wheel PEUGEOT 5008 2016 Owner's Manual

[x] Cancel search | Manufacturer: PEUGEOT, Model Year: 2016, Model line: 5008, Model: PEUGEOT 5008 2016Pages: 364, PDF Size: 12.98 MB

Page 173 of 364

171

5008_en_Chap08_conduite_ed01-2015

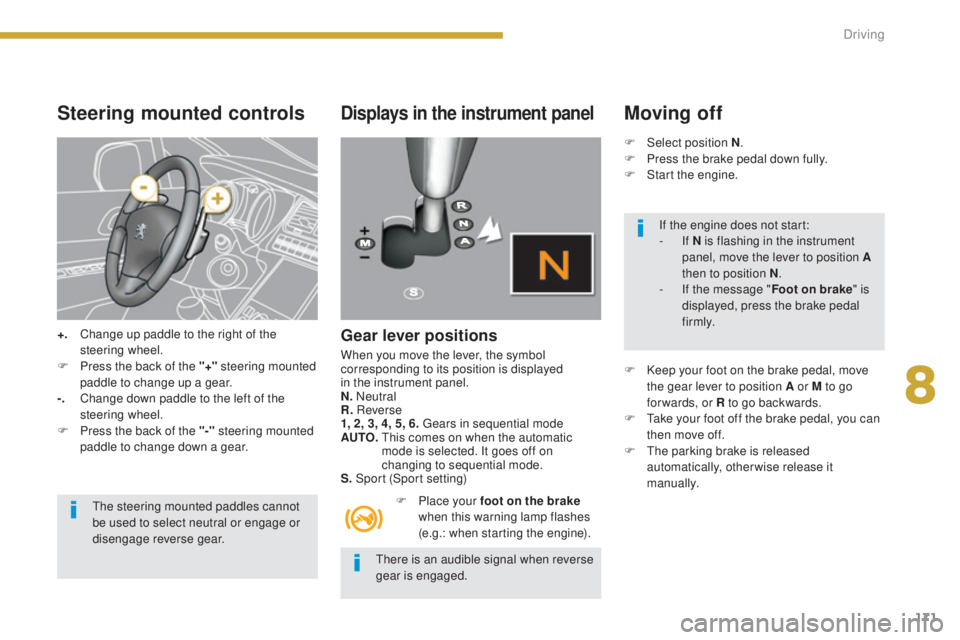

Steering mounted controls

+. Change up paddle to the right of the steering wheel.

F

P

ress the back of the "+" steering mounted

paddle to change up a gear.

-.

C

hange down paddle to the left of the

steering wheel.

F

P

ress the back of the "-" steering mounted

paddle to change down a gear.

The steering mounted paddles cannot

be used to select neutral or engage or

disengage reverse gear.

Displays in the instrument panel

Gear lever positions

When you move the lever, the symbol

corresponding to its position is displayed

in the instrument panel.

N. Neutral

R. Reverse

1, 2, 3, 4, 5, 6. Gears in sequential mode

AUTO.

T

his comes on when the automatic

mode is selected. It goes off on

changing to sequential mode.

S. Sport (Sport setting)

F

P

lace your foot on the brake

when this warning lamp flashes

(e.g.: when starting the engine).

Moving off

F Select position N .

F P ress the brake pedal down fully.

F

S

tart the engine.

F

K

eep your foot on the brake pedal, move

the gear lever to position A or M to go

for wards, or R to go backwards.

F

T

ake your foot off the brake pedal, you can

then move off.

F

T

he parking brake is released

automatically, otherwise release it

manually.

There is an audible signal when reverse

gear is engaged. If the engine does not start:

-

If N is flashing in the instrument

panel, move the lever to position A

then to position N .

-

I

f the message " Foot on brake" is

displayed, press the brake pedal

f i r m l y.

8

Driving

Page 185 of 364

183

5008_en_Chap08_conduite_ed01-2015

Tyre under-inflation detection

System which automatically checks the

pressures of the tyres while driving.

The system continuously monitors the

pressures of the four tyres, as soon as the

vehicle is moving.

A pressure sensor is located in the valve of

each tyre (except the spare wheel).

The system triggers an alert if a drop in

pressure is detected in one or more tyres.This system does not avoid the need

to check the tyre pressures regularly

(including the spare wheel) and before

a long journey.

Driving with under-inflated tyres

adversely affects road holding,

extends braking distances and causes

premature tyre wear, particularly under

arduous conditions (vehicle loaded,

high speed, long journey).

