lock OPEL ZAFIRA TOURER 2016 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 2016, Model line: ZAFIRA TOURER, Model: OPEL ZAFIRA TOURER 2016Pages: 301, PDF Size: 9.16 MB

Page 192 of 301

190Driving and operating

Deactivation

The system can be deactivated.

Press V repeatedly until the following

message appears in the Driver

Information Centre.

General information for both

variants of forward collision alert

9 Warning

Forward collision alert is just a

warning system and does not

apply the brakes. When

approaching a vehicle ahead too

rapidly, it may not provide you

enough time to avoid a collision.

The driver accepts full

responsibility for the appropriate

following distance based on traffic, weather and visibility conditions.

The complete attention of the

driver is always required while

driving. The driver must always be

ready to take action and apply the

brakes.

System limitations

The system is designed to warn only for vehicles, but may react also onother metallic objects.

In the following cases, forward

collision alert may not detect a vehicle ahead or sensor performance is

limited:

■ on winding roads

■ when weather limits visibility, such as fog, rain, or snow

■ when the sensor is blocked by snow, ice, slush, mud, dirt, or

windscreen damage

Following distance

indication

The following distance indication

displays the distance to a preceding

moving vehicle. The system uses,

depending on the vehicle equipment,

either the radar behind the radiator

grille or the front camera in the

windscreen to detect the distance of

a vehicle directly ahead in your path.

It is active at speeds above 40 km/h.

When a preceding vehicle is detected ahead, the distance is indicated in

seconds, displayed on a page in the

Driver Information Centre 3 118.

Press MENU on the turn signal lever

to select Vehicle Information Menu

X and turn the adjuster wheel to

choose following distance indication

page.

Page 194 of 301

192Driving and operating

results immediately in a strong

braking. This function helps the driver brake quicker and stronger before theimminent collision.9 Warning

Active emergency braking is not

designed to apply strong

autonomous braking or to avoid automatically a collision. It is

designed to reduce the vehicle

speed before collision. It may not

react on stopped vehicles,

pedestrians or animals. After a

sudden lane change, the system

needs a certain time to detect the

next preceding vehicle.

The complete attention of the

driver is always required while

driving. The driver shall always be ready to take action and apply the brakes and steer to avoid

collisions. The system is designed

to work with all occupants wearing their seat belts.

System limitations

The active emergency braking has

limited or no function during rain,

snow or heavy dirt, as the radar

sensor can be covered by a water

film, dust, ice or snow. In case of

sensor blockage, clean the sensor

cover.

In some seldom cases the active

emergency braking system may

provide a short automatic braking in

situations that seem to be

unnecessary, for instance due to

traffic signs in a curve or due to

vehicles in another lane. This is

acceptable operation, the vehicle

does not need service. Firmly apply

the accelerator pedal to override the

automatic braking.

Settings Settings can be changed in the Auto

collision preparation menu in the

vehicle personalisation, 3 130.

Fault

In the event of a system service

requirement, a message is displayed

in the Driver Information Centre.

If the system does not work as it

should, vehicle messages are

displayed in the Driver Information

Centre.

Vehicle messages 3 124.

Page 212 of 301

210Driving and operating

Pressing Y switches between petrol

and natural gas operation. Switching

is not possible at high loads (e.g.

strong acceleration, running at full

throttle). The LED status shows the

current operating mode.1 off=natural gas

operation1 illumi‐

nates=petrol operation1 flashes=no switching is

possible, one type of

fuel is empty

As soon as the natural gas tank is empty, petrol operation is

automatically engaged until the

ignition is switched off.

If the natural gas tank is not refuelled, the system must be manually

switched to petrol operation before

the engine is started-up again. This

will prevent damage to the catalytic

converter (overheating caused by

irregular fuel supply).

If the selector switch is operated

several times within a short time, a

switchover block is activated. The

engine remains in the current

operating mode. The block remains

active until the ignition is switched off.

A slight loss of power and torque can be expected during petrol operation.

You must therefore adapt your driving

style (e.g. during overtaking

manoeuvres) and vehicle loads (e.g.

towing loads) accordingly.

