key battery OPEL VIVARO B 2019 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2019, Model line: VIVARO B, Model: OPEL VIVARO B 2019Pages: 235, PDF Size: 5.67 MB

Page 139 of 235

Driving and operating137Resetting with electronic key

system

To reset the fuel cut-off system and

enable the vehicle to be driven:

1. Insert the electronic key in the card reader 3 133.

2. Press START/STOP without

depressing any pedals.

3. Wait a few minutes to allow the fuel system to be reset.

If the engine does not start, repeat the procedure.

Electronic key system 3 23.

Power button 3 133.

Refuelling 3 162.

Overrun cut-off The fuel supply is automatically cut off

during overrun, i.e. when the vehicle

is driven with a gear engaged but

accelerator pedal is released.

Depending on driving conditions, the

overrun cut-off may be deactivated.Stop-start system

The stop-start system helps to save

fuel and to reduce the exhaust

emissions. When conditions allow, it

switches off the engine as soon as the

vehicle is at a low speed or at a

standstill, e.g. at a traffic light or in a

traffic jam. It restarts the engine

automatically as soon as the clutch pedal is depressed.

A vehicle battery sensor ensures that

an Autostop is only performed if the

vehicle battery is sufficiently charged

for a restart.

Switch off engine and ignition before

exiting the vehicle.

Activation

The stop-start system is available as

soon as the engine is started, the

vehicle starts-off and the conditions

as stated below in this section are

fulfilled.

If the below conditions are not

fulfilled, an Autostop is prohibited and

control indicator \ illuminates in the

instrument cluster 3 102.Deactivation

Deactivate the stop-start system

manually by pressing Î. LED in the

button illuminates to indicate

deactivation and a corresponding message appears in the Driver

Information Centre 3 103.

If deactivated manually, it is possible to reactivate the stop-start system by

pressing Î again. The LED

extinguishes in the button and a

corresponding message appears in

the Driver Information Centre. The

system is reactivated automatically

the next time the ignition is switched

on.

Page 177 of 235

Vehicle care175disconnecting the main vehicle

battery or before jump starting the vehicle.

The terminals are designed for

additional electrical consumers up to

a maximum of 50 A.

Jump starting 3 199.

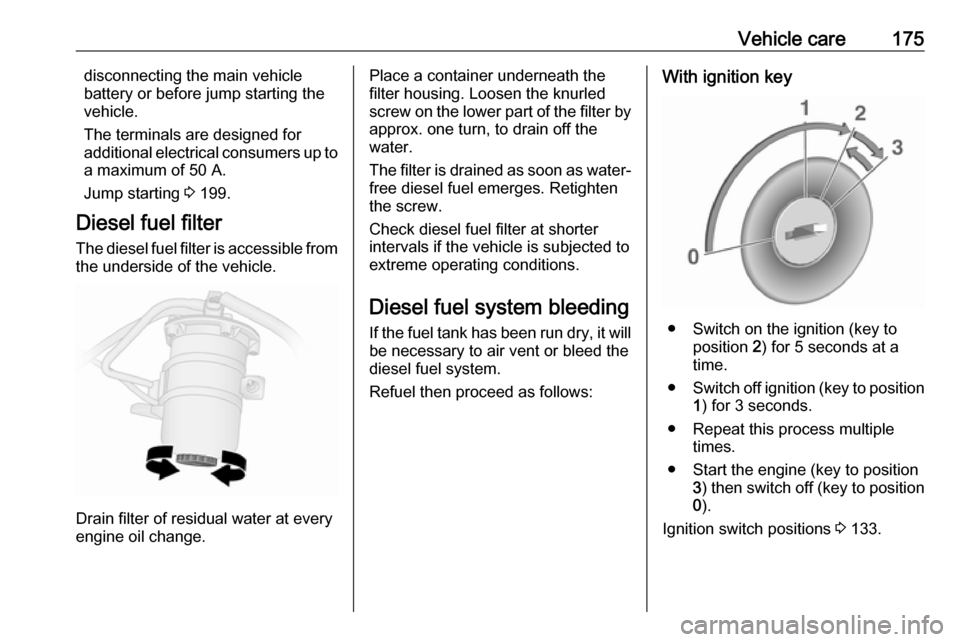

Diesel fuel filter The diesel fuel filter is accessible from the underside of the vehicle.