The tyre pressures for your vehicle can

be found on the tyre pressure label (see

the "Identification markings" section).

The tyre pressures must be checked

when the tyres cold (vehicle stopped

for 1 hour or after driving for less then

6 miles (10 km) at moderate speed).

Other wise, add 0.3 bar to the values

indicated on the label.

Driving with under-inflated tyres

increases fuel consumption.

The tyre under-inflation detection

system is an aid to driving which does

not replace the need for vigilance on

the part of the driver.

8

Driving

Page 186 of 364

184

5008_en_Chap08_conduite_ed01-2015

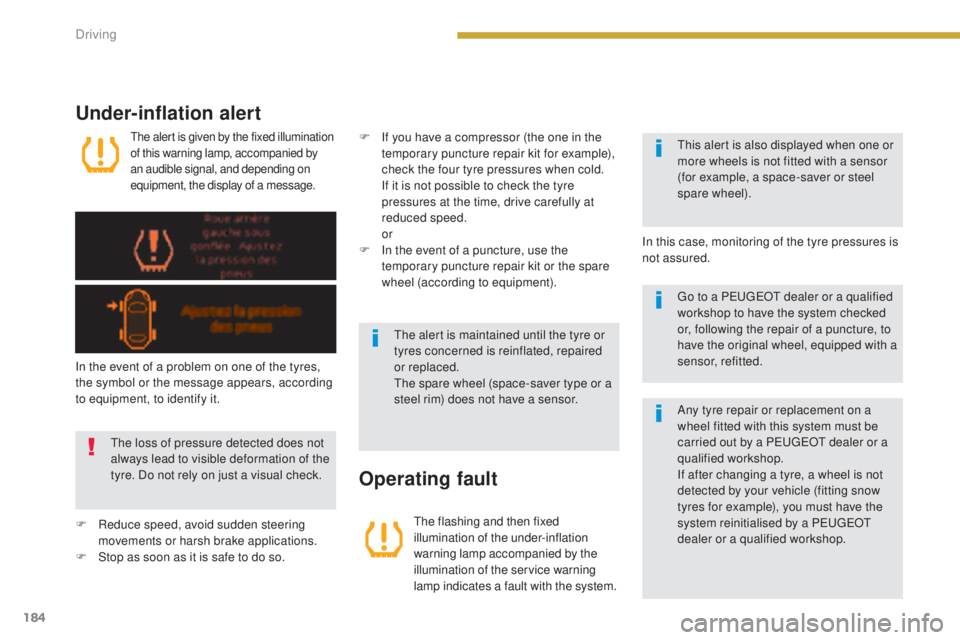

The alert is given by the fixed illumination

of this warning lamp, accompanied by

an audible signal, and depending on

equipment, the display of a message.

Under-inflation alert

The flashing and then fixed

illumination of the under-inflation

warning lamp accompanied by the

illumination of the service warning

lamp indicates a fault with the system.

Operating fault

In the event of a problem on one of the tyres,

the symbol or the message appears, according

to equipment, to identify it.

F

R

educe speed, avoid sudden steering

movements or harsh brake applications.

F

S

top as soon as it is safe to do so.The loss of pressure detected does not

always lead to visible deformation of the

tyre. Do not rely on just a visual check. The alert is maintained until the tyre or

tyres concerned is reinflated, repaired

or replaced.

The spare wheel (space-saver type or a

steel rim) does not have a sensor.This alert is also displayed when one or

more wheels is not fitted with a sensor

(for example, a space-saver or steel

spare wheel).

In this case, monitoring of the tyre pressures is

not assured. Go to a PEUGEOT dealer or a qualified

workshop to have the system checked

or, following the repair of a puncture, to

have the original wheel, equipped with a

sensor, refitted.

F

I

f you have a compressor (the one in the

temporary puncture repair kit for example),

check the four tyre pressures when cold.

I

f it is not possible to check the tyre

pressures at the time, drive carefully at

reduced speed.

or

F

I

n the event of a puncture, use the

temporary puncture repair kit or the spare

wheel (according to equipment).

Any tyre repair or replacement on a

wheel fitted with this system must be

carried out by a PEUGEOT dealer or a

qualified workshop.

If after changing a tyre, a wheel is not

detected by your vehicle (fitting snow

tyres for example), you must have the

system reinitialised by a PEUGEOT

dealer or a qualified workshop.

