wheel bolts Peugeot 308 2017 Owner's Manual - RHD (UK, Australia)

[x] Cancel search | Manufacturer: PEUGEOT, Model Year: 2017, Model line: 308, Model: Peugeot 308 2017Pages: 392, PDF Size: 10.13 MB

Page 222 of 392

220

"Multimedia"

Multimedia support, hands-free kit, DVD player,

driving aids, vehicle tracking system, ...

Accessories

A wide range of accessories and genuine parts is available from the PeugeOt dealer network.th

ese accessories and parts are all suitable for your vehicle and benefit from Pe ugeOt' s recommendation and warranty.

"Transport solutions"

Boot liners, roof bars, bicycle carrier on roof

bars, ski carrier, roof box, towbar harness, ...

to

w bar, which mst be fitted by P

e

uge

Ot

dealer or a qualified workshop.

Conversion kits

You can obtain an "en terprise" kit to convert a

trade vehicle to a private car and vice-versa.

"Styling"

alloy wheels from 15 inch to 18 inch, finishers

for wheels, door sills, gear lever knobs, ...

"Ligne S": 16 and 17 inch alloy wheels, body

kit, stickers, interior and exterior mirror shells,

gear lever knob, door sills, mats*, …

"Comfort"

Door deflectors, side blinds and rear blind,

cigarette lighter, boot dividers, coat hanger

fixed to head restraint, front centre armrest,

under shelf storage, front and rear parking

sensors, styling mudflaps, window film, boot

management system, ...

*

t

o a

void any risk of jamming of the pedals:

-

e

nsure that the mat is positioned and

secured correctly,

-

n

ever fit one mat on top of another.

"Security and safety"

Anti-theft alarm, window engraving, wheel

security bolts, child seats and booster

cushions, breathalyzer, first aid kit, warning

triangle, high visibility jacket, stolen vehicle

tracking system, temporary puncture repair kit,

snow chains, non-slip covers, front foglamps

kit, dog guard, ...

"Protection"

Mats*, seat covers compatible with lateral

airbags, mud flaps, side protection rubbing

strips, bumper protection rubbing strips,

bumper protectors, boot sill finishers, boot

mat,

...

Practical information

Page 248 of 392

246

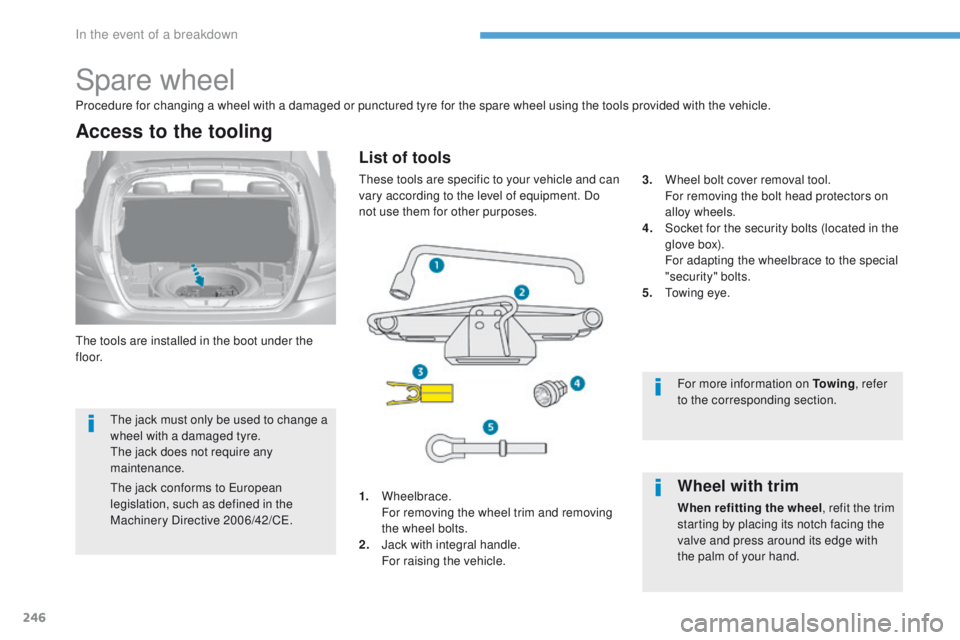

Spare wheel

the tools are installed in the boot under the

f l o o r.

Access to the tooling

1. Wheelbrace. F

or removing the wheel trim and removing

the wheel bolts.

2.

J

ack with integral handle.

F

or raising the vehicle. 3.

W

heel bolt cover removal tool.

F

or removing the bolt head protectors on

alloy wheels.

4.

S

ocket for the security bolts (located in the

glove box).

F

or adapting the wheelbrace to the special

"security" bolts.

5.

t

o

wing eye.

Procedure for changing a wheel with a damaged or punctured tyre for the spare wheel using the tools provided with the vehicle.

For more information on To w i n g, refer

to the corresponding section.Wheel with trim

When refitting the wheel , refit the trim

starting by placing its notch facing the

valve and press around its edge with

the palm of your hand.

