clock OPEL ZAFIRA C 2018 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2018, Model line: ZAFIRA C, Model: OPEL ZAFIRA C 2018Pages: 341, PDF Size: 9.99 MB

Page 252 of 341

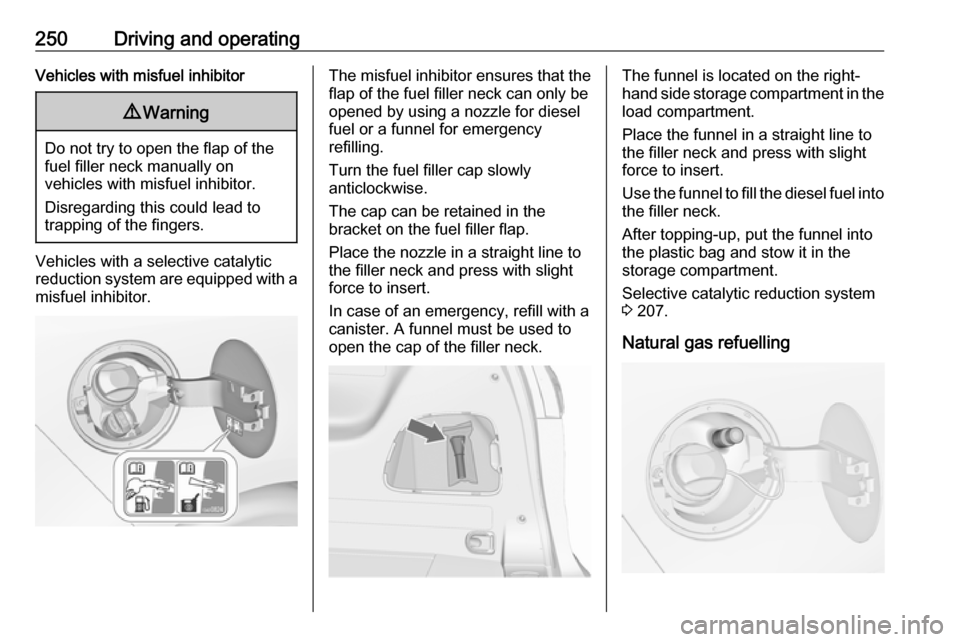

250Driving and operatingVehicles with misfuel inhibitor9Warning

Do not try to open the flap of the

fuel filler neck manually on

vehicles with misfuel inhibitor.

Disregarding this could lead to

trapping of the fingers.

Vehicles with a selective catalytic

reduction system are equipped with a

misfuel inhibitor.

The misfuel inhibitor ensures that the flap of the fuel filler neck can only be

opened by using a nozzle for diesel

fuel or a funnel for emergency

refilling.

Turn the fuel filler cap slowly

anticlockwise.

The cap can be retained in the

bracket on the fuel filler flap.

Place the nozzle in a straight line to the filler neck and press with slight

force to insert.

In case of an emergency, refill with a

canister. A funnel must be used to

open the cap of the filler neck.The funnel is located on the right-

hand side storage compartment in the load compartment.

Place the funnel in a straight line to

the filler neck and press with slight force to insert.

Use the funnel to fill the diesel fuel into

the filler neck.

After topping-up, put the funnel into

the plastic bag and stow it in the storage compartment.

Selective catalytic reduction system

3 207.

Natural gas refuelling

Page 254 of 341

252Driving and operating

ACME Adapter: Screw the nut of the

filling nozzle onto the adapter. Press

locking lever on filler nozzle down.

DISH filler neck: Place the filler nozzle

into the adapter. Press locking lever

on filler nozzle down.

Bayonet filler neck: Place filler nozzle

on the adapter and turn clockwise or

anticlockwise through one quarter

turn. Pull locking lever of filler nozzle

fully.

EURO filler neck: Press the filler

nozzle onto the adapter until it

engages.

Press the button at the liquid gas

supply point. The filling system stops

or begins to run slowly when 80% of

the tank volume is reached

(maximum fill level).

Release button on filling system to

stop the filling process. Release the

locking lever and remove the filler

nozzle. A small quantity of liquid gas

may escape.

Remove adapter and stow in vehicle. Fit protective cap to prevent the

penetration of foreign bodies into the

filler opening and the system.9 Warning

Due to the system design, an

escape of liquid gas after

releasing the locking lever is

unavoidable. Avoid inhaling.

9 Warning

The liquid gas tank should only be

filled to 80% capacity, for safety

reasons.

The multivalve on the liquid gas tank

automatically limits the fill quantity. If

a larger quantity is added, we

recommend not exposing the vehicle

to the sun until the excess amount

has been used up.

Filling adapter

As filling systems are not

standardised, different adapters are

required which are available from

Opel Distributors and from Opel

Authorised Repairers.

ACME adapter: Belgium, Germany,

Ireland, Luxembourg, Switzerland

Page 259 of 341

Driving and operating257Checking the tensioning of the

coupling ball bar

● Red marking on rotary knob must

point towards green marking on

coupling ball bar.

