lock OPEL VIVARO C 2020.25 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2020.25, Model line: VIVARO C, Model: OPEL VIVARO C 2020.25Pages: 287, PDF Size: 28.79 MB

Page 203 of 287

Driving and operating201ActivationInfo Display without touchscreen

Press Qto activate the system.

The system is switched on when the

LED in the button is illuminated.

Info Display with touchscreen

The system can be activated in the

vehicle personalisation 3 124.

The system is only operable at

vehicle speeds above 60 km/h and if

lane markings are available.

When the system recognises an

unintended lane change, the control

indicator ) flashes yellow.

Simultaneously a chime sounds.

Deactivation

Info Display without touchscreen

Press Q to deactivate the system.

The LED in the button Q

extinguishes.Info Display with touchscreen

The system can be deactivated in the

vehicle personalisation 3 124.

At speeds below 60 km/h the system

is inoperable.

Fault

Info Display without touchscreen

The LED of the Q flashes.Info Display with touchscreen

The control indicator Q flashes and

an error message is displayed.

Seek the assistance of a workshop.

The system cannot operate when no

lane marking is detected.

System limitations

The system may not operate properly

when:

● vehicle speed is below 60 km/h● driving on winding or hilly roads

● driving in the dark

● weather limits visibility, such as fog, rain, or snow

● the camera is blocked by snow, ice, slush, mud, dirt, windscreen

damage or affected by foreign

items, e.g. stickers

● the sun is shining directly into the

camera lens

● close vehicles ahead

● banked roads

● road edges

● roads with poor lane markings

● sudden lighting changes

Driver alert

The driver alert system monitores the driving time and the vigilance of the

driver. Monitoring the vigilance of the

Page 206 of 287

204Driving and operatingFor more information, contact a

dealer or a qualified workshop.Caution

The use of any other type of (bio)

fuel (vegetable or animal oils, pure

or diluted, domestic fuel etc.) is

strictly prohibited (risk of damage

to the engine and fuel system).

Note

The only Diesel additives authorised for use are those that meet the

B715000 standard.

Low temperature operation

At temperatures below 0 °C, some

diesel products with biodiesel blends may clog, freeze or gel, which mayaffect the fuel supply system. Starting

and engine operation may not work

properly. Make sure to fill winter

grade diesel fuel at ambient

temperatures below 0 °C.

Arctic grade diesel fuel can be used

in extreme low temperatures below

-20 °C. Using this fuel grade in warm

or hot climates is not recommended

and may cause engine stalling, poor starting or damage on the fuel

injection system.

Refuelling9 Danger

Before refuelling, switch off

ignition and any external heaters

with combustion chambers.

Follow the operating and safety

instructions of the filling station

when refuelling.

9 Danger

Fuel is flammable and explosive.

No smoking. No naked flames or

sparks.

If a smell of fuel can be noticed

inside the vehicle, have the cause of this remedied immediately by aworkshop.

A label with symbols at the fuel filler

flap is indicating the allowed fuel

types. In Europe the pump nozzles of

the filling stations are marked with

these symbols. Refuel only the

allowed fuel type.Caution

In case of misfuelling, do not

switch on ignition.