List of tools

these tools are specific to your vehicle and can

vary according to the level of equipment. Do

not use them for other purposes.

th

e jack must only be used to change a

wheel with a damaged tyre.

th

e jack does not require any

maintenance.

th

e jack conforms to

e

u

ropean

legislation, such as defined in the

Machinery Directive 2006/42/C

e.

In the event of a breakdown

Page 250 of 392

248

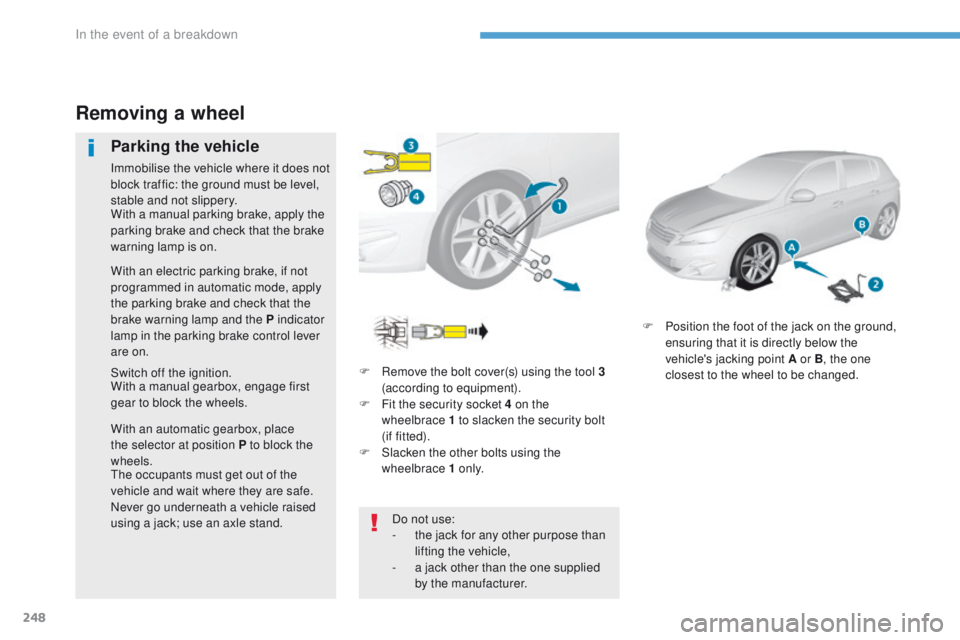

F Remove the bolt cover(s) using the tool 3 (according to equipment).

F

F

it the security socket 4 on the

wheelbrace

1 to slacken the security bolt

(if fitted).

F

S

lacken the other bolts using the

wheelbrace 1 o n l y. F

P

osition the foot of the jack on the ground,

ensuring that it is directly below the

vehicle's jacking point A or B , the one

closest to the wheel to be changed.

Removing a wheel

Parking the vehicle

Immobilise the vehicle where it does not

block traffic: the ground must be level,

stable and not slippery.

Switch off the ignition. With a manual parking brake, apply the

parking brake and check that the brake

warning lamp is on.

With an electric parking brake, if not

programmed in automatic mode, apply

the parking brake and check that the

brake warning lamp and the P indicator

lamp in the parking brake control lever

are on.

With a manual gearbox, engage first

gear to block the wheels.

With an automatic gearbox, place

the selector at position P to block the

wheels.

th

e occupants must get out of the

vehicle and wait where they are safe.

Never go underneath a vehicle raised

using a jack; use an axle stand. Do not use:

-

t

he jack for any other purpose than

lifting the vehicle,

-

a j

ack other than the one supplied

by the manufacturer.

In the event of a breakdown

Page 251 of 392

249

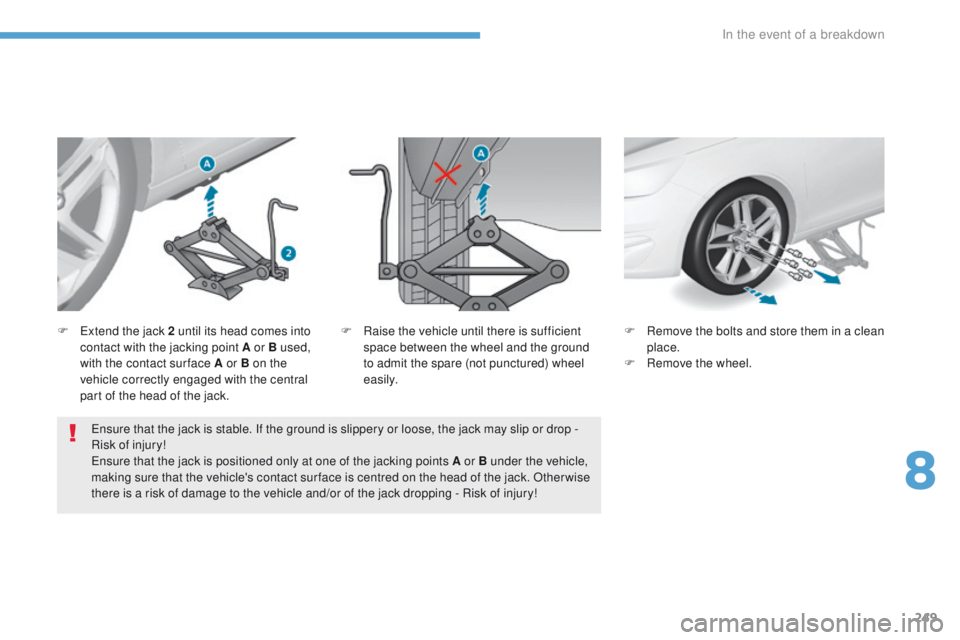

ensure that the jack is stable. If the ground is slippery or loose, the jack may slip or drop -

