OPEL ZAFIRA C 2018.5 Manual user

Manufacturer: OPEL, Model Year: 2018.5, Model line: ZAFIRA C, Model: OPEL ZAFIRA C 2018.5Pages: 341, PDF Size: 10.22 MB

Page 291 of 341

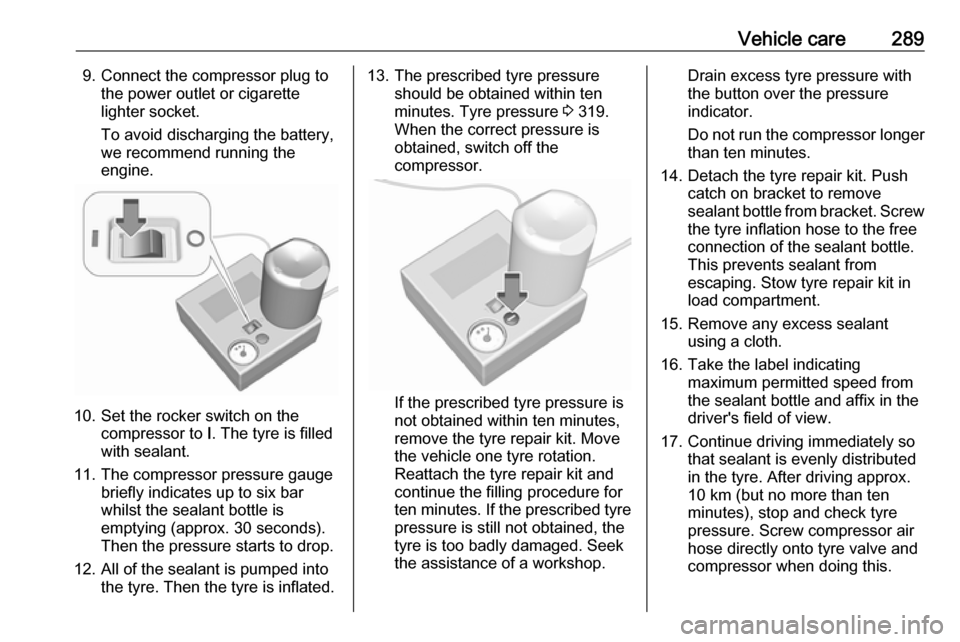

Vehicle care2899. Connect the compressor plug tothe power outlet or cigarette

lighter socket.

To avoid discharging the battery,

we recommend running the

engine.

10. Set the rocker switch on the compressor to I. The tyre is filled

with sealant.

11. The compressor pressure gauge briefly indicates up to six bar

whilst the sealant bottle is

emptying (approx. 30 seconds).

Then the pressure starts to drop.

