ESP OPEL VIVARO B 2019 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2019, Model line: VIVARO B, Model: OPEL VIVARO B 2019Pages: 235, PDF Size: 5.67 MB

Page 166 of 235

164Driving and operatingTrailer hitch

General information

Entrust retrofitting of towing

equipment to a workshop. It may be

necessary to make changes that

affect the cooling system, heat

shields or other equipment. Only use

towing equipment that has been

approved for your vehicle.

Driving characteristics and towing tips

In the case of trailers with brakes,

attach the breakaway stopping cable.

Before attaching a trailer, lubricate

the coupling ball. However, do not do so if a stabiliser, which acts on thecoupling ball, is being used to reduce

snaking movements. For trailers with

low driving stability the use of a

stabiliser is recommended.

A maximum speed of 80 km/h must

not be exceeded, even in countries

where higher speeds are permitted.If the trailer starts snaking, drive more slowly, do not attempt to correct the

steering and brake sharply if

necessary.

When driving downhill, drive in the

same gear as if driving uphill and

drive at a similar speed.

Adjust tyre pressure to the value

specified for full load 3 216.

Trailer towing

Trailer loads The permissible trailer loads are

vehicle and engine-dependent

maximum values which must not be

exceeded. The actual trailer load is the difference between the actual

gross weight of the trailer and the

actual coupling socket load with the

trailer coupled.

The permissible trailer loads are

specified in the vehicle documents. In

general, they are valid for gradients

up to max. 12%.

The permitted trailer load applies up

to the specified incline and up to an

altitude of 1000 m above sea level.Since engine power decreases as

altitude increases due to the air

becoming thinner, therefore reducing

climbing ability, the permissible gross

train weight also decreases by 10% for every 1000 m of additional

altitude. The gross train weight does

not have to be reduced when driving

on roads with slight inclines (less than 8%, e.g. motorways).

The permissible gross train weight

must not be exceeded. This weight is

specified on the identification plate

3 210.

Vertical coupling load

The vertical coupling load is the load

exerted by the trailer on the coupling

ball. It can be varied by changing the

weight distribution when loading the

trailer.

The maximum permissible vertical

coupling load is specified on the

towing equipment identification plate

and in the vehicle documents. Always aim for the maximum load, especially in the case of heavy trailers. The

vertical coupling load should never

fall below 25 kg.

Page 172 of 235

170Vehicle careCaution

Do not allow the engine oil level todrop below the minimum level!

We recommend the use of the same

grade of engine oil that was used at

the last change.

Between the MIN and MAX marks a

volume of approx. 2.1 l for engines R9M 408, R9M 413 and R9M 415

respectively approx. 3.5 l for engines

R9M 450 and R9M 452 can be filled

in.

The engine oil level must not exceed the maximum mark MAX on the

dipstick.Caution

Overfilled engine oil must be

drained or suctioned out. If the oil exceeds the maximum level, do

not start the vehicle and contact a

workshop.

To prevent spillage when

replenishing the engine oil, we

recommend using a funnel to top-up the engine oil. Ensure funnel is

securely located onto the filler pipe.

After topping-up, put the funnel into a

plastic bag and stow it securely.

A stabilization of the engine oil

consumption will not take place until

the vehicle has been driven several

thousand kilometres. Only then can

the actual degree of consumption be

established.

If consumption exceeds more than

0.6 l every 1000 km after this running-

in period, consult a workshop.

Fit the cap on straight and tighten it.

Engine air filter

Engine air flow indicator

On certain models, an indicator is

located in the engine induction

system and indicates if the air-intake

to the engine is restricted.

Clear:No restrictionRed tell-tale:Restricted

If the red tell-tale is displayed when

the engine is running, consult a

workshop.

