valve Peugeot 308 2017 Owner's Manual

[x] Cancel search | Manufacturer: PEUGEOT, Model Year: 2017, Model line: 308, Model: Peugeot 308 2017Pages: 392, PDF Size: 10.16 MB

Page 215 of 392

213

308_en_Chap07_info-pratiques_ed01-2016

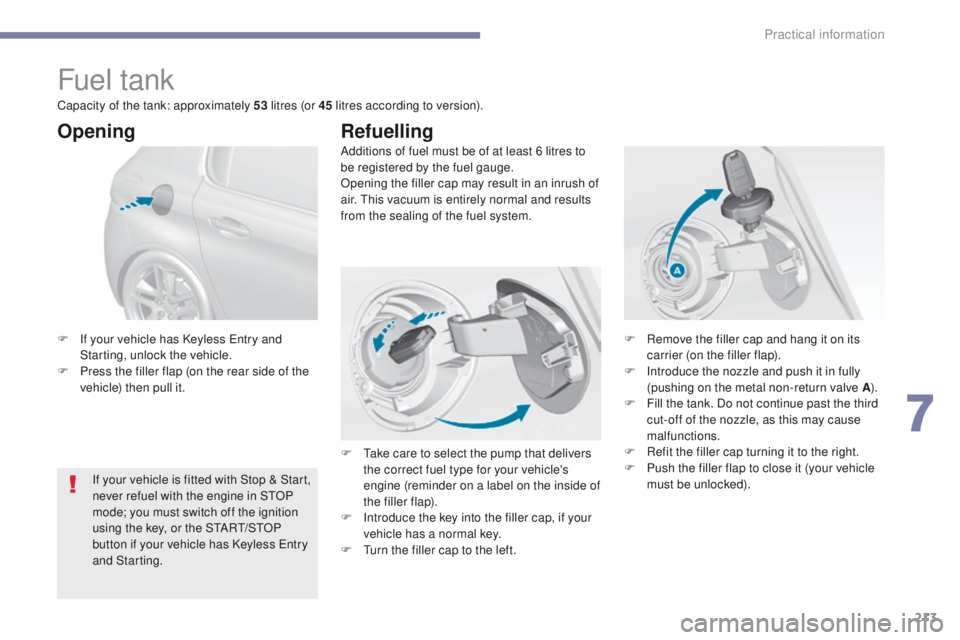

Fuel tank

Additions of fuel must be of at least 6 litres to

be registered by the fuel gauge.

Opening the filler cap may result in an inrush of

air. t

h

is vacuum is entirely normal and results

from the sealing of the fuel system.

Opening

If your vehicle is fitted with Stop & Start,

never refuel with the engine in StO P

mode; you must switch off the ignition

using the key, or the S

tA

R

t/

S

tO

P

button if your vehicle has Keyless

e

n

try

and Starting.

F

I

f your vehicle has Keyless e

n

try and

Starting, unlock the vehicle.

F

P

ress the filler flap (on the rear side of the

vehicle) then pull it.

Refuelling

F Remove the filler cap and hang it on its carrier (on the filler flap).

F

I

ntroduce the nozzle and push it in fully

(pushing on the metal non-return valve A ).

F

F

ill the tank. Do not continue past the third

cut-off of the nozzle, as this may cause

malfunctions.

F

R

efit the filler cap turning it to the right.

F

P

ush the filler flap to close it (your vehicle

must be unlocked).

F

t

a

ke care to select the pump that delivers

the correct fuel type for your vehicle's

engine (reminder on a label on the inside of

the filler flap).

Capacity of the tank: approximately 53

litres (or 45 litres according to version).

F

I

ntroduce the key into the filler cap, if your

vehicle has a normal key.

F

t

u

rn the filler cap to the left.