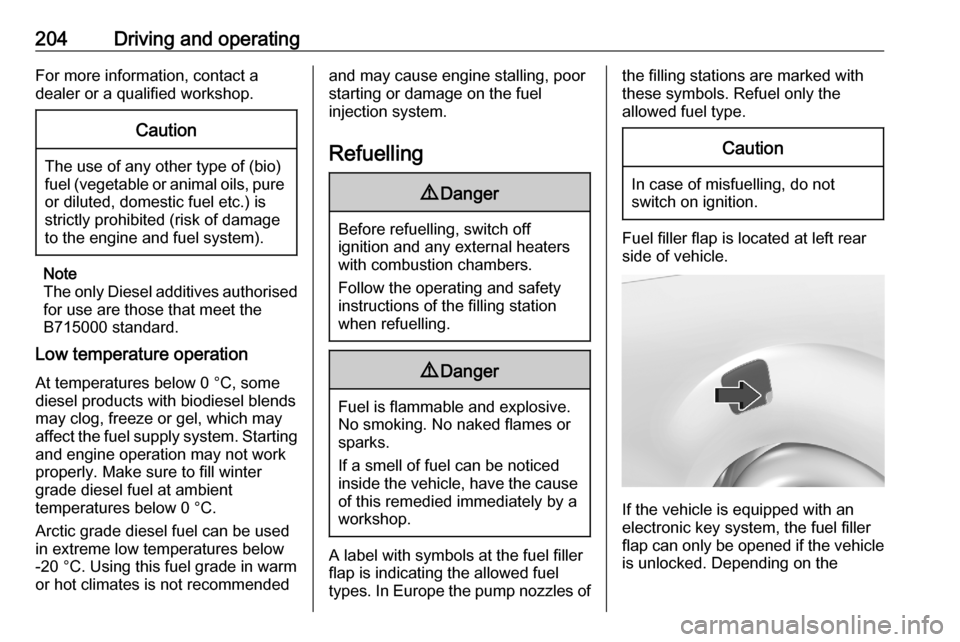

Fuel filler flap is located at left rear

side of vehicle.

If the vehicle is equipped with an

electronic key system, the fuel filler

flap can only be opened if the vehicle

is unlocked. Depending on the

Page 207 of 287

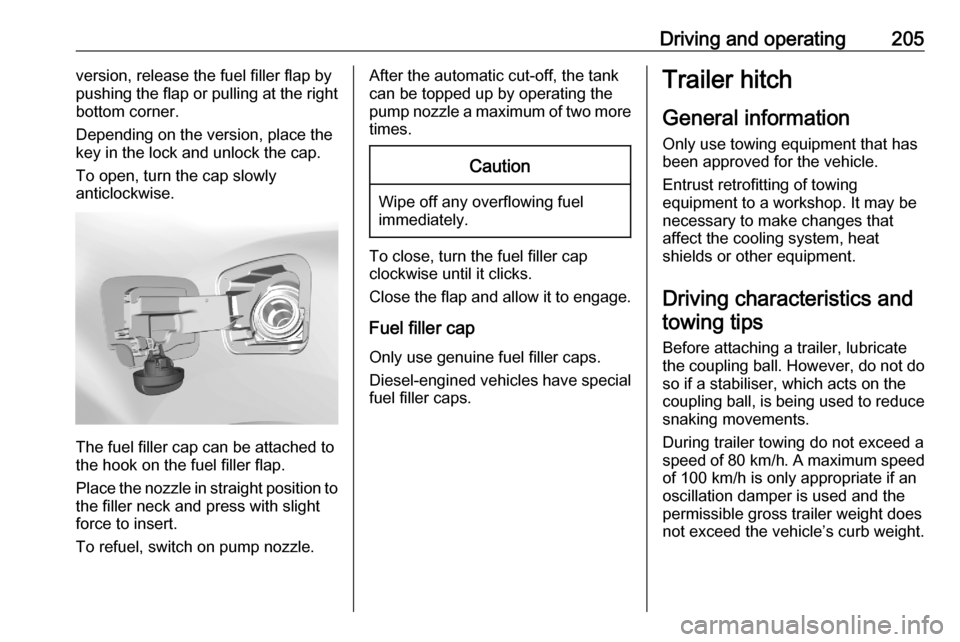

Driving and operating205version, release the fuel filler flap by

pushing the flap or pulling at the right bottom corner.

Depending on the version, place the

key in the lock and unlock the cap.

To open, turn the cap slowly

anticlockwise.

The fuel filler cap can be attached to

the hook on the fuel filler flap.

Place the nozzle in straight position to the filler neck and press with slight

force to insert.

To refuel, switch on pump nozzle.

After the automatic cut-off, the tank can be topped up by operating the

pump nozzle a maximum of two more

times.Caution

Wipe off any overflowing fuel

immediately.

To close, turn the fuel filler cap

clockwise until it clicks.

Close the flap and allow it to engage.

Fuel filler cap

Only use genuine fuel filler caps.

Diesel-engined vehicles have special fuel filler caps.

Trailer hitch

General information

Only use towing equipment that has

been approved for the vehicle.

Entrust retrofitting of towing

equipment to a workshop. It may be

necessary to make changes that

affect the cooling system, heat

shields or other equipment.

Driving characteristics and towing tips

Before attaching a trailer, lubricate

the coupling ball. However, do not do so if a stabiliser, which acts on thecoupling ball, is being used to reduce

snaking movements.

During trailer towing do not exceed a

speed of 80 km/h. A maximum speed

of 100 km/h is only appropriate if an

oscillation damper is used and the

permissible gross trailer weight does

not exceed the vehicle’s curb weight.

Page 209 of 287

Driving and operating207Always aim for the maximum vertical

coupling load, especially in the case

of heavy trailers. The vertical coupling

load should never fall below 25 kg.

