bonnet PEUGEOT 5008 2020 User Guide

[x] Cancel search | Manufacturer: PEUGEOT, Model Year: 2020, Model line: 5008, Model: PEUGEOT 5008 2020Pages: 308, PDF Size: 10.1 MB

Page 182 of 308

180

Practical information

8.Engine oil filler cap

9. Engine oil dipstick

10. Priming pump*

11 . Degassing screw*

The Diesel fuel system operates under

very high pressure.

All work on this circuit must be carried out

only by a PEUGEOT dealer or a qualified

workshop.

Checking levels

Check all of the following levels regularly in

accordance with the manufacturer's service

schedule. Top them up if required, unless

otherwise indicated.

If a level drops significantly, have the

corresponding system checked by a PEUGEOT

dealer or a qualified workshop.

The fluids must comply with the manufacturer's requirements and with

the vehicle's engine.

Take care when working under the bonnet, as certain areas of the engine

may be extremely hot (risk of burns) and the

cooling fan could start at any time (even with

the ignition off).

* Depending on engine.

Take care with objects or clothing that

could be caught in the blades of the fan!

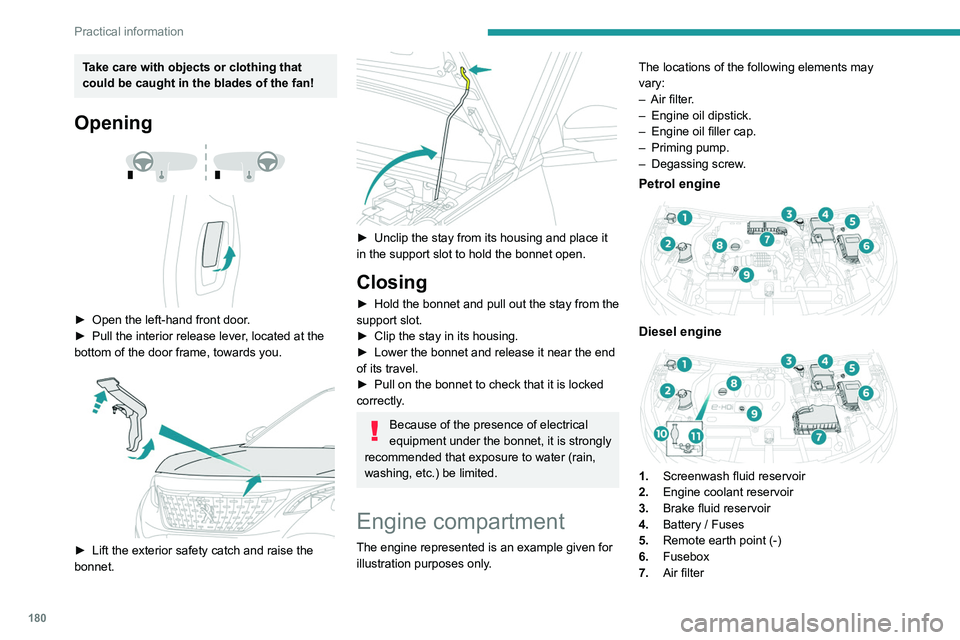

Opening

► Open the left-hand front door .

► Pull the interior release lever , located at the

bottom of the door frame, towards you.

► Lift the exterior safety catch and raise the

bonnet.

► Unclip the stay from its housing and place it

in the support slot to hold the bonnet open.

Closing

► Hold the bonnet and pull out the stay from the

support slot.

►

Clip the stay in its housing.

►

Lower the bonnet and release it near the end

of its travel.

►

Pull on the bonnet to check that it is locked

correctly

.

Because of the presence of electrical

equipment under the bonnet, it is strongly

recommended that exposure to water (rain,

washing, etc.) be limited.

