichever comes sooner

Along with the ‘full service’, carry out the following:

MRenew timing belt (Section 36).

MRenew the spark plugs (DOHC models only),

(Section 37).

MRenew automatic transmission fluid (Section 38) *.

* Note: If a vehicle is used for heavy-duty work (e.g. taxi work,

caravan/trailer towing, mostly short-distance, stop-start city driving)

the fluid must be changed every 36 months or 27 000 miles (45 000

km), whichever occurs first.

Page 176 of 525

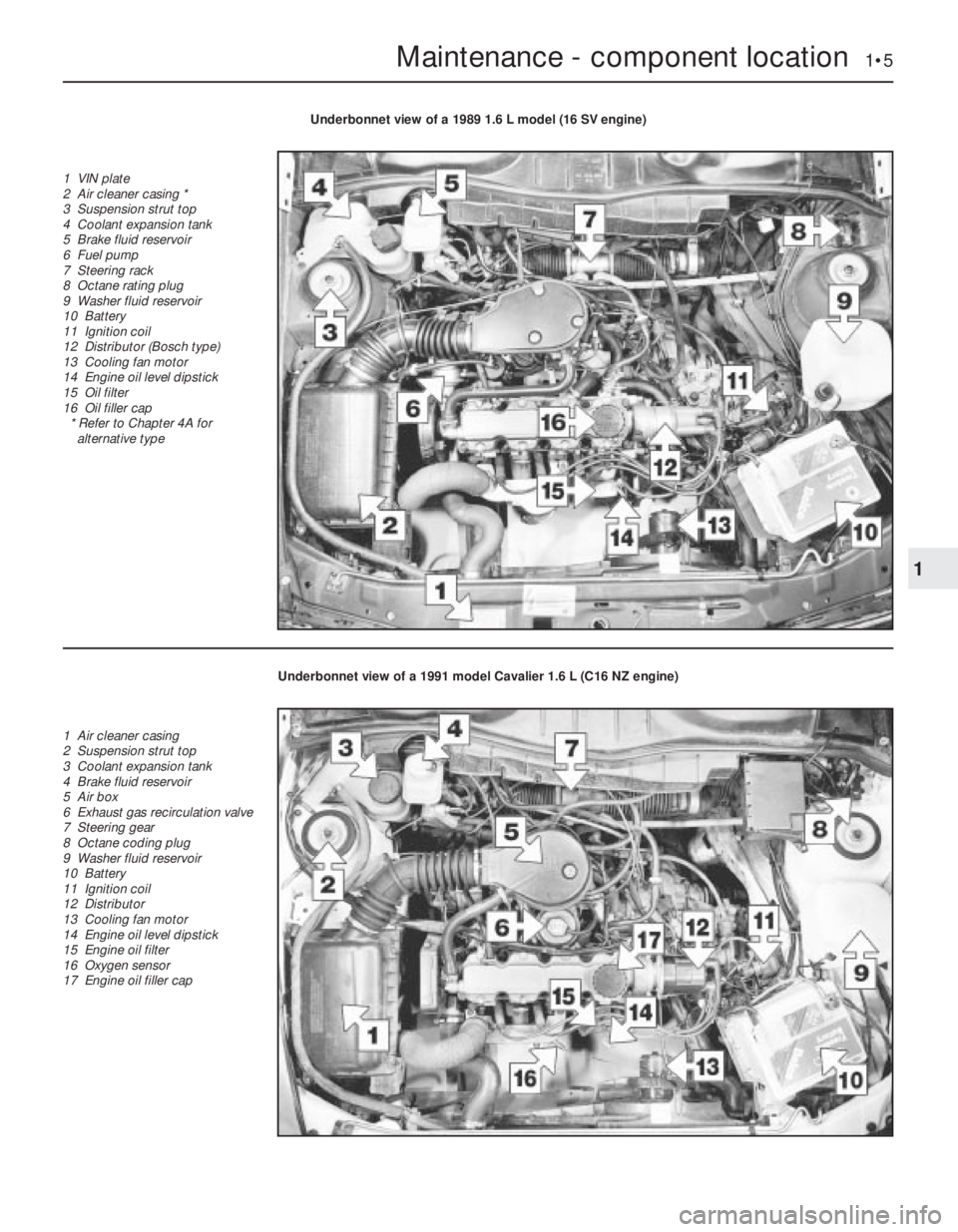

Maintenance - component location 1•5

1

Underbonnet view of a 1989 1.6 L model (16 SV engine)

1 VIN plate

2 Air cleaner casing *

3 Suspension strut top

4 Coolant expansion tank

5 Brake fluid reservoir

6 Fuel pump

7 Steering rack

8 Octane rating plug

9 Washer fluid reservoir

10 Battery

11 Ignition coil

12 Distributor (Bosch type)

13 Cooling fan motor

14 Engine oil level dipstick

15 Oil filter

16 Oil filler cap

* Refer to Chapter 4A for

alternative type

Underbonnet view of a 1991 model Cavalier 1.6 L (C16 NZ engine)

1 Air cleaner casing

2 Suspension strut top

3 Coolant expansion tank

4 Brake fluid reservoir

5 Air box

6 Exhaust gas recirculation valve

7 Steering gear

8 Octane coding plug

9 Washer fluid reservoir

10 Battery

11 Ignition coil

12 Distributor

13 Cooling fan motor

14 Engine oil level dipstick

15 Engine oil filter

16 Oxygen sensor

17 Engine oil filler cap