Every six months run the petrol tank

down until control indicator Y

illuminates, then refuel. This is

necessary to maintain fuel quality as

well as system function necessary for

petrol operation.

Fill the tank completely at regular intervals to prevent corrosion in the

tank.Refuelling9 Danger

Before refuelling, switch off engine

and any external heaters with

combustion chambers. Switch off

any mobile phones.

Follow the operating and safety

instructions of the filling station

when refuelling.

Page 213 of 301

Driving and operating2119Danger

Fuel is flammable and explosive.

No smoking. No naked flames or

sparks.

If you can smell fuel in your

vehicle, have the cause of this

remedied immediately by a

workshop.

Caution

In case of misfuelling, do not

switch on ignition.

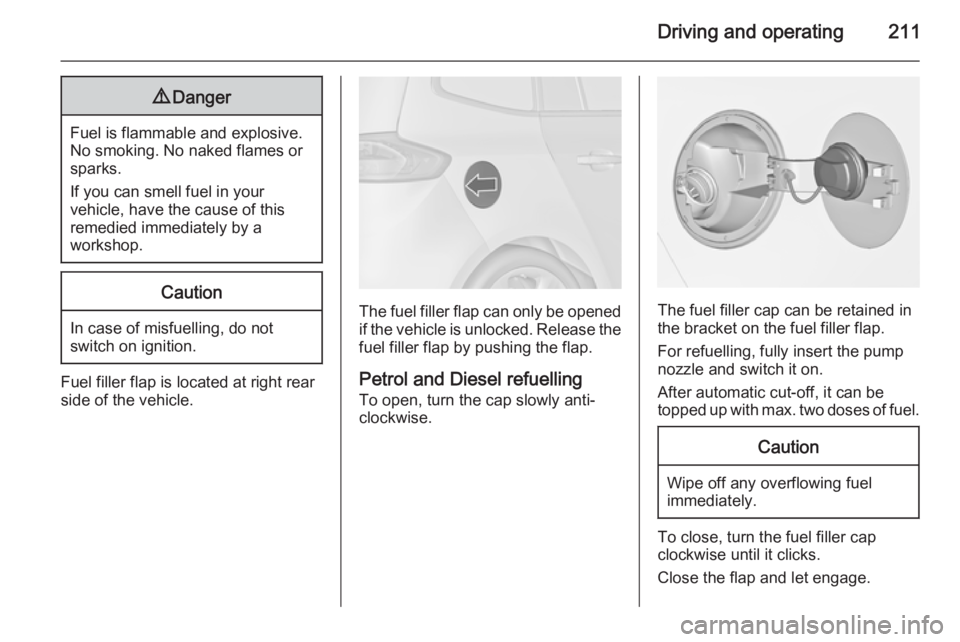

Fuel filler flap is located at right rear

side of the vehicle.

The fuel filler flap can only be opened

if the vehicle is unlocked. Release the

fuel filler flap by pushing the flap.

Petrol and Diesel refuelling

To open, turn the cap slowly anti-

clockwise.The fuel filler cap can be retained in

the bracket on the fuel filler flap.

For refuelling, fully insert the pump

nozzle and switch it on.

After automatic cut-off, it can be

topped up with max. two doses of fuel.

Caution

Wipe off any overflowing fuel

immediately.

To close, turn the fuel filler cap

clockwise until it clicks.

Close the flap and let engage.