Page 185 of 235

Vehicle care183Instrument panel

illumination

Have bulbs replaced by a workshop.Electrical system

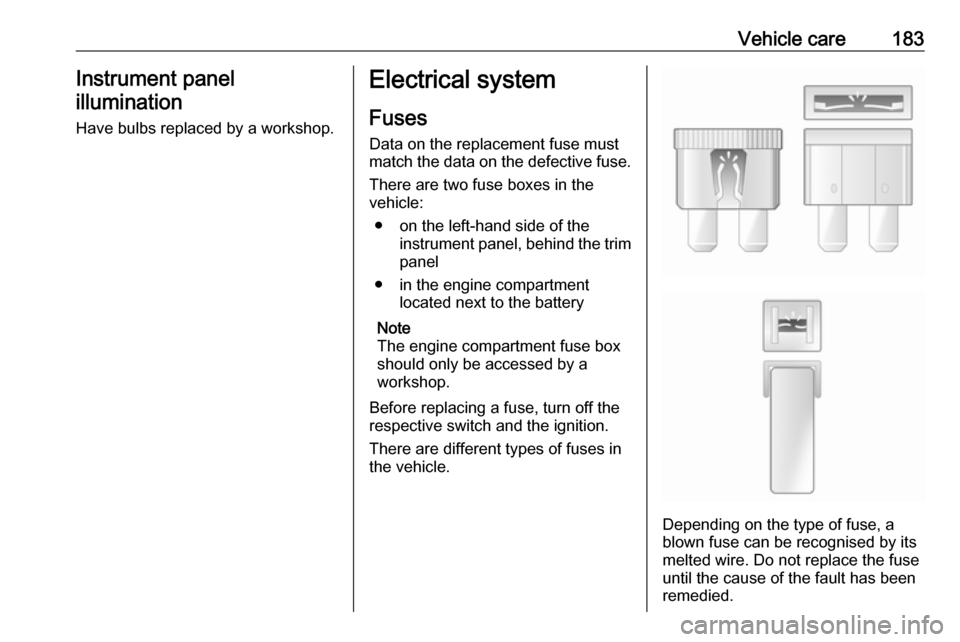

Fuses Data on the replacement fuse must

match the data on the defective fuse.

There are two fuse boxes in the

vehicle:

● on the left-hand side of the instrument panel, behind the trim

panel

● in the engine compartment located next to the battery

Note

The engine compartment fuse box

should only be accessed by a

workshop.

Before replacing a fuse, turn off the

respective switch and the ignition.

There are different types of fuses in the vehicle.

Depending on the type of fuse, a

blown fuse can be recognised by its

melted wire. Do not replace the fuse

until the cause of the fault has been

remedied.

Page 191 of 235

Vehicle care189

The tyre pressure information label

on the driver's door frame indicates

the original equipment tyres and the

correspondent tyre pressures.

Always inflate tyres to the pressures

shown on the label.

Tyre pressures 3 216.

The tyre pressure data refers to cold tyres. It applies to summer and winter tyres.

Always inflate the spare tyre to the

highest pressure specified for this

tyre size.

Incorrect tyre pressures will impair

safety, vehicle handling, comfort and

fuel economy and will increase tyre

wear.

The tyre pressure table shows all

possible tyre combinations 3 216.

For the tyres approved for your

vehicle, refer to the EEC Certificate of

Conformity provided with your vehicle or other national registration

documents.

The driver is responsible for correct

adjustment of tyre pressure.9 Warning

If the pressure is too low, this can

result in considerable tyre warm-

up and internal damage, leading to tread separation and even to tyre

blow-out at high speeds.

9 Warning

For specific tyres the

recommended tyre pressure as

shown in the tyre pressure table may exceed the maximum tyre

pressure as indicated on the tyre.

Never exceed the maximum tyre

pressure as indicated on the tyre.

Temperature dependency

Tyre pressure depends on the

temperature of the tyre. During

driving, tyre temperature and

pressure increase.

Tyre pressure values provided on the

tyre information label and tyre

pressure chart are valid for cold tyres, which means at 20 °C. The pressure

increases by nearly 10 kPa (0.1 bar)

for a 10 °C temperature increase.

This must be considered when warm

tyres are checked.

Trailer towing

When towing a trailer with a fully laden vehicle, the tyre pressure must

be increased by 20 kPa / 0.2 bar

(3.0 psi) and the maximum speed

limited to 100 km/h.

Trailer towing 3 164.

