warning OPEL ZAFIRA TOURER 2016 Owners Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 2016, Model line: ZAFIRA TOURER, Model: OPEL ZAFIRA TOURER 2016Pages: 301, PDF Size: 9.16 MB

Page 204 of 301

202Driving and operating

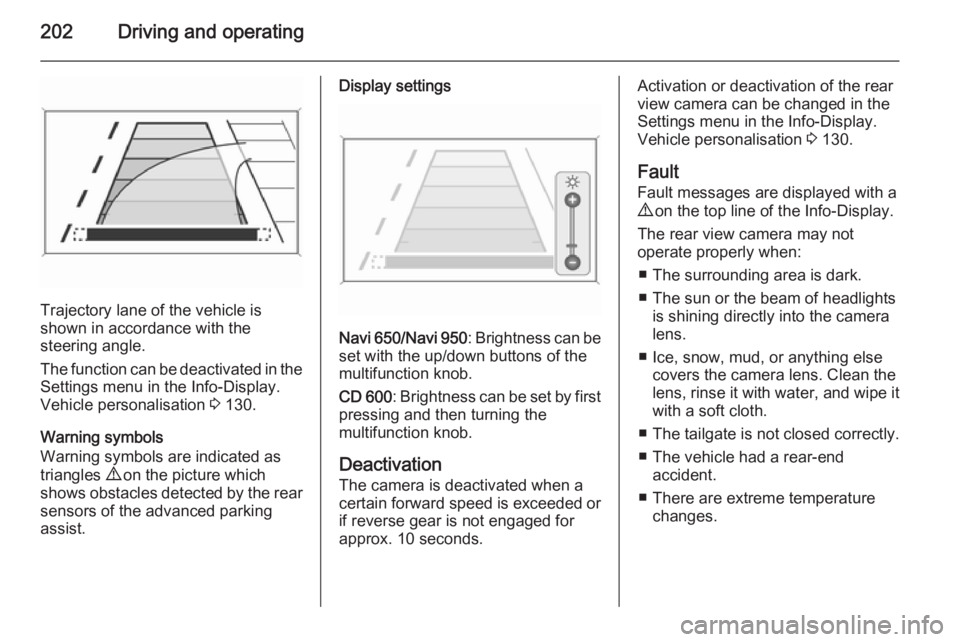

Trajectory lane of the vehicle is

shown in accordance with the

steering angle.

The function can be deactivated in the

Settings menu in the Info-Display.

Vehicle personalisation 3 130.

Warning symbols

Warning symbols are indicated as

triangles 9 on the picture which

shows obstacles detected by the rear sensors of the advanced parking

assist.

Display settings

Navi 650 /Navi 950 : Brightness can be

set with the up/down buttons of the

multifunction knob.

CD 600 : Brightness can be set by first

pressing and then turning the

multifunction knob.

Deactivation

The camera is deactivated when a

certain forward speed is exceeded or

if reverse gear is not engaged for

approx. 10 seconds.

Activation or deactivation of the rear

view camera can be changed in the

Settings menu in the Info-Display.

Vehicle personalisation 3 130.

Fault

Fault messages are displayed with a

9 on the top line of the Info-Display.

The rear view camera may not

operate properly when:

■ The surrounding area is dark.

■ The sun or the beam of headlights is shining directly into the camera

lens.

■ Ice, snow, mud, or anything else covers the camera lens. Clean the

lens, rinse it with water, and wipe it

with a soft cloth.

■ The tailgate is not closed correctly.

■ The vehicle had a rear-end accident.

■ There are extreme temperature changes.