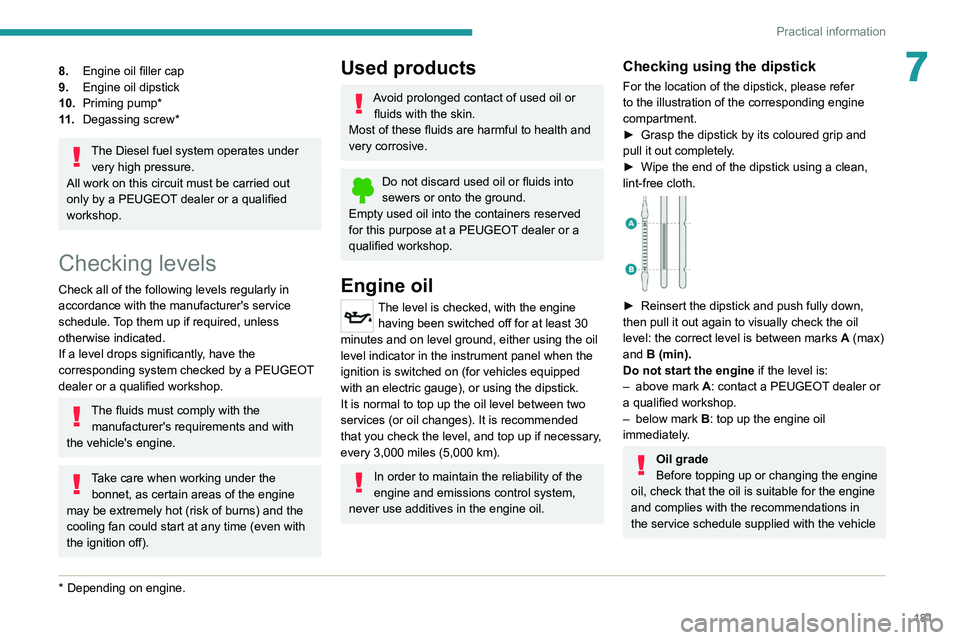

Engine compartment

The engine represented is an example given for

illustration purposes only. The locations of the following elements may

vary:

–

Air filter

.

–

Engine oil dipstick.

–

Engine oil filler cap.

–

Priming pump.

–

Degassing screw

.

Petrol engine

Diesel engine

1.

Screenwash fluid reservoir

2. Engine coolant reservoir

3. Brake fluid reservoir

4. Battery / Fuses

5. Remote earth point (-)

6. Fusebox

7. Air filter

Page 183 of 308

181

Practical information

78.Engine oil filler cap

9. Engine oil dipstick

10. Priming pump*

11 . Degassing screw*

The Diesel fuel system operates under

very high pressure.

All work on this circuit must be carried out

only by a PEUGEOT dealer or a qualified

workshop.

Checking levels

Check all of the following levels regularly in

accordance with the manufacturer's service

schedule. Top them up if required, unless

otherwise indicated.

If a level drops significantly, have the

corresponding system checked by a PEUGEOT

dealer or a qualified workshop.

The fluids must comply with the manufacturer's requirements and with

the vehicle's engine.

Take care when working under the bonnet, as certain areas of the engine

may be extremely hot (risk of burns) and the

cooling fan could start at any time (even with

the ignition off).

* Depending on engine.

Used products

Avoid prolonged contact of used oil or fluids with the skin.

Most of these fluids are harmful to health and

very corrosive.

Do not discard used oil or fluids into

sewers or onto the ground.

Empty used oil into the containers reserved

for this purpose at a PEUGEOT dealer or a

qualified workshop.

Engine oil

The level is checked, with the engine having been switched off for at least 30

minutes and on level ground, either using the oil

level indicator in the instrument panel when the

ignition is switched on (for vehicles equipped

with an electric gauge), or using the dipstick.

It is normal to top up the oil level between two

services (or oil changes). It is recommended

that you check the level, and top up if necessary,

every 3,000 miles (5,000 km).

In order to maintain the reliability of the

engine and emissions control system,

never use additives in the engine oil.

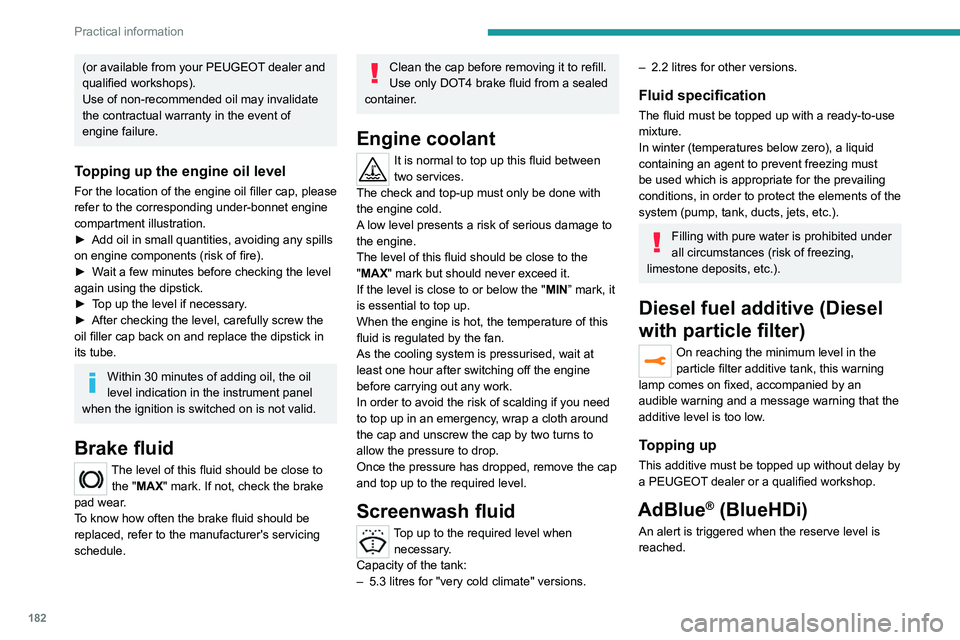

Checking using the dipstick

For the location of the dipstick, please refer

to the illustration of the corresponding engine

compartment.

