clock OPEL VIVARO B 2018 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2018, Model line: VIVARO B, Model: OPEL VIVARO B 2018Pages: 237, PDF Size: 5.57 MB

Page 178 of 237

176Vehicle careDaytime running light with LEDs

Daytime running lights consist of

LEDs which cannot be changed.

Consult a workshop in case of a

defective LED.

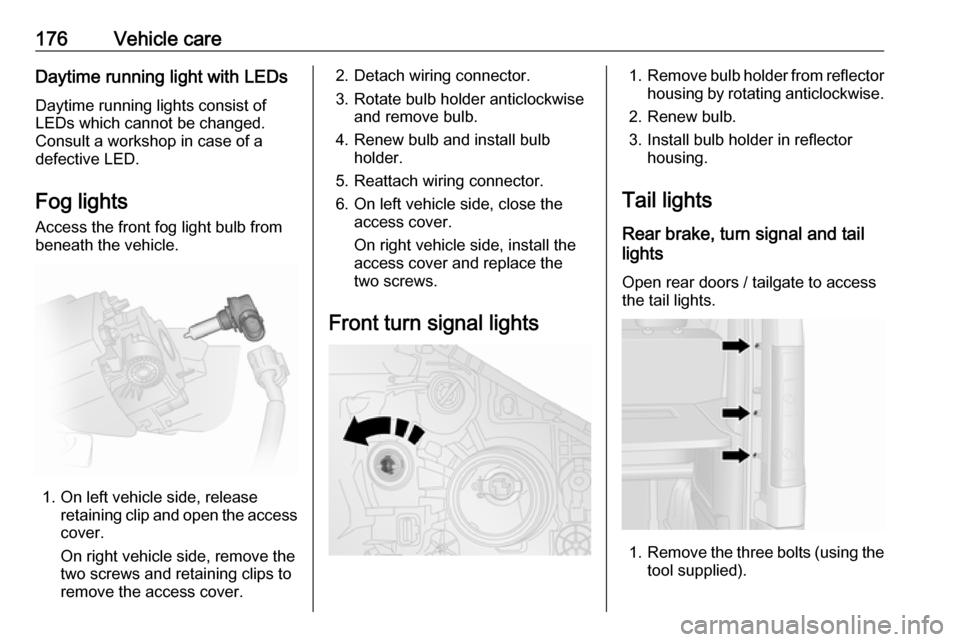

Fog lights

Access the front fog light bulb from

beneath the vehicle.

1. On left vehicle side, release retaining clip and open the accesscover.

On right vehicle side, remove the

two screws and retaining clips to

remove the access cover.

2. Detach wiring connector.

3. Rotate bulb holder anticlockwise and remove bulb.

4. Renew bulb and install bulb holder.

5. Reattach wiring connector.

6. On left vehicle side, close the access cover.

On right vehicle side, install the

access cover and replace the

two screws.

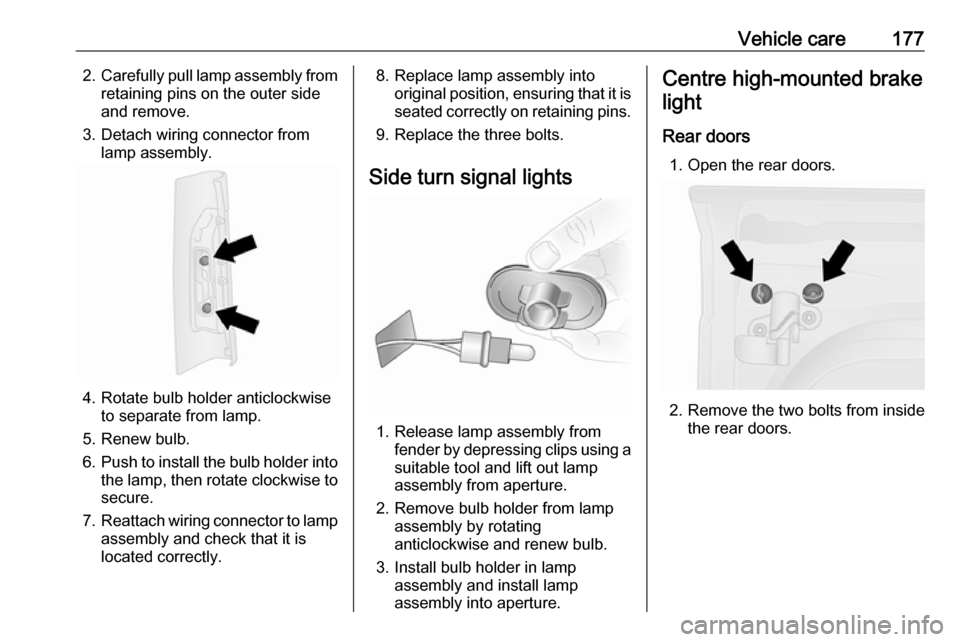

Front turn signal lights1. Remove bulb holder from reflector

housing by rotating anticlockwise.

