boot PEUGEOT 308 2018 Owner's Manual

[x] Cancel search | Manufacturer: PEUGEOT, Model Year: 2018, Model line: 308, Model: Peugeot 308 2018Pages: 360, PDF Size: 12.38 MB

Page 108 of 360

106

The stowing rings are designed to

secure luggage using different types of

retaining nets.

Such nets are available as an option or

as an accessory.

For more information, contact a

PEUGEOT dealer.

For the installation of a high load

retaining net, refer to the corresponding

section.

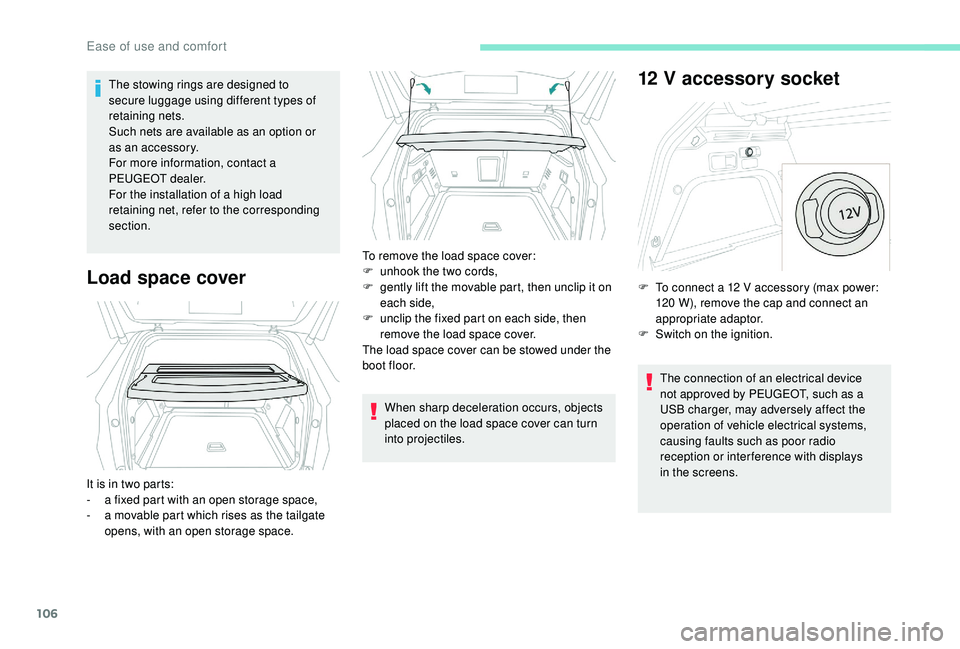

Load space cover

When sharp deceleration occurs, objects

placed on the load space cover can turn

into projectiles.

12 V accessory socket

The connection of an electrical device

not approved by PEUGEOT, such as a

USB charger, may adversely affect the

operation of vehicle electrical systems,

causing faults such as poor radio

reception or inter ference with displays

in the screens.

It is in two parts:

-

a f

ixed part with an open storage space,

-

a m

ovable part which rises as the tailgate

opens, with an open storage space. To remove the load space cover:

F

u

nhook the two cords,

F

g

ently lift the movable part, then unclip it on

each side,

F

u

nclip the fixed part on each side, then

remove the load space cover.

The load space cover can be stowed under the

boot floor. F

T

o connect a 12 V accessory (max power:

120 W), remove the cap and connect an

appropriate adaptor.

F

S

witch on the ignition.

