PEUGEOT 5008 2015 Owners Manual

Manufacturer: PEUGEOT, Model Year: 2015, Model line: 5008, Model: PEUGEOT 5008 2015Pages: 364, PDF Size: 12.82 MB

Page 221 of 364

219

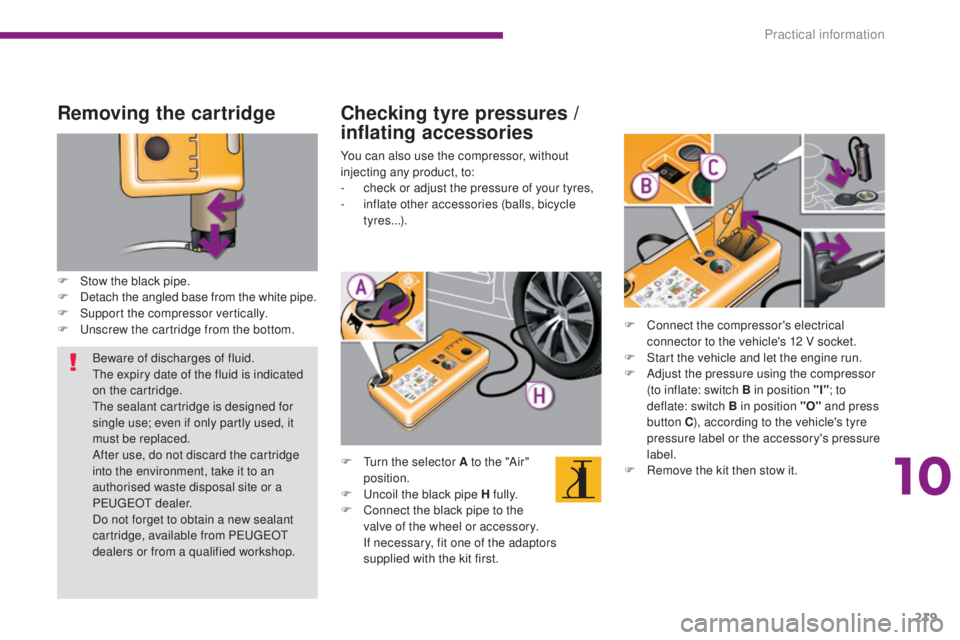

Removing the cartridge

F Stow the black pipe.

F D etach the angled base from the white pipe.

F

S

upport the compressor vertically.

F

U

nscrew the cartridge from the bottom.

Checking tyre pressures /

inflating accessories

You can also use the compressor, without

injecting any product, to:

-

c

heck or adjust the pressure of your tyres,

-

i

nflate other accessories (balls, bicycle

tyres...).

F

T

urn the selector A to the "Air"

position.

F

U

ncoil the black pipe H fully.

F

C

onnect the black pipe to the

valve of the wheel or accessory.

I

f necessary, fit one of the adaptors

supplied with the kit first. F

C

onnect the compressor's electrical

connector to the vehicle's 12 V socket.

F

S

tart the vehicle and let the engine run.

F

A

djust the pressure using the compressor

(to inflate: switch B in position "I" ; to

deflate: switch B in position "O" and press

button C ), according to the vehicle's tyre

pressure label or the accessory's pressure

label.

F

R

emove the kit then stow it.

Beware of discharges of fluid.

The expiry date of the fluid is indicated

on the cartridge.

The sealant cartridge is designed for

single use; even if only partly used, it

must be replaced.

After use, do not discard the cartridge

into the environment, take it to an

authorised waste disposal site or a

PEUGEOT dealer.

Do not forget to obtain a new sealant

cartridge, available from PEUGEOT

dealers or from a qualified workshop.