2. Renew bulb.

3. Install bulb holder in reflector housing.

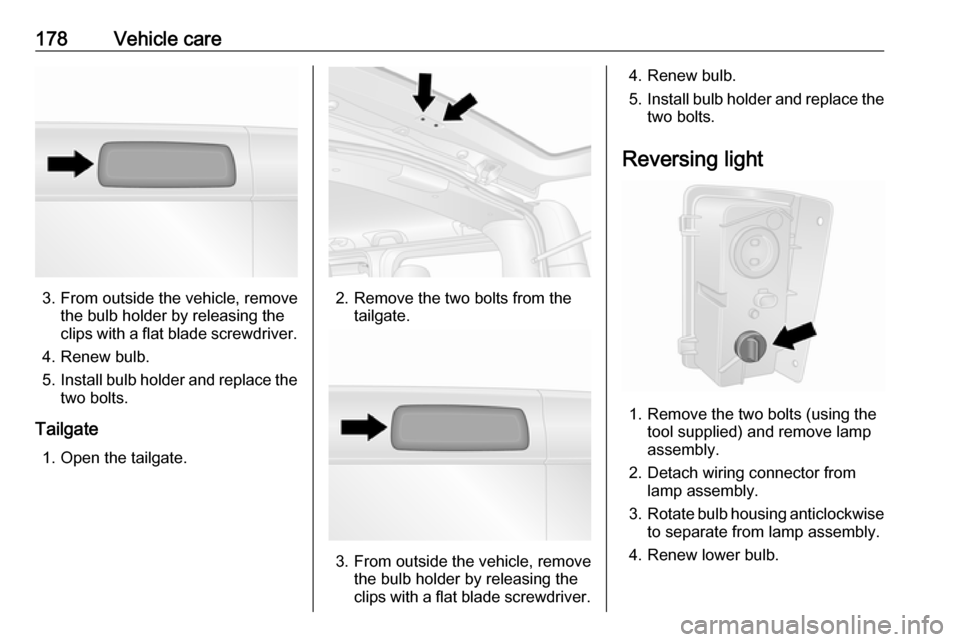

Tail lights

Rear brake, turn signal and tail

lights

Open rear doors / tailgate to access

the tail lights.

1. Remove the three bolts (using the

tool supplied).

Page 179 of 237

Vehicle care1772.Carefully pull lamp assembly from

retaining pins on the outer side

and remove.

3. Detach wiring connector from lamp assembly.

4. Rotate bulb holder anticlockwiseto separate from lamp.

5. Renew bulb.

6. Push to install the bulb holder into

the lamp, then rotate clockwise to secure.

7. Reattach wiring connector to lamp

assembly and check that it is

located correctly.

8. Replace lamp assembly into original position, ensuring that it isseated correctly on retaining pins.

9. Replace the three bolts.

Side turn signal lights

1. Release lamp assembly from fender by depressing clips using a

suitable tool and lift out lamp

assembly from aperture.

2. Remove bulb holder from lamp assembly by rotating

anticlockwise and renew bulb.

3. Install bulb holder in lamp assembly and install lamp

assembly into aperture.

