stop start OPEL ZAFIRA C 2017.25 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2017.25, Model line: ZAFIRA C, Model: OPEL ZAFIRA C 2017.25Pages: 291, PDF Size: 9.02 MB

Page 163 of 291

Driving and operating1611. Continuously drive the vehiclefor 10 minutes making sure that

vehicle speed is always higher

than 20 km/h.

2. If AdBlue refill is detected successfully, AdBlue supply-

driven limitations will disappear.

If AdBlue refill is still not detected,

seek the assistance of a workshop.

If AdBlue must be refilled at

temperatures below -11 °C, the

refilling of AdBlue may not be

detected by the system. In this

event, park the vehicle in a space

with a higher ambient temperature

until AdBlue is liquefied.

Note

When unscrewing the protective cap

from the filler neck, ammonia fumes

may emerge. Do not inhale as the fumes have a pungent smell. The

fumes are not harmful by inhalation.

The AdBlue tank should be filled

completely. This must be done if the

warning message regarding

prevention of an engine restart is

already displayed.The vehicle must be parked on a level surface.

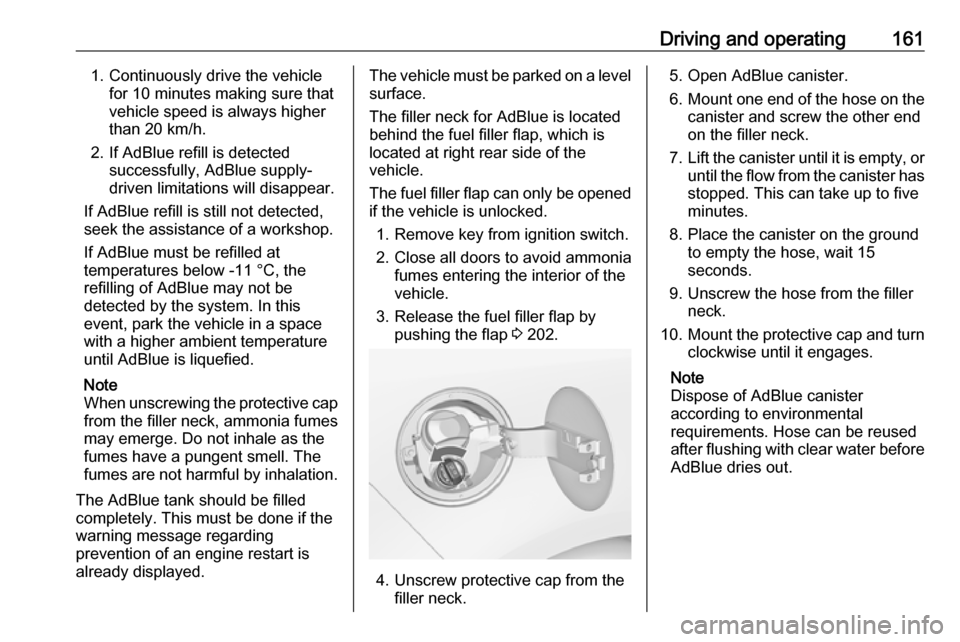

The filler neck for AdBlue is located

behind the fuel filler flap, which is located at right rear side of the

vehicle.

The fuel filler flap can only be opened

if the vehicle is unlocked.

1. Remove key from ignition switch.

2. Close all doors to avoid ammonia fumes entering the interior of the

vehicle.

3. Release the fuel filler flap by pushing the flap 3 202.

4. Unscrew protective cap from the

filler neck.

5. Open AdBlue canister.

6. Mount one end of the hose on the

canister and screw the other end

on the filler neck.

7. Lift the canister until it is empty, or

until the flow from the canister has stopped. This can take up to five

minutes.

8. Place the canister on the ground to empty the hose, wait 15

seconds.

9. Unscrew the hose from the filler neck.

10. Mount the protective cap and turn

clockwise until it engages.

Note

Dispose of AdBlue canister

according to environmental

requirements. Hose can be reused

after flushing with clear water before

AdBlue dries out.