►

Grasp the dipstick by its coloured grip and

pull it out completely

.

►

Wipe the end of the dipstick using a clean,

lint-free cloth.

► Reinsert the dipstick and push fully down,

then pull it out again to visually check the oil

level: the correct level is between marks A

(max)

and B (min).

Do not start the engine if the level is:

–

above mark

A: contact a PEUGEOT dealer or

a qualified workshop.

–

below mark B

: top up the engine oil

immediately.

Oil grade

Before topping up or changing the engine

oil, check that the oil is suitable for the engine

and complies with the recommendations in

the service schedule supplied with the vehicle

Page 184 of 308

182

Practical information

For more information on the Indicators and in

particular the AdBlue range indicators, refer to

the corresponding section.

To avoid the vehicle being immobilised in

accordance with regulations, you must top up the

AdBlue tank.

For more information on AdBlue

® (BlueHDi),

and in particular the supply of AdBlue, refer to

the corresponding section.

Checks

Unless otherwise indicated, check these

components in accordance with the

manufacturer's service schedule and according

to your engine.

Otherwise, have them checked by a PEUGEOT

dealer or a qualified workshop.

Only use products recommended by

PEUGEOT or products of equivalent

quality and specification.

In order to optimise the operation of

components as important as those in the

braking system, PEUGEOT selects and offers

very specific products.

12 V battery

The battery does not require any maintenance.

However, check regularly that the terminals

are correctly tightened (versions without quick

(or available from your PEUGEOT dealer and

qualified workshops).

Use of non-recommended oil may invalidate

the contractual warranty in the event of

engine failure.

Topping up the engine oil level

For the location of the engine oil filler cap, please

refer to the corresponding under-bonnet engine

compartment illustration.

►

Add oil in small quantities, avoiding any spills

on engine components (risk of fire).

►

W

ait a few minutes before checking the level

again using the dipstick.

►

T

op up the level if necessary.

►

After checking the level, carefully screw the

oil filler cap back on

and replace the dipstick in

its tube.

Within 30 minutes of adding oil, the oil

level indication in the instrument panel

when the ignition is switched on is not valid.

Brake fluid

The level of this fluid should be close to the "MAX" mark. If not, check the brake

pad wear.

To know how often the brake fluid should be

replaced, refer to the manufacturer's servicing

schedule.

Clean the cap before removing it to refill.

Use only DOT4 brake fluid from a sealed

container.

Engine coolant

It is normal to top up this fluid between

two services.

The check and top-up must only be done with

the engine cold.

A low level presents a risk of serious damage to

the engine.

The level of this fluid should be close to the

"MAX" mark but should never exceed it.

If the level is close to or below the " MIN” mark, it

is essential to top up.

When the engine is hot, the temperature of this

fluid is regulated by the fan.

As the cooling system is pressurised, wait at

least one hour after switching off the engine

before carrying out any work.

In order to avoid the risk of scalding if you need

to top up in an emergency, wrap a cloth around

the cap and unscrew the cap by two turns to

allow the pressure to drop.

Once the pressure has dropped, remove the cap

and top up to the required level.

Screenwash fluid

Top up to the required level when necessary.

Capacity of the tank:

–

5.3 litres for "very cold climate" versions.

– 2.2 litres for other versions.

Fluid specification

The fluid must be topped up with a ready-to-use

mixture.

In winter (temperatures below zero), a liquid

containing an agent to prevent freezing must

be used which is appropriate for the prevailing

conditions, in order to protect the elements of the

system (pump, tank, ducts, jets, etc.).

Filling with pure water is prohibited under

all circumstances (risk of freezing,

limestone deposits, etc.).

Diesel fuel additive (Diesel

with particle filter)

On reaching the minimum level in the

particle filter additive tank, this warning

lamp comes on fixed, accompanied by an

audible warning and a message warning that the

additive level is too low.

Topping up

This additive must be topped up without delay by

a PEUGEOT dealer or a qualified workshop.

AdBlue® (BlueHDi)

An alert is triggered when the reserve level is

reached.