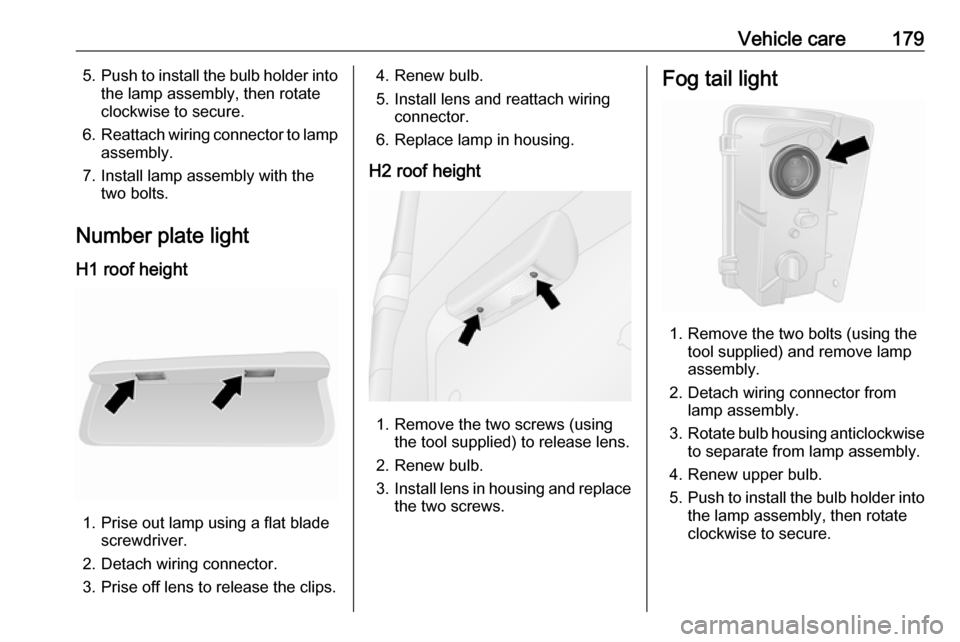

Centre high-mounted brake

light

Rear doors 1. Open the rear doors.

2. Remove the two bolts from inside the rear doors.

Page 180 of 237

178Vehicle care

3. From outside the vehicle, removethe bulb holder by releasing the

clips with a flat blade screwdriver.

4. Renew bulb.

5. Install bulb holder and replace the

two bolts.

Tailgate 1. Open the tailgate.2. Remove the two bolts from the tailgate.

3. From outside the vehicle, remove the bulb holder by releasing the

clips with a flat blade screwdriver.

4. Renew bulb.

5. Install bulb holder and replace the

two bolts.

Reversing light

1. Remove the two bolts (using the tool supplied) and remove lamp

assembly.

2. Detach wiring connector from lamp assembly.

3. Rotate bulb housing anticlockwise

to separate from lamp assembly.

4. Renew lower bulb.

Page 181 of 237

Vehicle care1795.Push to install the bulb holder into

the lamp assembly, then rotate

clockwise to secure.

6. Reattach wiring connector to lamp

assembly.

7. Install lamp assembly with the two bolts.

Number plate light

H1 roof height

1. Prise out lamp using a flat blade screwdriver.

2. Detach wiring connector.

3. Prise off lens to release the clips.

4. Renew bulb.

5. Install lens and reattach wiring connector.

6. Replace lamp in housing.

H2 roof height

1. Remove the two screws (using the tool supplied) to release lens.

2. Renew bulb.

3. Install lens in housing and replace

the two screws.

Fog tail light

1. Remove the two bolts (using the tool supplied) and remove lamp

assembly.

2. Detach wiring connector from lamp assembly.

3. Rotate bulb housing anticlockwise

to separate from lamp assembly.

4. Renew upper bulb.

5. Push to install the bulb holder into

the lamp assembly, then rotate

clockwise to secure.

Page 187 of 237

Vehicle care185No.Circuit40Rear power outlet41Starting / Body control module42Heated seats43Tachograph44Windscreen wiper45Heating / Air conditioning

After having changed defective fuses,

replace the trim panel.