Driving

Page 214 of 364

212

5008_en_Chap10_infos-pratiques_ed01-2015

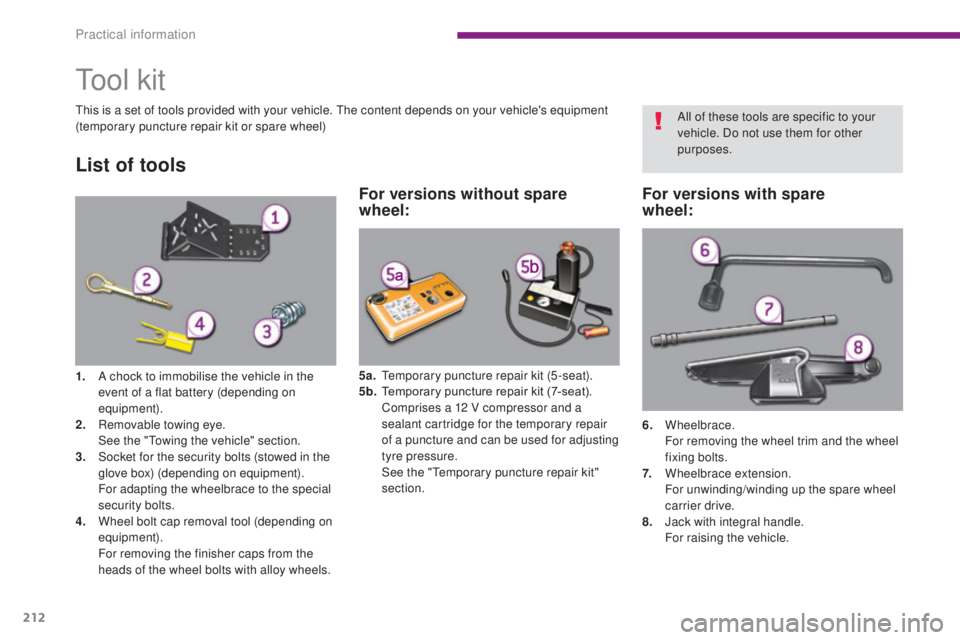

Tool kit

This is a set of tools provided with your vehicle. The content depends on your vehicle's equipment

(temporary puncture repair kit or spare wheel)

List of tools

5a. Temporary puncture repair kit (5-seat).

5b. T emporary puncture repair kit (7-seat).

C

omprises a 12 V compressor and a

sealant cartridge for the temporary repair

of a puncture and can be used for adjusting

tyre pressure.

S

ee the "Temporary puncture repair kit"

section. 6.

Wheelbrace.

F

or removing the wheel trim and the wheel

fixing bolts.

7.

W

heelbrace extension.

F

or unwinding/winding up the spare wheel

carrier drive.

8.

J

ack with integral handle.

F

or raising the vehicle.

1. A c

hock to immobilise the vehicle in the

event of a flat battery (depending on

equipment).

2.

R

emovable towing eye.

S

ee the "Towing the vehicle" section.

3.

S

ocket for the security bolts (stowed in the

glove box) (depending on equipment).

F

or adapting the wheelbrace to the special

security bolts.

4.

W

heel bolt cap removal tool (depending on

equipment).

F

or removing the finisher caps from the

heads of the wheel bolts with alloy wheels. All of these tools are specific to your

vehicle. Do not use them for other

purposes.

For versions without spare

wheel:

For versions with spare

wheel:

Practical information

Page 215 of 364

213

5008_en_Chap10_infos-pratiques_ed01-2015

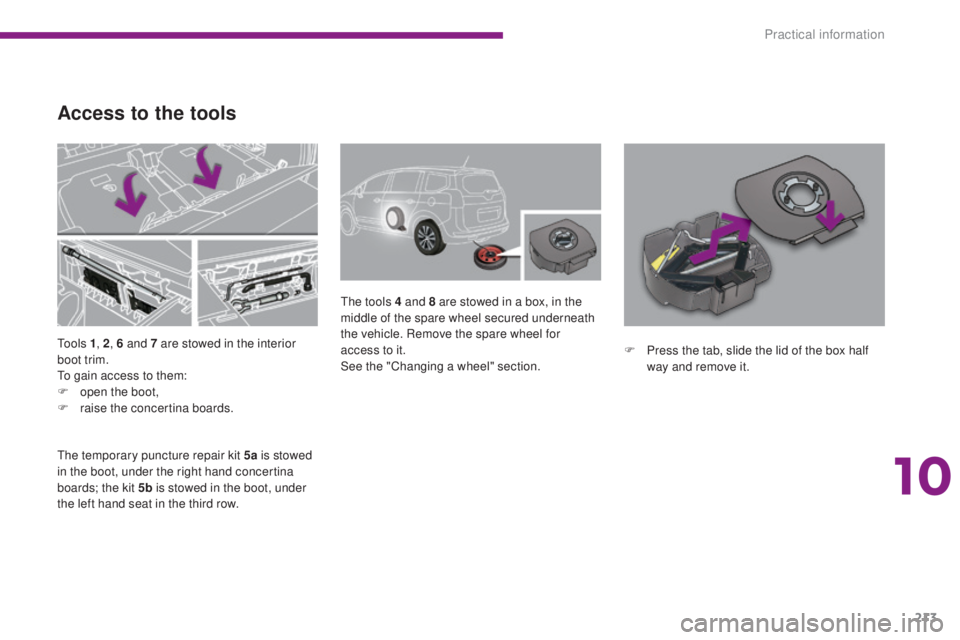

To o l s 1, 2, 6 and 7 are stowed in the interior

boot trim.

To gain access to them:

F

o

pen the boot,

F

r

aise the concertina boards. The tools 4 and 8 are stowed in a box, in the

middle of the spare wheel secured underneath

the vehicle. Remove the spare wheel for

access to it.

See the "Changing a wheel" section.

Access to the tools

The temporary puncture repair kit 5a

is stowed

in the boot, under the right hand concertina

boards; the kit 5b is stowed in the boot, under

the left hand seat in the third row. F

P

ress the tab, slide the lid of the box half

way and remove it.

10

Practical information

Page 217 of 364

215

5008_en_Chap10_infos-pratiques_ed01-2015

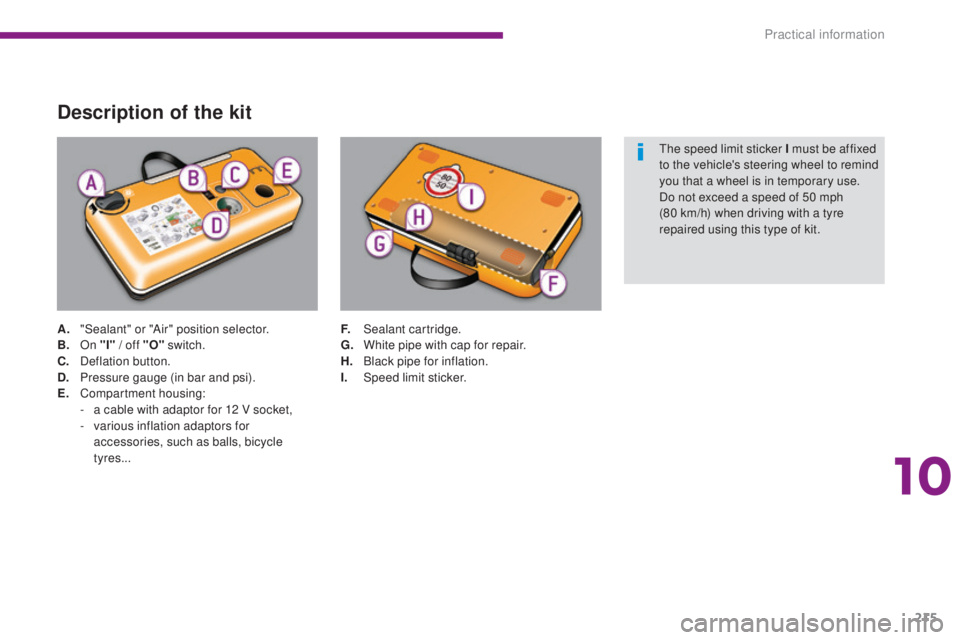

Description of the kit

A. "Sealant" or "Air" position selector.

B. On "I" / off "O" switch.

C.

D

eflation button.

D.

P

ressure gauge (in bar and psi).

E.

C

ompartment housing:

-

a c

able with adaptor for 12 V socket,

-

v

arious inflation adaptors for

accessories, such as balls, bicycle

tyres... F. S

ealant cartridge.

G. W hite pipe with cap for repair.

H.

B

lack pipe for inflation.

I.