Page 166 of 291

164Driving and operating● The automatic neutral shiftfunction automatically shifts gear

to idling when the vehicle is

stopped with a forward gear

engaged and the brake pedal is

pressed.

● When SPORT mode is engaged,

the vehicle shifts at higher engine

speeds (unless cruise control is

on). SPORT mode 3 171.

● Special programmes automatically adapt the gearshift

points when driving up inclines or down hills.

● In snowy or icy conditions or on other slippery surfaces, the

electronic transmission control

enables the driver to select

manually first, second or third

gear for starting off.

Kickdown If the accelerator pedal is pressed

down completely in automatic mode, the transmission shifts to a lower gear

depending on engine speed.Fault

In the event of a fault a message is

displayed in the Driver Information

Centre. Vehicle messages 3 123.

The transmission no longer shifts

automatically. Continued travel is

possible with manual shifting.

Only the highest gear is available.

Depending on the fault, 2nd gear may also be available in manual mode.

Shift only when vehicle is at a

standstill.

Have the cause of the fault remedied by a workshop.

Interruption of power supply In the event of an interruption of

power supply, the selector lever

cannot be moved out of the P

position. The ignition key cannot be removed from the ignition switch.

If the vehicle battery is discharged,

start the vehicle using jump leads

3 251.

If the vehicle battery is not the cause

of the fault, release the selector lever.

1. Apply the parking brake.

2. Release the selector lever trim from the centre console at the

front, fold it upwards and rotate it

to the left.

Page 167 of 291

Driving and operating1653. Push down the release lever andmove the selector lever out of P or

N . If these positions are engaged

again, the selector lever will be

locked in position again. Have the cause of the power supply

interruption remedied by a

workshop.

4. Mount the selector lever trim onto

the centre console and refit.Manual transmission

To engage reverse, depress the

clutch pedal and then press the

release button on the selector lever

and engage the gear.

If the gear does not engage, set the

lever to neutral, release the clutch

pedal and depress again; then repeat

gear selection.

Do not slip the clutch unnecessarily.

When operating, depress the clutch

pedal completely. Do not use the

pedal as a foot rest.

Caution

It is not advisable to drive with the hand resting on the selector lever.

Gear shift indication 3 114.

Stop-start system 3 154.

Page 170 of 291

168Driving and operatingVehicles with automatic transmission:Engaging D and then depressing the

accelerator pedal releases the

electric parking brake automatically.

This is not possible when the switch

m is pulled at the same time.

Dynamic braking when vehicle is

moving

When the vehicle is moving and the

switch m is kept pulled, the electric

parking brake system will decelerate the vehicle, but will not apply

statically.

As soon as the switch m is released,

dynamic braking will be stopped.

Functionality check

When the vehicle is not moving, the

electric parking brake might be

applied automatically. This is done to

check the system.

Fault

Failure mode of electric parking brake

is indicated by a control indicator j

and by a vehicle message which is

displayed in the Driver Information

Centre. Vehicle messages 3 123.Apply electric parking brake: pull and

hold switch m for more than five

seconds. If control indicator m

illuminates, electric parking brake is

applied.

Release electric parking brake: push

and hold the switch m for more than

two seconds. If control indicator m

extinguishes, electric parking brake is

released.

Control indicator m flashes: electric

parking brake is not fully applied or

released. When continuously

flashing, release electric parking

brake and retry applying.

Brake assist If brake pedal is depressed quickly

and forcefully, maximum brake force

is automatically applied.

Operation of brake assist might

become apparent by a pulse in the

brake pedal and a greater resistance

when depressing the brake pedal.Maintain steady pressure on the

brake pedal as long as full braking is

required. Maximum brake force is

automatically reduced when brake

pedal is released.

Hill start assist The system helps prevent unintendedmovement when driving away on

inclines.

When releasing the brake pedal after

stopping on an incline, the brakes

remain on for a further two seconds.

The brakes release automatically as

soon as the vehicle begins to

accelerate or the two seconds holding

time is over.

The hill start assist is not active during

an Autostop.

Page 218 of 291

216Vehicle care

Move the safety catch sideways to theleft vehicle side and open the bonnet.

