warning OPEL ZAFIRA C 2018.5 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2018.5, Model line: ZAFIRA C, Model: OPEL ZAFIRA C 2018.5Pages: 341, PDF Size: 10.22 MB

Page 267 of 341

Vehicle care265

Batteries do not belong in household

waste. They must be disposed of at

an appropriate recycling collection

point.

Laying up the vehicle for more than

four weeks can lead to battery

discharge. Disconnect the clamp from the negative terminal of the vehicle

battery.

Ensure the ignition is switched off

before connecting or disconnecting

the vehicle battery.

Vehicle battery discharge protection

3 139.

Disconnecting the battery

If the vehicle's battery is to be

disconnected (e.g. for maintenance

work), the alarm siren must be

deactivated as follows: switch the

ignition on then off, then disconnect

the vehicle's battery within

15 seconds.

Replacing the vehicle battery Note

Any deviation from the instructions

given in this section may lead to

temporary deactivation or

disturbance of the stop-start system.

When the vehicle battery is being

replaced, please ensure that there

are no open ventilation holes in the

vicinity of the positive terminal. If a

ventilation hole is open in this area, it

must be closed off with a dummy cap, and the ventilation in the vicinity of the

negative terminal must be opened.

Only use vehicle batteries that allow the fuse box to be mounted above the

vehicle battery.

Ensure that the battery is always replaced by the same type of battery.We recommend that you have the

vehicle battery replaced by a

workshop.

Stop-start system 3 201.

Charging the vehicle battery9 Warning

On vehicles with stop-start

system, ensure that the charging potential does not exceed

14.6 volts when using a battery

charger. Otherwise the vehicle

battery might be damaged.

Jump starting 3 296.

Page 268 of 341

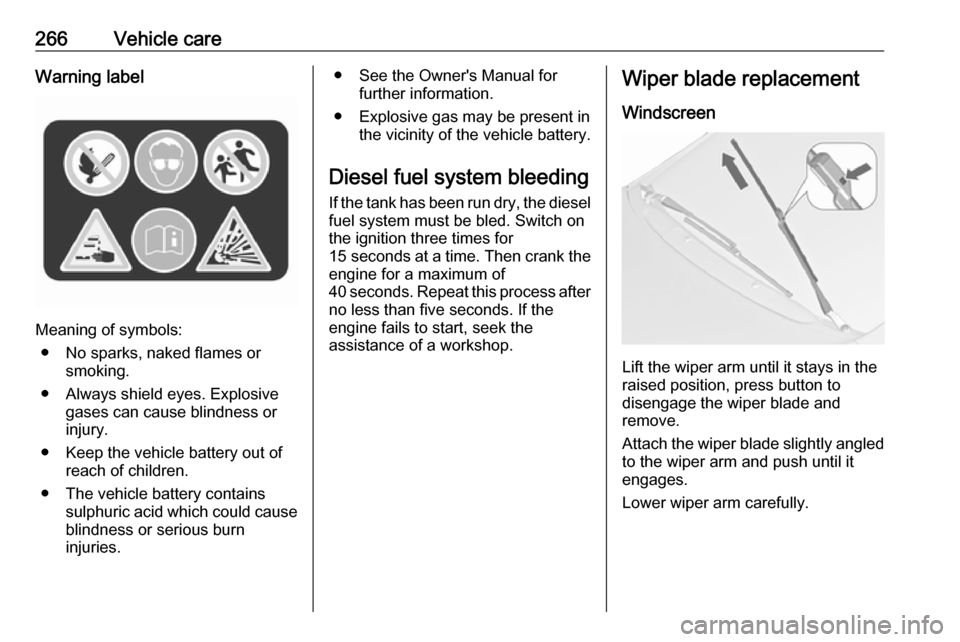

266Vehicle careWarning label

Meaning of symbols:● No sparks, naked flames or smoking.

● Always shield eyes. Explosive gases can cause blindness or

injury.