Spe

ed limit sticker.The speed limit sticker I must be affixed

to the vehicle's steering wheel to remind

you that a wheel is in temporary use.

Do not exceed a speed of 50 mph

(80

km/h) when driving with a tyre

repaired using this type of kit.

10

Practical information

Page 219 of 364

217

5008_en_Chap10_infos-pratiques_ed01-2015

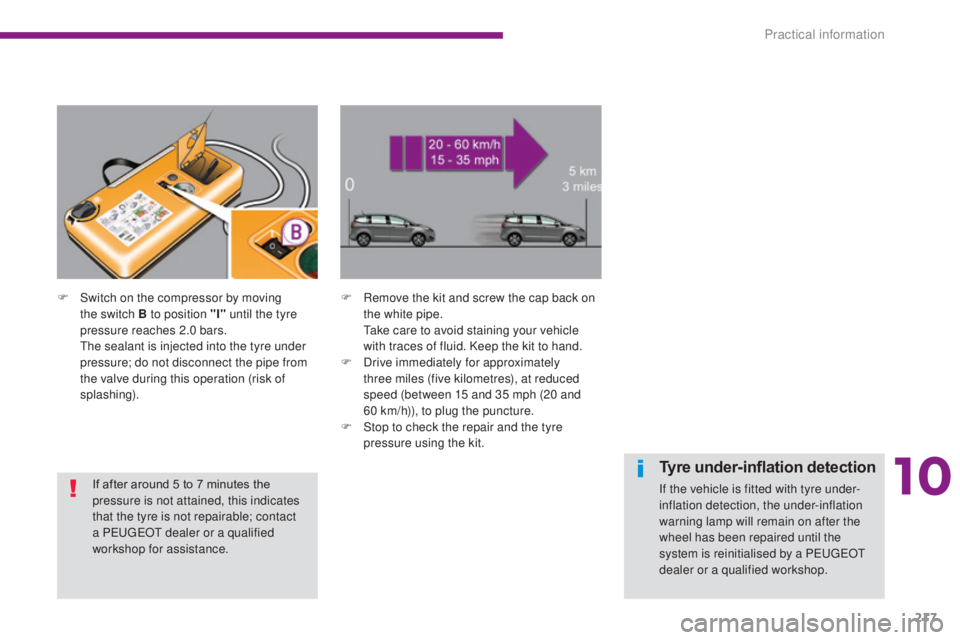

F Switch on the compressor by moving the switch B to position "I" until the tyre

pressure reaches 2.0 bars.

T

he sealant is injected into the tyre under

pressure; do not disconnect the pipe from

the valve during this operation (risk of

splashing). F

R emove the kit and screw the cap back on

the white pipe.

T

ake care to avoid staining your vehicle

with traces of fluid. Keep the kit to hand.

F

D

rive immediately for approximately

three miles (five kilometres), at reduced

speed (between 15 and 35 mph (20 and

60

km/h)), to plug the puncture.

F

S

top to check the repair and the tyre

pressure using the kit.

Tyre under-inflation detection

If the vehicle is fitted with tyre under-

inflation detection, the under-inflation

warning lamp will remain on after the

wheel has been repaired until the

system is reinitialised by a PEUGEOT

dealer or a qualified workshop.

If after around 5 to 7 minutes the

pressure is not attained, this indicates

that the tyre is not repairable; contact

a PEUGEOT dealer or a qualified

workshop for assistance.

10

Practical information

Page 220 of 364

218

5008_en_Chap10_infos-pratiques_ed01-2015

F Connect the compressor's electric plug to the vehicle's 12 V socket.

F

S

tart the vehicle again and leave the

engine running.