The bonnet is held open

automatically by a lifter.

If the bonnet is opened during an

Autostop, the engine will be restarted automatically for safety reasons.

Closing Before closing the bonnet, press the

support into the holder.

Lower the bonnet and allow it to fall

into the latch from a low height

(20-25 cm). Check that the bonnet is

engaged.

Caution

Do not press the bonnet into the

latch, to avoid dents.

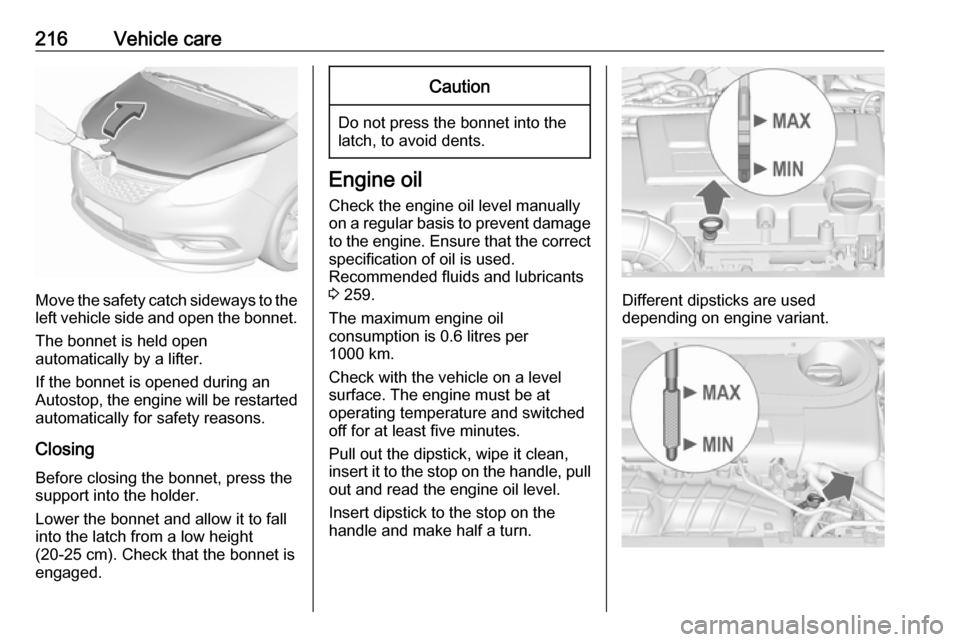

Engine oil

Check the engine oil level manually

on a regular basis to prevent damage

to the engine. Ensure that the correct specification of oil is used.

Recommended fluids and lubricants

3 259.

The maximum engine oil

consumption is 0.6 litres per

1000 km.

Check with the vehicle on a level

surface. The engine must be at

operating temperature and switched

off for at least five minutes.

Pull out the dipstick, wipe it clean, insert it to the stop on the handle, pull

out and read the engine oil level.

Insert dipstick to the stop on the

handle and make half a turn.

Different dipsticks are used

depending on engine variant.

Page 222 of 291

220Vehicle care

Batteries do not belong in household

waste. They must be disposed of at

an appropriate recycling collection

point.

Laying up the vehicle for more than

four weeks can lead to battery

discharge. Disconnect the clamp from the negative terminal of the vehicle

battery.

Ensure the ignition is switched off

before connecting or disconnecting

the vehicle battery.

Vehicle battery discharge protection

3 141.

Disconnecting the battery

If the vehicle's battery is to be

disconnected (e.g. for maintenance

work), the alarm siren must be

deactivated as follows: switch the

ignition on then off, then disconnect

the vehicle's battery within

15 seconds.

Replacing the vehicle battery Note

Any deviation from the instructions

given in this section may lead to

temporary deactivation of the stop-

start system.

When the vehicle battery is being

replaced, please ensure that there

are no open ventilation holes in the

vicinity of the positive terminal. If a

ventilation hole is open in this area, it

must be closed off with a dummy cap,

and the ventilation in the vicinity of the negative terminal must be opened.