Risk of injury!

en

sure that the jack is positioned only at one of the jacking points A or B under the vehicle,

making sure that the vehicle's contact sur face is centred on the head of the jack. Other wise

there is a risk of damage to the vehicle and/or of the jack dropping - Risk of injury! F

R

emove the bolts and store them in a clean

place.

F

R

emove the wheel.

F

e

x

tend the jack 2 until its head comes into

contact with the jacking point A or B used,

with the contact sur face A or B on the

vehicle correctly engaged with the central

part of the head of the jack. F

Ra

ise the vehicle until there is sufficient

space between the wheel and the ground

to admit the spare (not punctured) wheel

easily.

8

In the event of a breakdown

Page 252 of 392

250

Fitting a wheel

Fitting the "space-saver"

spare wheel

If your vehicle is fitted with alloy wheels,

when tightening the bolts on fitting, it

is normal to notice that the washers

do not come into contact with the

"space-saver" spare wheel. t

h

e wheel

is secured by the conical sur face of

each bolt. F

P

ut the wheel in place on the hub.

F

S

crew in the bolts fully by hand.

F P re-tighten the security bolt using the

wheelbrace 1 fitted with the security

socket

4 (according to equipment).

F

P

re-tighten the other bolts using the

wheelbrace 1 o n l y. F

L

ower the vehicle fully.

F

F

old the jack 2 and detach it.

In the event of a breakdown

Page 253 of 392

251

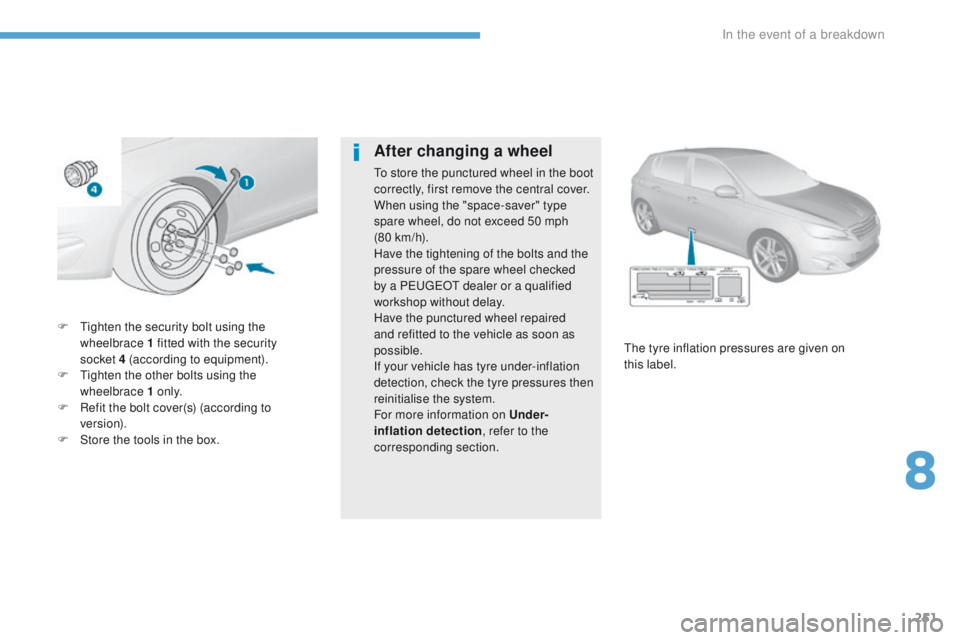

F tighten the security bolt using the wheelbrace 1 fitted with the security

socket

4 (according to equipment).

F

t

i

ghten the other bolts using the

wheelbrace 1 o n l y.

F

R

efit the bolt cover(s) (according to

ve r s i o n).

F

S

tore the tools in the box.

th

e tyre inflation pressures are given on

this

label.

After changing a wheel

to store the punctured wheel in the boot

correctly, first remove the central cover.

When using the "space-saver" type

spare wheel, do not exceed 50 mph

(80

km/h).

Have the tightening of the bolts and the

pressure of the spare wheel checked

by a P

e

uge

Ot

dealer or a qualified

workshop without delay.

Have the punctured wheel repaired

and refitted to the vehicle as soon as

possible.

If your vehicle has tyre under-inflation

detection, check the tyre pressures then

reinitialise the system.

For more information on Under-

inflation detection , refer to the

corresponding section.

8

In the event of a breakdown