10

Practical information

Page 222 of 364

220

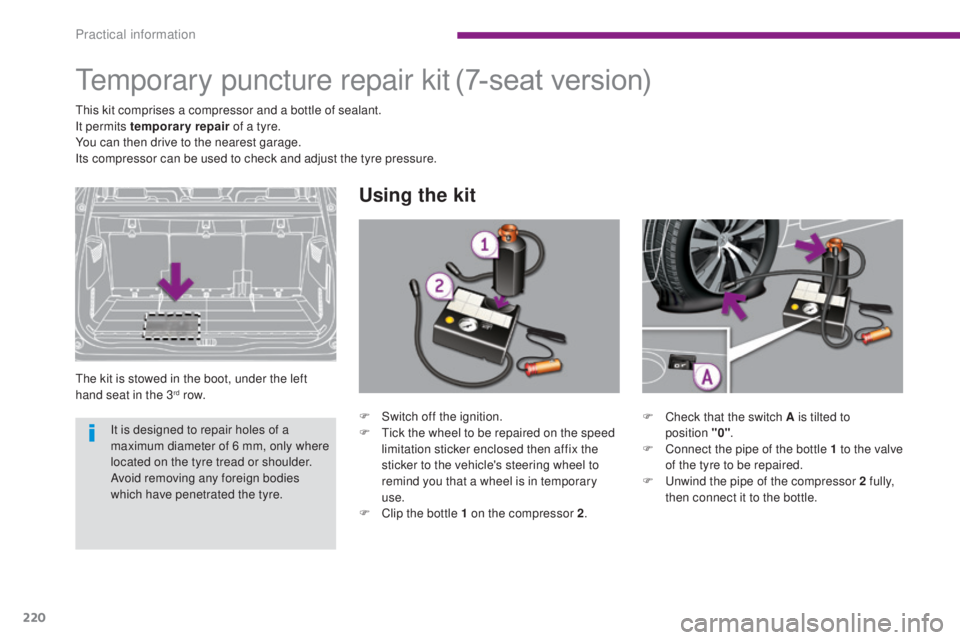

Temporary puncture repair kit

The kit is stowed in the boot, under the left

hand seat in the 3rd row.

Using the kit

(7-seat version)

This kit comprises a compressor and a bottle of sealant.

It permits temporary repair of a tyre.

You can then drive to the nearest garage.

Its compressor can be used to check and adjust the tyre pressure.

F

C

heck that the switch A is tilted to

position

"0".

F

C

onnect the pipe of the bottle 1 to the valve

of the tyre to be repaired.

F

U

nwind the pipe of the compressor 2 fully,

then connect it to the bottle.

F

S

witch off the ignition.

F

T

ick the wheel to be repaired on the speed

limitation sticker enclosed then affix the

sticker to the vehicle's steering wheel to

remind you that a wheel is in temporary

use.

F

C

lip the bottle 1 on the compressor 2.

It is designed to repair holes of a

maximum diameter of 6 mm, only where

located on the tyre tread or shoulder.

Avoid removing any foreign bodies

which have penetrated the tyre.