Page 214 of 301

212Driving and operating

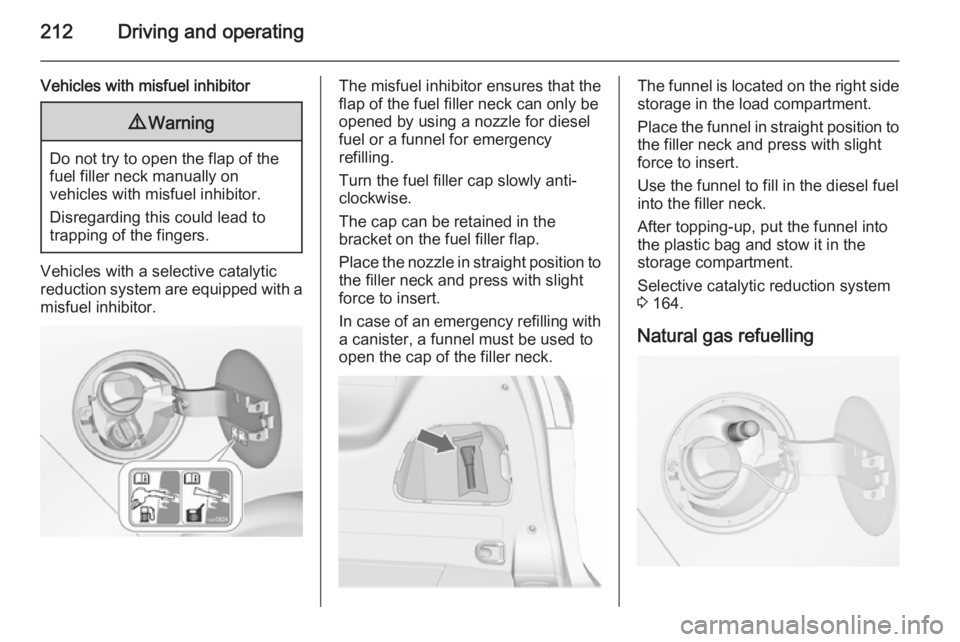

Vehicles with misfuel inhibitor9Warning

Do not try to open the flap of the

fuel filler neck manually on

vehicles with misfuel inhibitor.

Disregarding this could lead to

trapping of the fingers.

Vehicles with a selective catalytic

reduction system are equipped with a

misfuel inhibitor.

The misfuel inhibitor ensures that the flap of the fuel filler neck can only be

opened by using a nozzle for diesel

fuel or a funnel for emergency

refilling.

Turn the fuel filler cap slowly anti-

clockwise.

The cap can be retained in the

bracket on the fuel filler flap.

Place the nozzle in straight position to

the filler neck and press with slight

force to insert.

In case of an emergency refilling with a canister, a funnel must be used to

open the cap of the filler neck.The funnel is located on the right side storage in the load compartment.

Place the funnel in straight position to

the filler neck and press with slight

force to insert.

Use the funnel to fill in the diesel fuel

into the filler neck.

After topping-up, put the funnel into

the plastic bag and stow it in the

storage compartment.

Selective catalytic reduction system

3 164.

Natural gas refuelling

Page 215 of 301

Driving and operating213

The fuel filler flap can only be opened

if the vehicle is unlocked. Release the

fuel filler flap by pushing the flap.9 Warning

Refuel only with a maximum

output pressure of 250 bar. Use

only temperature compensated

filling stations.

The refuelling procedure must be

completed, i.e. the filler neck must be

vented.

The capacity of the natural gas tank depends on outside temperature,

filling pressure and type of refuelling

system. Capacities 3 285.

Close the flap and allow it to engage. Terms for "natural gas vehicles"

abroad:

GermanErdgasfahrzeugeEnglishNGVs = Natural Gas Vehi‐

clesFrenchVéhicules au gaz naturel -

or - Véhicules GNVItalianMetano auto

Terms for "natural gas" abroad:

GermanErdgasEnglishCNG = Compressed

Natural GasFrenchGNV = Gaz Naturel (pour)

Véhicules - or -

CGN = carburantgaz

naturelItalianMetano (per auto)

Liquid gas refuelling

Follow the operating and safety

instructions of the filling station when

refuelling.

The filling valve for the liquid gas is

behind the fuel filler cap.