● Keep the vehicle battery out of reach of children.

● The vehicle battery contains sulphuric acid which could cause

blindness or serious burn

injuries.

● See the Owner's Manual for further information.

● Explosive gas may be present in the vicinity of the vehicle battery.

Diesel fuel system bleeding If the tank has been run dry, the diesel

fuel system must be bled. Switch on

the ignition three times for

15 seconds at a time. Then crank the

engine for a maximum of 40 seconds. Repeat this process after

no less than five seconds. If the

engine fails to start, seek the

assistance of a workshop.Wiper blade replacement

Windscreen

Lift the wiper arm until it stays in the

raised position, press button to

disengage the wiper blade and

remove.

Attach the wiper blade slightly angled

to the wiper arm and push until it

engages.

Lower wiper arm carefully.

Page 282 of 341

280Vehicle careNo.Circuit1–2Trailer outlet3Parking assist4Selective catalytic reduction

system5–6–7Power seat8–9Selective catalytic reduction

system10Nitrogen oxide sensor11Trailer module/Trailer socket12Trailer module13Trailer outlet14–15–No.Circuit16Interior mirror/Rear view

camera17Power outlet18–19–20–21Heated front seats22–23–24Selective catalytic reduction

system25–26–27–28–29–30–No.Circuit31–32Active damping system/Lane

departure warning

Page 284 of 341

282Vehicle careDirectional tyres

Fit directional tyres such that they roll in the direction of travel. The rolling

direction is indicated by a symbol

(e.g. an arrow) on the sidewall.

Tyre pressure

Check the pressure of cold tyres at least every 14 days and before any

long journey. Do not forget the spare

wheel. This also applies to vehicles

with tyre pressure monitoring system.

Tyre pressure 3 319.

The tyre pressure information label

on the front left or right door frame

indicates the original equipment tyres

and the correspondent tyre

pressures.

The tyre pressure data refers to cold

tyres. It applies to summer and winter tyres.

Always inflate the spare tyre to the

pressure specified for full load.

The ECO tyre pressure serves to

achieve the smallest amount of fuel

consumption possible.

Incorrect tyre pressures will impair

safety, vehicle handling, comfort and

fuel economy and will increase tyre

wear.

Tyre pressures differ depending on

various options. For the correct tyre

pressure value, follow the procedure

below:

1. Identify the engine identifier code.

Engine data 3 312.

2. Identify the respective tyre.

The tyre pressure tables show all possible tyre combinations 3 319.For the tyres approved for your

vehicle, refer to the EEC Certificate of

Conformity provided with your vehicle

or other national registration

documents.

The driver is responsible for correct

adjustment of tyre pressure.9 Warning

If the pressure is too low, this can

result in considerable tyre warm-

up and internal damage, leading to tread separation and even to tyre

blow-out at high speeds.

9 Warning

For specific tyres the

recommended tyre pressure as

shown in the tyre pressure table may exceed the maximum tyre

pressure as indicated on the tyre.

Never exceed the maximum tyre

pressure as indicated on the tyre.

If the tyre pressure must be reduced

or increased on a vehicle with tyre

pressure monitoring system, switch

Page 286 of 341

284Vehicle careSelect Tyre pressure page under

Vehicle Information Menu ?

3 117.

System status and pressure warnings are displayed by a message

indicating the corresponding tyre in the Driver Information Centre.

The system considers the tyre

temperature for the warnings.

A detected low tyre pressure

condition is indicated by control

indicator w 3 115.

If w illuminates, stop as soon as

possible and inflate the tyres as

recommended 3 319.

If w flashes for 60-90 seconds and

then illuminates continuously, there is

a fault in the system. Consult a

workshop.

After inflating, some driving may be

required to update the tyre pressure

values in the Driver Information

Centre. During this time w may

illuminate.