Drain filter of residual water at every

engine oil change.

Place a container underneath the

filter housing. Loosen the knurled

screw on the lower part of the filter by approx. one turn, to drain off the

water.

The filter is drained as soon as water-

free diesel fuel emerges. Retighten

the screw.

Check diesel fuel filter at shorter

intervals if the vehicle is subjected to

extreme operating conditions.

Diesel fuel system bleeding

If the fuel tank has been run dry, it will be necessary to air vent or bleed the

diesel fuel system.

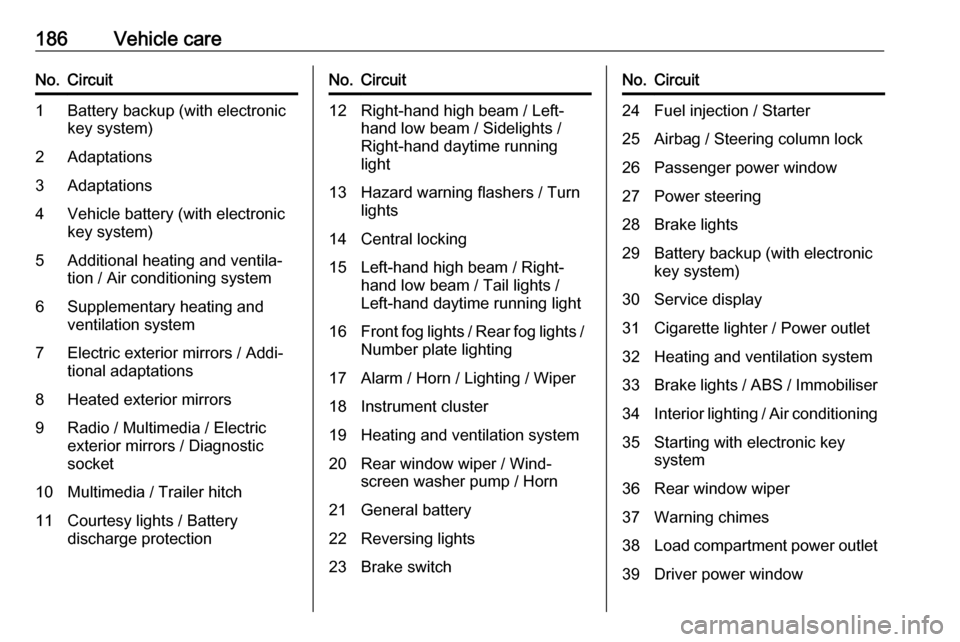

Refuel then proceed as follows:With ignition key

● Switch on the ignition (key to position 2) for 5 seconds at a

time.

● Switch off ignition (key to position

1 ) for 3 seconds.

● Repeat this process multiple times.

● Start the engine (key to position 3) then switch off (key to position

0 ).

Ignition switch positions 3 133.