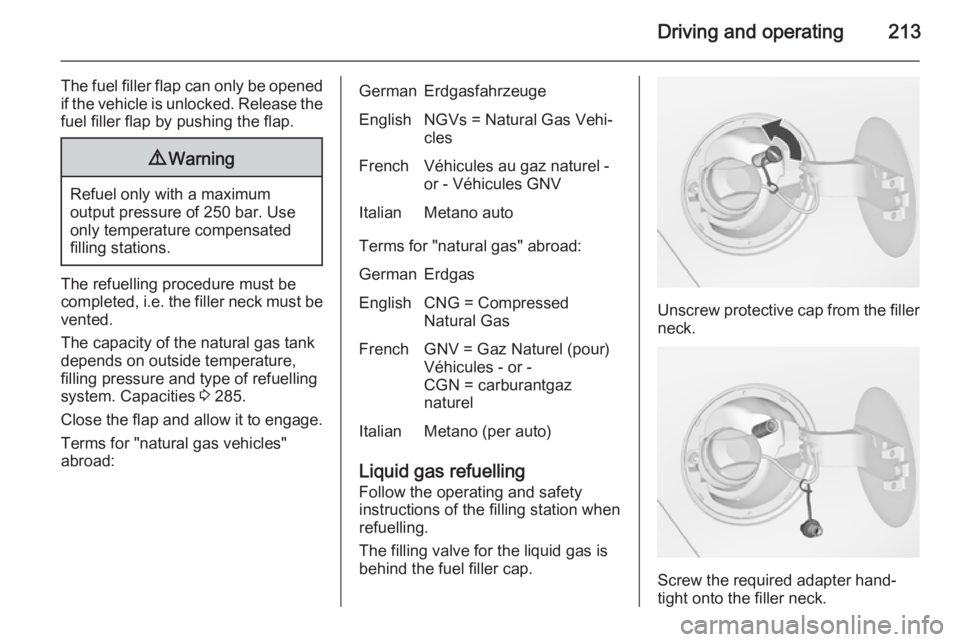

Unscrew protective cap from the filler neck.

Screw the required adapter hand-

tight onto the filler neck.

Page 216 of 301

214Driving and operating

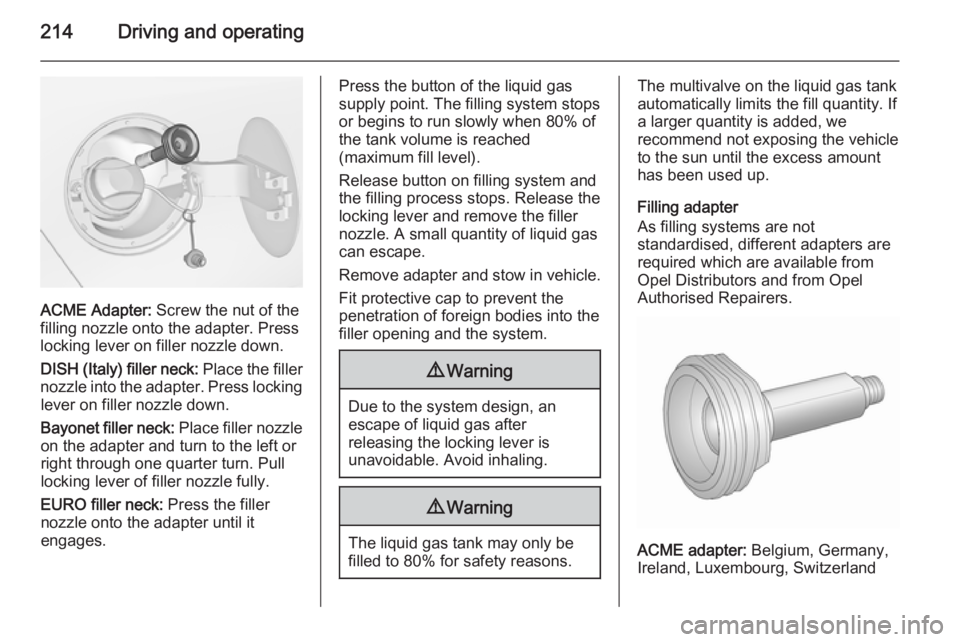

ACME Adapter: Screw the nut of the

filling nozzle onto the adapter. Press

locking lever on filler nozzle down.

DISH (Italy) filler neck: Place the filler

nozzle into the adapter. Press locking lever on filler nozzle down.

Bayonet filler neck: Place filler nozzle

on the adapter and turn to the left or

right through one quarter turn. Pull

locking lever of filler nozzle fully.