Page 205 of 301

Driving and operating203Traffic sign assistant

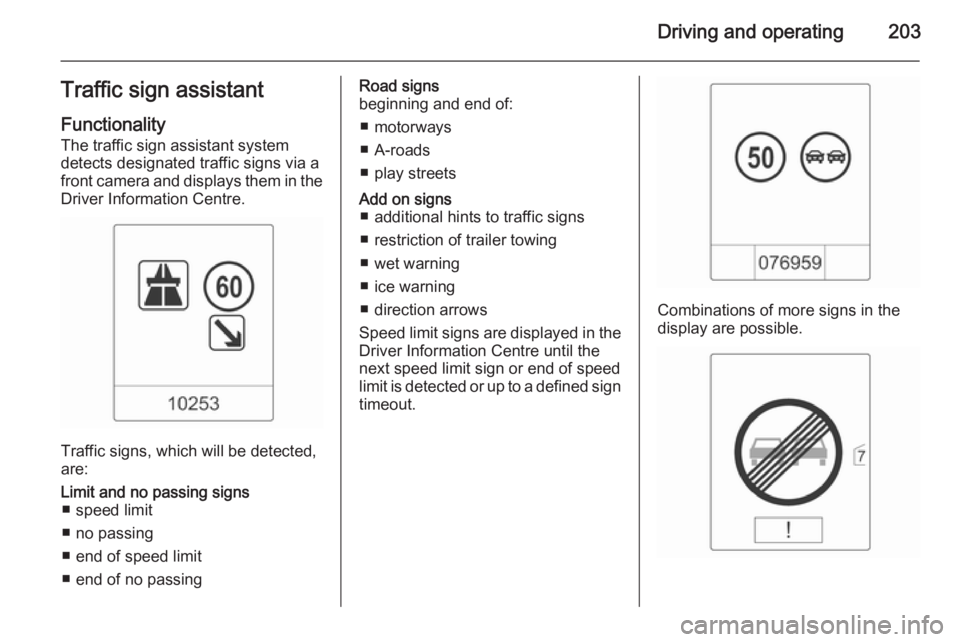

Functionality The traffic sign assistant system

detects designated traffic signs via a

front camera and displays them in the

Driver Information Centre.

Traffic signs, which will be detected,

are:

Limit and no passing signs ■ speed limit

■ no passing

■ end of speed limit

■ end of no passingRoad signs

beginning and end of:

■ motorways

■ A-roads

■ play streetsAdd on signs ■ additional hints to traffic signs

■ restriction of trailer towing

■ wet warning

■ ice warning

■ direction arrows

Speed limit signs are displayed in the

Driver Information Centre until the

next speed limit sign or end of speed

limit is detected or up to a defined sign timeout.

Combinations of more signs in the

display are possible.

Page 208 of 301

206Driving and operatingsigns. Do not ignore traffic signs

which are not displayed by the

system.

The system does not discern any

other than the conventional traffic signs that might give or end a

speed limit.

Do not let this special feature

tempt you into taking risks when

driving.

Always adapt speed to the road

conditions.

The driver assistance systems do not relieve the driver from full

responsibility for vehicle

operation.

Lane departure warning

The lane departure warning system

observes the lane markings between

which the vehicle is driving via a front camera. The system detects lane

changes and warns the driver in the

event of an unintended lane change

via visual and acoustic signals.

Criteria for the detection of an

unintended lane change are:

■ No operation of turn signals.

■ No brake pedal operation.

■ No active accelerator operation or speeding-up.

■ No active steering.

If the driver is active, no warning will

be issued.