Page 192 of 308

190

In the event of a breakdown

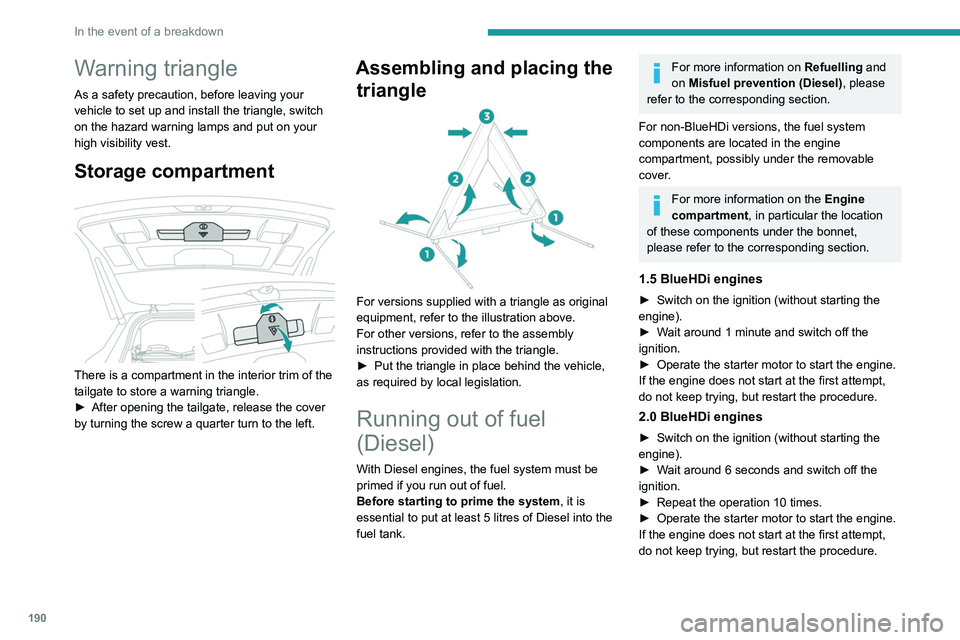

Warning triangle

As a safety precaution, before leaving your

vehicle to set up and install the triangle, switch

on the hazard warning lamps and put on your

high visibility vest.

Storage compartment

There is a compartment in the interior trim of the

tailgate to store a warning triangle.

►

After opening the tailgate, release the cover

by turning the screw a quarter turn to the left.

Assembling and placing the triangle

For versions supplied with a triangle as original

equipment, refer to the illustration above.

For other versions, refer to the assembly

instructions provided with the triangle.

►

Put the triangle in place behind the vehicle,

as required by local legislation.

Running out of fuel

(Diesel)

With Diesel engines, the fuel system must be

primed if you run out of fuel.

Before starting to prime the system, it is

essential to put at least 5 litres of Diesel into the

fuel tank.

For more information on Refuelling and

on Misfuel prevention (Diesel), please

refer to the corresponding section.

For non-BlueHDi versions, the fuel system

components are located in the engine

compartment, possibly under the removable

cover.

For more information on the Engine

compartment, in particular the location

of these components under the bonnet,

please refer to the corresponding section.

1.5 BlueHDi engines

► Switch on the ignition (without starting the

engine).

►

W

ait around 1 minute and switch off the

ignition.

►

Operate the starter motor to start the engine.

If the engine does not start at the first attempt,

do not keep trying, but restart the procedure.

2.0 BlueHDi engines

► Switch on the ignition (without starting the

engine).

►

W

ait around 6 seconds and switch off the

ignition.

►

Repeat the operation 10

times.

►

Operate the starter motor to start the engine.

If the engine does not start at the first attempt,

do not keep trying, but restart the procedure.

2.0 HDi engines

► Open the bonnet and then, if necessary,

unclip the cover to access the priming pump.

► Loosen the degassing bolt.

► Operate the priming pump until fuel

appears in the transparent tube.

► Retighten the degassing bolt.

► Operate the starter motor until the engine

starts (if the engine does not start at the first

attempt, wait around 15 seconds before trying

again).

► If the engine does not start after a few

attempts, operate the priming pump again, then

the starter motor.

► Put the cover back in place and clip it in, then

close the bonnet.

Tool kit

Set of tools supplied with the vehicle.

Its content depends on your vehicle's equipment:

– Temporary puncture repair kit.

– Spare wheel.

Accessing the tools

Page 193 of 308

191

In the event of a breakdown

82.0 HDi engines

► Open the bonnet and then, if necessary,

unclip the cover to access the priming pump.

►

Loosen the degassing bolt.

► Operate the priming pump until fuel

appears in the transparent tube.

►

Retighten the degassing bolt.

►

Operate the starter motor until the engine

starts (if the engine does not start at the first

attempt, wait around 15

seconds before trying

again).

►

If the engine does not start after a few

attempts, operate the priming pump again, then

the starter motor

.

►

Put the cover back in place and clip it in, then

close the bonnet.

Tool kit

Set of tools supplied with the vehicle.

Its content depends on your vehicle's equipment:

–

T

emporary puncture repair kit.

–

Spare wheel.