12. All of the sealant is pumped into the tyre. Then the tyre is inflated.

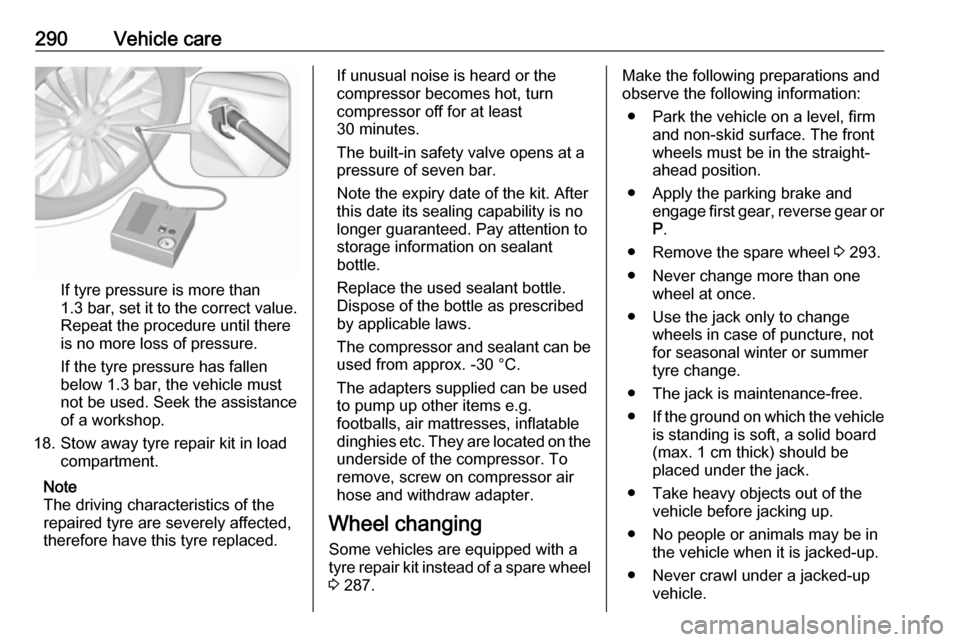

13. The prescribed tyre pressureshould be obtained within ten

minutes. Tyre pressure 3 319.

When the correct pressure is

obtained, switch off the

compressor.

If the prescribed tyre pressure is

not obtained within ten minutes,

remove the tyre repair kit. Move

the vehicle one tyre rotation.

Reattach the tyre repair kit and

continue the filling procedure for

ten minutes. If the prescribed tyre

pressure is still not obtained, the

tyre is too badly damaged. Seek

the assistance of a workshop.

Drain excess tyre pressure with

the button over the pressure indicator.

Do not run the compressor longer

than ten minutes.

14. Detach the tyre repair kit. Push catch on bracket to remove

sealant bottle from bracket. Screw the tyre inflation hose to the free

connection of the sealant bottle.

This prevents sealant from

escaping. Stow tyre repair kit in

load compartment.

15. Remove any excess sealant using a cloth.

16. Take the label indicating maximum permitted speed from

the sealant bottle and affix in the

driver's field of view.

17. Continue driving immediately so that sealant is evenly distributed

in the tyre. After driving approx.

10 km (but no more than ten

minutes), stop and check tyre

pressure. Screw compressor air

hose directly onto tyre valve and

compressor when doing this.

Page 292 of 341

290Vehicle care

If tyre pressure is more than

1.3 bar , set it to the correct value.

Repeat the procedure until there

is no more loss of pressure.

If the tyre pressure has fallen

below 1.3 bar, the vehicle must

not be used. Seek the assistance

of a workshop.

18. Stow away tyre repair kit in load compartment.

Note

The driving characteristics of the

repaired tyre are severely affected,

therefore have this tyre replaced.

If unusual noise is heard or the

compressor becomes hot, turn

compressor off for at least

30 minutes.

The built-in safety valve opens at a

pressure of seven bar.

Note the expiry date of the kit. After

this date its sealing capability is no

longer guaranteed. Pay attention to

storage information on sealant

bottle.

Replace the used sealant bottle. Dispose of the bottle as prescribed

by applicable laws.

The compressor and sealant can be used from approx. -30 °C.

The adapters supplied can be used

to pump up other items e.g.

footballs, air mattresses, inflatable

dinghies etc. They are located on the

underside of the compressor. To

remove, screw on compressor air hose and withdraw adapter.

Wheel changing

Some vehicles are equipped with a

tyre repair kit instead of a spare wheel 3 287.Make the following preparations and

observe the following information:

● Park the vehicle on a level, firm and non-skid surface. The front

wheels must be in the straight-

ahead position.

● Apply the parking brake and engage first gear, reverse gear or

P .

● Remove the spare wheel 3 293.

● Never change more than one wheel at once.

● Use the jack only to change wheels in case of puncture, not

for seasonal winter or summer

tyre change.

● The jack is maintenance-free.

● If the ground on which the vehicle

is standing is soft, a solid board

(max. 1 cm thick) should be

placed under the jack.

● Take heavy objects out of the vehicle before jacking up.