EURO filler neck: Press the filler

nozzle onto the adapter until it

engages.

Press the button of the liquid gas supply point. The filling system stops

or begins to run slowly when 80% of

the tank volume is reached

(maximum fill level).

Release button on filling system and

the filling process stops. Release the

locking lever and remove the filler

nozzle. A small quantity of liquid gas

can escape.

Remove adapter and stow in vehicle.

Fit protective cap to prevent the

penetration of foreign bodies into the

filler opening and the system.9 Warning

Due to the system design, an

escape of liquid gas after

releasing the locking lever is

unavoidable. Avoid inhaling.

9 Warning

The liquid gas tank may only be

filled to 80% for safety reasons.

The multivalve on the liquid gas tank

automatically limits the fill quantity. If

a larger quantity is added, we

recommend not exposing the vehicle

to the sun until the excess amount

has been used up.

Filling adapter

As filling systems are not

standardised, different adapters are

required which are available from

Opel Distributors and from Opel

Authorised Repairers.

ACME adapter: Belgium, Germany,

Ireland, Luxembourg, Switzerland

Page 221 of 301

Driving and operating219

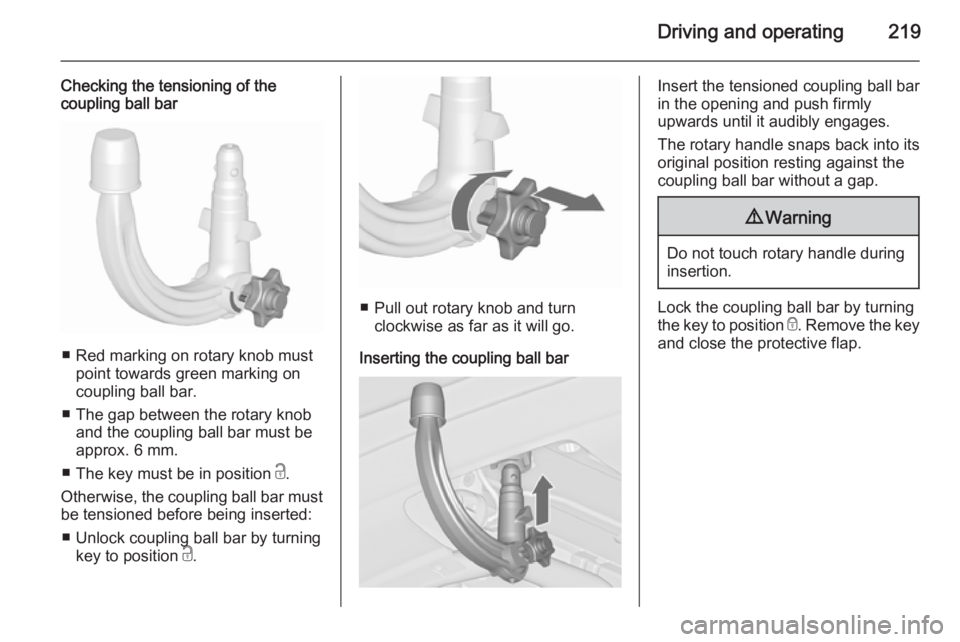

Checking the tensioning of the

coupling ball bar

■ Red marking on rotary knob must

point towards green marking on

coupling ball bar.

■ The gap between the rotary knob and the coupling ball bar must beapprox. 6 mm.

■ The key must be in position c.

Otherwise, the coupling ball bar must be tensioned before being inserted:

■ Unlock coupling ball bar by turning key to position c.

■ Pull out rotary knob and turn

clockwise as far as it will go.

Inserting the coupling ball bar

Insert the tensioned coupling ball bar

in the opening and push firmly

upwards until it audibly engages.

The rotary handle snaps back into its

original position resting against the

coupling ball bar without a gap.9 Warning

Do not touch rotary handle during

insertion.

Lock the coupling ball bar by turning

the key to position e. Remove the key

and close the protective flap.