Page 192 of 235

190Vehicle careTyre pressure monitoring

system

The tyre pressure monitoring system

uses radio and sensor technology to

check tyre pressure levels.Caution

Tyre pressure monitoring system

warns only about low tyre pressure condition and does not replace

regular tyre maintenance by the

driver.

All wheels must be equipped with pressure sensors and the tyres must

have the prescribed pressure.

Note

In countries where the tyre pressure

monitoring system is legally

required, the use of wheels without

pressure sensors will invalidate the

vehicle operating permit.

The tyre pressure monitoring system

sensors monitor the air pressure in

the tyres and transmit tyre pressure

readings to a receiver located in the

vehicle.

Tyre pressure chart 3 216.

Low tyre pressure condition

A detected low tyre pressure

condition is indicated by illumination

of control indicator w 3 101 and a

corresponding message appears in

the Driver Information Centre.

If w illuminates, stop as soon as

possible and inflate the tyres as

recommended 3 216.

After inflating, some driving may be

required to update the tyre pressure

values in the system. During this time

w may illuminate.

If

w illuminates at lower temperatures

and extinguishes after some driving,

this could be an indicator for

approaching a low tyre pressure

condition. Check tyre pressure of all

four tyres.

If the tyre pressure must be reduced

or increased, switch off ignition.

Only mount wheels with pressure

sensors, otherwise w flashes for

several seconds then illuminates

continuously together with control

indicator j 3 99 and a

corresponding message appears in

the Driver Information Centre.

A spare wheel or temporary spare

wheel is not equipped with pressure

sensors. The tyre pressure

monitoring system is not operational

for these wheels. For the further three wheels, the tyre pressure monitoring

system remains operational.

Control indicator w and the

corresponding message appears at

each ignition cycle until the tyres are

inflated to the correct tyre pressure.

Driver Information Centre 3 103.

Vehicle messages 3 104.

Page 193 of 235

Vehicle care191PunctureA puncture or severely under-inflated

tyre is indicated by illumination of

control indicator w together with C

3 99 and a corresponding message

appears in the Driver Information

Centre. Stop vehicle and switch off

engine.

Tyre pressure 3 216.

Tyre repair kit 3 193.

Spare wheel 3 197.

Wheel changing 3 196.

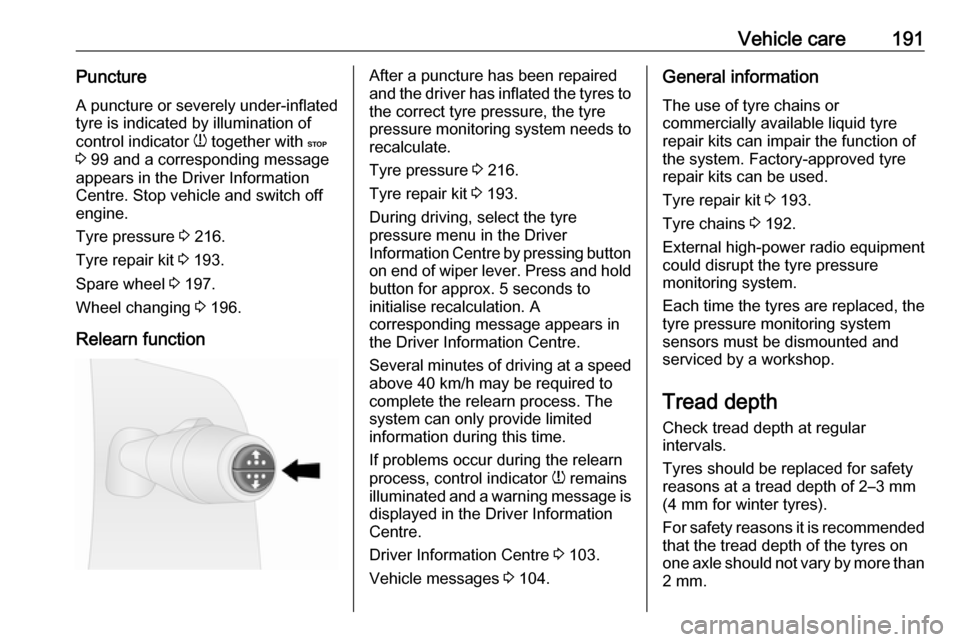

Relearn functionAfter a puncture has been repaired

and the driver has inflated the tyres to

the correct tyre pressure, the tyre

pressure monitoring system needs to recalculate.