● No people or animals may be in the vehicle when it is jacked-up.

● Never crawl under a jacked-up vehicle.

Page 293 of 341

Vehicle care291●Do not start the vehicle when it is

raised on the jack.

● Clean wheel nuts and thread with

a clean cloth before mounting the

wheel.9 Warning

Do not grease wheel bolt, wheel

nut and wheel nut cone.

1. Disengage wheel nut caps with a

screwdriver and remove. Pull off

the wheel cover. Vehicle tools

3 281.

Alloy wheels: Disengage wheel

nut caps with a screwdriver and

remove. To protect the wheel,

place a soft cloth between the

screwdriver and the alloy wheel.

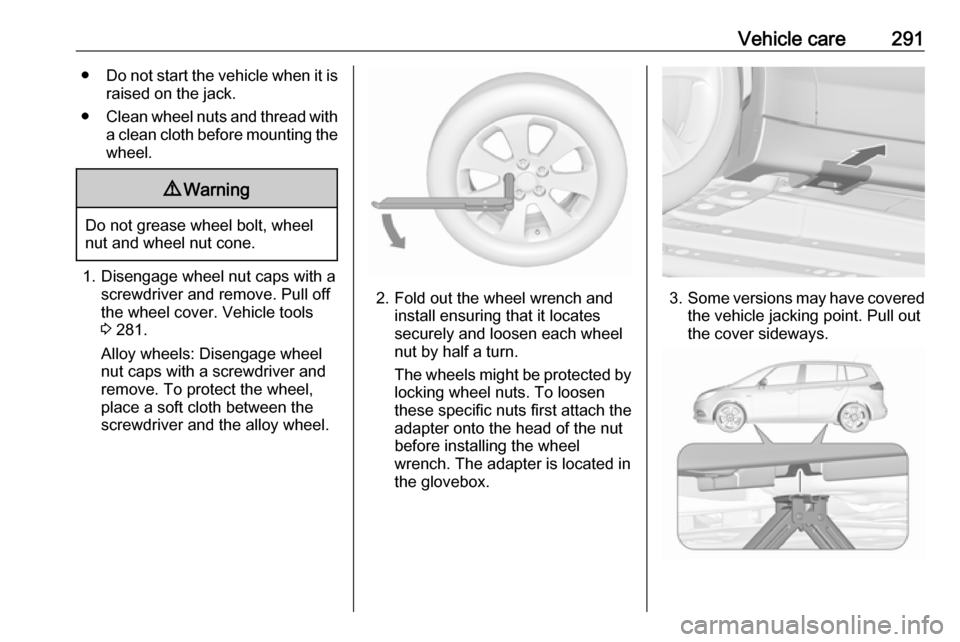

2. Fold out the wheel wrench and install ensuring that it locates

securely and loosen each wheel

nut by half a turn.