Practical information

Page 223 of 364

221

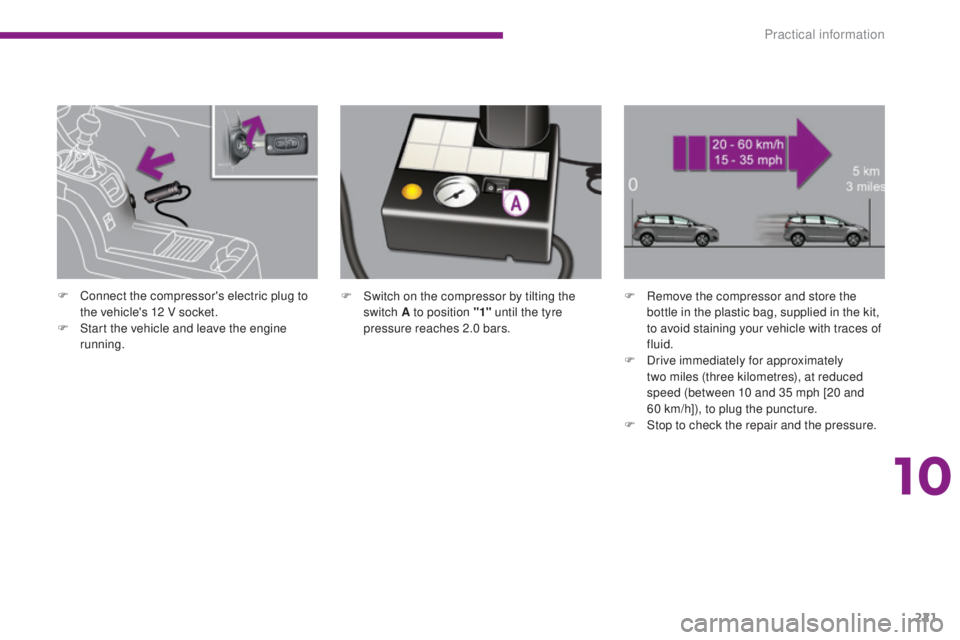

F Switch on the compressor by tilting the switch A to position "1" until the tyre

pressure reaches 2.0 bars. F

R emove the compressor and store the

bottle in the plastic bag, supplied in the kit,

to avoid staining your vehicle with traces of

fluid.

F

D

rive immediately for approximately

two miles (three kilometres), at reduced

speed (between 10 and 35 mph [20 and

60

km/h]), to plug the puncture.

F

S

top to check the repair and the pressure.

F

C

onnect the compressor's electric plug to

the vehicle's 12 V socket.

F

S

tart the vehicle and leave the engine

running.

10

Practical information

Page 224 of 364

222

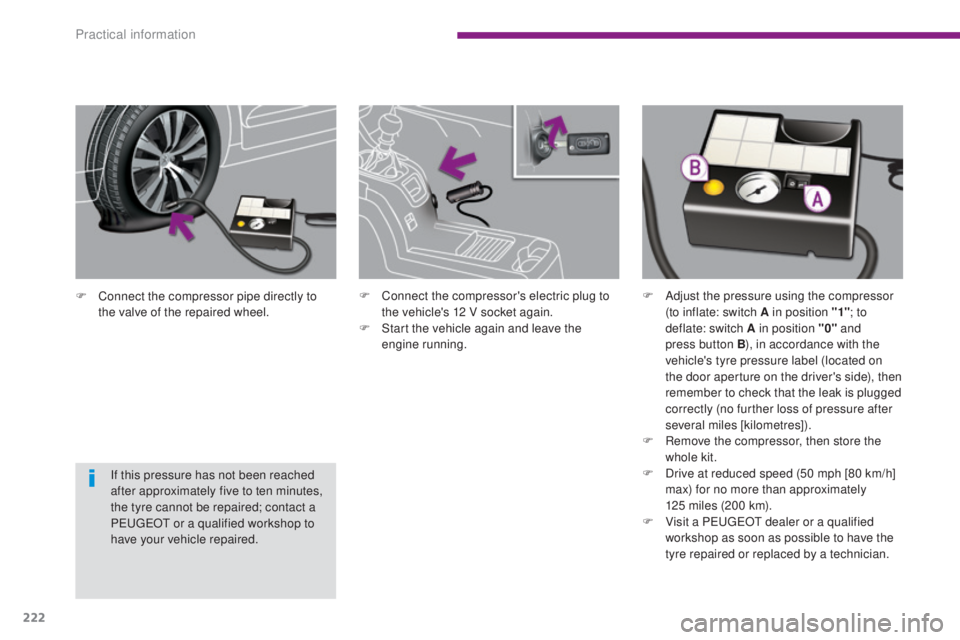

F Connect the compressor pipe directly to the valve of the repaired wheel.