7

Practical information

Page 243 of 392

241

308_en_Chap08_en-cas-de-panne_ed01-2016

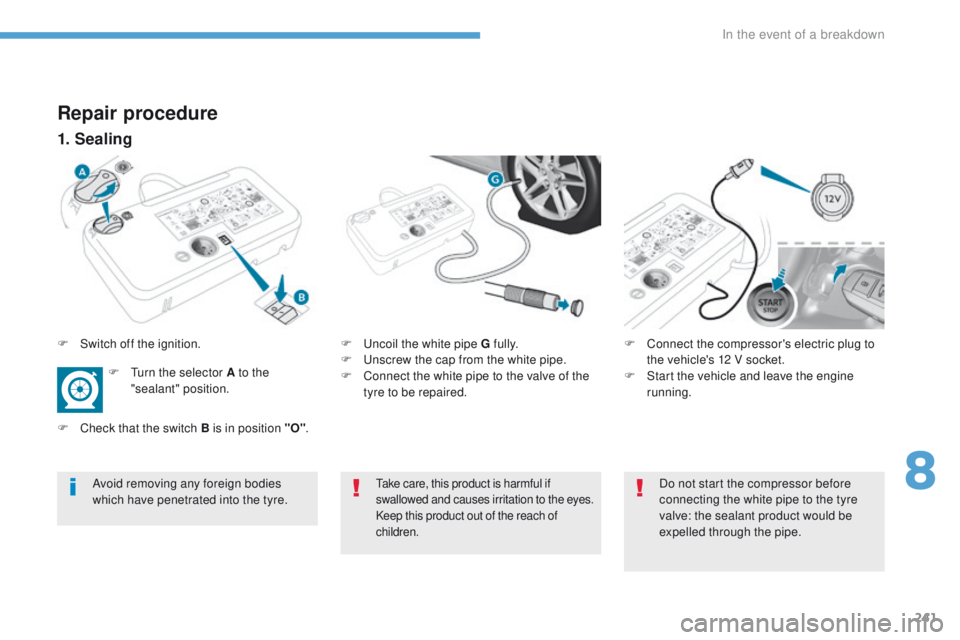

Repair procedure

1. Sealing

F uncoil the white pipe G fully.

F

un screw the cap from the white pipe.

F

C

onnect the white pipe to the valve of the

tyre to be repaired. F

C onnect the compressor's electric plug to

the vehicle's 12 V socket.

F

S

tart the vehicle and leave the engine

running.

take care, this product is harmful if

swallowed and causes irritation to the eyes.

Keep this product out of the reach of

children.Avoid removing any foreign bodies

which have penetrated into the tyre. Do not start the compressor before

connecting the white pipe to the tyre

valve: the sealant product would be

expelled through the pipe.

F

S

witch off the ignition.

F t

u

rn the selector A to the

"sealant" position.

F

C

heck that the switch B is in position "O"

.

8

In the event of a breakdown

Page 244 of 392

242

308_en_Chap08_en-cas-de-panne_ed01-2016

If after around 5 to 7 minutes the

pressure is not attained, this indicates

that the tyre is not repairable; contact

a P

e

uge

Ot

dealer or a qualified

workshop for assistance.

F

S

witch on the compressor by moving

the switch B to position "I" until the tyre

pressure reaches 2.0 bars.

t

h

e sealant is injected into the tyre under

pressure; do not disconnect the pipe from

the valve during this operation (risk of

splashing). F

R

emove the kit and screw the cap back on

the white pipe.

t

a

ke care to avoid staining your vehicle

with traces of fluid. Keep the kit to hand.

F

D

rive immediately for approximately

three miles (five kilometres), at reduced

speed (between 12 and 37 mph (20 and

60 km/h)), to plug the puncture.

F

S

top to check the repair and the tyre

pressure using the kit.