If w illuminates at lower temperatures

and extinguishes after some driving,

this could be an indicator for

approaching a low tyre pressure

condition. Check tyre pressure.

Vehicle messages 3 122.

If the tyre pressure must be reduced

or increased, switch off ignition.

Only mount wheels with pressure

sensors, otherwise the tyre pressure

will not be displayed and w

illuminates continuously.

A temporary spare wheel is not

equipped with pressure sensors. The

tyre pressure monitoring system is

not operational for these wheels.

Control indicator w illuminates. For

the further three wheels the system

remains operational.

The use of commercially available

liquid tyre repair kits can impair the

function of the system. Factory-

approved repair kits can be used.Operating electronic devices or being close to facilities using similar wave

frequencies could disrupt the tyre

pressure monitoring system.

Each time the tyres are replaced, tyre pressure monitoring system sensors

must be dismounted and serviced. For the screwed sensor: replace

valve core and sealing ring. For

clipped sensor: replace complete

valve stem.

Vehicle loading status Adjust tyre pressure to load condition

according to the tyre information label or tyre pressure chart 3 319, and

select the appropriate setting in the Tyre load menu in the Driver

Information Centre 3 117. This

setting is the reference for the tyre

pressure warnings.

The Tyre load menu only appears if

the vehicle is at a standstill and the parking brake is applied. On vehicles

with automatic transmission the

selector lever has to be in P.

Page 287 of 341

Vehicle care285

Select Tyre load page under Vehicle

Information Menu ? in the Driver

Information Centre 3 117.

Select: ● Light for comfort pressure up to

3 people.

● Eco for Eco pressure up to

3 people.

● Max for full load.

Tyre pressure sensor matching

process

Each tyre pressure sensor has a

unique identification code. The

identification code must be matched

to a new wheel position after rotating

the wheels or exchanging the

complete wheel set and if one or more

tyre pressure sensors were replaced. The tyre pressure sensor matching

process should also be performed

after replacing a spare wheel with a

road wheel containing the tyre

pressure sensor.

The malfunction light w and the

warning message or code should

extinguish at the next ignition cycle.

The sensors are matched to the

wheel positions, using a relearn tool,

in the following order: left side front

wheel, right side front wheel, right

side rear wheel and left side rear

wheel. The turn signal light at the

current active position is illuminated

until sensor is matched.

Consult your workshop for service.

There are two minutes to match the

first wheel position, and five minutes

overall to match all four wheel

positions. If it takes longer, the

matching process stops and must be

restarted.

The tyre pressure sensor matching

process is:

1. Apply the parking brake.2. Turn the ignition on.

3. On vehicles with automatic transmission: set the selector

lever to P.

On vehicles with manual

transmission: select neutral.

4. Press MENU on the turn signal

lever to select the Vehicle

Information Menu ? in the

Driver Information Centre.

5. Turn the adjuster wheel to scroll to

the tyre pressure menu.

Page 289 of 341

Vehicle care287Changing tyre and wheelsize

If tyres of a different size than those

fitted at the factory are used, it may be necessary to reprogramme the

nominal tyre pressure and make

other vehicle modifications.

After converting to a different tyre

size, have the label with tyre

pressures replaced. 3 2839 Warning

The use of unsuitable tyres or

wheels may lead to accidents and will invalidate the vehicle

operating permit.

Wheel covers

Wheel covers and tyres that are

factory approved for the respective

vehicle and comply with all of the

relevant wheel and tyre combination

requirements must be used.

If the wheel covers and tyres used are

not factory approved, the tyres must

not have a rim protection ridge.

Wheel covers must not impair brake

cooling.9 Warning

Use of unsuitable tyres or wheel

covers could lead to sudden

pressure loss and thereby

accidents.

Vehicles with steel wheels: When

using locking wheel nuts, do not

attach wheel covers.

Tyre chains

Tyre chains are only permitted on the

front wheels.