The wheels might be protected by

locking wheel nuts. To loosen

these specific nuts first attach the

adapter onto the head of the nut

before installing the wheel

wrench. The adapter is located in

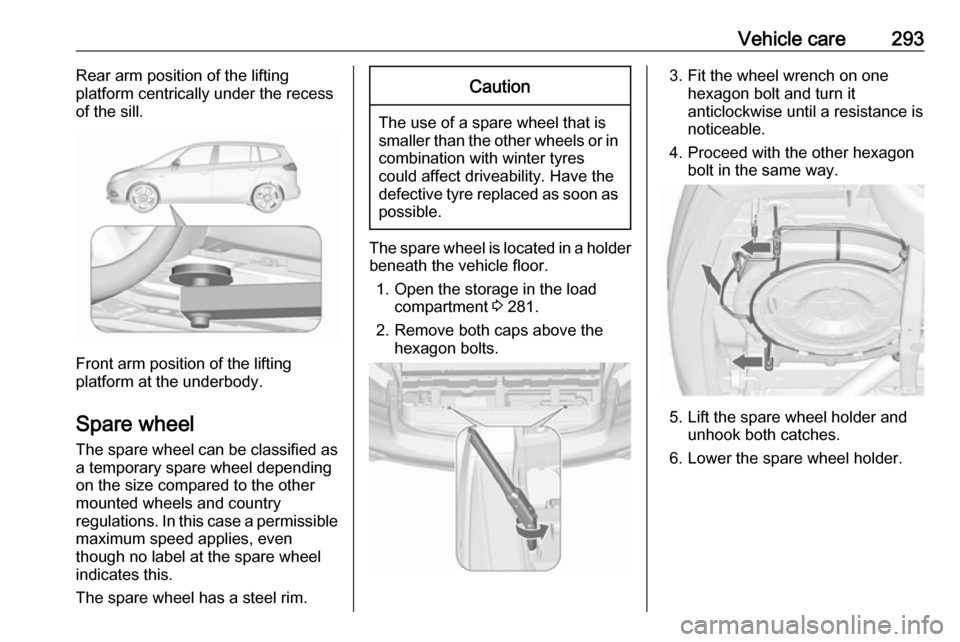

the glovebox.3. Some versions may have covered

the vehicle jacking point. Pull out

the cover sideways.

Page 294 of 341

292Vehicle care4. Ensure the jack is correctlypositioned under the relevant

vehicle jacking point.

5. Set the jack to the necessary height. Position it directly below

the jacking point in a manner that

prevents it from slipping.

Attach wheel wrench and with the

jack correctly aligned rotate wheel wrench until wheel is clear of the

ground.

6. Unscrew the wheel nuts. 7. Change the wheel. Spare wheel 3 293

8. Screw on the wheel nuts.

9. Lower the vehicle and remove jack.

10. Install the wheel wrench ensuring that it is located securely and

tighten each nut in a crosswise

sequence. Tightening torque is

140 Nm.

11. Align the valve hole in the wheel cover with the tyre valve before

installing.

Install wheel nut caps.

12. Install vehicle jacking point cover.

13. Stow the replaced wheel 3 293,

the vehicle tools 3 281 and the

adapter for the locking wheel nuts

3 66.

14. Check the tyre pressure of the installed tyre and the wheel nut

torque as soon as possible.

Have the defective tyre renewed or

repaired as soon as possible.

Jacking position for lifting platform

Page 295 of 341

Vehicle care293Rear arm position of the lifting

platform centrically under the recess

of the sill.

Front arm position of the lifting

platform at the underbody.

Spare wheel The spare wheel can be classified as

a temporary spare wheel depending

on the size compared to the other

mounted wheels and country

regulations. In this case a permissible maximum speed applies, even

though no label at the spare wheel

indicates this.

The spare wheel has a steel rim.

Caution

The use of a spare wheel that is smaller than the other wheels or in combination with winter tyres

could affect driveability. Have the defective tyre replaced as soon as

possible.

The spare wheel is located in a holder

beneath the vehicle floor.

1. Open the storage in the load compartment 3 281.

2. Remove both caps above the hexagon bolts.

3. Fit the wheel wrench on one hexagon bolt and turn it

anticlockwise until a resistance is

noticeable.

4. Proceed with the other hexagon bolt in the same way.

5. Lift the spare wheel holder andunhook both catches.

6. Lower the spare wheel holder.

Page 296 of 341

294Vehicle care

7. Detach the safety cable.

8. Lower holder all the way andremove spare wheel.

9. Change the wheel.

The damaged wheel must be

secured in the load compartment,

see below.

10. Lift the empty spare wheel holder and insert the safety cable.

11. Lift the spare wheel holder further

and engage in both catches. The

open sides of the catches must

point in the direction of travel.

12. Close the empty spare wheel holder by turning both hexagon

bolts clockwise using the wheel

wrench.

13. Fit the caps above both hexagon bolts.

14. Stow wheel wrench and the jack in the storage in front of the

tailgate.