● The gap between the rotary knob

and the coupling ball bar must be approx. 6 mm.

● The key must be in position c.

Otherwise, the coupling ball bar must be tensioned before being inserted:

● Unlock coupling ball bar by turning key to position c.

● Pull out rotary knob and turn

clockwise as far as it will go.

Inserting the coupling ball bar

Insert the tensioned coupling ball bar

in the opening and push firmly

upwards until it audibly engages.

The rotary handle snaps back into its

original position, resting against the

coupling ball bar without a gap.9 Warning

Do not touch rotary handle during

insertion.

Lock the coupling ball bar by turning

the key to position e. Remove the key

and close the protective flap.

Eye for break-away stopping cable

Page 260 of 341

258Driving and operatingAttach breakaway stopping cable to

eye.

Check that the coupling ball bar is correctly installed

● Green marking on rotary knob must point towards green

marking on coupling ball bar.

● There must be no gap between the rotary handle and the

coupling ball bar.

● The coupling ball bar must be firmly engaged in the opening.

● The coupling ball bar must be locked and the key removed.9Warning

Towing a trailer is permitted only

when a coupling ball bar is fitted correctly. If the coupling ball bardoes not engage correctly, seekthe assistance of a workshop.

Dismounting the coupling ball bar

Open the protective flap and turn the

key to position c to unlock the

coupling ball bar.

Pull out rotary handle and turn

clockwise as far as it will go. Pull out coupling ball bar downwards.

Insert sealing plug in opening. Fold away socket.

Trailer stability assist

If the system detects snaking

movements, engine power is reduced

and the vehicle/trailer combination is

selectively braked until the snaking ceases. While system is working keep steering wheel as still as possible.

Trailer stability assist (TSA) is a

function of the Electronic Stability

Control 3 218.

Page 271 of 341

Vehicle care269Low beam (1)

1. Rotate cap anticlockwise andremove it.

2. Rotate the bulb holderanticlockwise to disengage.

Withdraw the bulb holder from the

reflector housing.

3. Remove the bulb from the plug connector by pulling.

4. Replace the bulb and connect it to

the plug connector.

5. Insert the bulb holder, engaging the lugs into the reflector housing

and rotate clockwise to secure.

6. Fit the cap and rotate clockwise.

High beam (2)

1. Rotate cap anticlockwise and remove it.

Page 272 of 341

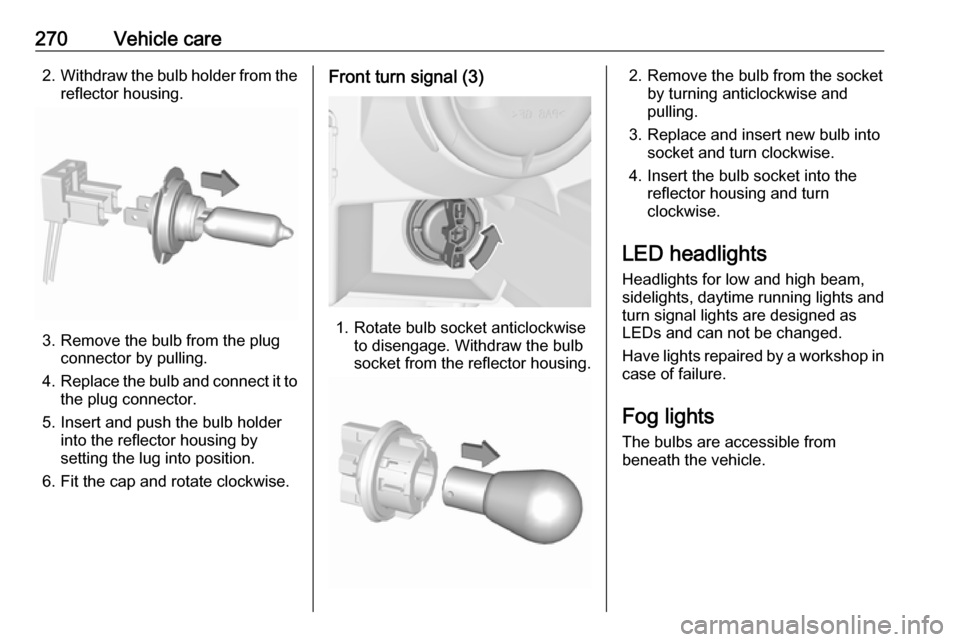

270Vehicle care2.Withdraw the bulb holder from the

reflector housing.

3. Remove the bulb from the plug connector by pulling.

4. Replace the bulb and connect it to

the plug connector.

5. Insert and push the bulb holder into the reflector housing by

setting the lug into position.

6. Fit the cap and rotate clockwise.

Front turn signal (3)

1. Rotate bulb socket anticlockwise to disengage. Withdraw the bulb

socket from the reflector housing.

2. Remove the bulb from the socket by turning anticlockwise and

pulling.

3. Replace and insert new bulb into socket and turn clockwise.

4. Insert the bulb socket into the reflector housing and turn

clockwise.