Rear axle load

When the trailer is coupled and the

towing vehicle fully loaded, the

permissible rear axle load (see

identification plate or vehicle

documents) may be exceeded by

60 kg , the gross vehicle weight rating

must not be exceeded. If the

permissible rear axle load is

exceeded, a maximum speed of

100 km/h applies.

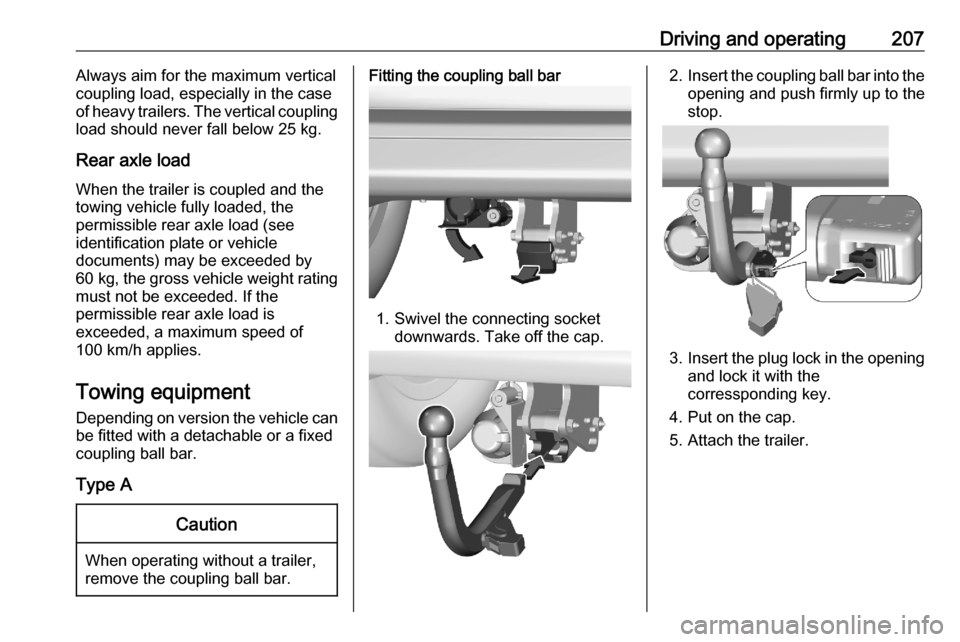

Towing equipment Depending on version the vehicle canbe fitted with a detachable or a fixed

coupling ball bar.

Type ACaution

When operating without a trailer,

remove the coupling ball bar.

Fitting the coupling ball bar

1. Swivel the connecting socket downwards. Take off the cap.

2.Insert the coupling ball bar into the

opening and push firmly up to the stop.

3. Insert the plug lock in the opening

and lock it with the

corressponding key.