Ease of use and comfort

Page 109 of 360

107

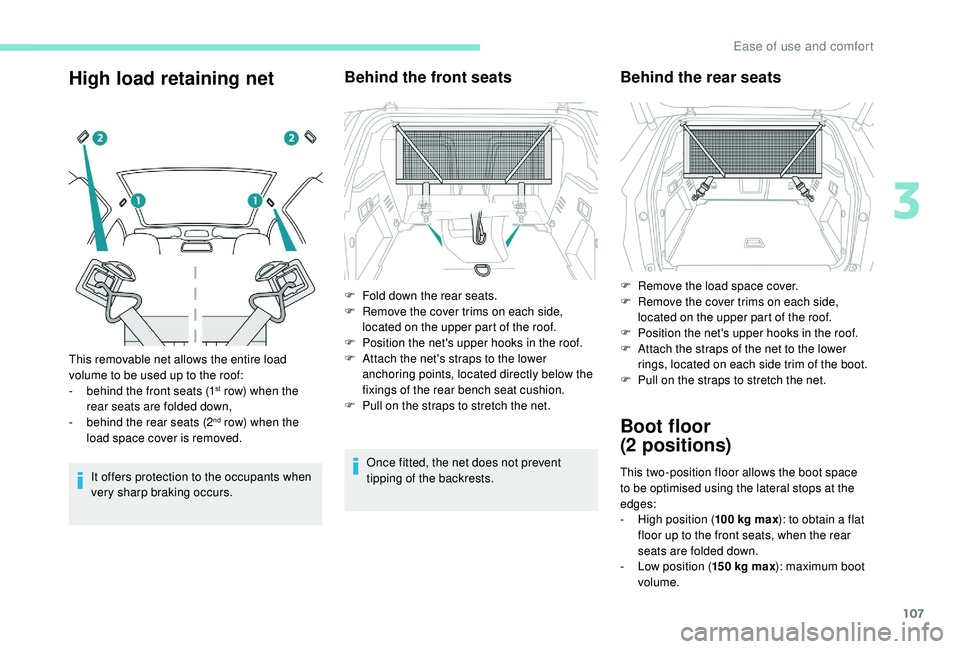

High load retaining net

It offers protection to the occupants when

very sharp braking occurs.

Behind the front seats

Once fitted, the net does not prevent

tipping of the backrests.

This removable net allows the entire load

volume to be used up to the roof:

-

b

ehind the front seats (1

st row) when the

rear seats are folded down,

-

b

ehind the rear seats (2

nd row) when the

load space cover is removed. F

F

old down the rear seats.

F

R

emove the cover trims on each side,

located on the upper part of the roof.

F

P

osition the net's upper hooks in the roof.

F

A

ttach the net's straps to the lower

anchoring points, located directly below the

fixings of the rear bench seat cushion.

F

P

ull on the straps to stretch the net.

Behind the rear seats

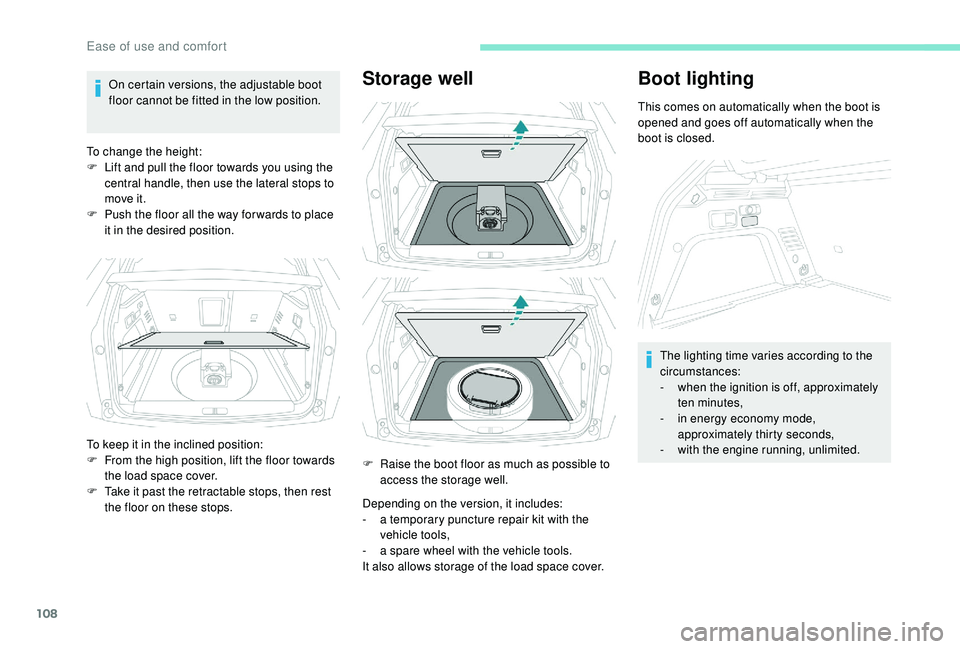

Boot floor

(2

positions)

This two-position floor allows the boot space

to be optimised using the lateral stops at the

edges:

-

Hig

h position ( 100

kg max): to obtain a flat

floor up to the front seats, when the rear

seats are folded down.

-

L

ow position ( 150

kg max): maximum boot

volume.