If this pressure has not been reached

after approximately five to ten minutes,

the tyre cannot be repaired; contact a

PEUGEOT or a qualified workshop to

have your vehicle repaired. F

C onnect the compressor's electric plug to

the vehicle's 12 V socket again.

F

S

tart the vehicle again and leave the

engine running. F

A djust the pressure using the compressor

(to inflate: switch A in position "1" ; to

deflate: switch A

in position "0" and

press button B ), in accordance with the

vehicle's tyre pressure label (located on

the door aperture on the driver's side), then

remember to check that the leak is plugged

correctly (no further loss of pressure after

several miles [kilometres]).

F

R

emove the compressor, then store the

whole kit.

F

D

rive at reduced speed (50 mph [80 km/h]

max) for no more than approximately

125

miles (200 km).

F

V

isit a PEUGEOT dealer or a qualified

workshop as soon as possible to have the

tyre repaired or replaced by a technician.

Practical information

Page 225 of 364

223

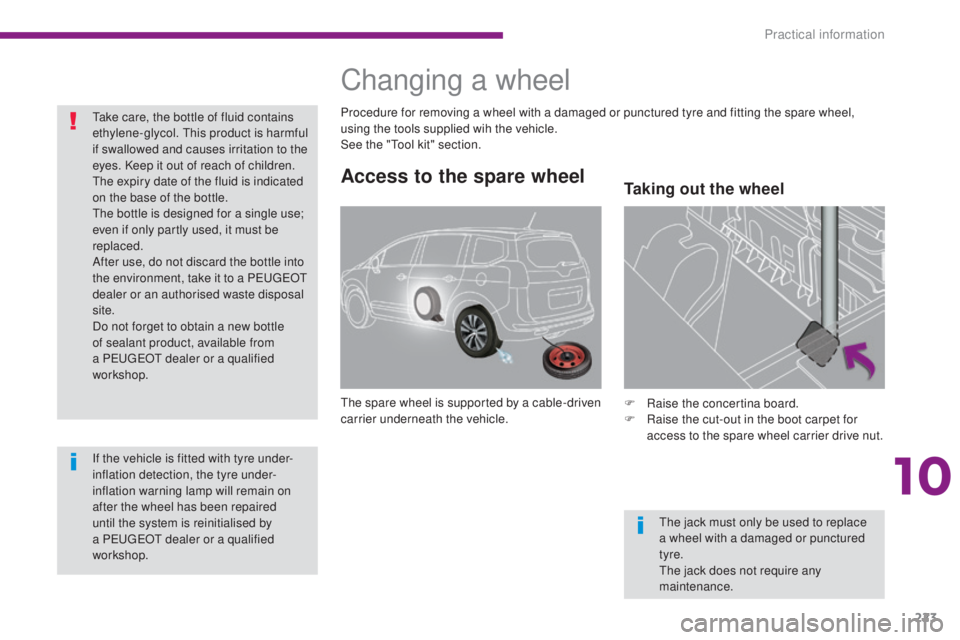

Access to the spare wheel

The spare wheel is supported by a cable-driven

carrier underneath the vehicle.F

Ra ise the concertina board.

F

R

aise the cut-out in the boot carpet for

access to the spare wheel carrier drive nut.

Take care, the bottle of fluid contains

ethylene-glycol. This product is harmful

if swallowed and causes irritation to the

eyes. Keep it out of reach of children.

The expiry date of the fluid is indicated

on the base of the bottle.

The bottle is designed for a single use;

even if only partly used, it must be

replaced.

After use, do not discard the bottle into

the environment, take it to a PEUGEOT

dealer or an authorised waste disposal

site.

Do not forget to obtain a new bottle

of sealant product, available from

a PEUGEOT dealer or a qualified

workshop.

If the vehicle is fitted with tyre under-

inflation detection, the tyre under-

inflation warning lamp will remain on

after the wheel has been repaired

until the system is reinitialised by

a PEUGEOT dealer or a qualified

workshop.

