light OPEL ZAFIRA TOURER 2016 Repair Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 2016, Model line: ZAFIRA TOURER, Model: OPEL ZAFIRA TOURER 2016Pages: 301, PDF Size: 9.16 MB

Page 209 of 301

Driving and operating207

At speeds below 56 km/h the system

is inoperable.

Fault

The lane departure warning system

may not operate properly when:

■ The windscreen is not clean.

■ There are adverse environmental conditions like heavy rain, snow,

direct sunlight or shadows.

The system can not operate when no

lane marking is detected.Fuel

Fuel for petrol enginesOnly use unleaded fuel that complies

with European standard EN 228 or

E DIN 51626-1 or equivalent.

Your engine is capable of running

with E10 fuel that fulfills these

standards. E10 fuel contains up to

10 % bioethanol.

Use fuel with the recommended

octane rating 3 276. Use of fuel with

too low an octane rating can reduce

engine power and torque and slightly increases fuel consumption.Caution

Do not use fuel or fuel additives

that contain metallic compounds

such as manganese-based

additives. This may cause engine

damage.

Caution

Use of fuel that does not comply to EN 228 or E DIN 51626-1 or

equivalent can lead to deposits or

engine damage and may affect

your warranty.

Caution

Use of fuel with too low an octane

rating could lead to uncontrolled combustion and engine damage.

Fuel for diesel engines

Only use diesel fuel that complies

with EN 590.

In countries outside the European

Union use Euro-Diesel fuel with a

sulphur concentration below 50 ppm.

Page 211 of 301

Driving and operating209

Fill the tank completely at regular

intervals to prevent corrosion in the

tank.

Faults and remedies

If gas mode is not possible, check the following:

■ Is there enough liquid gas present?

■ Is there enough petrol present for starting?

Due to extreme temperatures in

combination with the gas

composition, it may take slightly

longer before the system switches

from petrol to gas mode.

In extreme situations, the system may

also switch back to petrol mode if the

minimum requirements are not

fulfilled.

Seek the assistance of a workshop in the event of all other faults.Caution

Repairs and adjustments may onlybe made by trained specialists in

order to maintain the safety and

warranty on the LPG system.

Liquid gas is given a particular odour

(odorised) so that any leaks can be

detected easily.

9 Warning

If you smell gas in the vehicle or in

the immediate vicinity, switch to petrol mode immediately. No

smoking. No naked flames or

ignition sources.

If the gas odour persists, do not start

the engine. Have the cause of the

fault remedied by a workshop.

When using underground car parks,

follow the instructions of the operator

and local laws.

Note

In the event of an accident, switch off

the ignition and lights.

Fuel for natural gas

operation Use natural gas with a methane

content of approx. 78 - 99 %. L-gas

(low) has approx. 78 - 87 % and H-gas (high) has approx. 87 - 99 %. Biogas

with the same methane content can

also be used if it has been chemically

prepared and desulphurised.

Only use natural gas or biogas that complies with DIN 51624.

Liquid gas or LPG must not be used.

Fuel selector

Page 212 of 301

210Driving and operating

Pressing Y switches between petrol

and natural gas operation. Switching

is not possible at high loads (e.g.

strong acceleration, running at full

throttle). The LED status shows the

current operating mode.1 off=natural gas

operation1 illumi‐

nates=petrol operation1 flashes=no switching is

possible, one type of

fuel is empty

As soon as the natural gas tank is empty, petrol operation is

automatically engaged until the

ignition is switched off.

If the natural gas tank is not refuelled, the system must be manually

switched to petrol operation before

the engine is started-up again. This

will prevent damage to the catalytic

converter (overheating caused by

irregular fuel supply).

If the selector switch is operated

several times within a short time, a

switchover block is activated. The

engine remains in the current

operating mode. The block remains

active until the ignition is switched off.

A slight loss of power and torque can be expected during petrol operation.

You must therefore adapt your driving

style (e.g. during overtaking

manoeuvres) and vehicle loads (e.g.

towing loads) accordingly.

Every six months run the petrol tank

down until control indicator Y

illuminates, then refuel. This is

necessary to maintain fuel quality as

well as system function necessary for

petrol operation.

Fill the tank completely at regular intervals to prevent corrosion in the

tank.Refuelling9 Danger

Before refuelling, switch off engine

and any external heaters with

combustion chambers. Switch off

any mobile phones.

Follow the operating and safety

instructions of the filling station

when refuelling.