In the event of a breakdown

Page 245 of 392

243

308_en_Chap08_en-cas-de-panne_ed01-2016

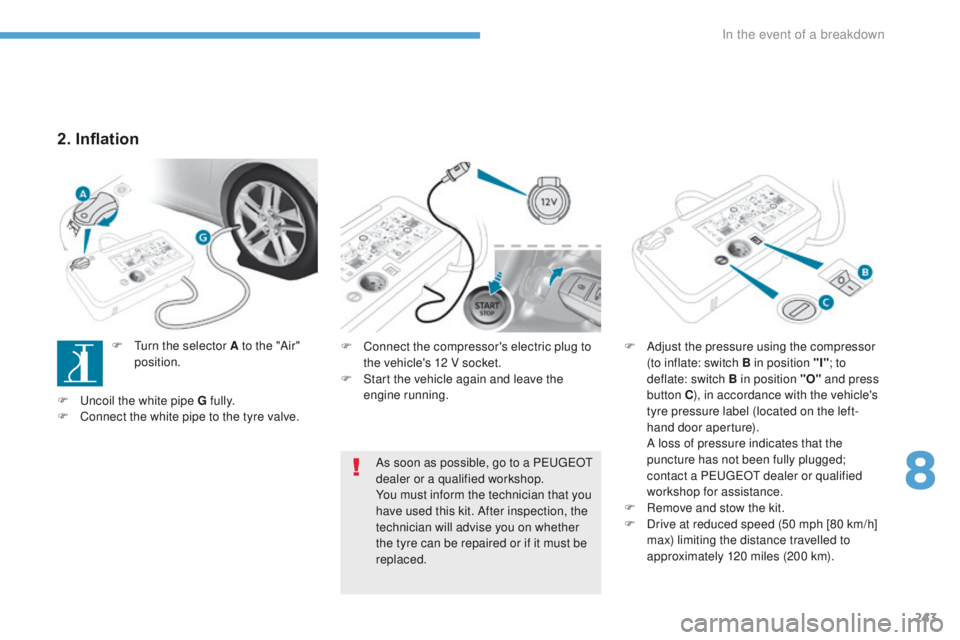

F Connect the compressor's electric plug to

the vehicle's 12 V socket.

F

S

tart the vehicle again and leave the

engine running. F

A djust the pressure using the compressor

(to inflate: switch B in position "I" ; to

deflate: switch B in position "O" and press

button C ), in accordance with the vehicle's

tyre pressure label (located on the left-

hand door aperture).

A l

oss of pressure indicates that the

puncture has not been fully plugged;

contact a P

e

uge

Ot

dealer or qualified

workshop for assistance.

F

R

emove and stow the kit.

F

D

rive at reduced speed (50 mph [80 km/h]

max) limiting the distance travelled to

approximately 120 miles (200 km).

As soon as possible, go to a P

e

uge

Ot

dealer or a qualified workshop.

You must inform the technician that you

have used this kit. After inspection, the

technician will advise you on whether

the tyre can be repaired or if it must be

replaced.

2. Inflation

F turn the selector A to the "Air" position.

F

u

n

coil the white pipe G fully.

F

C

onnect the white pipe to the tyre valve.

8

In the event of a breakdown

Page 247 of 392

245

308_en_Chap08_en-cas-de-panne_ed01-2016

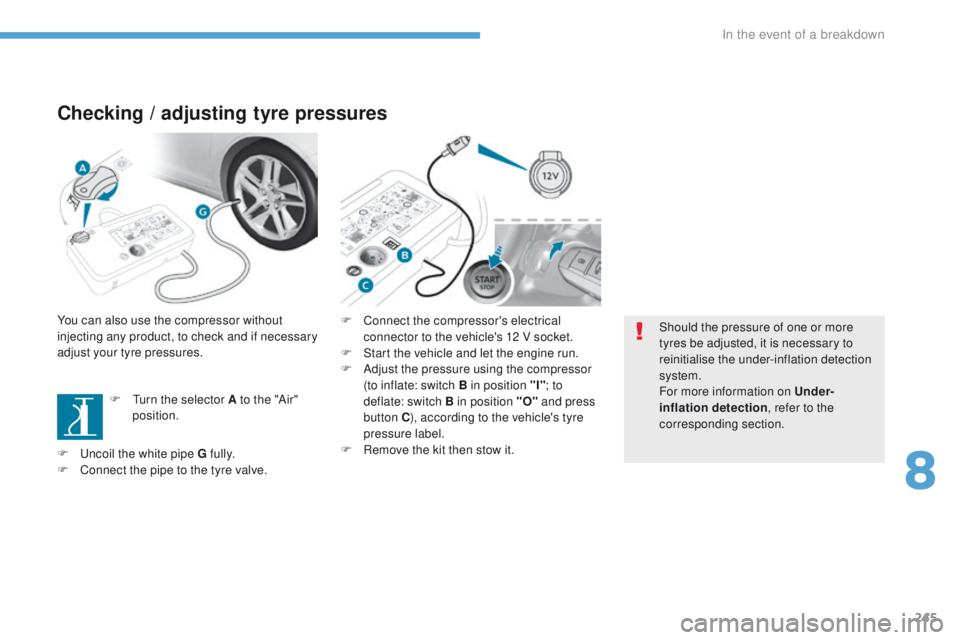

Checking / adjusting tyre pressures

You can also use the compressor without

injecting any product, to check and if necessary

adjust your tyre pressures.