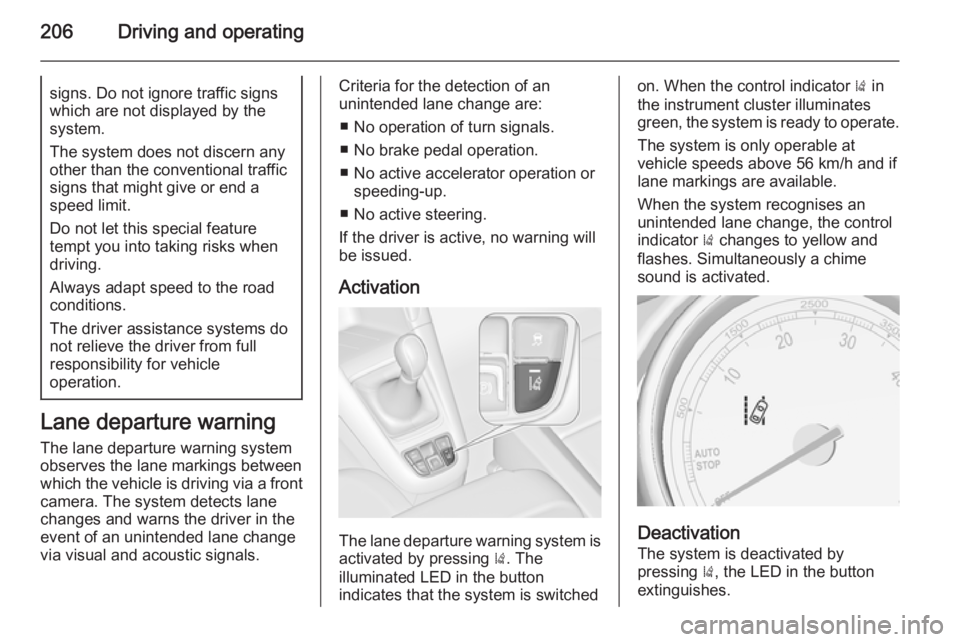

Activation

The lane departure warning system is activated by pressing ). The

illuminated LED in the button

indicates that the system is switched

on. When the control indicator ) in

the instrument cluster illuminates

green, the system is ready to operate.

The system is only operable at

vehicle speeds above 56 km/h and if

lane markings are available.

When the system recognises an

unintended lane change, the control

indicator ) changes to yellow and

flashes. Simultaneously a chime

sound is activated.

Deactivation

The system is deactivated by

pressing ), the LED in the button

extinguishes.

Page 209 of 301

Driving and operating207

At speeds below 56 km/h the system

is inoperable.

Fault

The lane departure warning system

may not operate properly when:

■ The windscreen is not clean.

■ There are adverse environmental conditions like heavy rain, snow,

direct sunlight or shadows.

The system can not operate when no

lane marking is detected.Fuel

Fuel for petrol enginesOnly use unleaded fuel that complies

with European standard EN 228 or

E DIN 51626-1 or equivalent.

Your engine is capable of running

with E10 fuel that fulfills these

standards. E10 fuel contains up to

10 % bioethanol.

Use fuel with the recommended

octane rating 3 276. Use of fuel with

too low an octane rating can reduce

engine power and torque and slightly increases fuel consumption.Caution

Do not use fuel or fuel additives

that contain metallic compounds

such as manganese-based

additives. This may cause engine

damage.

Caution

Use of fuel that does not comply to EN 228 or E DIN 51626-1 or

equivalent can lead to deposits or

engine damage and may affect

your warranty.

Caution

Use of fuel with too low an octane

rating could lead to uncontrolled combustion and engine damage.

Fuel for diesel engines

Only use diesel fuel that complies

with EN 590.

In countries outside the European

Union use Euro-Diesel fuel with a

sulphur concentration below 50 ppm.

Page 211 of 301

Driving and operating209

Fill the tank completely at regular

intervals to prevent corrosion in the

tank.

Faults and remedies

If gas mode is not possible, check the following:

■ Is there enough liquid gas present?

■ Is there enough petrol present for starting?

Due to extreme temperatures in

combination with the gas

composition, it may take slightly

longer before the system switches

from petrol to gas mode.

In extreme situations, the system may

also switch back to petrol mode if the

minimum requirements are not

fulfilled.

Seek the assistance of a workshop in the event of all other faults.Caution

Repairs and adjustments may onlybe made by trained specialists in

order to maintain the safety and

warranty on the LPG system.

Liquid gas is given a particular odour

(odorised) so that any leaks can be

detected easily.

9 Warning

If you smell gas in the vehicle or in

the immediate vicinity, switch to petrol mode immediately. No

smoking. No naked flames or

ignition sources.

If the gas odour persists, do not start

the engine. Have the cause of the

fault remedied by a workshop.

When using underground car parks,

follow the instructions of the operator

and local laws.

Note

In the event of an accident, switch off

the ignition and lights.