Accessing the tools

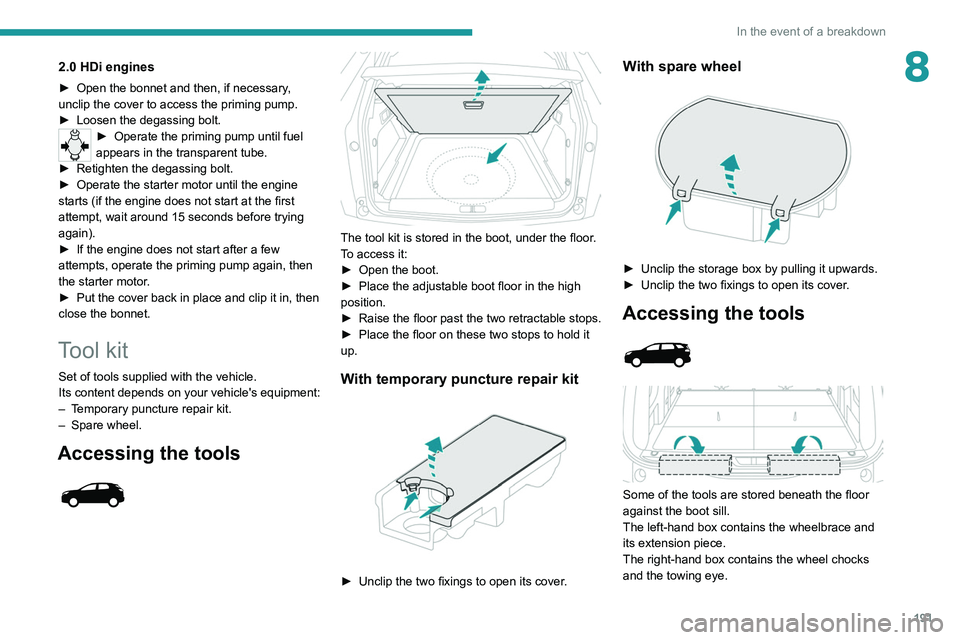

The tool kit is stored in the boot, under the floor.

To access it:

►

Open the boot.

►

Place the adjustable boot floor in the high

position.

►

Raise the floor past the two retractable stops.

►

Place the floor on these two stops to hold it

up.

With temporary puncture repair kit

► Unclip the two fixings to open its cover .

With spare wheel

► Unclip the storage box by pulling it upwards.

► Unclip the two fixings to open its cover .

Accessing the tools

Some of the tools are stored beneath the floor

against the boot sill.

The left-hand box contains the wheelbrace and

its extension piece.

The right-hand box contains the wheel chocks

and the towing eye.

Page 204 of 308

202

In the event of a breakdown

Always replace a failed bulb with a new bulb

of the same type and specification. To avoid

lighting imbalance, replace the bulbs in pairs.

Refitting the lamp units

Perform the operations in the reverse

order to dismantling.

Light-emitting diode (LED)

headlamps and lamps

Depending on version, the affected types of

headlamps / lamps are:

–

Full LED technology headlamps.

–

Direction indicator side repeaters.

–

Side spotlamps.

–

Third brake lamp.

For the replacement of this type of bulb,

you must contact a PEUGEOT dealer or

a qualified workshop.

Do not touch the "Full LED" technology

headlamps - risk of electrocution!

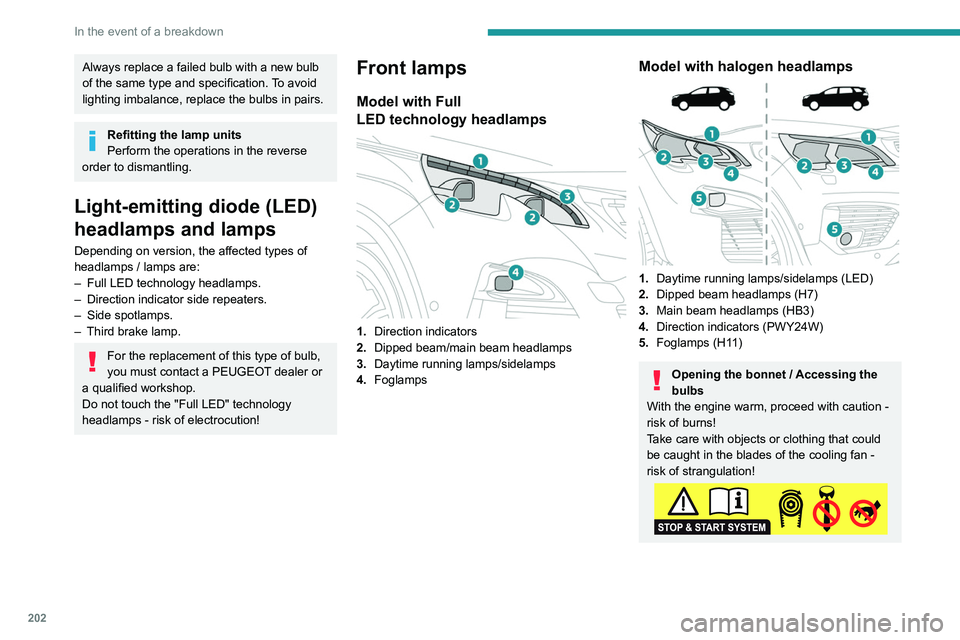

Front lamps

Model with Full

LED technology headlamps

1.Direction indicators

2. Dipped beam/main beam headlamps

3. Daytime running lamps/sidelamps

4. Foglamps

Model with halogen headlamps

1.Daytime running lamps/sidelamps (LED)

2. Dipped beam headlamps (H7)

3. Main beam headlamps (HB3)

4. Direction indicators (PWY24W)

5. Foglamps (H11)

Opening the bonnet / Accessing the

bulbs

With the engine warm, proceed with caution -

risk of burns!

