jacking OPEL VIVARO C 2020.25 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2020.25, Model line: VIVARO C, Model: OPEL VIVARO C 2020.25Pages: 287, PDF Size: 28.79 MB

Page 246 of 287

244Vehicle care

2. Disconnect the connector fromthe cartridge by turning it a quarter

turn anti-clockwise.

3. Pull pipe assembly out slightly, then disconnect connector from

the air hose by turning it a quarter

turn anticlockwise.

4. Remove air hose.

Keep the kit vertical and unscrew

the cartridge from the bottom.

5. To fit the new cartridge and new pipe, carry out these operations in

reverse order.

Wheel changing

Make the following preparations and

observe the following information:

● Park the vehicle on a level, firm and non-skid surface. The front

wheels must be in the straight-

ahead position.

● If necessary, place a chock under

the wheel diagonally opposite the

wheel to be changed.

● Apply the parking brake and engage first gear, reverse gear or

P .

● If the ground on which the vehicle

is standing is soft, a solid board

(max. 1 cm thick) should be

placed under the jack.

● Take heavy objects out of the vehicle before jacking up.

● No people or animals may be in the vehicle when it is jacked-up.

● Never crawl under a jacked-up vehicle.

● Do not start the vehicle when it is

raised on the jack.

● Before screwing in the wheel bolts, clean them.

Page 247 of 287

Vehicle care2459Warning

Do not grease wheel bolts.

Tightening torques

Caution

If the vehicle is equipped with alloy

wheels, tighten the wheel bolts

manually at least for the first five

turns.

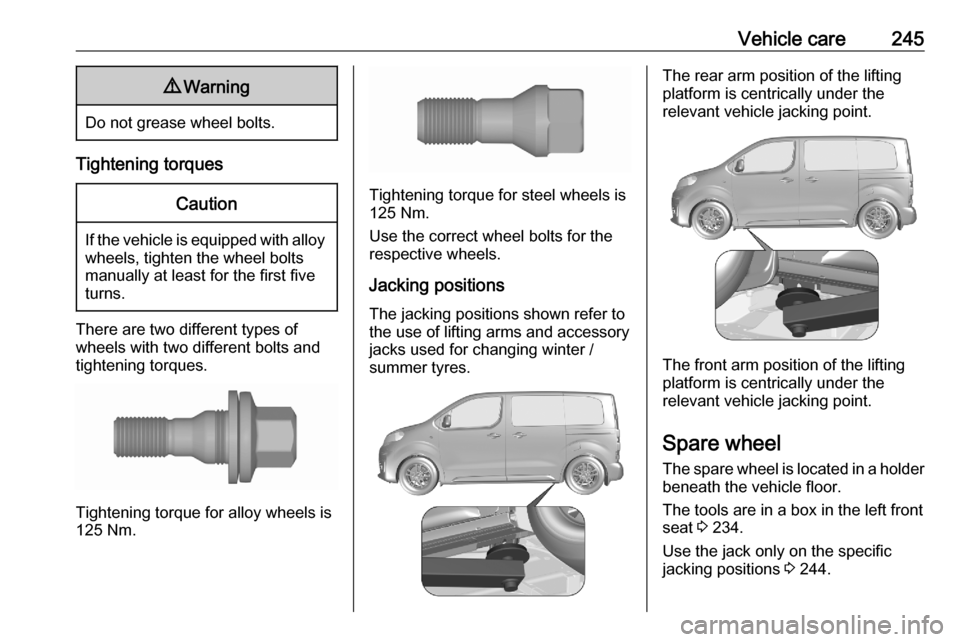

There are two different types of

wheels with two different bolts and tightening torques.

Tightening torque for alloy wheels is

125 Nm.

Tightening torque for steel wheels is

125 Nm.

Use the correct wheel bolts for the respective wheels.