Changing a wheel

Procedure for removing a wheel with a damaged or punctured tyre and fitting the spare wheel,

using the tools supplied wih the vehicle.

See the "Tool kit" section.

The jack must only be used to replace

a wheel with a damaged or punctured

tyre.

The jack does not require any

maintenance.

Taking out the wheel

10

Practical information

Page 226 of 364

224

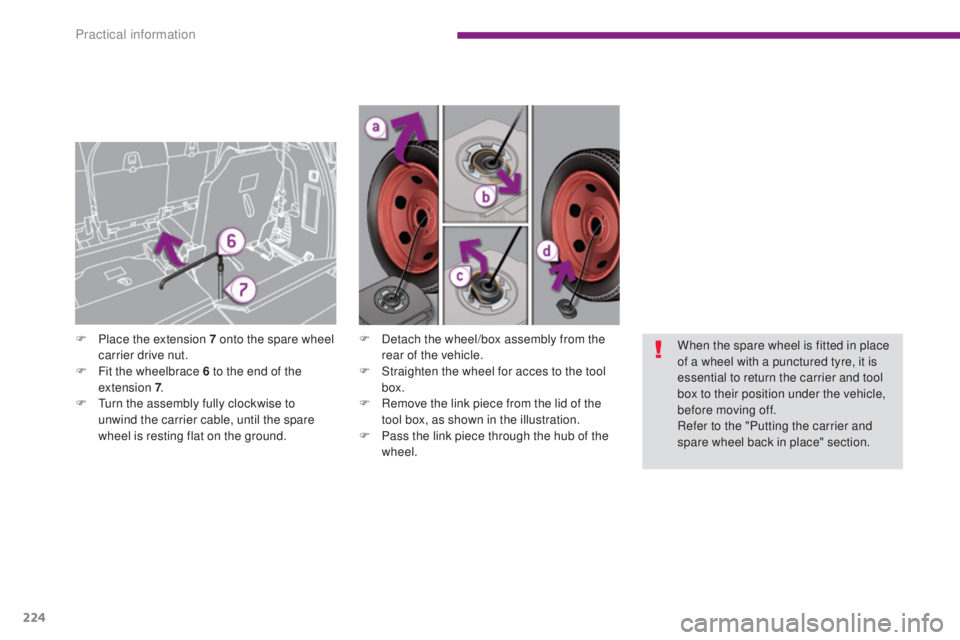

F Detach the wheel/box assembly from the rear of the vehicle.

F

S

traighten the wheel for acces to the tool

box.

F

R

emove the link piece from the lid of the

tool box, as shown in the illustration.

F

P

ass the link piece through the hub of the

wheel.

F

P

lace the extension 7 onto the spare wheel

carrier drive nut.

F

F

it the wheelbrace 6 to the end of the

extension 7 .

F

T

urn the assembly fully clockwise to

unwind the carrier cable, until the spare

wheel is resting flat on the ground. When the spare wheel is fitted in place

of a wheel with a punctured tyre, it is

essential to return the carrier and tool

box to their position under the vehicle,

before moving off.

Refer to the "Putting the carrier and

spare wheel back in place" section.