Fuel for natural gas

operation Use natural gas with a methane

content of approx. 78 - 99 %. L-gas

(low) has approx. 78 - 87 % and H-gas (high) has approx. 87 - 99 %. Biogas

with the same methane content can

also be used if it has been chemically

prepared and desulphurised.

Only use natural gas or biogas that complies with DIN 51624.

Liquid gas or LPG must not be used.

Fuel selector

Page 214 of 301

212Driving and operating

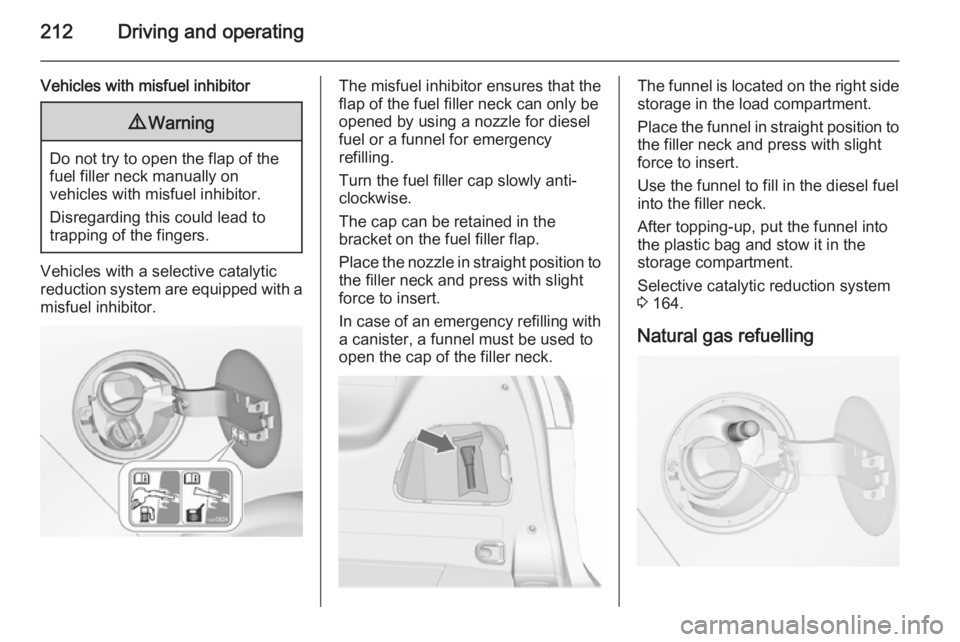

Vehicles with misfuel inhibitor9Warning

Do not try to open the flap of the

fuel filler neck manually on

vehicles with misfuel inhibitor.

Disregarding this could lead to

trapping of the fingers.

Vehicles with a selective catalytic

reduction system are equipped with a

misfuel inhibitor.

The misfuel inhibitor ensures that the flap of the fuel filler neck can only be

opened by using a nozzle for diesel

fuel or a funnel for emergency

refilling.

Turn the fuel filler cap slowly anti-

clockwise.

The cap can be retained in the

bracket on the fuel filler flap.

Place the nozzle in straight position to

the filler neck and press with slight

force to insert.

In case of an emergency refilling with a canister, a funnel must be used to

open the cap of the filler neck.The funnel is located on the right side storage in the load compartment.

Place the funnel in straight position to

the filler neck and press with slight

force to insert.

Use the funnel to fill in the diesel fuel

into the filler neck.

After topping-up, put the funnel into

the plastic bag and stow it in the

storage compartment.

Selective catalytic reduction system

3 164.