Take care with objects or clothing that could

be caught in the blades of the cooling fan -

risk of strangulation!

Halogen bulbs (Hx)

To ensure good quality lighting, check

that the bulb is correctly positioned in its

housing.

Direction indicators

Rapid flashing of a direction indicator

lamp (left or right) indicates that one of

the bulbs on the corresponding side has

failed.

► Turn the connector a quarter turn

anti-clockwise.

► Pull the bulb connector.

► Remove the bulb and replace it.

Amber coloured bulbs must be replaced

by bulbs with identical specifications and

colour.

Page 212 of 308

210

In the event of a breakdown

Version 2 (Eco)

Fuse N°Rating (A)Functions

F16 25 AFront foglamps.

F18 10 ARight-hand main beam headlamp.

F19 10 ALeft-hand main beam headlamp.

12 V battery

Procedure for starting the engine using another

battery or charging a discharged battery.

Lead-acid starter batteries

These batteries contain harmful

substances (sulphuric acid and lead).

They must be disposed of in accordance

with regulations and must never under any

circumstances be discarded with household

waste.

Take used remote control batteries and

vehicle batteries to a special collection point.

Protect your eyes and face before

handling the battery.

All operations on the battery must be carried

out in a well ventilated area and away from

naked flames and sources of sparks, to avoid

any risk of explosion or fire.

Wash your hands afterwards.

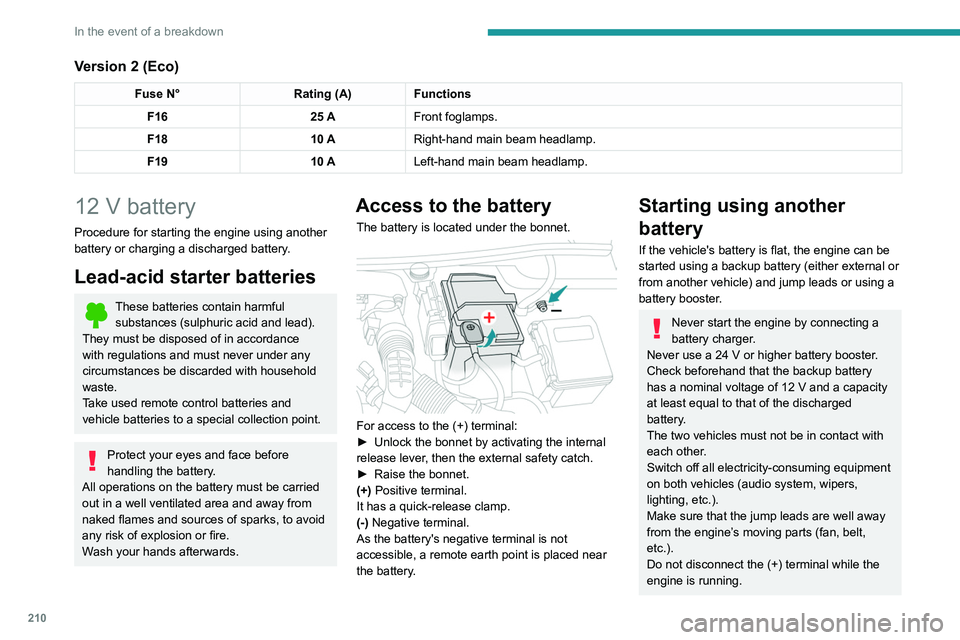

Access to the battery

The battery is located under the bonnet.

For access to the (+) terminal:

► Unlock the bonnet by activating the internal

release lever

, then the external safety catch.

►

Raise the bonnet.

(+)

Positive terminal.

It has a quick-release clamp.

(-) Negative terminal.

As the battery's negative terminal is not

accessible, a remote earth point is placed near

the battery.

Starting using another

battery

If the vehicle's battery is flat, the engine can be

started using a backup battery (either external or

from another vehicle) and jump leads or using a

battery booster.

Never start the engine by connecting a

battery charger.

Never use a 24

V or higher battery booster.

Check beforehand that the backup battery

has a nominal voltage of 12

V and a capacity

at least equal to that of the discharged

battery.

The two vehicles must not be in contact with

each other.

Switch off all electricity-consuming equipment

on both vehicles (audio system, wipers,

lighting, etc.).

Make sure that the jump leads are well away

from the engine’s moving parts (fan, belt,

etc.).