Page 214 of 301

212Driving and operating

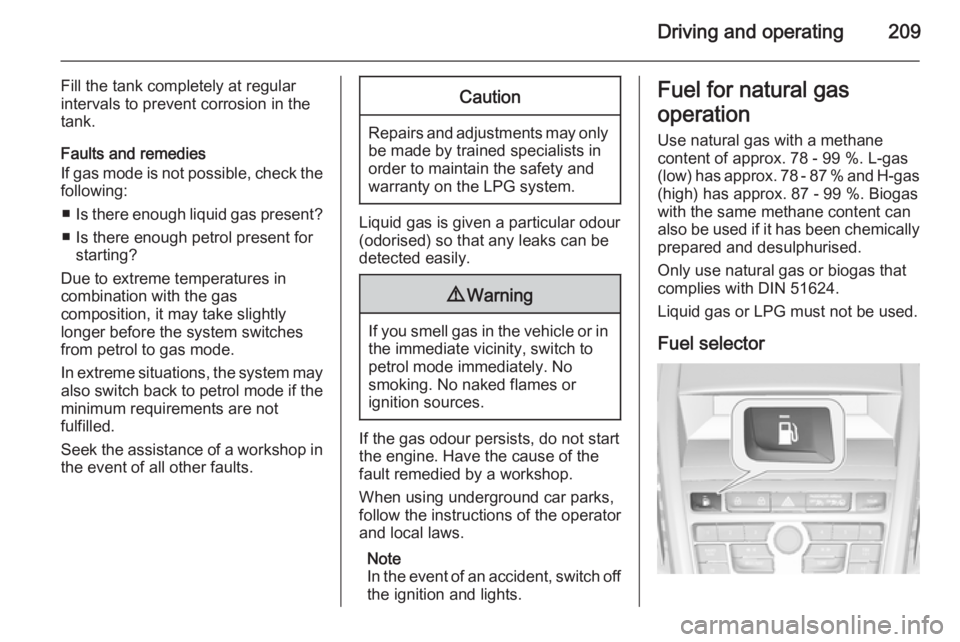

Vehicles with misfuel inhibitor9Warning

Do not try to open the flap of the

fuel filler neck manually on

vehicles with misfuel inhibitor.

Disregarding this could lead to

trapping of the fingers.

Vehicles with a selective catalytic

reduction system are equipped with a

misfuel inhibitor.

The misfuel inhibitor ensures that the flap of the fuel filler neck can only be

opened by using a nozzle for diesel

fuel or a funnel for emergency

refilling.

Turn the fuel filler cap slowly anti-

clockwise.

The cap can be retained in the

bracket on the fuel filler flap.

Place the nozzle in straight position to

the filler neck and press with slight

force to insert.

In case of an emergency refilling with a canister, a funnel must be used to

open the cap of the filler neck.The funnel is located on the right side storage in the load compartment.

Place the funnel in straight position to

the filler neck and press with slight

force to insert.

Use the funnel to fill in the diesel fuel

into the filler neck.

After topping-up, put the funnel into

the plastic bag and stow it in the

storage compartment.

Selective catalytic reduction system

3 164.

Natural gas refuelling

Page 218 of 301

216Driving and operating

General informationThe official fuel consumption and

specific CO 2 emission figures quoted

relate to the EU base model with

standard equipment.

Fuel consumption data and CO 2

emission data are determined

according to regulation

R (EC) No. 715/2007 (in the version

respectively applicable), taking into

consideration the vehicle weight in

running order, as specified by the

regulation.

The figures are provided only for the

purpose of comparison between

different vehicle variants and must

not be taken as a guarantee for the

actual fuel consumption of a

particular vehicle. Additional

equipment may result in slightly

higher results than the stated

consumption and CO 2 figures.

Furthermore, fuel consumption is

dependent on personal driving style

as well as road and traffic conditions.Natural gas

The fuel consumption information

was obtained using reference fuel

G20 (methane proportion

99 - 100 mol%) under prescribed

driving conditions. When using

natural gas with a lower proportion of

methane, the fuel consumption can

differ from the specified values.Trailer hitch

General information

Only use towing equipment that has

been approved for your vehicle.

Vehicles with natural gas engines

require special towing equipment.

Entrust retrofitting of towing

equipment to a workshop. It may be

necessary to make changes that

affect the cooling system, heat

shields or other equipment.

The bulb outage detection function for

trailer brake light cannot detect a

partial bulb outage. E.g. in case of

4x 5 Watt bulbs, the function only

detects lamp outage when only a

single 5 Watt lamp remains or none

remain.

Fitting of towing equipment could

cover the opening of the towing eye.