15. Close the storage compartment cover.

When stowing the spare wheel in the

spare wheel holder, note that the

wheel is positioned with the tyre valve

above the recess of the wheel holder.Stowing a damaged full size

wheel in the load compartment

The spare wheel holder is not

designed for other tyre sizes than the

spare wheel.

A damaged wheel wider than the

spare wheel must be stowed in the

load compartment and secured with a strap. Vehicle tools 3 281.

The seats of the third row must be folded down 3 79.

1. Position the wheel close to the left

sidewall of the load compartment.

2. Place the loop end of the strap through the front lashing eye on

the left side.

Page 297 of 341

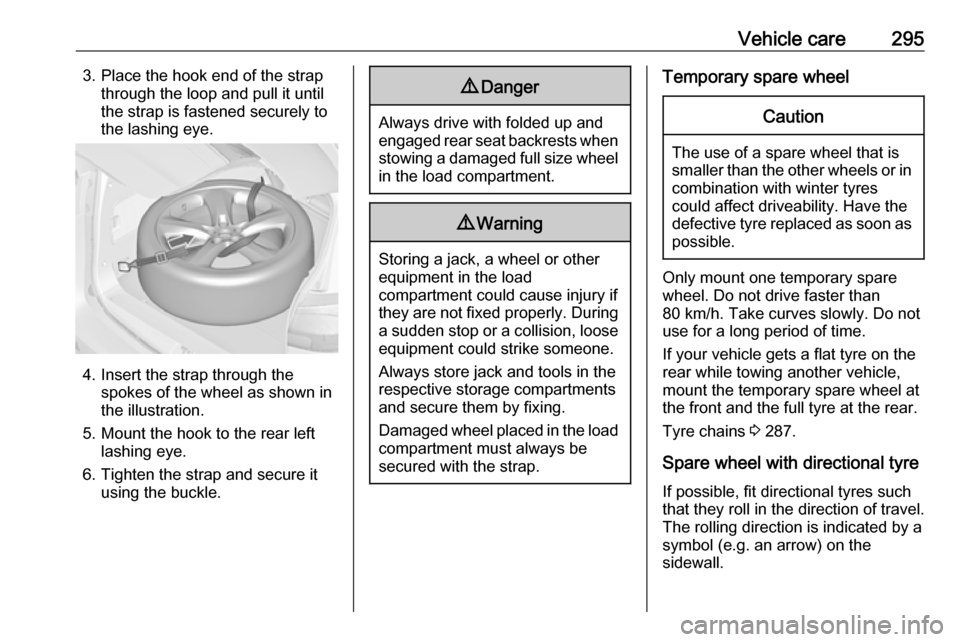

Vehicle care2953. Place the hook end of the strapthrough the loop and pull it until

the strap is fastened securely to

the lashing eye.

4. Insert the strap through the spokes of the wheel as shown in

the illustration.

5. Mount the hook to the rear left lashing eye.

6. Tighten the strap and secure it using the buckle.

9 Danger

Always drive with folded up and

engaged rear seat backrests when stowing a damaged full size wheel

in the load compartment.

9 Warning

Storing a jack, a wheel or other

equipment in the load

compartment could cause injury if they are not fixed properly. During a sudden stop or a collision, looseequipment could strike someone.

Always store jack and tools in the

respective storage compartments

and secure them by fixing.

Damaged wheel placed in the load

compartment must always be

secured with the strap.

Temporary spare wheelCaution

The use of a spare wheel that is smaller than the other wheels or in combination with winter tyres

could affect driveability. Have the defective tyre replaced as soon as

possible.

Only mount one temporary spare

wheel. Do not drive faster than

80 km/h. Take curves slowly. Do not use for a long period of time.

If your vehicle gets a flat tyre on the

rear while towing another vehicle,

mount the temporary spare wheel at

the front and the full tyre at the rear.

Tyre chains 3 287.