F

R

emove the load space cover.

F

R

emove the cover trims on each side,

located on the upper part of the roof.

F

P

osition the net's upper hooks in the roof.

F

A

ttach the straps of the net to the lower

rings, located on each side trim of the boot.

F

P

ull on the straps to stretch the net.

3

Ease of use and comfort

Page 110 of 360

108

On certain versions, the adjustable boot

floor cannot be fitted in the low position.

To change the height:

F

L

ift and pull the floor towards you using the

central handle, then use the lateral stops to

move it.

F

P

ush the floor all the way for wards to place

it in the desired position.Storage well

Depending on the version, it includes:

- a t emporary puncture repair kit with the

vehicle tools,

-

a s

pare wheel with the vehicle tools.

It also allows storage of the load space cover.

Boot lighting

This comes on automatically when the boot is

opened and goes off automatically when the

boot is closed.

The lighting time varies according to the

circumstances:

-

w

hen the ignition is off, approximately

ten minutes,

-

i

n energy economy mode,

approximately thirty seconds,

-

w

ith the engine running, unlimited.

To keep it in the inclined position:

F

F

rom the high position, lift the floor towards

the load space cover.

F

T

ake it past the retractable stops, then rest

the floor on these stops. F

R

aise the boot floor as much as possible to

access the storage well.

Ease of use and comfort

Page 114 of 360

112

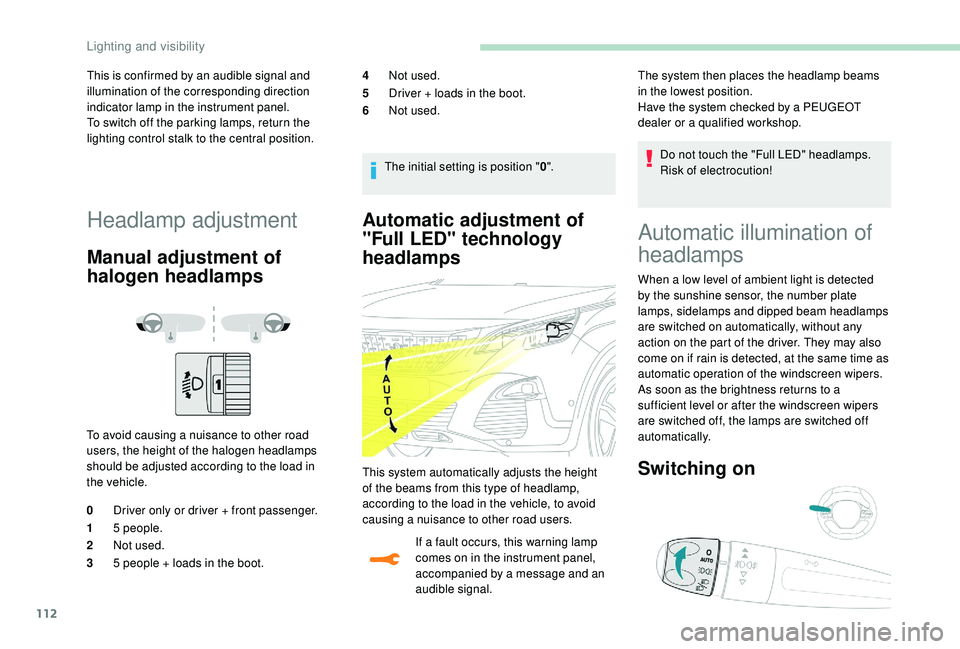

Automatic adjustment of

"Full LED" technology

headlamps

If a fault occurs, this warning lamp

comes on in the instrument panel,

accompanied by a message and an

audible signal.Do not touch the "Full LED" headlamps.

Risk of electrocution!

The system then places the headlamp beams

in the lowest position.

Have the system checked by a PEUGEOT

dealer or a qualified workshop.

Automatic illumination of

headlamps

This is confirmed by an audible signal and

illumination of the corresponding direction

indicator lamp in the instrument panel.

To switch off the parking lamps, return the

lighting control stalk to the central position.

Headlamp adjustment

Manual adjustment of

halogen headlamps

To avoid causing a nuisance to other road

users, the height of the halogen headlamps

should be adjusted according to the load in

the vehicle.

0

Driver only or driver + front passenger.

1 5

people.

2 Not used.

3 5

people + loads in the boot. 4

Not used.