Practical information

Page 227 of 364

225

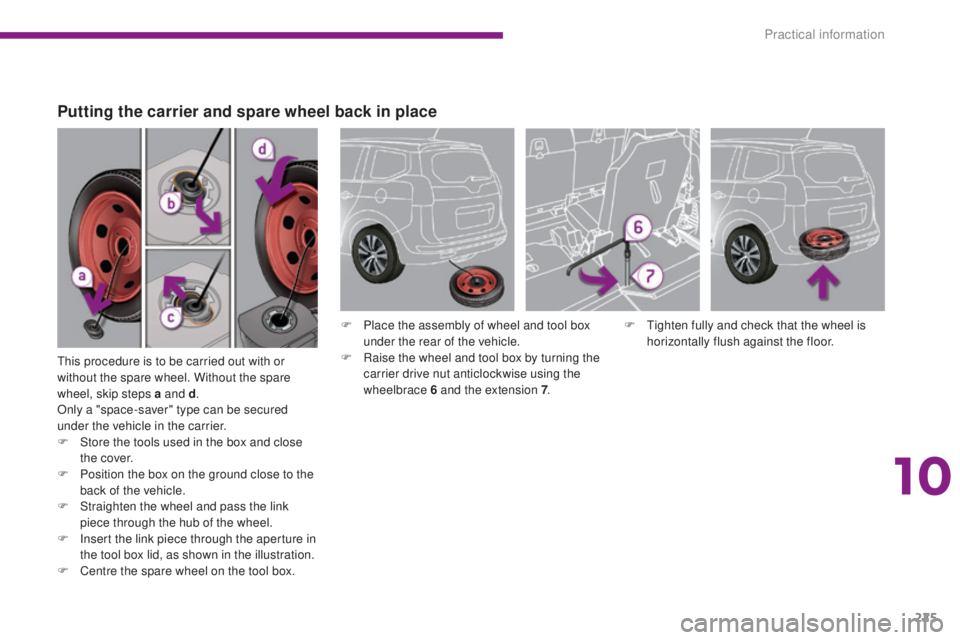

This procedure is to be carried out with or

without the spare wheel. Without the spare

wheel, skip steps a and d.

Only a "space-saver" type can be secured

under the vehicle in the carrier.

F

S

tore the tools used in the box and close

the cover.

F

P

osition the box on the ground close to the

back of the vehicle.

F

S

traighten the wheel and pass the link

piece through the hub of the wheel.

F

I

nsert the link piece through the aperture in

the tool box lid, as shown in the illustration.

F

C

entre the spare wheel on the tool box. F

T

ighten fully and check that the wheel is

horizontally flush against the floor.

F

P

lace the assembly of wheel and tool box

under the rear of the vehicle.

F R aise the wheel and tool box by turning the

carrier drive nut anticlockwise using the

wheelbrace 6 and the extension 7 .

Putting the carrier and spare wheel back in place

10

Practical information

Page 228 of 364

226

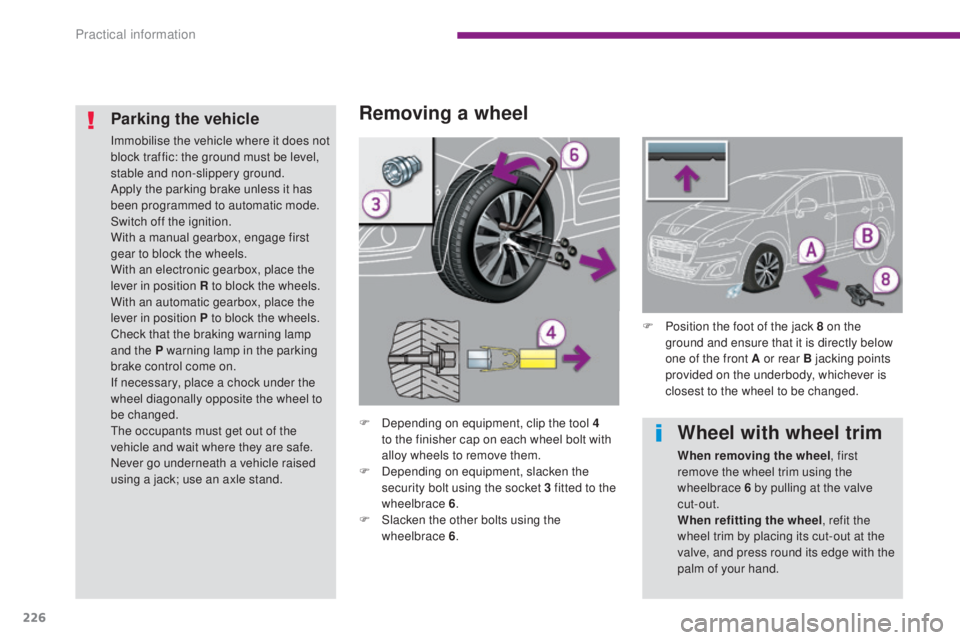

Removing a wheel

F Depending on equipment, clip the tool 4 to the finisher cap on each wheel bolt with

alloy wheels to remove them.