Only use vehicle batteries that allow

the fuse box to be mounted above the

vehicle battery.In vehicles with an AGM (Absorptive

Glass Mat) battery, ensure the battery

is replaced with another AGM battery.

An AGM battery can be identified by

the label on the battery. We

recommend the use of an original

Opel vehicle battery.

Note

Using an AGM vehicle battery

different from the original Opel

vehicle battery may result in a lower performance.

We recommend that you have the

vehicle battery replaced by a

workshop.

Stop-start system 3 154.

Page 223 of 291

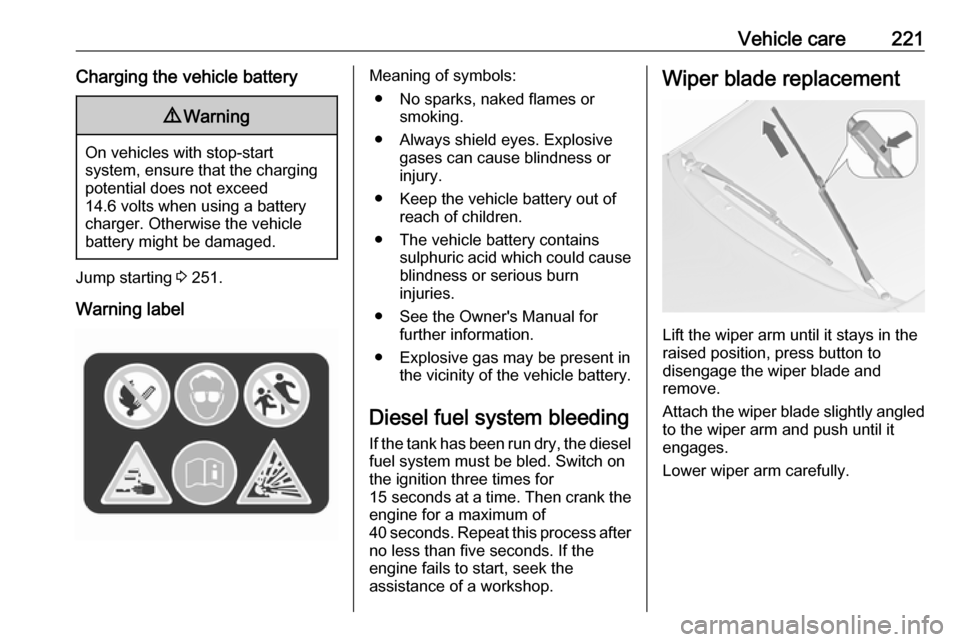

Vehicle care221Charging the vehicle battery9Warning

On vehicles with stop-start

system, ensure that the charging potential does not exceed

14.6 volts when using a battery

charger. Otherwise the vehicle

battery might be damaged.

Jump starting 3 251.

Warning label

Meaning of symbols: ● No sparks, naked flames or smoking.

● Always shield eyes. Explosive gases can cause blindness or

injury.

● Keep the vehicle battery out of reach of children.

● The vehicle battery contains sulphuric acid which could cause

blindness or serious burn

injuries.

● See the Owner's Manual for further information.

● Explosive gas may be present in the vicinity of the vehicle battery.

Diesel fuel system bleeding If the tank has been run dry, the diesel

fuel system must be bled. Switch on

the ignition three times for

15 seconds at a time. Then crank the

engine for a maximum of 40 seconds. Repeat this process after

no less than five seconds. If the

engine fails to start, seek the

assistance of a workshop.Wiper blade replacement

Lift the wiper arm until it stays in the

raised position, press button to

disengage the wiper blade and

remove.

Attach the wiper blade slightly angled

to the wiper arm and push until it

engages.

Lower wiper arm carefully.