5 Driver + loads in the boot.

6 Not used.

The initial setting is position " 0".

This system automatically adjusts the height

of the beams from this type of headlamp,

according to the load in the vehicle, to avoid

causing a nuisance to other road users. When a low level of ambient light is detected

by the sunshine sensor, the number plate

lamps,

sidelamps and dipped beam headlamps

are switched on automatically, without any

action on the part of the driver. They may also

come on if rain is detected, at the same time as

automatic operation of the windscreen wipers.

As soon as the brightness returns to a

sufficient level or after the windscreen wipers

are switched off, the lamps are switched off

automatically.

Switching on

Lighting and visibility

Page 206 of 360

204

- Certain materials (fabrics) absorb sound waves: pedestrians may not be detected.

-

A

ccumulated snow or dead leaves on the

road sur face can inter fere with the vehicle's

sensors.

-

A f

ront or rear impact to the vehicle can

distort the settings of the sensors, which is

not always detected by the system: distance

measurements may be incorrect.

-

T

he tilting of the vehicle if the boot is

very loaded can affect the distance

measurements.

-

T

he sensors may be affected by poor

weather conditions (heavy rain, thick fog,

snowfall, etc.).

Recommendations on care

In bad or wintry weather, ensure that the

sensors are not covered with mud, ice or

snow. When reverse gear is engaged, an

audible signal (long beep) indicates that

the sensors may be dirty. High pressure washing

When washing your vehicle, direct the

lance at least 30

cm away from the

sensors.

Operating fault

If a fault occurs when shifting

to reverse, this warning lamp

comes on in the instrument panel,

accompanied by a message and an

audible signal (short beep).

Contact a PEUGEOT dealer or a qualified

workshop

to have the system checked.

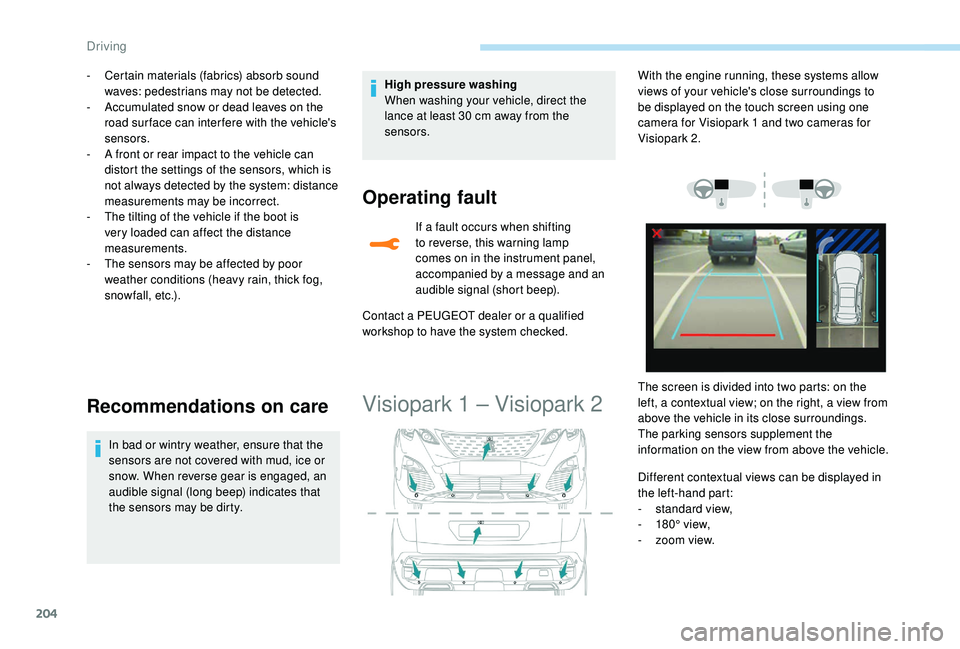

Visiopark 1 – Visiopark 2

Different contextual views can be displayed in

the left-hand part:

-

s

tandard view,

-

1

80° view,

-

z

oom view.

With the engine running, these systems allow

views of your vehicle's close surroundings to

be displayed on the touch screen using one

camera for Visiopark 1 and two cameras for

Visiopark 2.

The screen is divided into two parts: on the

left, a contextual view; on the right, a view from

above the vehicle in its close surroundings.

The parking sensors supplement the

information on the view from above the vehicle.