Do not disconnect the (+) terminal while the

engine is running.

Page 215 of 308

213

In the event of a breakdown

8approximately 15 minutes before starting the

engine.

If minor problems nevertheless persist following

this operation, contact a PEUGEOT

dealer or a

qualified workshop.

Referring to the relevant section, reset certain

equipment:

–

Remote control key or electronic key

(depending on version).

–

Sunroof and electric sun blind.

–

Electric windows.

–

Date and time.

–

Preset radio stations.

After reconnection of the battery, the “Collision risk detection system fault”

message is displayed on the instrument panel

when the ignition is switched on. This

operation is perfectly normal. The message

will disappear while driving.

The Stop & Start system may not be operational during the trip following the

first engine start.

In this case, the system will only be available

again after a continuous period with the

vehicle immobilised, the duration of which

depends on the exterior temperature and the

state of charge of the battery (up to about 8

hours).

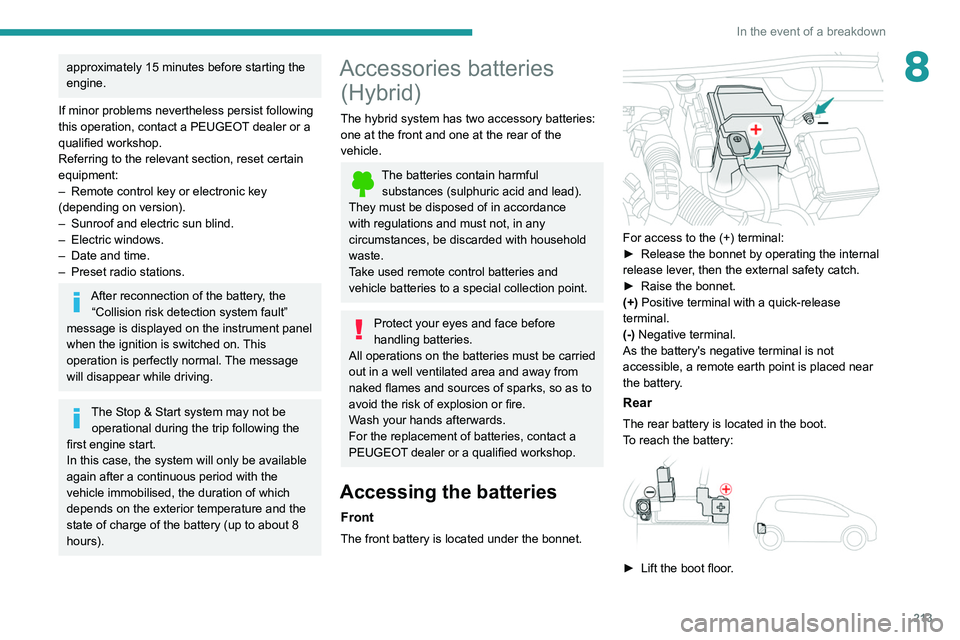

Accessories batteries (Hybrid)

The hybrid system has two accessory batteries:

one at the front and one at the rear of the

vehicle.

The batteries contain harmful substances (sulphuric acid and lead).

They must be disposed of in accordance

with regulations and must not, in any

circumstances, be discarded with household

waste.

Take used remote control batteries and

vehicle batteries to a special collection point.

Protect your eyes and face before

handling batteries.

All operations on the batteries must be carried

out in a well ventilated area and away from

naked flames and sources of sparks, so as to

avoid the risk of explosion or fire.

Wash your hands afterwards.

For the replacement of batteries,

contact a

PEUGEOT dealer or a qualified workshop.

Accessing the batteries

Front

The front battery is located under the bonnet.

For access to the (+) terminal:

► Release the bonnet by operating the internal

release lever

, then the external safety catch.

►

Raise the bonnet.

(+)

Positive terminal with a quick-release

terminal.

(-) Negative terminal.

As the battery's negative terminal is not

accessible, a remote earth point is placed near

the battery.

Rear

The rear battery is located in the boot.

To reach the battery:

► Lift the boot floor .