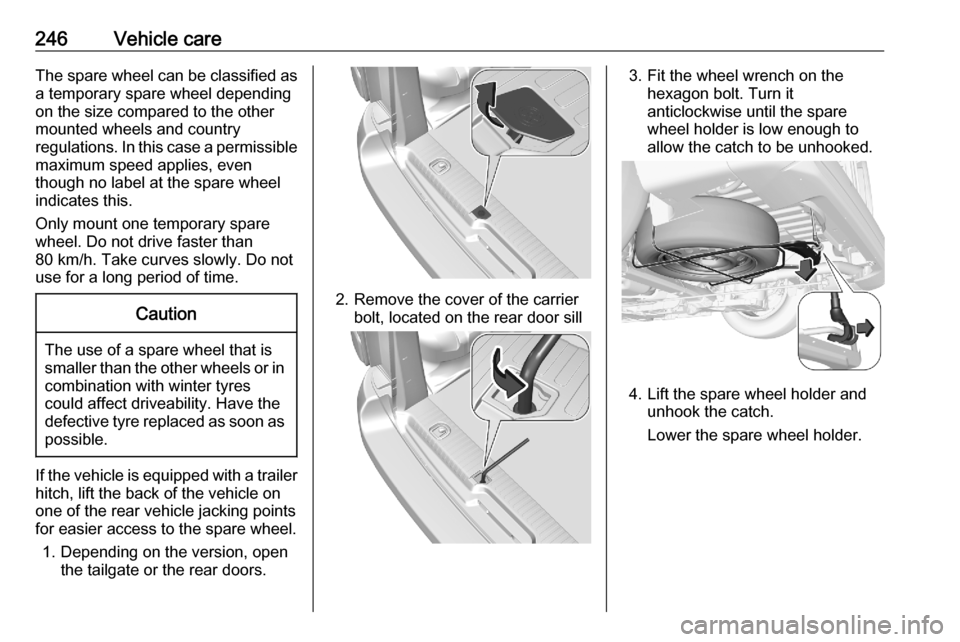

Jacking positions The jacking positions shown refer tothe use of lifting arms and accessoryjacks used for changing winter /

summer tyres.

The rear arm position of the lifting

platform is centrically under the

relevant vehicle jacking point.

The front arm position of the lifting

platform is centrically under the

relevant vehicle jacking point.

Spare wheel The spare wheel is located in a holder

beneath the vehicle floor.

The tools are in a box in the left front

seat 3 234.

Use the jack only on the specific

jacking positions 3 244.

Page 248 of 287

246Vehicle careThe spare wheel can be classified as

a temporary spare wheel depending

on the size compared to the other

mounted wheels and country

regulations. In this case a permissible maximum speed applies, even

though no label at the spare wheel

indicates this.

Only mount one temporary spare

wheel. Do not drive faster than

80 km/h. Take curves slowly. Do not use for a long period of time.Caution

The use of a spare wheel that issmaller than the other wheels or in

combination with winter tyres

could affect driveability. Have the defective tyre replaced as soon as

possible.

If the vehicle is equipped with a trailer hitch, lift the back of the vehicle on

one of the rear vehicle jacking points

for easier access to the spare wheel.