If this is the case use the coupling ball bar for towing. Always keep the

coupling ball bar in the vehicle.

Page 219 of 301

Driving and operating217Driving characteristics and

towing tips Before attaching a trailer, lubricate

the coupling ball. However, do not do

so if a stabiliser, which acts on the coupling ball, is being used to reduce snaking movements.

For trailers with low driving stability

and caravan trailers with a permitted

gross vehicle weight of more than

1300 kg the use of a stabiliser is

strongly recommended when driving

above 80 km/h.

If the trailer starts snaking, drive more

slowly, do not attempt to correct the

steering and brake sharply if

necessary.

When driving downhill, drive in the

same gear as if driving uphill and

drive at a similar speed.

Adjust tyre pressure to the value

specified for full load 3 286.Trailer towing

Trailer loads

The permissible trailer loads are

vehicle and engine-dependent

maximum values which must not be

exceeded. The actual trailer load is

the difference between the actual

gross weight of the trailer and the

actual coupling socket load with the

trailer coupled.

The permissible trailer loads are

specified in the vehicle documents. In general, they are valid for gradients

up to max. 12 %.

The permitted trailer load applies up to the specified incline and up to an

altitude of 1000 metres above sea

level. Since engine power decreases

as altitude increases due to the air

becoming thinner, therefore reducing

climbing ability, the permissible gross

train weight also decreases by 10 %

for every 1000 metres of additional

altitude. The gross train weight doesnot have to be reduced when driving

on roads with slight inclines (less than

8 %, e.g. motorways).

The permissible gross train weight

must not be exceeded. This weight is

specified on the identification plate

3 271.

Vertical coupling load

The vertical coupling load is the load

exerted by the trailer on the coupling

ball. It can be varied by changing the

weight distribution when loading the

trailer.

The maximum permissible vertical

coupling load (75 kg) 2)

is specified on

the towing equipment identification

plate and in the vehicle documents.

Always aim for the maximum load,

especially in the case of heavy

trailers. The vertical coupling load

should never fall below 25 kg.2) Engines B16DTH, B16DTJ, B20DTH and B20DTJ: Depending on the equipment the maximum permissible vertical coupling load can

be 75 kg or 60 kg.

Page 225 of 301

Vehicle care2239Danger

The ignition system and Xenon

headlights use extremely high

voltage. Do not touch.

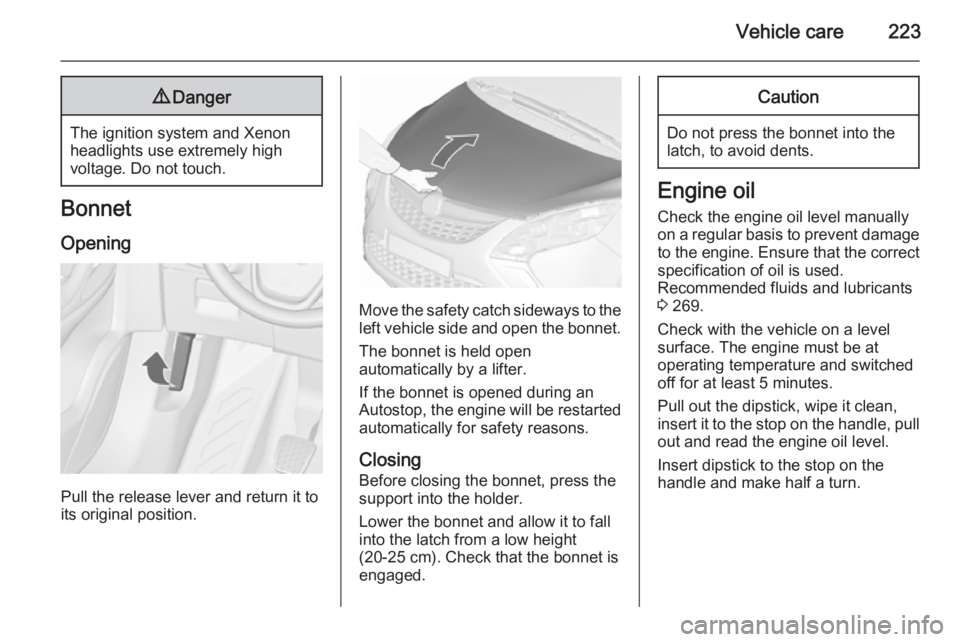

Bonnet

Opening

Pull the release lever and return it to

its original position.

Move the safety catch sideways to the left vehicle side and open the bonnet.

The bonnet is held open

automatically by a lifter.