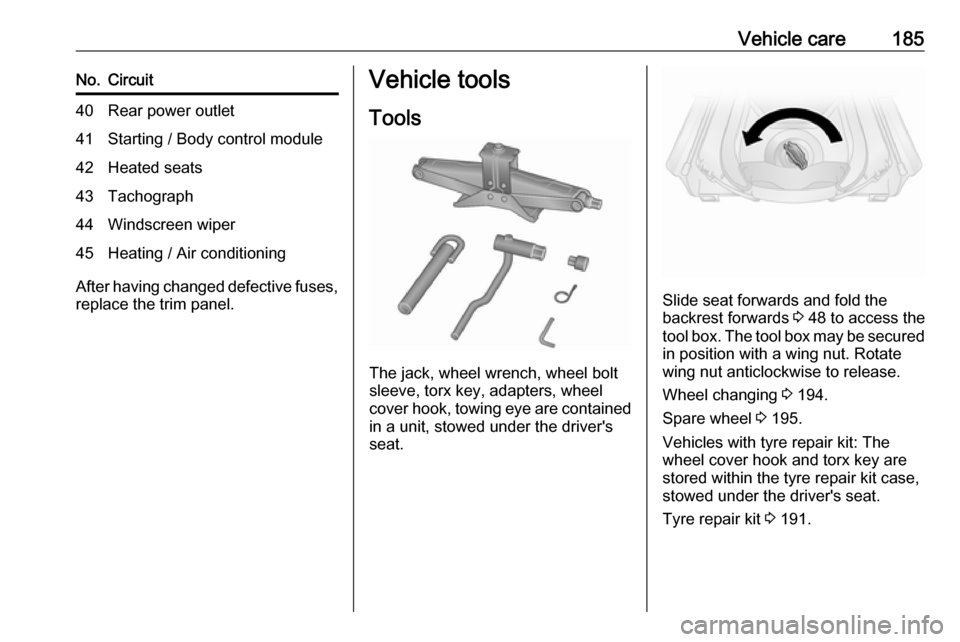

Vehicle tools

Tools

The jack, wheel wrench, wheel bolt

sleeve, torx key, adapters, wheel

cover hook, towing eye are contained

in a unit, stowed under the driver's

seat.

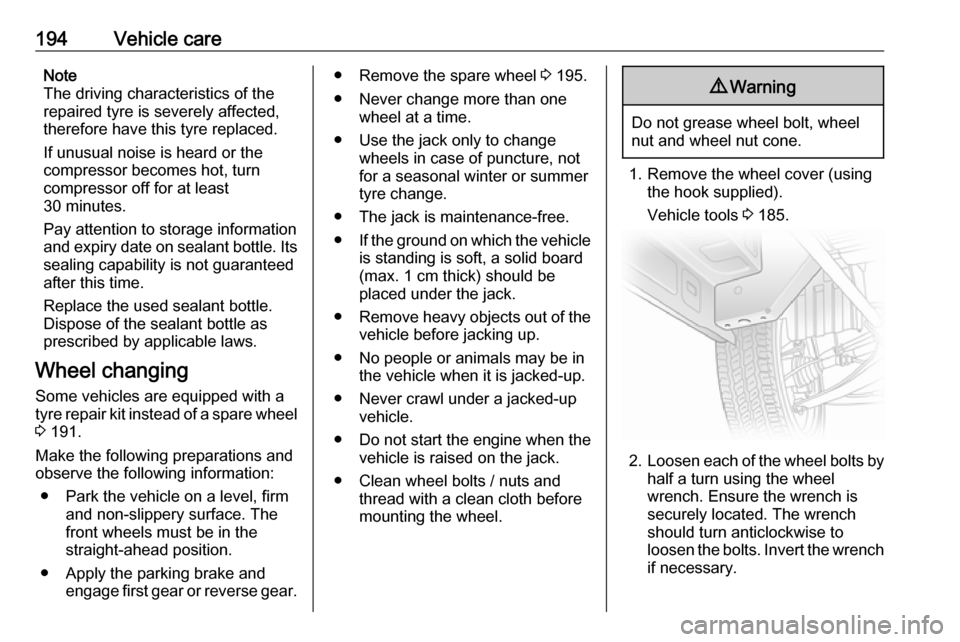

Slide seat forwards and fold the

backrest forwards 3 48 to access the

tool box. The tool box may be secured

in position with a wing nut. Rotate

wing nut anticlockwise to release.

Wheel changing 3 194.

Spare wheel 3 195.

Vehicles with tyre repair kit: The wheel cover hook and torx key are

stored within the tyre repair kit case,

stowed under the driver's seat.

Tyre repair kit 3 191.

Page 196 of 237

194Vehicle careNote

The driving characteristics of the repaired tyre is severely affected,

therefore have this tyre replaced.

If unusual noise is heard or the

compressor becomes hot, turn

compressor off for at least

30 minutes.

Pay attention to storage information

and expiry date on sealant bottle. Its

sealing capability is not guaranteed

after this time.

Replace the used sealant bottle. Dispose of the sealant bottle as

prescribed by applicable laws.