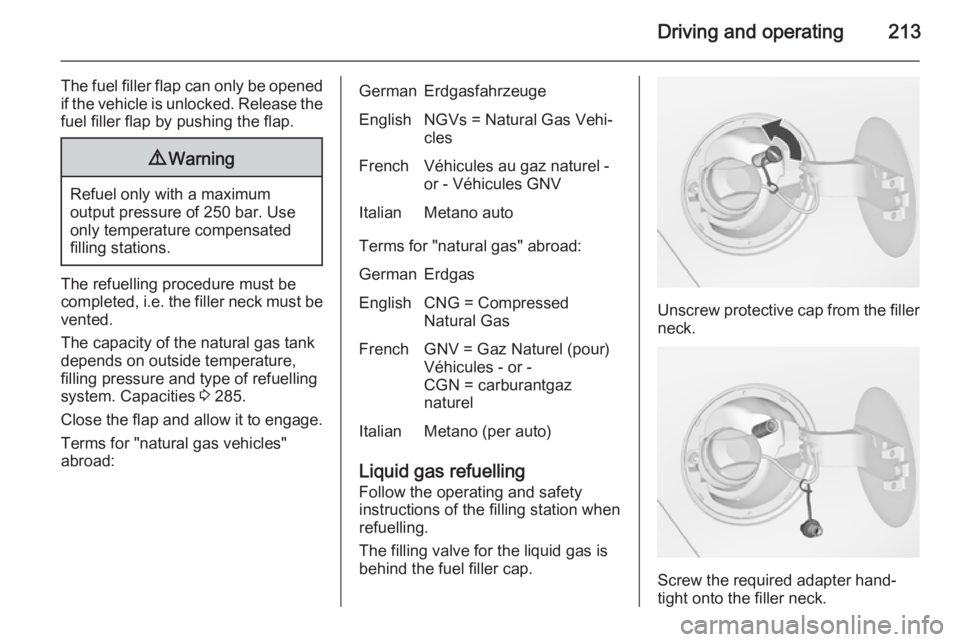

Natural gas refuelling

Page 215 of 301

Driving and operating213

The fuel filler flap can only be opened

if the vehicle is unlocked. Release the

fuel filler flap by pushing the flap.9 Warning

Refuel only with a maximum

output pressure of 250 bar. Use

only temperature compensated

filling stations.

The refuelling procedure must be

completed, i.e. the filler neck must be

vented.

The capacity of the natural gas tank depends on outside temperature,

filling pressure and type of refuelling

system. Capacities 3 285.

Close the flap and allow it to engage. Terms for "natural gas vehicles"

abroad:

GermanErdgasfahrzeugeEnglishNGVs = Natural Gas Vehi‐

clesFrenchVéhicules au gaz naturel -

or - Véhicules GNVItalianMetano auto

Terms for "natural gas" abroad:

GermanErdgasEnglishCNG = Compressed

Natural GasFrenchGNV = Gaz Naturel (pour)

Véhicules - or -

CGN = carburantgaz

naturelItalianMetano (per auto)

Liquid gas refuelling

Follow the operating and safety

instructions of the filling station when

refuelling.

The filling valve for the liquid gas is

behind the fuel filler cap.

Unscrew protective cap from the filler neck.

Screw the required adapter hand-

tight onto the filler neck.