4. Put on the cap.

5. Attach the trailer.

Page 210 of 287

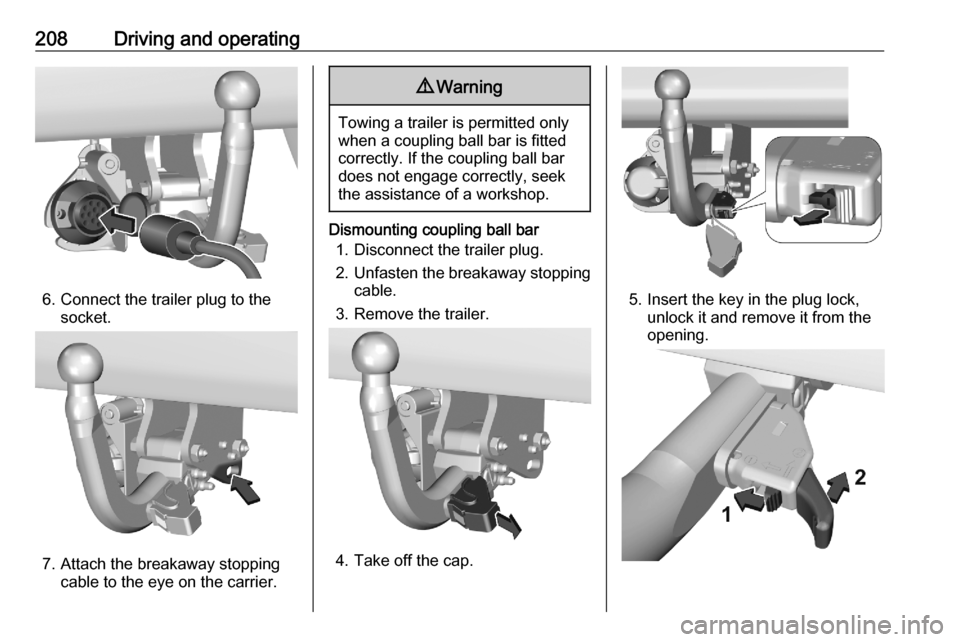

208Driving and operating

6. Connect the trailer plug to thesocket.

7. Attach the breakaway stoppingcable to the eye on the carrier.

9 Warning

Towing a trailer is permitted only

when a coupling ball bar is fitted correctly. If the coupling ball bardoes not engage correctly, seekthe assistance of a workshop.

Dismounting coupling ball bar

1. Disconnect the trailer plug.

2. Unfasten the breakaway stopping

cable.

3. Remove the trailer.

4. Take off the cap.

5. Insert the key in the plug lock, unlock it and remove it from the

opening.

Page 215 of 287

Vehicle care213● Open the bonnet, close all doorsand lock the vehicle.

● Disconnect the clamp from the negative terminal of the vehicle

battery. Note that all systems are

not functional, e.g. anti-theft

alarm system.

Putting back into operation

When the vehicle is to be put back into

operation:

● Connect the clamp to the negative terminal of the vehicle

battery. Initialize the power

windows 3 42.

● Check tyre pressure.

● Fill up the washer fluid reservoir.

● Check the engine oil level.

● Check the coolant level.

● Fit the number plates if necessary.End-of-life vehicle recovery

Information on end-of-life vehicle

recovery centres and the recycling of

end-of-life vehicles is available on our website, where legally required. Only

entrust this work to an authorised

recycling centre.Vehicle checks

Performing work9 Warning

Only perform engine compartment

checks when the ignition is off.

The cooling fan may start

operating even if the ignition is off.

Page 227 of 287

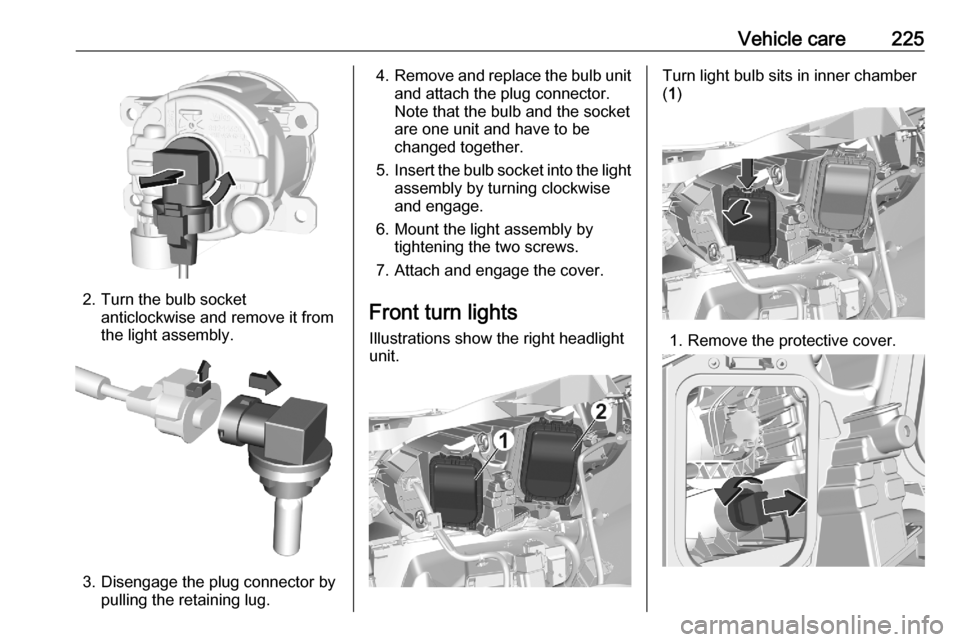

Vehicle care225

2. Turn the bulb socketanticlockwise and remove it from

the light assembly.

3. Disengage the plug connector by pulling the retaining lug.

4.Remove and replace the bulb unit

and attach the plug connector.

Note that the bulb and the socket

are one unit and have to be

changed together.

5. Insert the bulb socket into the light

assembly by turning clockwise

and engage.

6. Mount the light assembly by tightening the two screws.

7. Attach and engage the cover.

Front turn lights Illustrations show the right headlight

unit.Turn light bulb sits in inner chamber

( 1 )

1. Remove the protective cover.

Page 228 of 287

226Vehicle care2. Rotate the bulb socketanticlockwise to disengage and

withdraw from the reflector.