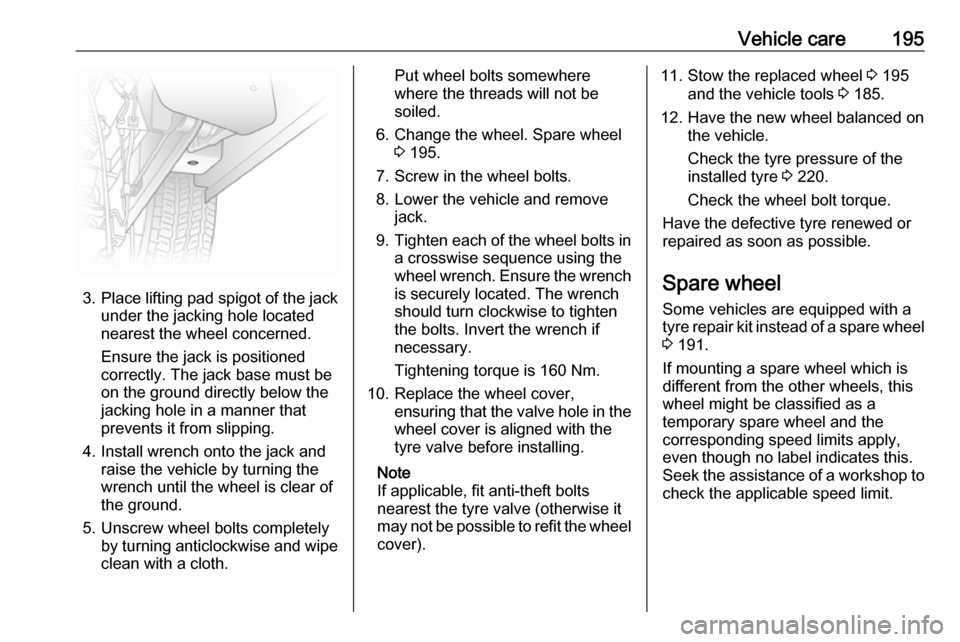

Wheel changing

Some vehicles are equipped with a

tyre repair kit instead of a spare wheel

3 191.

Make the following preparations and

observe the following information:

● Park the vehicle on a level, firm and non-slippery surface. The

front wheels must be in the

straight-ahead position.

● Apply the parking brake and engage first gear or reverse gear.● Remove the spare wheel 3 195.

● Never change more than one wheel at a time.

● Use the jack only to change wheels in case of puncture, not

for a seasonal winter or summer

tyre change.

● The jack is maintenance-free. ● If the ground on which the vehicle

is standing is soft, a solid board

(max. 1 cm thick) should be

placed under the jack.

● Remove heavy objects out of the

vehicle before jacking up.

● No people or animals may be in the vehicle when it is jacked-up.

● Never crawl under a jacked-up vehicle.

● Do not start the engine when the vehicle is raised on the jack.

● Clean wheel bolts / nuts and thread with a clean cloth before

mounting the wheel.9 Warning

Do not grease wheel bolt, wheel

nut and wheel nut cone.

1. Remove the wheel cover (using the hook supplied).

Vehicle tools 3 185.

2. Loosen each of the wheel bolts by

half a turn using the wheel

wrench. Ensure the wrench is

securely located. The wrench

should turn anticlockwise to

loosen the bolts. Invert the wrench if necessary.

Page 197 of 237

Vehicle care195

3.Place lifting pad spigot of the jack

under the jacking hole located

nearest the wheel concerned.

Ensure the jack is positioned

correctly. The jack base must be

on the ground directly below the

jacking hole in a manner that

prevents it from slipping.

4. Install wrench onto the jack and raise the vehicle by turning the

wrench until the wheel is clear of

the ground.

5. Unscrew wheel bolts completely by turning anticlockwise and wipe

clean with a cloth.

Put wheel bolts somewhere

where the threads will not be

soiled.

6. Change the wheel. Spare wheel 3 195.

7. Screw in the wheel bolts.

8. Lower the vehicle and remove jack.

9. Tighten each of the wheel bolts in

a crosswise sequence using the

wheel wrench. Ensure the wrench is securely located. The wrench

should turn clockwise to tighten

the bolts. Invert the wrench if

necessary.

Tightening torque is 160 Nm.

10. Replace the wheel cover, ensuring that the valve hole in thewheel cover is aligned with the

tyre valve before installing.