Driving

Page 225 of 360

223

Maintenance

Correct operation is only possible if the towball

and its carrier are kept clean.

Before cleaning the vehicle with a high-

pressure jet wash, the towball must be removed

and the protective plug fitted to the carrier.Apply the label provided to a clearly visible

area, close to the carrier or in the boot.

Go to a PEUGEOT dealer or a qualified

workshop for any work on the towbar

system.

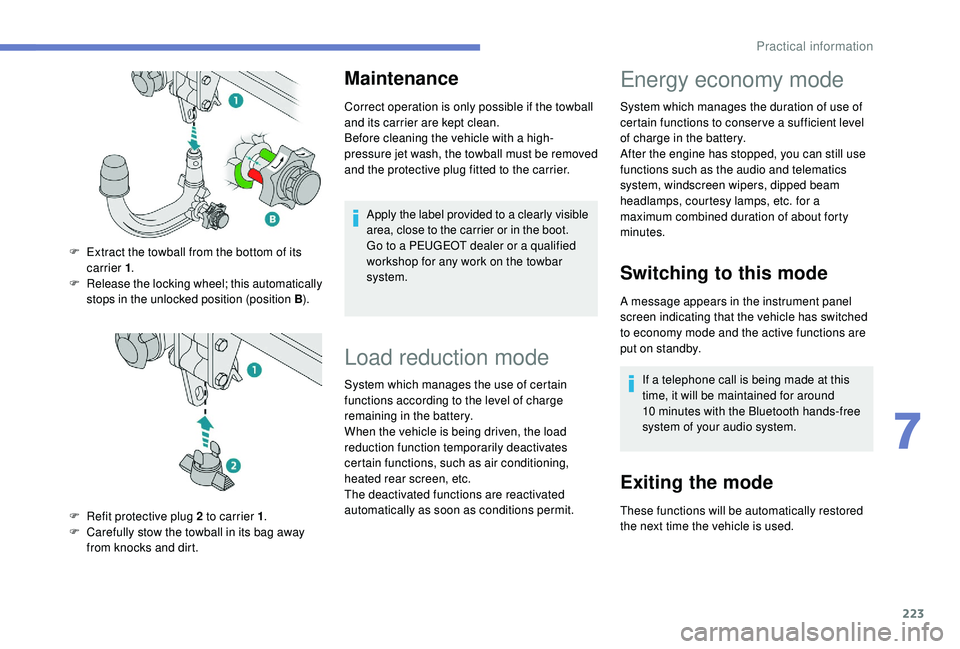

F

E

xtract the towball from the bottom of its

carrier 1 .

F

R

elease the locking wheel; this automatically

stops in the unlocked position (position B ).

F

R

efit protective plug 2 to carrier 1 .

F

C

arefully stow the towball in its bag away

from knocks and dirt.

Load reduction mode

System which manages the use of certain

functions according to the level of charge

remaining in the battery.

When the vehicle is being driven, the load

reduction function temporarily deactivates

certain functions, such as air conditioning,

heated rear screen, etc.

The deactivated functions are reactivated

automatically as soon as conditions permit.

Energy economy mode

System which manages the duration of use of

certain functions to conser ve a sufficient level

of charge in the battery.

After the engine has stopped, you can still use

functions such as the audio and telematics

system,

windscreen wipers, dipped beam

headlamps,

courtesy lamps, etc. for a

maximum combined duration of about forty

minutes.

Switching to this mode

A message appears in the instrument panel

screen indicating that the vehicle has switched

to economy mode and the active functions are

put on standby.

If a telephone call is being made at this

time, it will be maintained for around

10

minutes with the Bluetooth hands-free

system of your audio system.

Exiting the mode

These functions will be automatically restored

the next time the vehicle is used.

7

Practical information

Page 240 of 360

238

With 1.5 BlueHDi and 2.0

BlueHDi 180 S&S engines

F Fill the fuel tank with at least 5 litres of

Diesel.

F

S

witch on the ignition (without starting the

engine).

F

W

ait around 1 minute and switch off the

ignition.

F

O

perate the starter to run the engine.

If the engine does not start, repeat the

procedure.

With 2.0 HDi engines

F Put it back in place, clip in the cover and ensure it is clipped in.

F

C

lose the bonnet.