If the bonnet is opened during an

Autostop, the engine will be restarted automatically for safety reasons.

Closing

Before closing the bonnet, press the

support into the holder.

Lower the bonnet and allow it to fall

into the latch from a low height

(20-25 cm). Check that the bonnet is

engaged.

Caution

Do not press the bonnet into the

latch, to avoid dents.

Engine oil

Check the engine oil level manuallyon a regular basis to prevent damage

to the engine. Ensure that the correct specification of oil is used.

Recommended fluids and lubricants

3 269.

Check with the vehicle on a level

surface. The engine must be at

operating temperature and switched

off for at least 5 minutes.

Pull out the dipstick, wipe it clean,

insert it to the stop on the handle, pull

out and read the engine oil level.

Insert dipstick to the stop on the

handle and make half a turn.

Page 231 of 301

Vehicle care229Diesel fuel system

bleeding

If the tank has been run dry, the diesel fuel system must be bled. Switch on

the ignition three times for

15 seconds at a time. Then crank the

engine for a maximum of

40 seconds. Repeat this process after no less than 5 seconds. If the enginefails to start, seek the assistance of a

workshop.

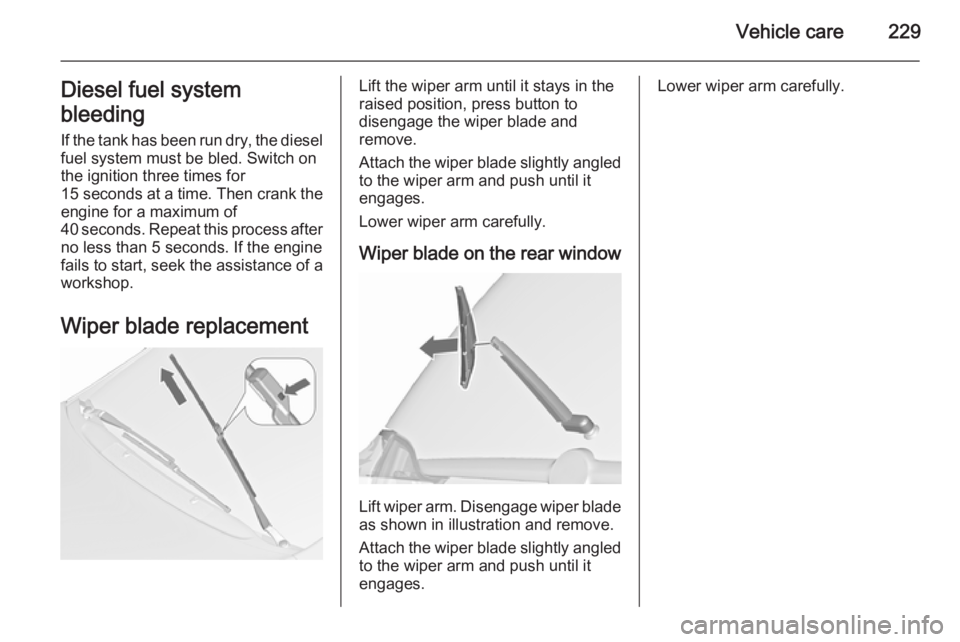

Wiper blade replacementLift the wiper arm until it stays in the

raised position, press button to

disengage the wiper blade and

remove.

Attach the wiper blade slightly angled

to the wiper arm and push until it

engages.

Lower wiper arm carefully.

Wiper blade on the rear window

Lift wiper arm. Disengage wiper blade as shown in illustration and remove.

Attach the wiper blade slightly angled

to the wiper arm and push until it

engages.

Lower wiper arm carefully.