Tyre pressure 3 216.

Tyre repair kit 3 193.

During driving, select the tyre

pressure menu in the Driver

Information Centre by pressing button

on end of wiper lever. Press and hold button for approx. 5 seconds to

initialise recalculation. A

corresponding message appears in

the Driver Information Centre.

Several minutes of driving at a speed above 40 km/h may be required to

complete the relearn process. The system can only provide limited

information during this time.

If problems occur during the relearn

process, control indicator w remains

illuminated and a warning message is displayed in the Driver Information

Centre.

Driver Information Centre 3 103.

Vehicle messages 3 104.General information

The use of tyre chains or

commercially available liquid tyre

repair kits can impair the function of

the system. Factory-approved tyre

repair kits can be used.

Tyre repair kit 3 193.

Tyre chains 3 192.

External high-power radio equipment

could disrupt the tyre pressure

monitoring system.

Each time the tyres are replaced, the

tyre pressure monitoring system

sensors must be dismounted and

serviced by a workshop.

Tread depth Check tread depth at regular

intervals.

Tyres should be replaced for safety

reasons at a tread depth of 2–3 mm

(4 mm for winter tyres).

For safety reasons it is recommended

that the tread depth of the tyres on

one axle should not vary by more than 2 mm.

Page 194 of 235

192Vehicle care

The legally permissible minimum

tread depth (1.6 mm) has been

reached when the tread has worn

down as far as one of the tread wear

indicators (TWI). Their position is

indicated by markings on the

sidewall.

Tyres age, even if they are not used.

We recommend tyre replacement

every 6 years.

Changing tyre and wheel

size

If tyres of a different size than those fitted at the factory are used, it may be necessary to reprogramme the

nominal tyre pressure and make

other vehicle modifications.

After converting to a different tyre

size, have the label with tyre

pressures replaced.

Tyre pressure monitoring system

3 190.9 Warning

The use of unsuitable tyres or

wheels may lead to accidents and will invalidate the vehicle

operating permit.

Wheel covers

Wheel covers and tyres that are

factory approved for the respective

vehicle and comply with all of the

relevant wheel and tyre combination

requirements must be used.

If the wheel covers and tyres used are

not factory approved, the tyres must

not have a rim protection ridge.

Wheel covers must not impair brake

cooling.9 Warning

Use of unsuitable tyres or wheel

covers could lead to sudden

pressure loss and thereby

accidents.

Tyre chains

Tyre chains are only permitted on the

front wheels.

Page 200 of 235

198Vehicle careCaution

The use of a spare wheel that issmaller than the other wheels or in combination with winter tyres

could affect driveability. Have the defective tyre replaced as soon as

possible.