Note

If applicable, fit anti-theft bolts

nearest the tyre valve (otherwise it

may not be possible to refit the wheel

cover).11. Stow the replaced wheel 3 195

and the vehicle tools 3 185.

12. Have the new wheel balanced on the vehicle.

Check the tyre pressure of the

installed tyre 3 220.

Check the wheel bolt torque.

Have the defective tyre renewed or

repaired as soon as possible.

Spare wheel

Some vehicles are equipped with a tyre repair kit instead of a spare wheel

3 191.

If mounting a spare wheel which is

different from the other wheels, this

wheel might be classified as a

temporary spare wheel and the

corresponding speed limits apply,

even though no label indicates this.

Seek the assistance of a workshop to

check the applicable speed limit.

Page 200 of 237

198Vehicle care

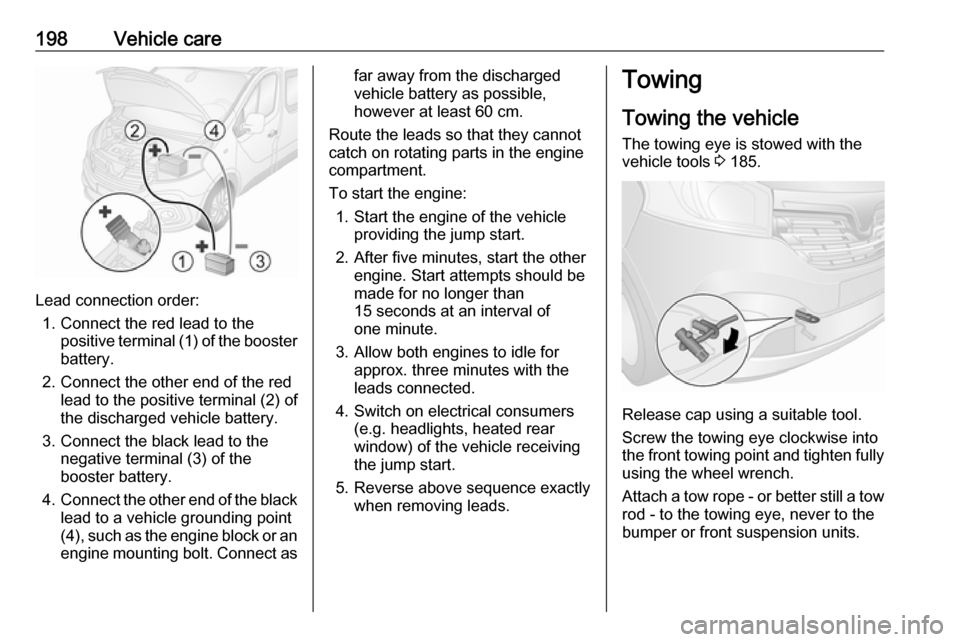

Lead connection order:1. Connect the red lead to the positive terminal (1) of the booster

battery.

2. Connect the other end of the red lead to the positive terminal (2) of

the discharged vehicle battery.

3. Connect the black lead to the negative terminal (3) of the

booster battery.

4. Connect the other end of the black

lead to a vehicle grounding point

(4), such as the engine block or an

engine mounting bolt. Connect as

far away from the discharged

vehicle battery as possible,

however at least 60 cm.

Route the leads so that they cannot

catch on rotating parts in the engine

compartment.

To start the engine: 1. Start the engine of the vehicle providing the jump start.

2. After five minutes, start the other engine. Start attempts should be

made for no longer than

15 seconds at an interval of

one minute.

3. Allow both engines to idle for approx. three minutes with the

leads connected.

4. Switch on electrical consumers (e.g. headlights, heated rear

window) of the vehicle receiving

the jump start.

5. Reverse above sequence exactly when removing leads.Towing

Towing the vehicle The towing eye is stowed with thevehicle tools 3 185.

Release cap using a suitable tool.

Screw the towing eye clockwise into

the front towing point and tighten fully

using the wheel wrench.

Attach a tow rope - or better still a tow rod - to the towing eye, never to the

bumper or front suspension units.