Page 188 of 235

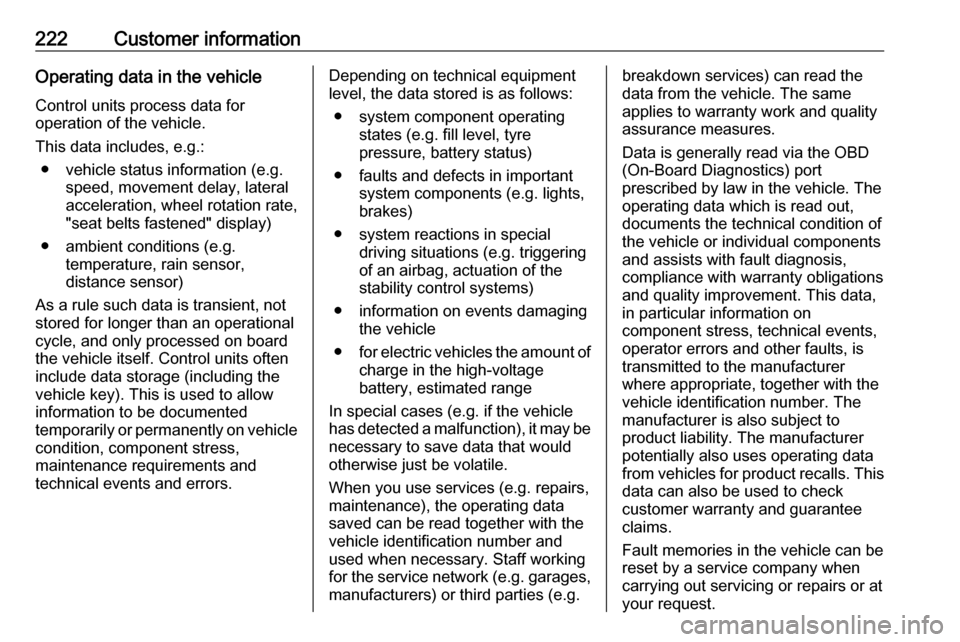

186Vehicle careNo.Circuit1Battery backup (with electronic

key system)2Adaptations3Adaptations4Vehicle battery (with electronic

key system)5Additional heating and ventila‐

tion / Air conditioning system6Supplementary heating and

ventilation system7Electric exterior mirrors / Addi‐

tional adaptations8Heated exterior mirrors9Radio / Multimedia / Electric

exterior mirrors / Diagnostic

socket10Multimedia / Trailer hitch11Courtesy lights / Battery

discharge protectionNo.Circuit12Right-hand high beam / Left-

hand low beam / Sidelights /

Right-hand daytime running

light13Hazard warning flashers / Turn

lights14Central locking15Left-hand high beam / Right-

hand low beam / Tail lights /

Left-hand daytime running light16Front fog lights / Rear fog lights /

Number plate lighting17Alarm / Horn / Lighting / Wiper18Instrument cluster19Heating and ventilation system20Rear window wiper / Wind‐

screen washer pump / Horn21General battery22Reversing lights23Brake switchNo.Circuit24Fuel injection / Starter25Airbag / Steering column lock26Passenger power window27Power steering28Brake lights29Battery backup (with electronic

key system)30Service display31Cigarette lighter / Power outlet32Heating and ventilation system33Brake lights / ABS / Immobiliser34Interior lighting / Air conditioning35Starting with electronic key

system36Rear window wiper37Warning chimes38Load compartment power outlet39Driver power window

Page 224 of 235

222Customer informationOperating data in the vehicleControl units process data for

operation of the vehicle.

This data includes, e.g.: ● vehicle status information (e.g. speed, movement delay, lateral

acceleration, wheel rotation rate, "seat belts fastened" display)

● ambient conditions (e.g. temperature, rain sensor,

distance sensor)

As a rule such data is transient, not

stored for longer than an operational

cycle, and only processed on board the vehicle itself. Control units often

include data storage (including the

vehicle key). This is used to allow

information to be documented

temporarily or permanently on vehicle

condition, component stress,

maintenance requirements and

technical events and errors.Depending on technical equipment

level, the data stored is as follows:

● system component operating states (e.g. fill level, tyre

pressure, battery status)

● faults and defects in important system components (e.g. lights,

brakes)

● system reactions in special driving situations (e.g. triggering

of an airbag, actuation of the

stability control systems)

● information on events damaging the vehicle

● for electric vehicles the amount of

charge in the high-voltage

battery, estimated range

In special cases (e.g. if the vehicle

has detected a malfunction), it may be

necessary to save data that would

otherwise just be volatile.

When you use services (e.g. repairs,

maintenance), the operating data

saved can be read together with the

vehicle identification number and

used when necessary. Staff working

for the service network ( e.g. garages,

manufacturers) or third parties (e.g.breakdown services) can read the

data from the vehicle. The same

applies to warranty work and quality

assurance measures.

Data is generally read via the OBD

(On-Board Diagnostics) port

prescribed by law in the vehicle. The operating data which is read out,

documents the technical condition of

the vehicle or individual components

and assists with fault diagnosis,

compliance with warranty obligations

and quality improvement. This data,

in particular information on

component stress, technical events,

operator errors and other faults, is

transmitted to the manufacturer

where appropriate, together with the

vehicle identification number. The

manufacturer is also subject to

product liability. The manufacturer

potentially also uses operating data

from vehicles for product recalls. This

data can also be used to check

customer warranty and guarantee

claims.

Fault memories in the vehicle can be

reset by a service company when

carrying out servicing or repairs or at

your request.