F

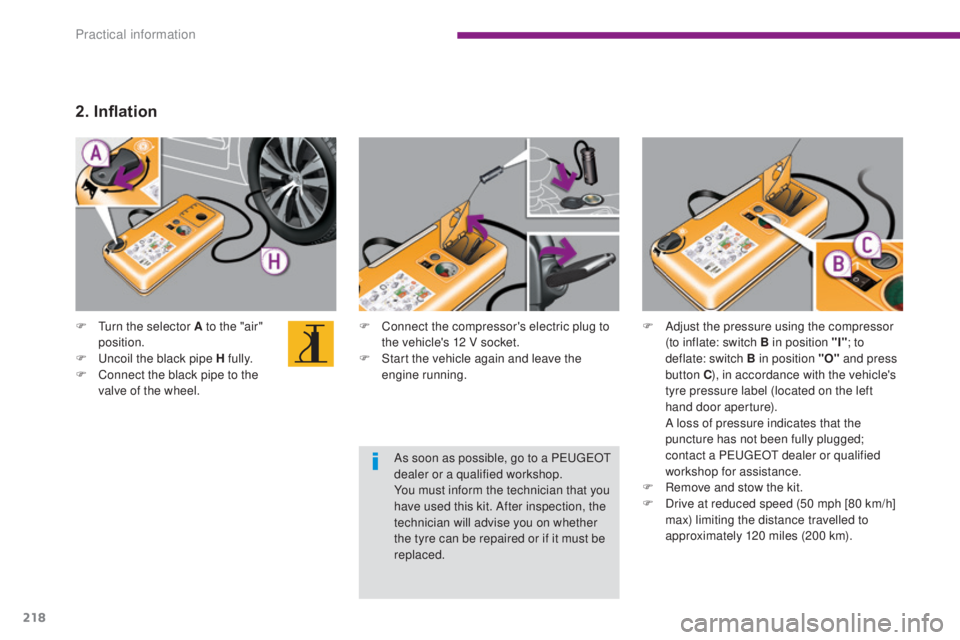

T

urn the selector A to the "air"

position.

F

U

ncoil the black pipe H fully.

F

C

onnect the black pipe to the

valve of the wheel.

2. Inflation

F Adjust the pressure using the compressor (to inflate: switch B in position "I" ; to

deflate: switch B

in position "O" and press

button C ), in accordance with the vehicle's

tyre pressure label (located on the left

hand door aperture).

A l

oss of pressure indicates that the

puncture has not been fully plugged;

contact a PEUGEOT dealer or qualified

workshop for assistance.

F

R

emove and stow the kit.

F

D

rive at reduced speed (50 mph [80 km/h]

max) limiting the distance travelled to

approximately 120 miles (200 km).

As soon as possible, go to a PEUGEOT

dealer or a qualified workshop.

You must inform the technician that you

have used this kit. After inspection, the

technician will advise you on whether

the tyre can be repaired or if it must be

replaced.

Practical information

Page 221 of 364

219

5008_en_Chap10_infos-pratiques_ed01-2015

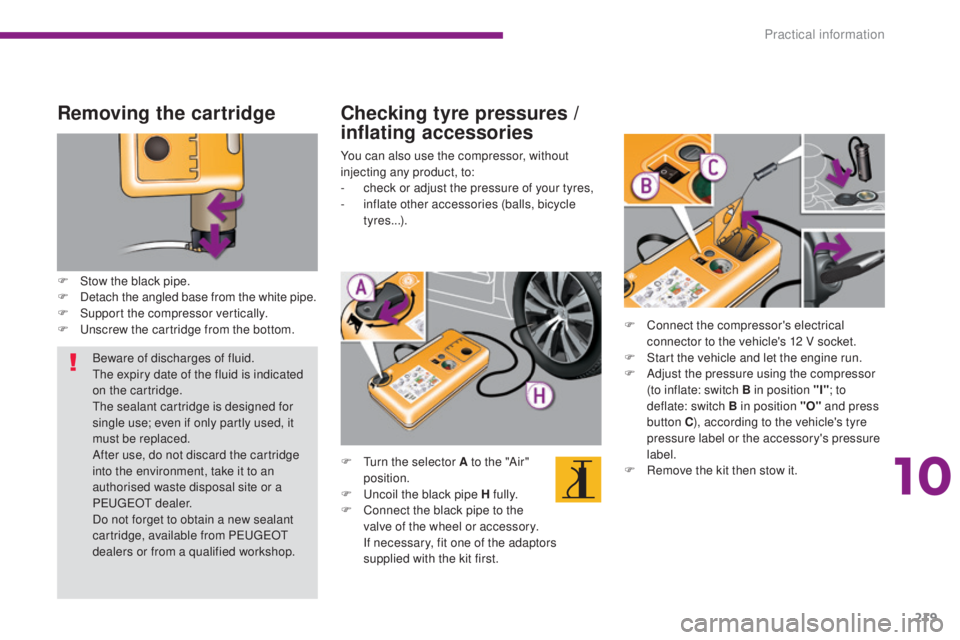

Removing the cartridge

F Stow the black pipe.

F D etach the angled base from the white pipe.

F

S

upport the compressor vertically.