Page 234 of 291

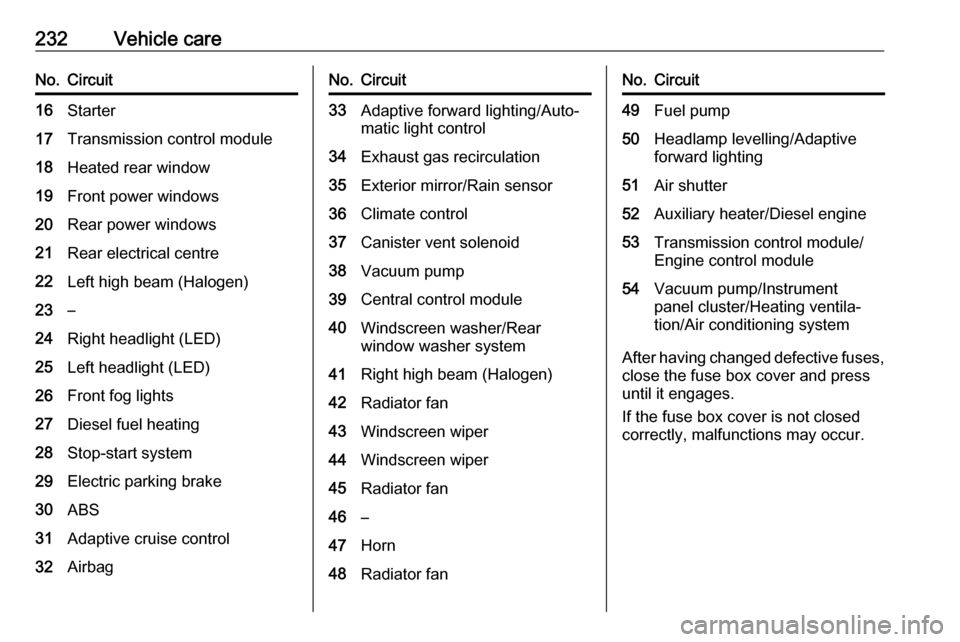

232Vehicle careNo.Circuit16Starter17Transmission control module18Heated rear window19Front power windows20Rear power windows21Rear electrical centre22Left high beam (Halogen)23–24Right headlight (LED)25Left headlight (LED)26Front fog lights27Diesel fuel heating28Stop-start system29Electric parking brake30ABS31Adaptive cruise control32AirbagNo.Circuit33Adaptive forward lighting/Auto‐

matic light control34Exhaust gas recirculation35Exterior mirror/Rain sensor36Climate control37Canister vent solenoid38Vacuum pump39Central control module40Windscreen washer/Rear

window washer system41Right high beam (Halogen)42Radiator fan43Windscreen wiper44Windscreen wiper45Radiator fan46–47Horn48Radiator fanNo.Circuit49Fuel pump50Headlamp levelling/Adaptive

forward lighting51Air shutter52Auxiliary heater/Diesel engine53Transmission control module/

Engine control module54Vacuum pump/Instrument

panel cluster/Heating ventila‐

tion/Air conditioning system

After having changed defective fuses,

close the fuse box cover and press

until it engages.

If the fuse box cover is not closed

correctly, malfunctions may occur.

Page 242 of 291

240Vehicle care

Select Tyre load page under Vehicle

Information Menu ? in the Driver

Information Centre 3 117.

Select: ● Light for comfort pressure up to

3 people.

● Eco for Eco pressure up to

3 people.

● Max for full load.

Tyre pressure sensor matching

process

Each tyre pressure sensor has a

unique identification code. The

identification code must be matched

to a new wheel position after rotating

the wheels or exchanging the

complete wheel set and if one or more

tyre pressure sensors were replaced. The tyre pressure sensor matching

process should also be performed

after replacing a spare wheel with a

road wheel containing the tyre

pressure sensor.

The malfunction light w and the

warning message or code should

extinguish at the next ignition cycle.

The sensors are matched to the

wheel positions, using a relearn tool,

in the following order: left side front

wheel, right side front wheel, right

side rear wheel and left side rear

wheel. The turn signal light at the

current active position is illuminated

until sensor is matched.

Consult your workshop for service.

There are two minutes to match the

first wheel position, and five minutes

overall to match all four wheel

positions. If it takes longer, the

matching process stops and must be

restarted.

The tyre pressure sensor matching

process is:

1. Apply the parking brake.2. Turn the ignition on.

3. On vehicles with automatic transmission: set the selector

lever to P.