Page 216 of 301

214Driving and operating

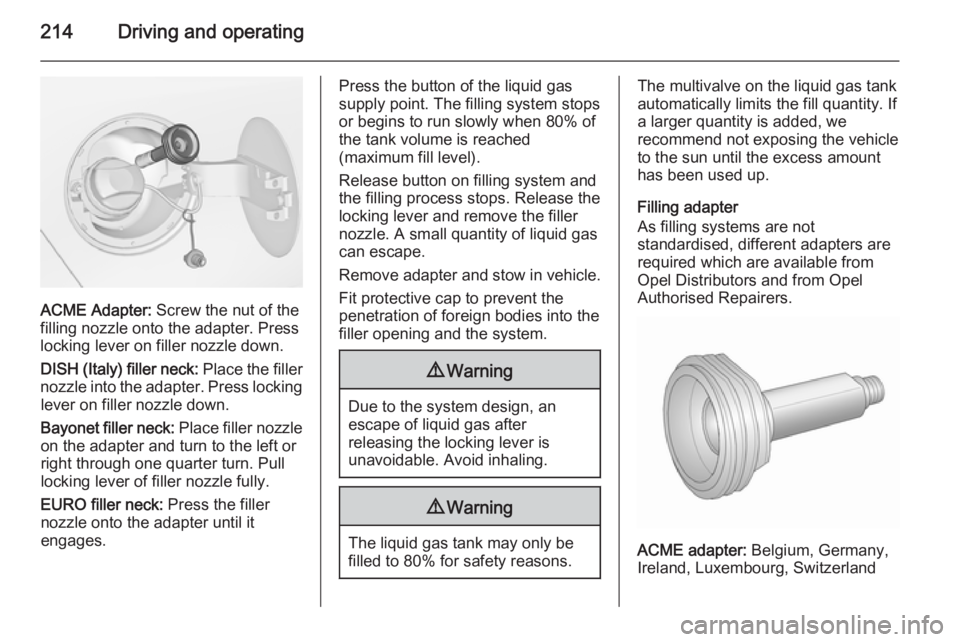

ACME Adapter: Screw the nut of the

filling nozzle onto the adapter. Press

locking lever on filler nozzle down.

DISH (Italy) filler neck: Place the filler

nozzle into the adapter. Press locking lever on filler nozzle down.

Bayonet filler neck: Place filler nozzle

on the adapter and turn to the left or

right through one quarter turn. Pull

locking lever of filler nozzle fully.

EURO filler neck: Press the filler

nozzle onto the adapter until it

engages.

Press the button of the liquid gas supply point. The filling system stops

or begins to run slowly when 80% of

the tank volume is reached

(maximum fill level).

Release button on filling system and

the filling process stops. Release the

locking lever and remove the filler

nozzle. A small quantity of liquid gas

can escape.

Remove adapter and stow in vehicle.

Fit protective cap to prevent the

penetration of foreign bodies into the

filler opening and the system.9 Warning

Due to the system design, an

escape of liquid gas after

releasing the locking lever is

unavoidable. Avoid inhaling.

9 Warning

The liquid gas tank may only be

filled to 80% for safety reasons.

The multivalve on the liquid gas tank

automatically limits the fill quantity. If

a larger quantity is added, we

recommend not exposing the vehicle

to the sun until the excess amount

has been used up.

Filling adapter

As filling systems are not

standardised, different adapters are

required which are available from

Opel Distributors and from Opel

Authorised Repairers.

ACME adapter: Belgium, Germany,

Ireland, Luxembourg, Switzerland

Page 221 of 301

Driving and operating219

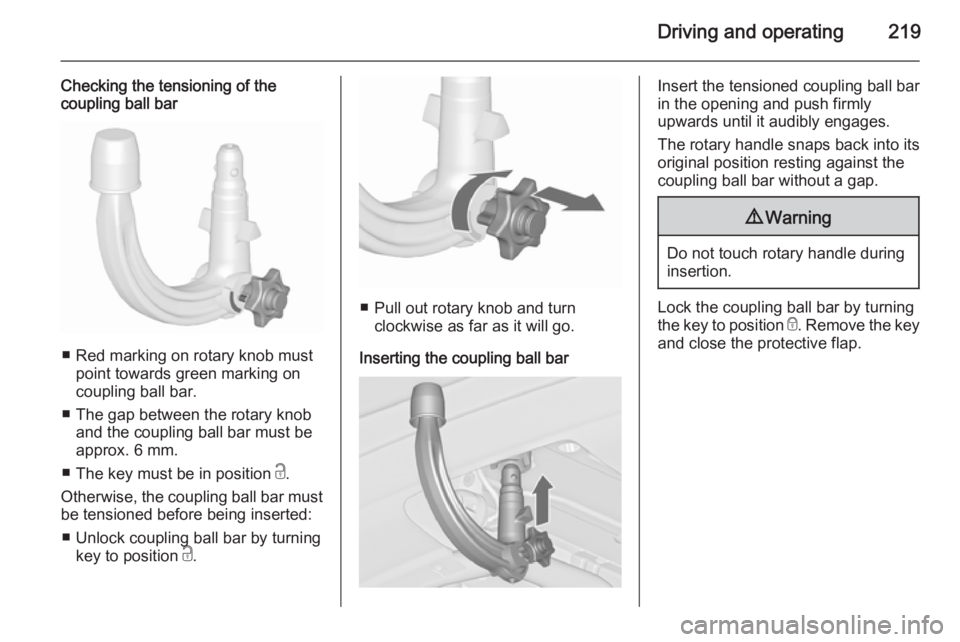

Checking the tensioning of the

coupling ball bar

■ Red marking on rotary knob must

point towards green marking on

coupling ball bar.