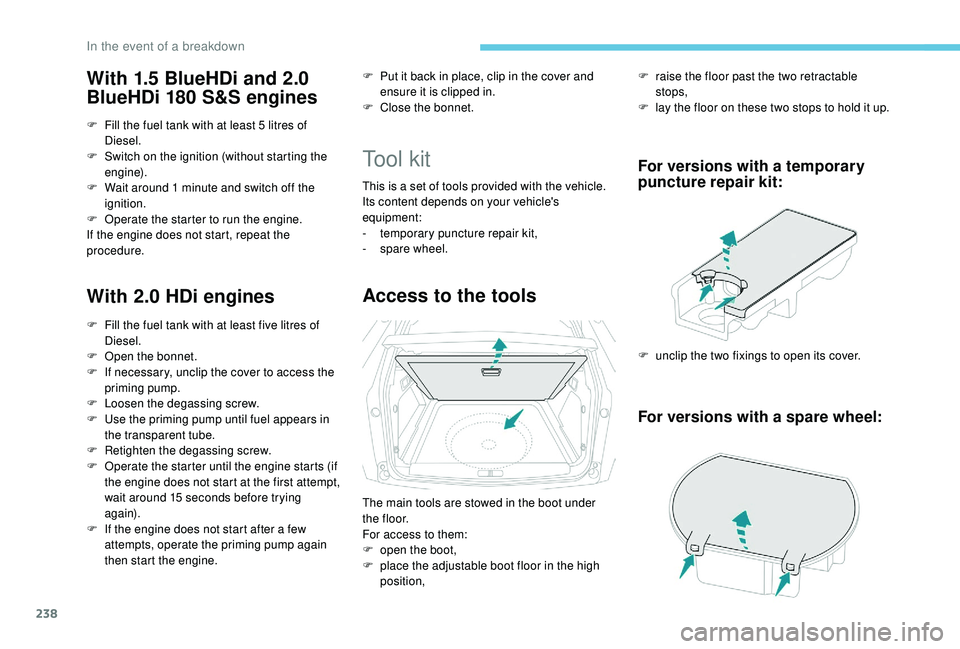

Tool kit

This is a set of tools provided with the vehicle.

Its content depends on your vehicle's

equipment:

-

t

emporary puncture repair kit,

-

spar

e wheel.

Access to the tools

F raise the floor past the two retractable stops,

F

l

ay the floor on these two stops to hold it up.

For versions with a temporary

puncture repair kit:

F unclip the two fixings to open its cover.

For versions with a spare wheel:

F Fill the fuel tank with at least five litres of Diesel.

F

O

pen the bonnet.

F

I

f necessary, unclip the cover to access the

priming pump.

F

L

oosen the degassing screw.

F

U

se the priming pump until fuel appears in

the transparent tube.

F

R

etighten the degassing screw.

F

O

perate the starter until the engine starts (if

the engine does not start at the first attempt,

wait around 15

seconds before trying

again).

F

I

f the engine does not start after a few

attempts, operate the priming pump again

then start the engine. The main tools are stowed in the boot under

t h e f l o o r.

For access to them:

F

o

pen the boot,

F

p

lace the adjustable boot floor in the high

position,

In the event of a breakdown

Page 243 of 360

241

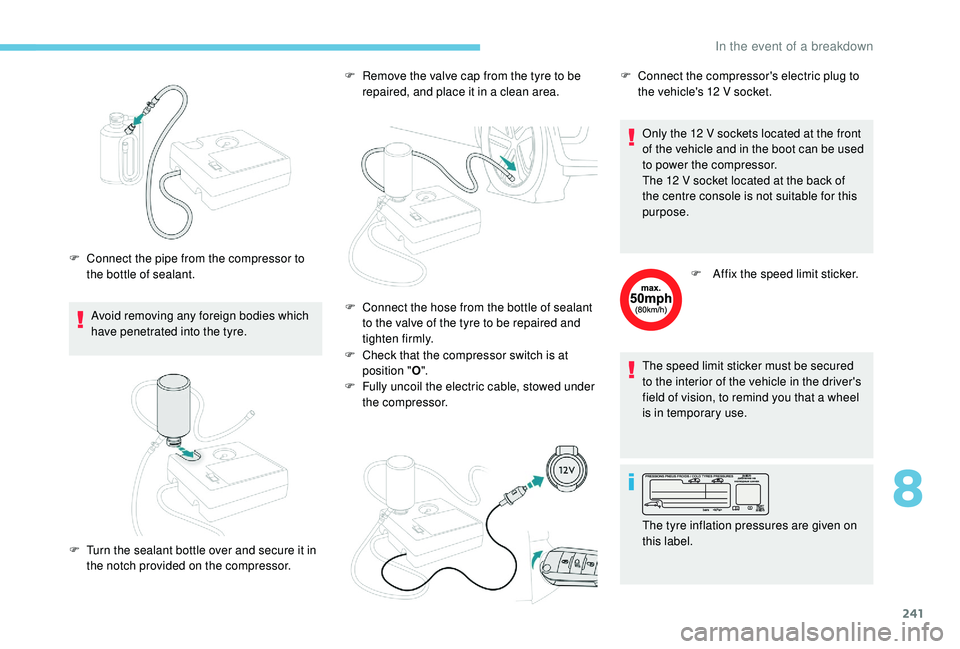

Avoid removing any foreign bodies which

have penetrated into the tyre.

F

C

onnect the pipe from the compressor to

the bottle of sealant. F

R

emove the valve cap from the tyre to be

repaired, and place it in a clean area.

F

C

heck that the compressor switch is at

position " O".

F

F

ully uncoil the electric cable, stowed under

the compressor. Only the 12

V sockets located at the front

of the vehicle and in the boot can be used

to power the compressor.

The 12 V socket located at the back of

the centre console is not suitable for this

purpose.

F

A

ffix the speed limit sticker.

The speed limit sticker must be secured

to the interior of the vehicle in the driver's

field of vision, to remind you that a wheel

is in temporary use.

F

T

urn the sealant bottle over and secure it in

the notch provided on the compressor. F

C onnect the hose from the bottle of sealant

to the valve of the tyre to be repaired and

tighten firmly. F

C

onnect the compressor's electric plug to

the vehicle's 12 V socket.

The tyre inflation pressures are given on

this label.

8

In the event of a breakdown

Page 245 of 360

243

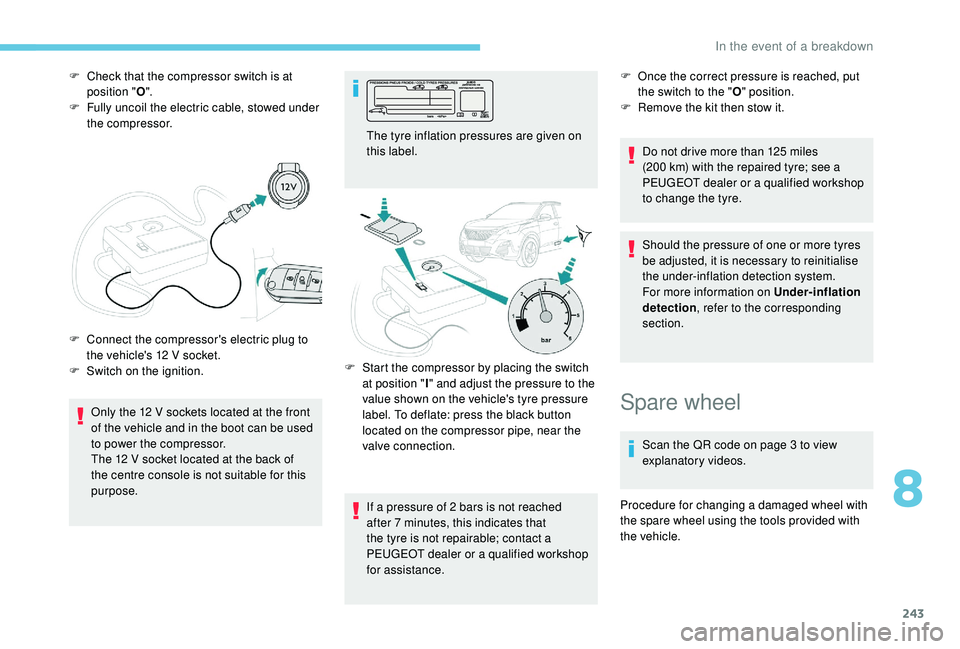

F Check that the compressor switch is at position " O".

F

F

ully uncoil the electric cable, stowed under

the compressor.

Only the 12

V sockets located at the front

of the vehicle and in the boot can be used

to power the compressor.

The 12

V socket located at the back of

the centre console is not suitable for this

purpose.

F

C

onnect the compressor's electric plug to

the vehicle's 12

V socket.