Always use fine mesh chains that add no more than 10 mm to the tyre tread

and the inboard sides (including chain lock).9 Warning

Damage may lead to tyre blowout.

Tyre chains are only permitted on

tyres of size 215/60 R16 and

225/50 R17.

The use of tyre chains is not permitted on the temporary spare wheel.

Tyre repair kit

Minor damage to the tyre tread can be

repaired with the tyre repair kit.

Do not remove foreign bodies from

the tyres.

Tyre damage exceeding 4 mm or that

is at the tyre's sidewall cannot be

repaired with the tyre repair kit.

Page 290 of 341

288Vehicle care9Warning

Do not drive faster than 80 km/h.

Do not use for a lengthy period.

Steering and handling may be

affected.

If you have a flat tyre:

Apply the parking brake and engage

first gear, reverse gear or P.

The tyre repair kit is on the left side in

the load compartment behind a cover.

1. Take the tyre repair kit from the compartment.

2. Remove the compressor.

3. Remove the electrical connection cable and air hose from the

stowage compartments on the

underside of the compressor.

4. Screw the compressor air hose to

the connection on the sealant

bottle.

5. Fit the sealant bottle into the retainer on the compressor.

Set the compressor near the tyre

in such a way that the sealant

bottle is upright.

6. Unscrew valve cap from defective

tyre.

7. Screw the filler hose to the tyre valve.

8. The switch on the compressor must be set to J.

Page 293 of 341

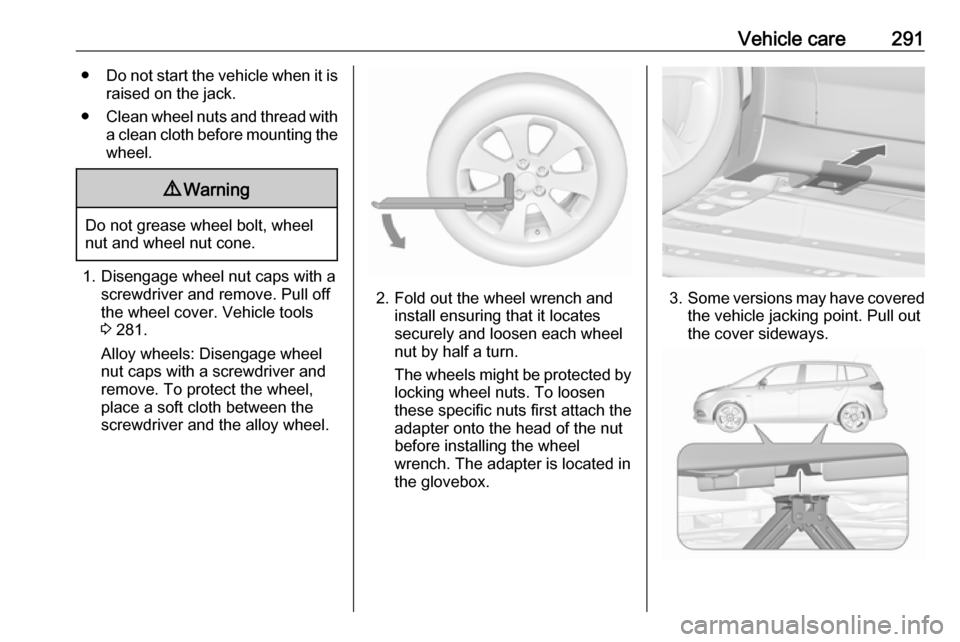

Vehicle care291●Do not start the vehicle when it is

raised on the jack.

● Clean wheel nuts and thread with

a clean cloth before mounting the

wheel.9 Warning

Do not grease wheel bolt, wheel

nut and wheel nut cone.

1. Disengage wheel nut caps with a

screwdriver and remove. Pull off

the wheel cover. Vehicle tools

3 281.

Alloy wheels: Disengage wheel

nut caps with a screwdriver and

remove. To protect the wheel,

place a soft cloth between the

screwdriver and the alloy wheel.