Page 222 of 301

220Driving and operating

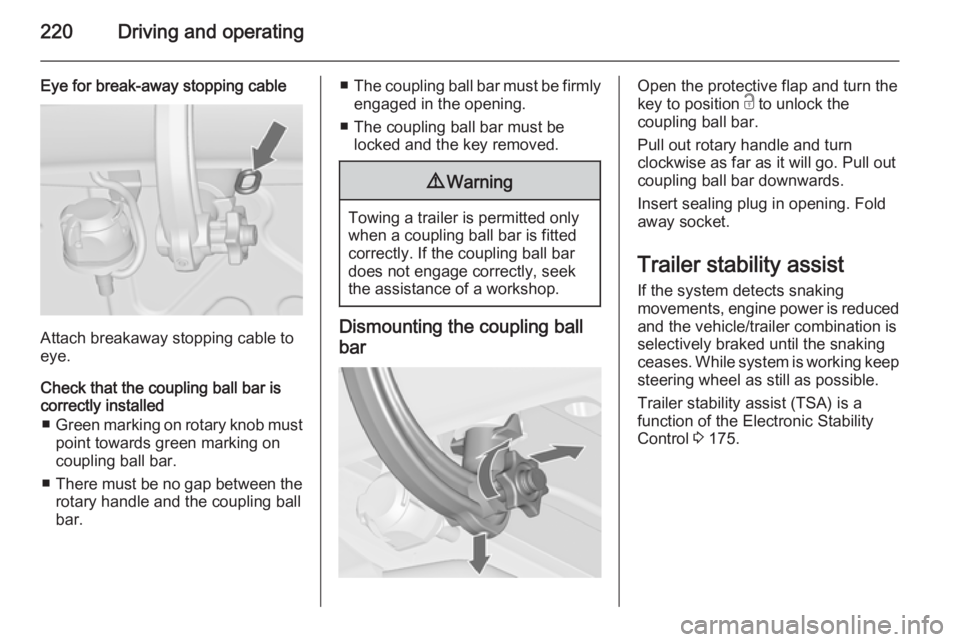

Eye for break-away stopping cable

Attach breakaway stopping cable to

eye.

Check that the coupling ball bar is correctly installed

■ Green marking on rotary knob must

point towards green marking on

coupling ball bar.

■ There must be no gap between the

rotary handle and the coupling ball

bar.

■ The coupling ball bar must be firmly

engaged in the opening.

■ The coupling ball bar must be locked and the key removed.9 Warning

Towing a trailer is permitted only

when a coupling ball bar is fitted correctly. If the coupling ball bardoes not engage correctly, seekthe assistance of a workshop.

Dismounting the coupling ball

bar

Open the protective flap and turn the

key to position c to unlock the

coupling ball bar.

Pull out rotary handle and turn

clockwise as far as it will go. Pull out coupling ball bar downwards.

Insert sealing plug in opening. Fold away socket.

Trailer stability assist If the system detects snaking

movements, engine power is reduced

and the vehicle/trailer combination is

selectively braked until the snaking ceases. While system is working keep steering wheel as still as possible.

Trailer stability assist (TSA) is a

function of the Electronic Stability

Control 3 175.

Page 224 of 301

222Vehicle care

■ Open the bonnet, close all doorsand lock the vehicle.

■ Disconnect the clamp from the negative terminal of the vehicle

battery. Beware that all systems are not functional, e.g. anti-theft alarm

system.

Putting back into operation When the vehicle is to be put back into

operation:

■ Connect the clamp to the negative terminal of the vehicle battery.

Activate the electronics of the

power windows.

■ Check tyre pressure.

■ Fill up the washer fluid reservoir.

■ Check the engine oil level.

■ Check the coolant level.

■ Fit the number plate if necessary.

End-of-life vehicle

recovery

Information on end-of-life vehicle

recovery centres and the recycling of

end-of-life vehicles is available on ourwebsite, where legally required. Only

entrust this work to an authorised

recycling centre.

Gas vehicles must be recycled by a

service centre authorised for gas

vehicles.Vehicle checks

Performing work9 Warning

Only perform engine compartment

checks when the ignition is off.

The cooling fan may start

operating even if the ignition is off.