3. Slightly press down the bulb, turn it anticlockwise and remove it

from the socket.

4. Replace and insert the new bulb into socket by turning clockwise.

5. Insert the bulb socket into the reflector and turn clockwise.

Tail lights

Tail light assembly All body styles except platform cab

1. Vehicles with a cover hiding the lower tail light assembly screw:

remove cover by carefully

releasing its retaining lugs with a

screwdriver and tilting the cover

slightly towards the outside.

2. Unscrew and remove the two screws.

3. Vehicles with air vent or coverbehind the tail light, in the trim:

Remove air vent or cover.

Page 230 of 287

228Vehicle care12. Clip in cover which may havecovered the lower tail light

assembly screw.

13. Attach cover or air vent behind the

tail light if removed before.

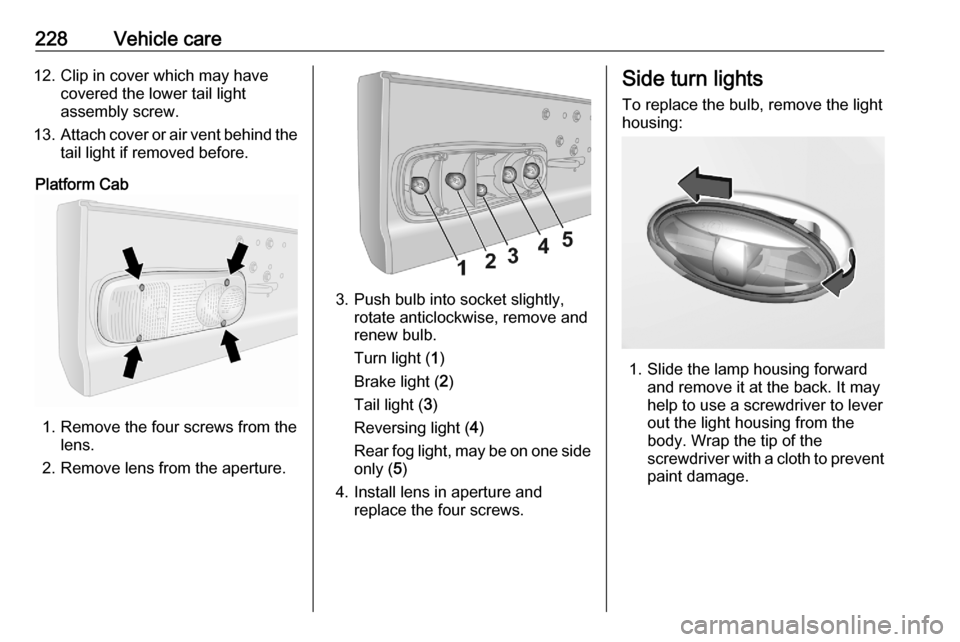

Platform Cab

1. Remove the four screws from the lens.

2. Remove lens from the aperture.

3. Push bulb into socket slightly, rotate anticlockwise, remove and

renew bulb.

Turn light ( 1)

Brake light ( 2)

Tail light ( 3)

Reversing light ( 4)

Rear fog light, may be on one side

only ( 5)

4. Install lens in aperture and replace the four screws.

Side turn lights

To replace the bulb, remove the light

housing:

1. Slide the lamp housing forward and remove it at the back. It may

help to use a screwdriver to lever

out the light housing from the

body. Wrap the tip of the

screwdriver with a cloth to prevent

paint damage.

Page 231 of 287

Vehicle care229

2.Pull the retaining lug upwards and

remove the bulb socket from the

plug connector.

3. Replace the complete unit.

4. Insert left end of the lamp, slide to

the left and insert right end.

Centre high-mounted brake light

Vehicles with hinged doors or

tailgate

1. Open the rear doors.

2. a) vehicles with tailgate:

Loose the inner trim from clips by

swiveling it upwards and

downwards. Pull trim off carefully.

b) vehicles with hinged doors:

Wrap a cloth around the tip of a

slot screwdriver to prevent paint

damage. Remove the inner cover

or air vent with the screwdriver.

3. Push the brake light assembly carefully out through the recess.

4. Detach the cable from the retainer

in the light assembly.

5. Remove the socket of the defect bulb by turning it a quarter turn

anti-clockwise.

6. Renew bulb.

7. Install brake light assembly like explained above, in reversed

order.