2. Fold out the wheel wrench and install ensuring that it locates

securely and loosen each wheel

nut by half a turn.

The wheels might be protected by

locking wheel nuts. To loosen

these specific nuts first attach the

adapter onto the head of the nut

before installing the wheel

wrench. The adapter is located in

the glovebox.3. Some versions may have covered

the vehicle jacking point. Pull out

the cover sideways.

Page 297 of 341

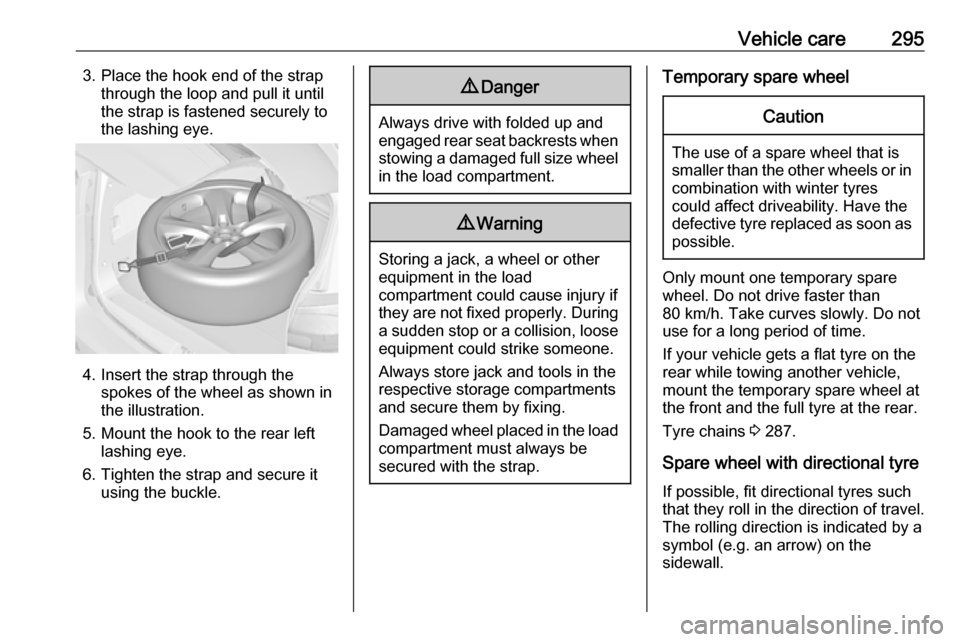

Vehicle care2953. Place the hook end of the strapthrough the loop and pull it until

the strap is fastened securely to

the lashing eye.

4. Insert the strap through the spokes of the wheel as shown in

the illustration.

5. Mount the hook to the rear left lashing eye.

6. Tighten the strap and secure it using the buckle.

9 Danger

Always drive with folded up and

engaged rear seat backrests when stowing a damaged full size wheel

in the load compartment.

9 Warning

Storing a jack, a wheel or other

equipment in the load

compartment could cause injury if they are not fixed properly. During a sudden stop or a collision, looseequipment could strike someone.

Always store jack and tools in the

respective storage compartments

and secure them by fixing.

Damaged wheel placed in the load

compartment must always be

secured with the strap.

Temporary spare wheelCaution

The use of a spare wheel that is smaller than the other wheels or in combination with winter tyres

could affect driveability. Have the defective tyre replaced as soon as

possible.

Only mount one temporary spare

wheel. Do not drive faster than

80 km/h. Take curves slowly. Do not use for a long period of time.

If your vehicle gets a flat tyre on the

rear while towing another vehicle,

mount the temporary spare wheel at

the front and the full tyre at the rear.

Tyre chains 3 287.

Spare wheel with directional tyre

If possible, fit directional tyres such

that they roll in the direction of travel.

The rolling direction is indicated by a

symbol (e.g. an arrow) on the

sidewall.