Page 232 of 301

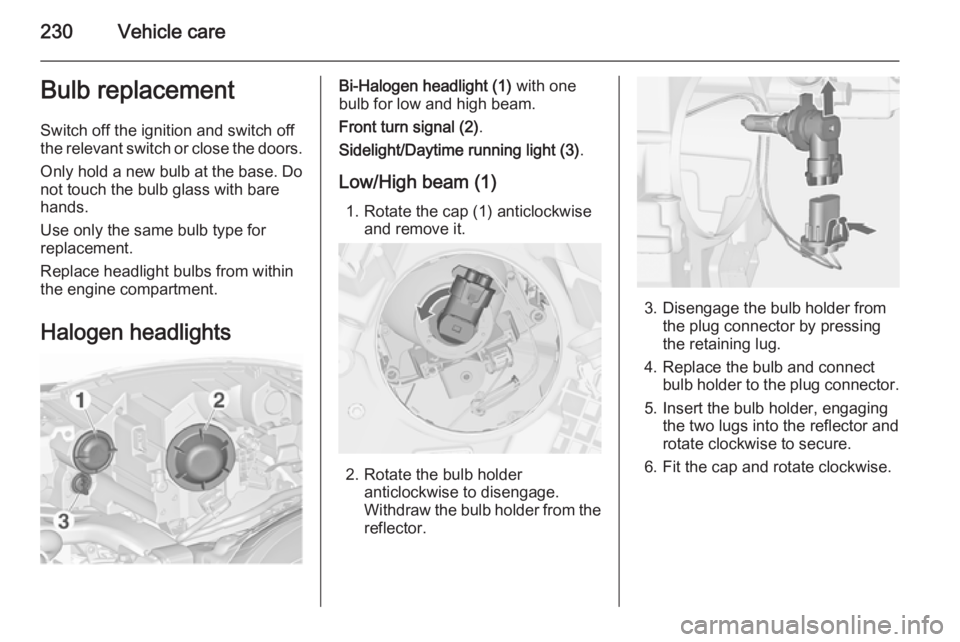

230Vehicle careBulb replacement

Switch off the ignition and switch off

the relevant switch or close the doors.

Only hold a new bulb at the base. Do not touch the bulb glass with bare

hands.

Use only the same bulb type for

replacement.

Replace headlight bulbs from within

the engine compartment.

Halogen headlightsBi-Halogen headlight (1) with one

bulb for low and high beam.

Front turn signal (2) .

Sidelight/Daytime running light (3) .

Low/High beam (1) 1. Rotate the cap (1) anticlockwise and remove it.

2. Rotate the bulb holder anticlockwise to disengage.

Withdraw the bulb holder from the

reflector.

3. Disengage the bulb holder from the plug connector by pressing

the retaining lug.

4. Replace the bulb and connect bulb holder to the plug connector.

5. Insert the bulb holder, engaging the two lugs into the reflector androtate clockwise to secure.

6. Fit the cap and rotate clockwise.

Page 233 of 301

Vehicle care231

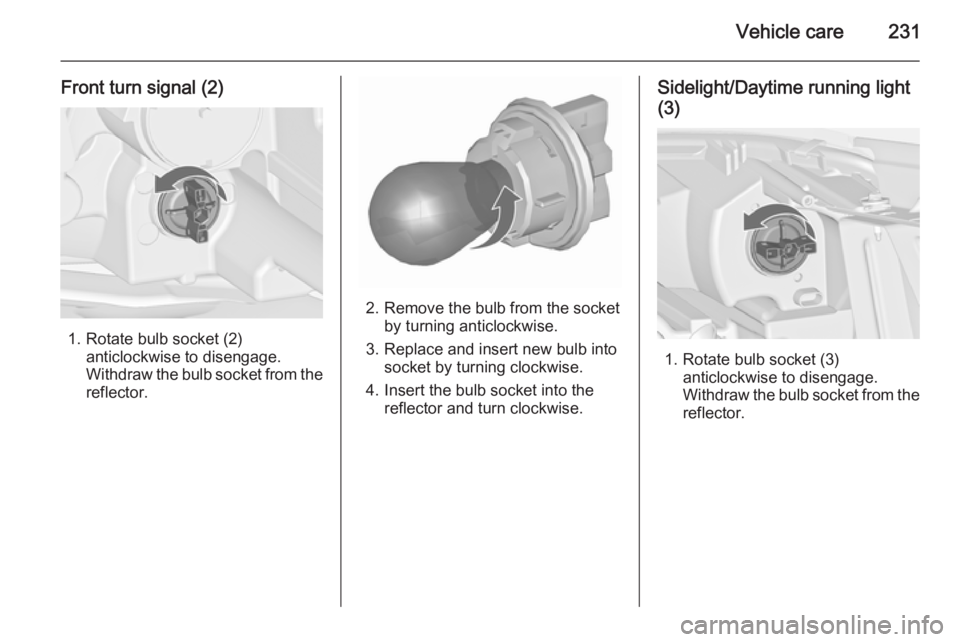

Front turn signal (2)

1. Rotate bulb socket (2)anticlockwise to disengage.

Withdraw the bulb socket from the

reflector.

2. Remove the bulb from the socket by turning anticlockwise.

3. Replace and insert new bulb into socket by turning clockwise.

4. Insert the bulb socket into the reflector and turn clockwise.

Sidelight/Daytime running light

(3)

1. Rotate bulb socket (3) anticlockwise to disengage.

Withdraw the bulb socket from the

reflector.