F

U

nscrew the cartridge from the bottom.

Checking tyre pressures /

inflating accessories

You can also use the compressor, without

injecting any product, to:

-

c

heck or adjust the pressure of your tyres,

-

i

nflate other accessories (balls, bicycle

tyres...).

F

T

urn the selector A to the "Air"

position.

F

U

ncoil the black pipe H fully.

F

C

onnect the black pipe to the

valve of the wheel or accessory.

I

f necessary, fit one of the adaptors

supplied with the kit first. F

C

onnect the compressor's electrical

connector to the vehicle's 12 V socket.

F

S

tart the vehicle and let the engine run.

F

A

djust the pressure using the compressor

(to inflate: switch B in position "I" ; to

deflate: switch B in position "O" and press

button C ), according to the vehicle's tyre

pressure label or the accessory's pressure

label.

F

R

emove the kit then stow it.

Beware of discharges of fluid.

The expiry date of the fluid is indicated

on the cartridge.

The sealant cartridge is designed for

single use; even if only partly used, it

must be replaced.

After use, do not discard the cartridge

into the environment, take it to an

authorised waste disposal site or a

PEUGEOT dealer.

Do not forget to obtain a new sealant

cartridge, available from PEUGEOT

dealers or from a qualified workshop.

10

Practical information

Page 222 of 364

220

5008_en_Chap10_infos-pratiques_ed01-2015

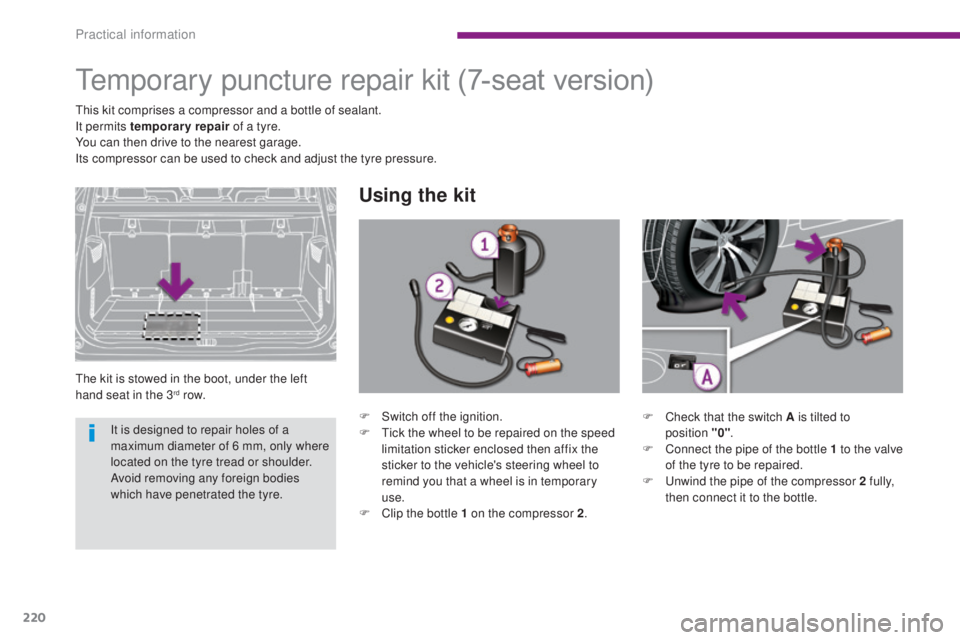

Temporary puncture repair kit

The kit is stowed in the boot, under the left

hand seat in the 3rd row.

Using the kit

(7-seat version)

This kit comprises a compressor and a bottle of sealant.

It permits temporary repair of a tyre.

You can then drive to the nearest garage.

Its compressor can be used to check and adjust the tyre pressure.

F

C

heck that the switch A is tilted to

position

"0".

F

C

onnect the pipe of the bottle 1 to the valve

of the tyre to be repaired.

F

U

nwind the pipe of the compressor 2 fully,

then connect it to the bottle.

F

S

witch off the ignition.

F

T

ick the wheel to be repaired on the speed

limitation sticker enclosed then affix the

sticker to the vehicle's steering wheel to

remind you that a wheel is in temporary

use.

F

C

lip the bottle 1 on the compressor 2.

It is designed to repair holes of a

maximum diameter of 6 mm, only where

located on the tyre tread or shoulder.

Avoid removing any foreign bodies

which have penetrated the tyre.

Practical information