LED headlights

Headlights for low and high beam,

sidelights, daytime running lights and turn signal lights are designed as

LEDs and can not be changed.

Have lights repaired by a workshop in

case of failure.

Fog lights

The bulbs are accessible from

beneath the vehicle.

Page 273 of 341

Vehicle care271

1. Remove the outer screws of thecover, as shown in the illustration.

2. Hinge away the cover.

Turn the bulb socket

anticlockwise and remove it from

the reflector housing.

3. Disengage the bulb socket from the plug connector by pressing

the retaining lug.

4. Remove and replace the bulb socket with bulb and attach to the

plug connector.

5. Insert the bulb socket into the reflector housing, turn clockwise

and engage.

6. Mount the cover with the screws.

Tail lights

1. Hinge out the screw cover.

2. Remove the screws, marked by the arrows.

Page 275 of 341

Vehicle care273

2.Turn the bulb holder anticlockwise

and remove it from the reflector.

3. Remove the bulb from the socket by pulling.

4. Replace and insert new bulb intosocket.

5. Insert the bulb socket into the reflector and turn clockwise.

6. Install the cover.

Rear fog light

The bulbs are accessible from

beneath the vehicle.

1. Turn the bulb socket anticlockwise and remove it from

the reflector.

2. Remove the bulb from the socket by turning anticlockwise.

3. Replace and insert new bulb into the socket by turning clockwise.

4. Insert the bulb socket into the reflector, turn clockwise and

engage.

Bulb check

Switch on the ignition, operate and

check all lights.

Page 276 of 341

274Vehicle careSide turn signal lightsTo replace bulb, remove lamp

housing:

1. Slide lamp to its left side and remove with its right end.

2. Turn bulb holder anticlockwiseand remove from housing.

3. Pull bulb from bulb holder and replace it.

4. Insert bulb holder and turnclockwise.

5. Insert left end of the lamp, slide to

the left and insert right end.

Number plate light

1. Insert screwdriver in recess of the

cover, press to the side and

release spring. Remove cover.

Page 296 of 341

294Vehicle careFront arm position of the lifting

platform at the underbody.

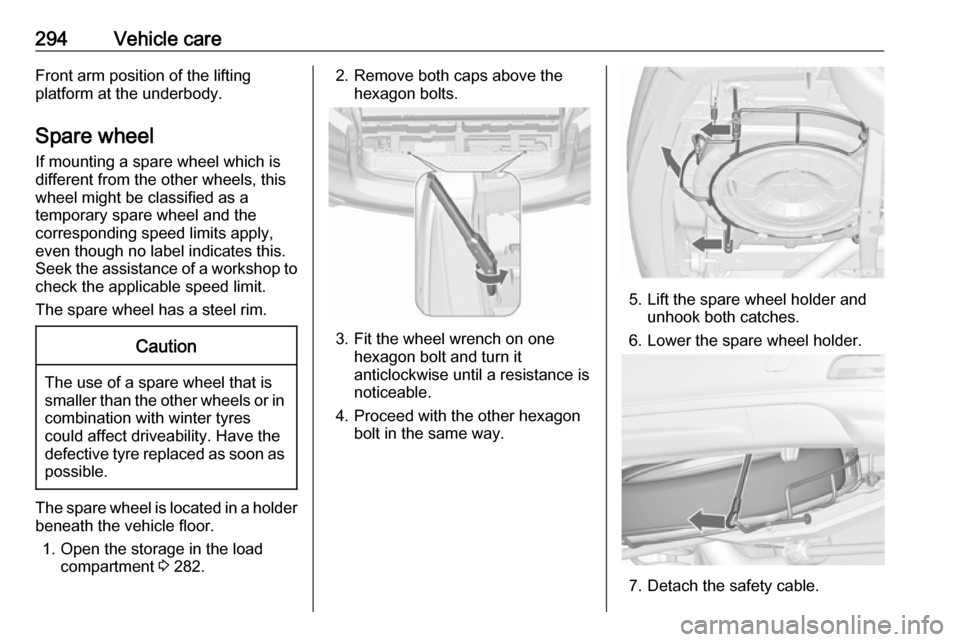

Spare wheel If mounting a spare wheel which is

different from the other wheels, this

wheel might be classified as a

temporary spare wheel and the

corresponding speed limits apply,

even though no label indicates this.

Seek the assistance of a workshop to

check the applicable speed limit.

The spare wheel has a steel rim.Caution

The use of a spare wheel that is smaller than the other wheels or in combination with winter tyres

could affect driveability. Have the defective tyre replaced as soon as

possible.

The spare wheel is located in a holder

beneath the vehicle floor.

1. Open the storage in the load compartment 3 282.

2. Remove both caps above the

hexagon bolts.

3. Fit the wheel wrench on one hexagon bolt and turn it

anticlockwise until a resistance is

noticeable.

4. Proceed with the other hexagon bolt in the same way.

5. Lift the spare wheel holder andunhook both catches.

6. Lower the spare wheel holder.

7. Detach the safety cable.