F

t

u

rn the selector A to the "Air"

position. F

C onnect the compressor's electrical

connector to the vehicle's 12 V socket.

F

S

tart the vehicle and let the engine run.

F

A

djust the pressure using the compressor

(to inflate: switch B in position "I" ; to

deflate: switch B in position "O" and press

button C ), according to the vehicle's tyre

pressure label.

F

R

emove the kit then stow it.Should the pressure of one or more

tyres be adjusted, it is necessary to

reinitialise the under-inflation detection

system.

For more information on Under-

inflation detection

, refer to the

corresponding section.

F

u

n

coil the white pipe G fully.

F

C

onnect the pipe to the tyre valve.

8

In the event of a breakdown

Page 248 of 392

246

308_en_Chap08_en-cas-de-panne_ed01-2016

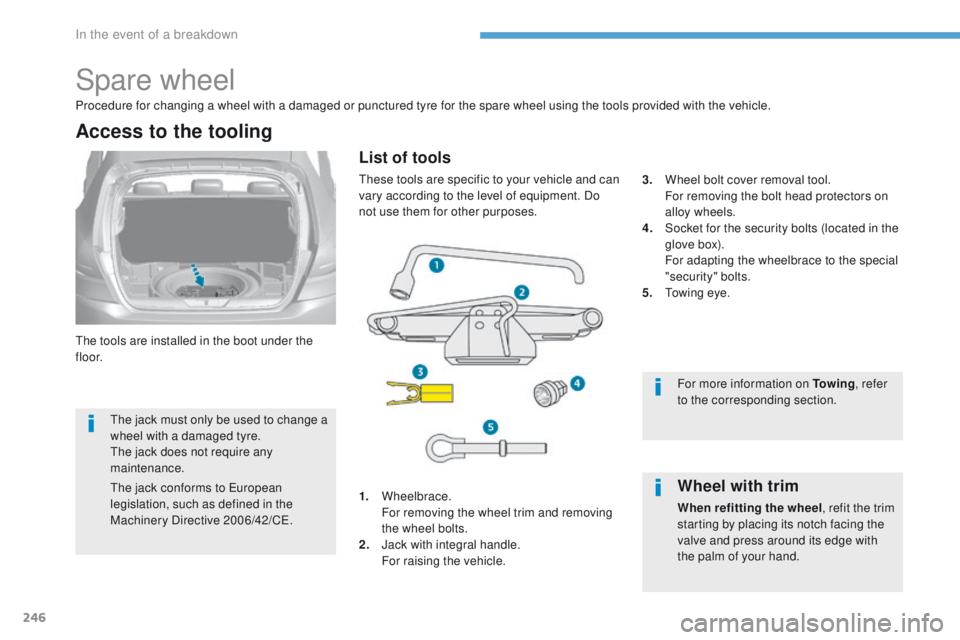

Spare wheel

the tools are installed in the boot under the

f l o o r.

Access to the tooling

1. Wheelbrace. F

or removing the wheel trim and removing

the wheel bolts.

2.

J

ack with integral handle.

F

or raising the vehicle. 3.

W

heel bolt cover removal tool.

F

or removing the bolt head protectors on

alloy wheels.

4.

S

ocket for the security bolts (located in the

glove box).

F

or adapting the wheelbrace to the special

"security" bolts.

5.

t

o

wing eye.

Procedure for changing a wheel with a damaged or punctured tyre for the spare wheel using the tools provided with the vehicle.

For more information on To w i n g, refer

to the corresponding section.Wheel with trim

When refitting the wheel , refit the trim

starting by placing its notch facing the

valve and press around its edge with

the palm of your hand.

List of tools

these tools are specific to your vehicle and can

vary according to the level of equipment. Do

not use them for other purposes.

th

e jack must only be used to change a

wheel with a damaged tyre.

th

e jack does not require any

maintenance.

th

e jack conforms to

e

u

ropean

legislation, such as defined in the

Machinery Directive 2006/42/C

e.

In the event of a breakdown