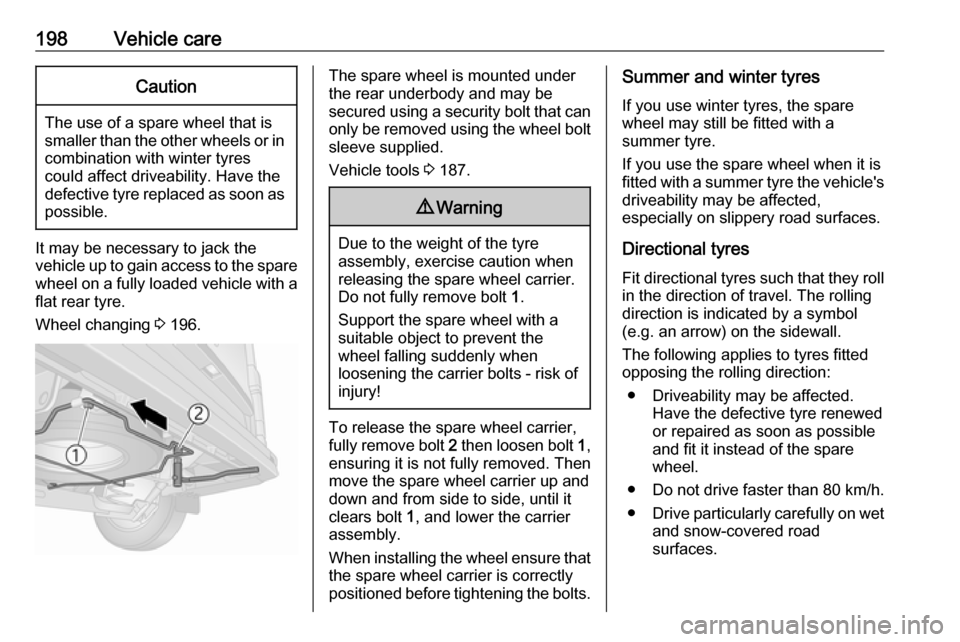

It may be necessary to jack the

vehicle up to gain access to the spare

wheel on a fully loaded vehicle with a

flat rear tyre.

Wheel changing 3 196.

The spare wheel is mounted under

the rear underbody and may be

secured using a security bolt that can

only be removed using the wheel bolt sleeve supplied.

Vehicle tools 3 187.9 Warning

Due to the weight of the tyre

assembly, exercise caution when

releasing the spare wheel carrier.

Do not fully remove bolt 1.

Support the spare wheel with a

suitable object to prevent the

wheel falling suddenly when

loosening the carrier bolts - risk of injury!

To release the spare wheel carrier,fully remove bolt 2 then loosen bolt 1,

ensuring it is not fully removed. Then

move the spare wheel carrier up and

down and from side to side, until it

clears bolt 1, and lower the carrier

assembly.

When installing the wheel ensure that

the spare wheel carrier is correctly

positioned before tightening the bolts.

Summer and winter tyres

If you use winter tyres, the spare

wheel may still be fitted with a

summer tyre.

If you use the spare wheel when it is

fitted with a summer tyre the vehicle's driveability may be affected,

especially on slippery road surfaces.

Directional tyres

Fit directional tyres such that they roll in the direction of travel. The rolling

direction is indicated by a symbol

(e.g. an arrow) on the sidewall.

The following applies to tyres fitted

opposing the rolling direction:

● Driveability may be affected. Have the defective tyre renewed

or repaired as soon as possible

and fit it instead of the spare

wheel.

● Do not drive faster than 80 km/h.

● Drive particularly carefully on wet

and snow-covered road

surfaces.

Page 206 of 235

204Vehicle carePaintwork damageRectify minor paintwork damage with

a touch-up pen before rust forms.

Have more extensive damage or rust

areas repaired by a workshop.

Underbody Some areas of the vehicle underbody

have a PVC undercoating while other

critical areas have a durable

protective wax coating.

After the underbody is washed, check

the underbody and have it waxed if

necessary.

Bitumen / rubber materials could

damage the PVC coating. Have

underbody work carried out by a

workshop.

Before and after winter, wash the

underbody and have the protective

wax coating checked.

Towing equipment Do not clean the coupling ball bar with

a steam-jet or high-pressure jet

cleaner.Interior care

Interior and upholstery Only clean the vehicle interior,

including the instrument panel fascia

and panelling, with a dry cloth or

interior cleaner.

Clean any leather upholstery with

clear water and a soft cloth. In case of

heavy soiling, use leather care.

The instrument cluster and the

displays should only be cleaned using a soft damp cloth. If necessary use aweak soap solution.

Clean fabric upholstery with a

vacuum cleaner and brush. Remove

stains with an upholstery cleaner.

Clothing fabrics may not be

colourfast. This could cause visible

discolourations, especially on light-

coloured upholstery. Removable

stains and discolourations should be

cleaned as soon as possible.

Clean seat belts with lukewarm water or interior cleaner.Caution

Close Velcro fasteners as open

Velcro fasteners on clothing could damage seat upholstery.

The same applies to clothing with

sharp-edged objects, like zips or

belts or studded jeans.

Plastic and rubber parts

Plastic and rubber parts can be

cleaned with the same cleaner as

used to clean the body. Use interior cleaner if necessary. Do not use any

other agent. Avoid solvents and petrol in particular. Do not use high-

pressure jet cleaners.