Page 228 of 308

226

Technical data

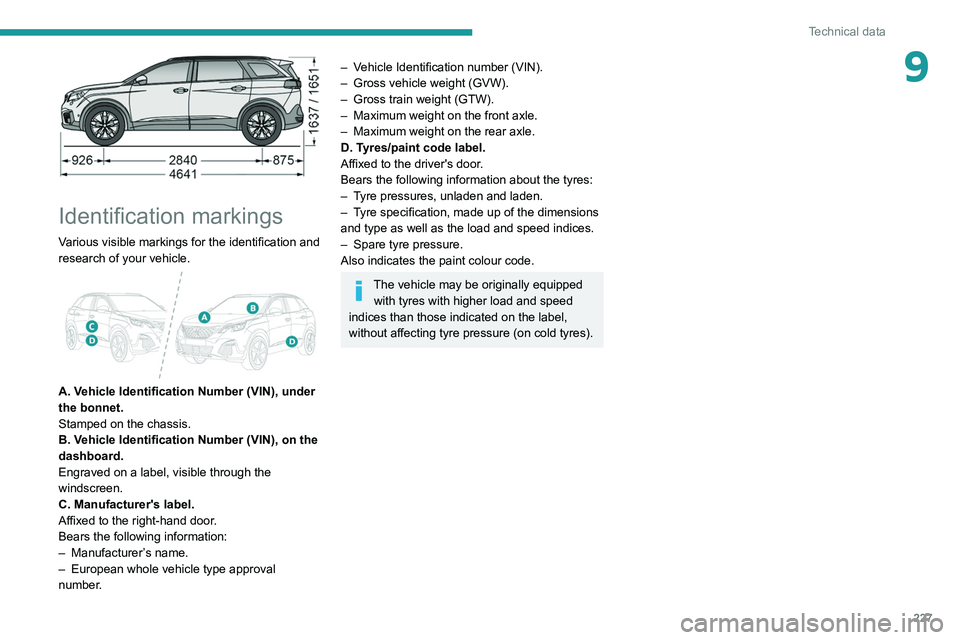

Identification markings

Various visible markings for the identification and

research of your vehicle.

A. Vehicle Identification Number (VIN), under

the bonnet.

Stamped on the chassis.

B. Vehicle Identification Number (VIN), on the

dashboard.

Engraved on a label, visible through the

windscreen.

C. Manufacturer's label.

Affixed to the right-hand door.

Bears the following information:

– Manufacturer’s name.

– European whole vehicle type approval

number.

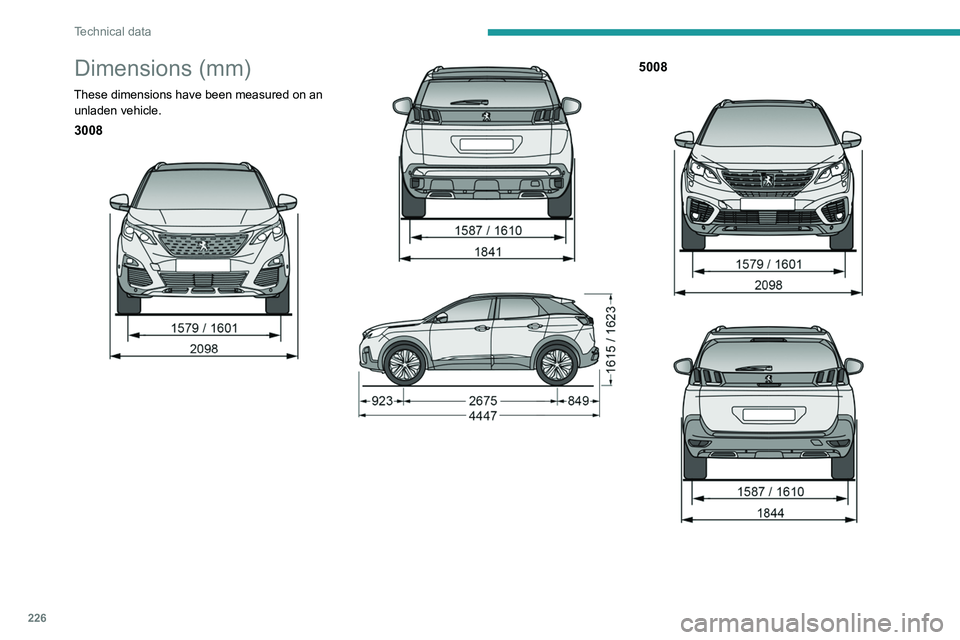

Dimensions (mm)

These dimensions have been measured on an unladen vehicle.

3008

5008

Page 229 of 308

227

Technical data

9

Identification markings

Various visible markings for the identification and

research of your vehicle.

A. Vehicle Identification Number (VIN), under

the bonnet.

Stamped on the chassis.

B. Vehicle Identification Number (VIN), on the

dashboard.

Engraved on a label, visible through the

windscreen.

C. Manufacturer's label.

Affixed to the right-hand door.

Bears the following information:

–

Manufacturer

’s name.

–

European whole vehicle type approval

number

.

– Vehicle Identification number (VIN).

– Gross vehicle weight (GVW).

–

Gross train weight (GTW).

–

Maximum weight on the front axle.

–

Maximum weight on the rear axle.

D. T

yres/paint code label.

Affixed to the driver's door.

Bears the following information about the tyres:

–

T

yre pressures, unladen and laden.

–

T

yre specification, made up of the dimensions

and type as well as the load and speed indices.

–

Spare tyre pressure.

Also indicates the paint colour code.

The vehicle may be originally equipped with tyres with higher load and speed

indices than those indicated on the label,

without affecting tyre pressure (on cold tyres).