Spare wheel with directional tyre

If possible, fit directional tyres such

that they roll in the direction of travel.

The rolling direction is indicated by a

symbol (e.g. an arrow) on the

sidewall.

Page 298 of 341

296Vehicle careThe following applies to tyres fitted

opposing the rolling direction:

● Driveability may be affected. Have the defective tyre renewed

or repaired as soon as possible

and fit it instead of the spare

wheel.

● Drive particularly carefully on wet

and snow-covered road

surfaces.Jump starting

Do not start with quick charger.

A vehicle with a discharged battery

can be started using jump leads and

the battery of another vehicle.

Do not start with quick charger.9 Warning

Be extremely careful when starting

with jump leads. Any deviation

from the following instructions can

lead to injuries or damage caused

by battery explosion or damage to the electrical systems of both

vehicles.

9 Warning

Avoid contact of the battery with

eyes, skin, fabrics and painted

surfaces. The fluid contains

sulphuric acid which can cause

injuries and damage in the event

of direct contact.

● Never expose the vehicle battery

to naked flames or sparks.

● A discharged vehicle battery can already freeze at a temperature

of 0 °C. Defrost the frozen vehicle

battery before connecting jump leads.

● Wear eye protection and protective clothing when

handling a battery.

● Use a booster vehicle battery with the same voltage (12 Volt).

Its capacity (Ah) must not be

much less than that of the

discharged vehicle battery.

● Use jump leads with insulated terminals and a cross section of

at least 16 mm 2

(25 mm 2

for

diesel engines).

● Do not disconnect the discharged

vehicle battery from the vehicle.

● Switch off all unnecessary electrical consumers.

● Do not lean over the battery during jump starting.

● Do not allow the terminals of one

lead to touch those of the other

lead.

Page 299 of 341

Vehicle care297● The vehicles must not come intocontact with each other during

the jump starting process.

● Apply the parking brake, transmission in neutral,

automatic transmission in P.

● Open the positive terminal protection cap of your vehicle in

the engine compartment and of

the booster vehicle battery.Lead connection order:

1. Connect the red lead to the positive terminal of the booster

battery.

2. Connect the other end of the red lead to the positive terminal of the

discharged battery.

3. Connect the black lead to the negative terminal of the booster

battery.

4. Connect the other end of the black

lead to a vehicle grounding point

of your vehicle in the engine

compartment.

Route the leads so that they cannot

catch on rotating parts in the engine

compartment.

To start the engine: 1. Start the engine of the vehicle providing the jump.

2. After five minutes, start the other engine. Start attempts should be

made for no longer than

15 seconds at an interval of one

minute.3. Allow both engines to idle for approx. three minutes with the

leads connected.

4. Switch on electrical consumers (e.g. headlights, heated rear

window) of the vehicle receiving

the jump start.

5. Reverse above sequence exactly when removing leads.

Page 300 of 341

298Vehicle careTowingTowing the vehicle

Disengage cap at bottom and removedownwards.

The towing eye is stowed with the

vehicle tools 3 281.

Screw in the towing eye as far as it will

go until it stops in a horizontal

position.

Attach a tow rope – or better still a tow

rod – to the towing eye.

The towing eye must only be used for towing and not for recovering the

vehicle.

Switch on ignition to release steering

wheel lock and to permit operation of

brake lights, horn and windscreen

wiper.

Caution

Deactivate the driver assistance

systems like active emergency

braking 3 233, otherwise the

vehicle may automatically brake during towing.

Switch the selector lever to neutral.

Release the parking brake.

Caution

Drive slowly. Do not drive jerkily.

Excessive tractive force can

damage the vehicle.

When the engine is not running,

considerably more force is needed to

brake and steer.

To prevent the entry of exhaust gases from the towing vehicle, switch on the

air recirculation and close the

windows.

Vehicles with automatic transmission: The vehicle must be towed facing

forwards, not faster than 80 km/h nor further than 100 km. In all other cases