F

S

witch on the ignition. The tyre inflation pressures are given on

this label.

If a pressure of 2

bars is not reached

after 7

minutes, this indicates that

the tyre is not repairable; contact a

PEUGEOT dealer or a qualified workshop

for assistance. F

O nce the correct pressure is reached, put

the switch to the " O" position.

F

R

emove the kit then stow it.

Do not drive more than 125

miles

(200

km) with the repaired tyre; see a

PEUGEOT dealer or a qualified workshop

to change the tyre.

Should the pressure of one or more tyres

be adjusted, it is necessary to reinitialise

the under-inflation detection system.

For more information on Under-inflation

detection , refer to the corresponding

section.

F

S

tart the compressor by placing the switch

at position " I" and adjust the pressure to the

value shown on the vehicle's tyre pressure

label. To deflate: press the black button

located on the compressor pipe, near the

valve connection.

Spare wheel

Scan the QR code on page 3 to view

explanatory videos.

Procedure for changing a damaged wheel with

the spare wheel using the tools provided with

the vehicle.

8

In the event of a breakdown

Page 246 of 360

244

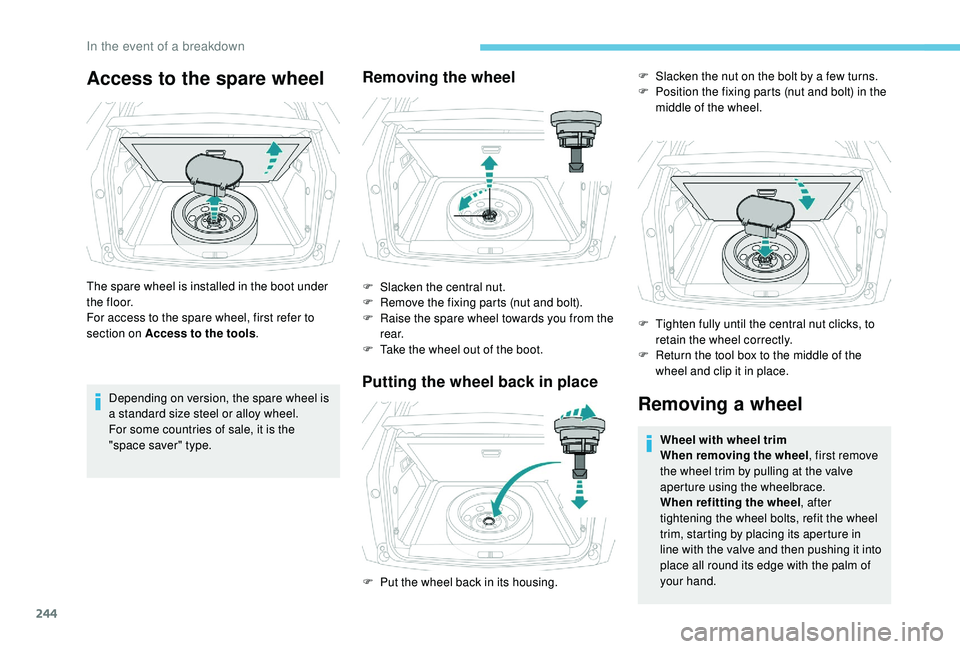

Access to the spare wheel

The spare wheel is installed in the boot under

t h e f l o o r.

For access to the spare wheel, first refer to

section on Access to the tools.

Depending on version, the spare wheel is

a standard size steel or alloy wheel.

For some countries of sale, it is the

"space saver" type.

Removing the wheel

F Slacken the central nut.

F R emove the fixing parts (nut and bolt).

F

R

aise the spare wheel towards you from the

r e a r.

F

T

ake the wheel out of the boot.

Putting the wheel back in place

Removing a wheel

Wheel with wheel trim

When removing the wheel , first remove

the wheel trim by pulling at the valve

aperture using the wheelbrace.

When refitting the wheel , after

tightening the wheel bolts, refit the wheel

trim, starting by placing its aperture in

line with the valve and then pushing it into

place all round its edge with the palm of

your hand.

F

P

ut the wheel back in its housing. F

S

lacken the nut on the bolt by a few turns.

F

P

osition the fixing parts (nut and bolt) in the

middle of the wheel.

F

T

ighten fully until the central nut clicks, to

retain the wheel correctly.

F

R

eturn the tool box to the middle of the

wheel and clip it in place.

In the event of a breakdown