Page 231 of 237

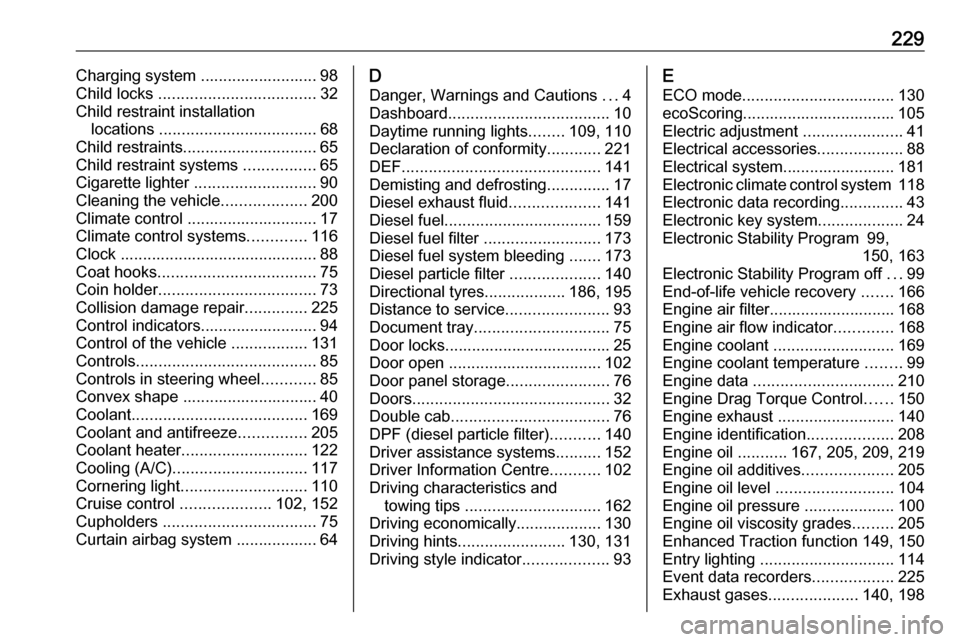

229Charging system .......................... 98

Child locks ................................... 32

Child restraint installation locations ................................... 68

Child restraints.............................. 65

Child restraint systems ................65

Cigarette lighter ........................... 90

Cleaning the vehicle ...................200

Climate control ............................. 17

Climate control systems .............116

Clock ............................................ 88

Coat hooks ................................... 75

Coin holder ................................... 73

Collision damage repair ..............225

Control indicators.......................... 94

Control of the vehicle .................131

Controls ........................................ 85

Controls in steering wheel ............85

Convex shape .............................. 40

Coolant ....................................... 169

Coolant and antifreeze ...............205

Coolant heater ............................ 122

Cooling (A/C) .............................. 117

Cornering light ............................ 110

Cruise control ....................102, 152

Cupholders .................................. 75

Curtain airbag system .................. 64D

Danger, Warnings and Cautions ...4

Dashboard .................................... 10

Daytime running lights ........109, 110

Declaration of conformity ............221

DEF ............................................ 141

Demisting and defrosting ..............17

Diesel exhaust fluid ....................141

Diesel fuel ................................... 159

Diesel fuel filter .......................... 173

Diesel fuel system bleeding .......173

Diesel particle filter ....................140

Directional tyres ..................186, 195

Distance to service .......................93

Document tray .............................. 75

Door locks..................................... 25

Door open .................................. 102

Door panel storage .......................76

Doors ............................................ 32

Double cab ................................... 76

DPF (diesel particle filter) ...........140

Driver assistance systems ..........152

Driver Information Centre ...........102

Driving characteristics and towing tips .............................. 162

Driving economically................... 130

Driving hints ........................ 130, 131

Driving style indicator ...................93E

ECO mode .................................. 130

ecoScoring.................................. 105

Electric adjustment ......................41

Electrical accessories ...................88

Electrical system......................... 181

Electronic climate control system 118

Electronic data recording ..............43

Electronic key system ...................24

Electronic Stability Program 99,

150, 163

Electronic Stability Program off ...99

End-of-life vehicle recovery .......166

Engine air filter............................ 168

Engine air flow indicator .............168

Engine coolant ........................... 169

Engine coolant temperature ........99

Engine data ............................... 210

Engine Drag Torque Control ......150

Engine exhaust .......................... 140

Engine identification ...................208

Engine oil ...........167, 205, 209, 219

Engine oil additives ....................205

Engine oil level .......................... 104

Engine oil pressure ....................100

Engine oil viscosity grades .........205

Enhanced Traction function 149, 150

Entry lighting .............................. 114

Event data recorders ..................225

Exhaust gases ....................140, 198