On vehicles with manual

transmission: select neutral.

4. Press MENU on the turn signal

lever to select the Vehicle

Information Menu ? in the

Driver Information Centre.

5. Turn the adjuster wheel to scroll to

the tyre pressure menu.

Page 246 of 291

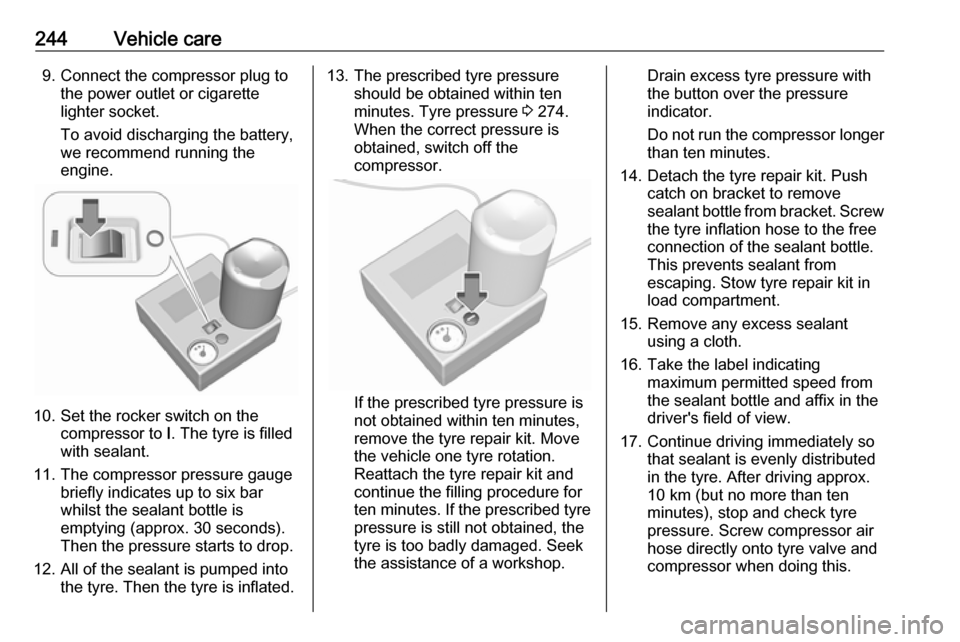

244Vehicle care9. Connect the compressor plug tothe power outlet or cigarette

lighter socket.

To avoid discharging the battery,

we recommend running the

engine.

10. Set the rocker switch on the compressor to I. The tyre is filled

with sealant.

11. The compressor pressure gauge briefly indicates up to six bar

whilst the sealant bottle is

emptying (approx. 30 seconds).

Then the pressure starts to drop.

12. All of the sealant is pumped into the tyre. Then the tyre is inflated.

13. The prescribed tyre pressureshould be obtained within ten

minutes. Tyre pressure 3 274.

When the correct pressure is

obtained, switch off the

compressor.

If the prescribed tyre pressure is

not obtained within ten minutes,

remove the tyre repair kit. Move

the vehicle one tyre rotation.

Reattach the tyre repair kit and

continue the filling procedure for

ten minutes. If the prescribed tyre

pressure is still not obtained, the

tyre is too badly damaged. Seek

the assistance of a workshop.

Drain excess tyre pressure with

the button over the pressure indicator.

Do not run the compressor longer

than ten minutes.

14. Detach the tyre repair kit. Push catch on bracket to remove

sealant bottle from bracket. Screw the tyre inflation hose to the free

connection of the sealant bottle.

This prevents sealant from

escaping. Stow tyre repair kit in

load compartment.

15. Remove any excess sealant using a cloth.

16. Take the label indicating maximum permitted speed from

the sealant bottle and affix in the

driver's field of view.

17. Continue driving immediately so that sealant is evenly distributed

in the tyre. After driving approx.

10 km (but no more than ten

minutes), stop and check tyre

pressure. Screw compressor air

hose directly onto tyre valve and

compressor when doing this.