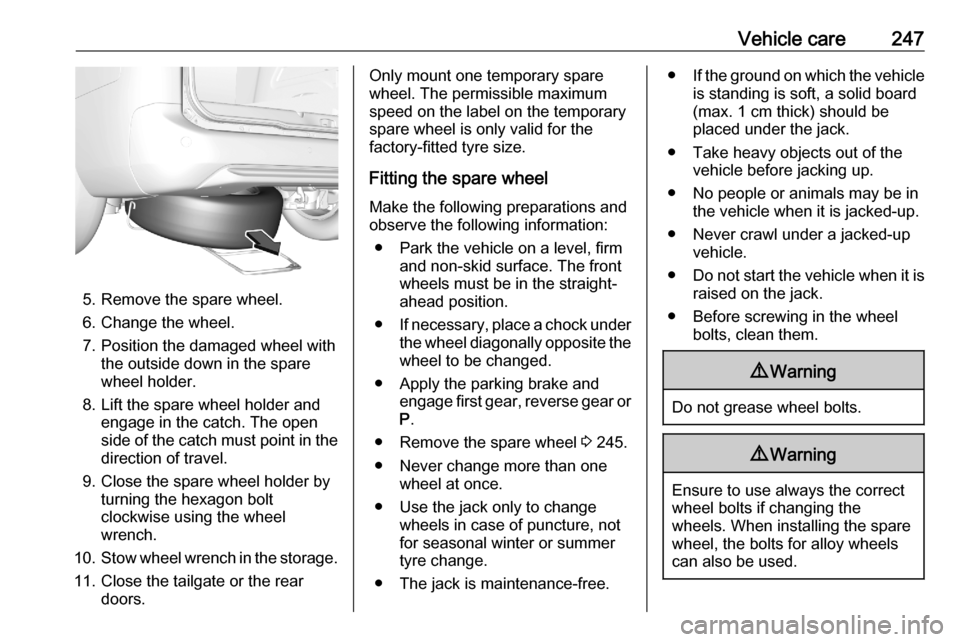

1. Depending on the version, open the tailgate or the rear doors.

2. Remove the cover of the carrierbolt, located on the rear door sill

3. Fit the wheel wrench on the hexagon bolt. Turn it

anticlockwise until the spare wheel holder is low enough to

allow the catch to be unhooked.

4. Lift the spare wheel holder and unhook the catch.

Lower the spare wheel holder.

Page 249 of 287

Vehicle care247

5. Remove the spare wheel.

6. Change the wheel.

7. Position the damaged wheel with the outside down in the spare

wheel holder.

8. Lift the spare wheel holder and engage in the catch. The open

side of the catch must point in the

direction of travel.

9. Close the spare wheel holder by turning the hexagon bolt

clockwise using the wheel

wrench.

10. Stow wheel wrench in the storage.

11. Close the tailgate or the rear doors.

Only mount one temporary spare

wheel. The permissible maximum

speed on the label on the temporary

spare wheel is only valid for the

factory-fitted tyre size.

Fitting the spare wheel

Make the following preparations and

observe the following information:

● Park the vehicle on a level, firm and non-skid surface. The front

wheels must be in the straight- ahead position.

● If necessary, place a chock under

the wheel diagonally opposite the

wheel to be changed.

● Apply the parking brake and engage first gear, reverse gear or

P .

● Remove the spare wheel 3 245.

● Never change more than one wheel at once.

● Use the jack only to change wheels in case of puncture, not

for seasonal winter or summer

tyre change.

● The jack is maintenance-free.● If the ground on which the vehicle

is standing is soft, a solid board

(max. 1 cm thick) should be

placed under the jack.

● Take heavy objects out of the vehicle before jacking up.

● No people or animals may be in the vehicle when it is jacked-up.

● Never crawl under a jacked-up vehicle.

● Do not start the vehicle when it is

raised on the jack.

● Before screwing in the wheel bolts, clean them.9Warning

Do not grease wheel bolts.

9Warning

Ensure to use always the correct

wheel bolts if changing the

wheels. When installing the spare

wheel, the bolts for alloy wheels can also be used.

Page 250 of 287

248Vehicle care

● Note that the spare wheel issecured by the conical contact ofeach bolt if the wheel bolts for the

alloy wheels are used. In this

case, the washers do not come

into contact with the spare wheel.

1. Steel wheels with cover: Pull off the wheel cover with the

designated tool 3 234.

Alloy wheels: Disengage wheel

bolt caps with the designated tool

3 234.2. Attach the wheel wrench and

loosen each wheel bolt by half a

turn.

The wheels might be protected by security wheel bolts. To loosen

these specific bolts, attach the

adapter onto the head of the bolt

before installing the wheel

wrench. The adapter is located in

the tool box. 3 2343. Ensure the jack is correctly

positioned under the relevant

vehicle jacking point. Position it

directly below the jacking point in

a manner that prevents it from

slipping.