F

D

epending on equipment, slacken the

security bolt using the socket 3 fitted to the

wheelbrace 6 .

F

S

lacken the other bolts using the

wheelbrace 6 .

Parking the vehicle

Immobilise the vehicle where it does not

block traffic: the ground must be level,

stable and non-slippery ground.

Apply the parking brake unless it has

been programmed to automatic mode.

Switch off the ignition.

With a manual gearbox, engage first

gear to block the wheels.

With an electronic gearbox, place the

lever in position R to block the wheels.

With an automatic gearbox, place the

lever in position P to block the wheels.

Check that the braking warning lamp

and the P warning lamp in the parking

brake control come on.

If necessary, place a chock under the

wheel diagonally opposite the wheel to

be changed.

The occupants must get out of the

vehicle and wait where they are safe.

Never go underneath a vehicle raised

using a jack; use an axle stand. F

P

osition the foot of the jack 8 on the

ground and ensure that it is directly below

one of the front A or rear B jacking points

provided on the underbody, whichever is

closest to the wheel to be changed.

Wheel with wheel trim

When removing the wheel , first

remove the wheel trim using the

wheelbrace 6 by pulling at the valve

cut-out.

When refitting the wheel , refit the

wheel trim by placing its cut-out at the

valve, and press round its edge with the

palm of your hand.

Practical information

Page 229 of 364

227

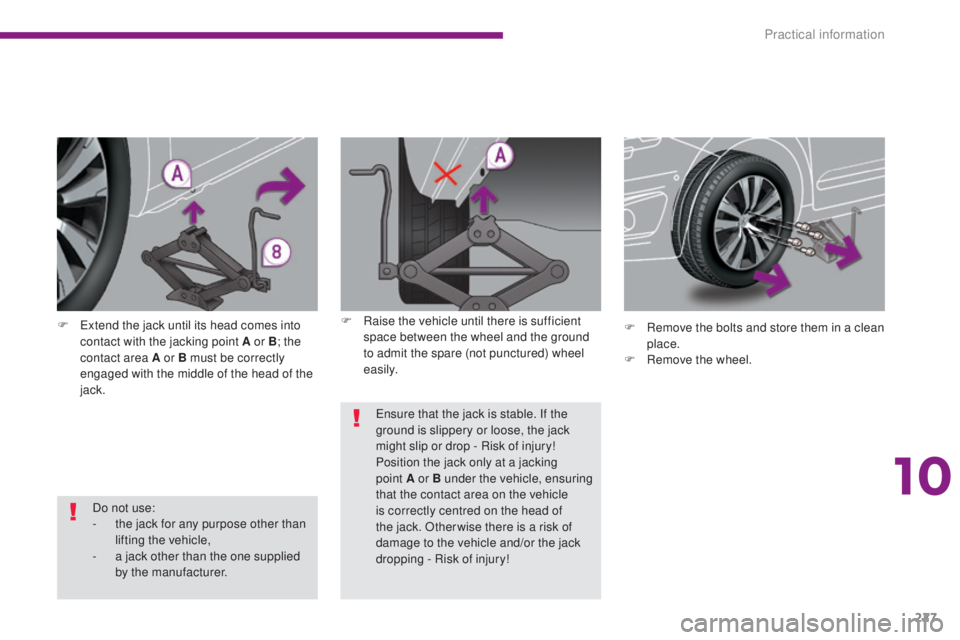

Do not use:

- t he jack for any purpose other than

lifting the vehicle,

-

a j

ack other than the one supplied

by the manufacturer.