■ The gap between the rotary knob and the coupling ball bar must beapprox. 6 mm.

■ The key must be in position c.

Otherwise, the coupling ball bar must be tensioned before being inserted:

■ Unlock coupling ball bar by turning key to position c.

■ Pull out rotary knob and turn

clockwise as far as it will go.

Inserting the coupling ball bar

Insert the tensioned coupling ball bar

in the opening and push firmly

upwards until it audibly engages.

The rotary handle snaps back into its

original position resting against the

coupling ball bar without a gap.9 Warning

Do not touch rotary handle during

insertion.

Lock the coupling ball bar by turning

the key to position e. Remove the key

and close the protective flap.

Page 222 of 301

220Driving and operating

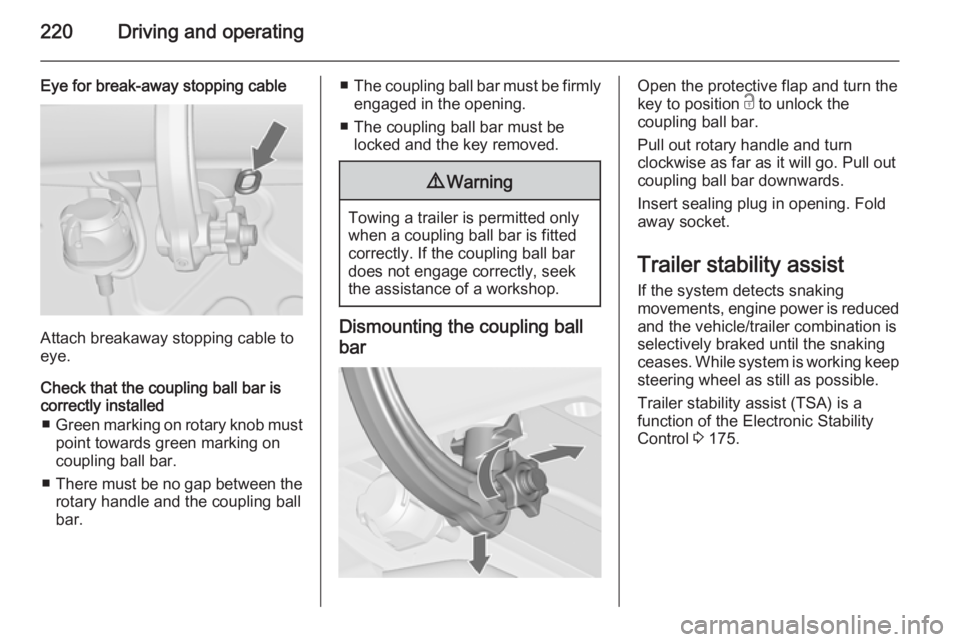

Eye for break-away stopping cable

Attach breakaway stopping cable to

eye.

Check that the coupling ball bar is correctly installed

■ Green marking on rotary knob must

point towards green marking on

coupling ball bar.

■ There must be no gap between the

rotary handle and the coupling ball

bar.

■ The coupling ball bar must be firmly

engaged in the opening.

■ The coupling ball bar must be locked and the key removed.9 Warning

Towing a trailer is permitted only

when a coupling ball bar is fitted correctly. If the coupling ball bardoes not engage correctly, seekthe assistance of a workshop.

Dismounting the coupling ball

bar

Open the protective flap and turn the

key to position c to unlock the

coupling ball bar.

Pull out rotary handle and turn

clockwise as far as it will go. Pull out coupling ball bar downwards.

Insert sealing plug in opening. Fold away socket.

Trailer stability assist If the system detects snaking

movements, engine power is reduced

and the vehicle/trailer combination is

selectively braked until the snaking ceases. While system is working keep steering wheel as still as possible.

Trailer stability assist (TSA) is a

function of the Electronic Stability

Control 3 175.