F

E

xtend the jack until its head comes into

contact with the jacking point A or B ; the

contact area A or B must be correctly

engaged with the middle of the head of the

jack. F

R

emove the bolts and store them in a clean

place.

F

R

emove the wheel.

Ensure that the jack is stable. If the

ground is slippery or loose, the jack

might slip or drop - Risk of injury!

Position the jack only at a jacking

point A or B under the vehicle, ensuring

that the contact area on the vehicle

is correctly centred on the head of

the jack. Otherwise there is a risk of

damage to the vehicle and/or the jack

dropping - Risk of injury!

F

Ra

ise the vehicle until there is sufficient

space between the wheel and the ground

to admit the spare (not punctured) wheel

easily.

10

Practical information

Page 230 of 364

228

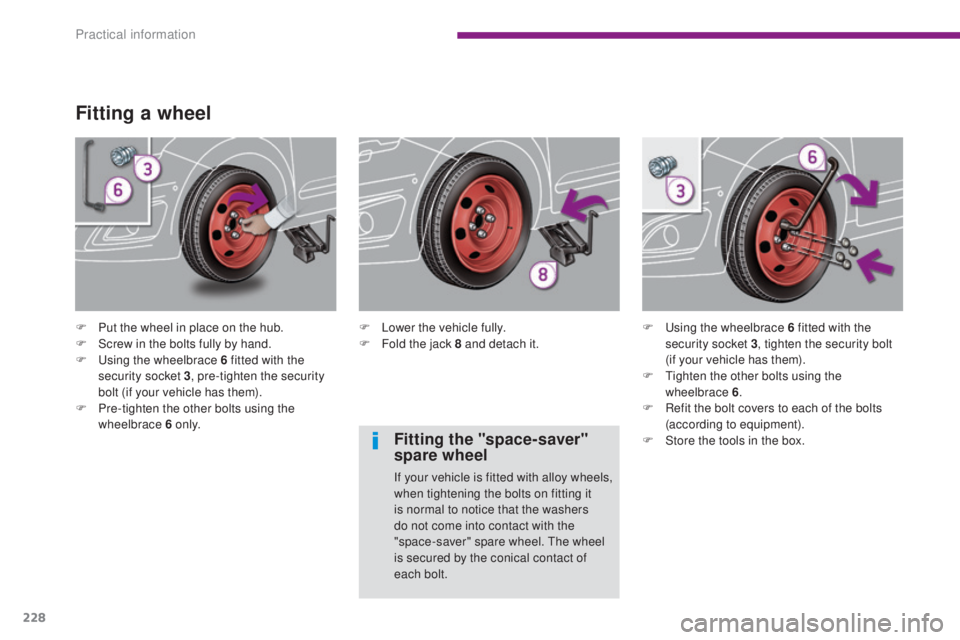

Fitting a wheel

F Put the wheel in place on the hub.

F S crew in the bolts fully by hand.

F

U

sing the wheelbrace 6 fitted with the

security socket 3 , pre-tighten the security

bolt (if your vehicle has them).

F

P

re-tighten the other bolts using the

wheelbrace 6 o n l y. F

L ower the vehicle fully.

F F old the jack 8 and detach it.F

U sing the wheelbrace 6 fitted with the

security socket 3 , tighten the security bolt

(if your vehicle has them).

F

T

ighten the other bolts using the

wheelbrace 6 .

F

R

efit the bolt covers to each of the bolts

(according to equipment).

F

S

tore the tools in the box.

Fitting the "space-saver"

spare wheel

If your vehicle is fitted with alloy wheels,

when tightening the bolts on fitting it

is normal to notice that the washers

do not come into contact with the

"space-saver" spare wheel. The wheel

is secured by the conical contact of

each bolt.

Practical information