wheel PEUGEOT 508 2021 Repair Manual

[x] Cancel search | Manufacturer: PEUGEOT, Model Year: 2021, Model line: 508, Model: PEUGEOT 508 2021Pages: 292, PDF Size: 8.61 MB

Page 174 of 292

172

Practical information

Sunroof

Do not operate the sunroof when using

roof bars - risk of major damage!

Bicycle / accessory carrier

Do not attach an accessory carrier to the

tailgate.

Very cold climate screen

(Depending on country of sale)

This removable device prevents the

accumulation of snow around the radiator

cooling fan.

In case of difficulty with installation/

removal

Contact a PEUGEOT dealer or a qualified

workshop.

Before any operation, ensure that the

engine is off and the cooling fan has

stopped.

It is essential to remove them when:

– the outside temperature exceeds

10°C.

–

recovery is in progress.

–

the speed is above 75 mph (120

km/h).

Snow chains

In wintry conditions, snow chains improve

traction as well as the behaviour of the vehicle

when braking.

Snow chains must be fitted only to the

front wheels. They must never be fitted to

"space-saver" type spare wheels.

Observe the legislation in force in your

country relating to the use of snow

chains and maximum authorised speeds.

Only use chains that have been designed to be

fitted to the type of wheel on the vehicle:

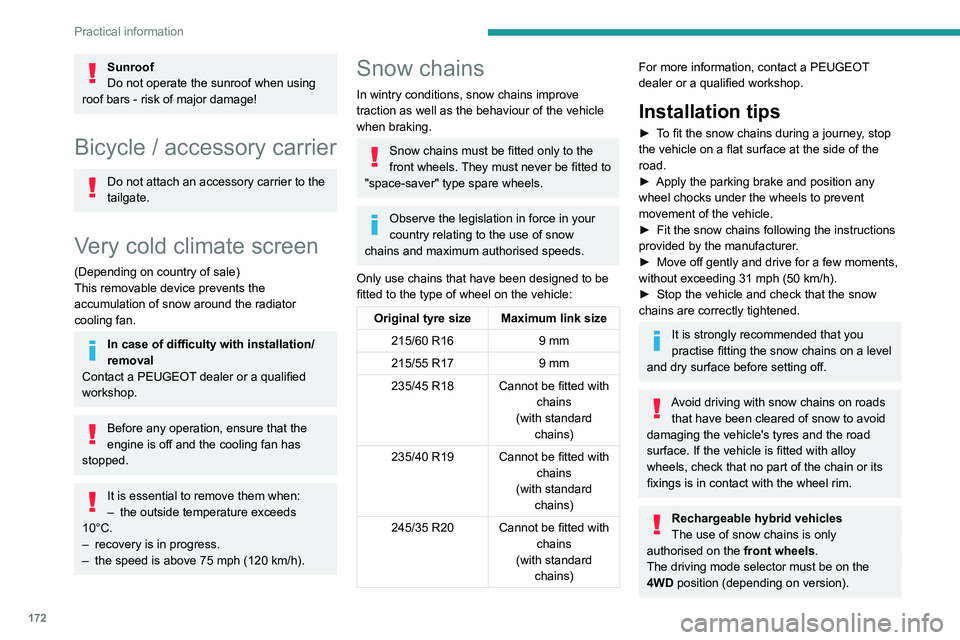

Original tyre size Maximum link size 215/60 R16 9 mm

215/55 R17 9 mm

235/45 R18 Cannot be fitted with

chains

(with standard chains)

235/40 R19 Cannot be fitted with chains

(with standard chains)

245/35 R20 Cannot be fitted with

chains

(with standard chains)

For more information, contact a PEUGEOT

dealer or a qualified workshop.

Installation tips

► To fit the snow chains during a journey, stop

the vehicle on a flat surface at the side of the

road.

►

Apply the parking brake and position any

wheel chocks under the wheels to prevent

movement of the vehicle.

►

Fit the snow chains following the instructions

provided by the manufacturer

.

►

Move off gently and drive for a few moments,

without exceeding 31

mph (50 km/h).

►

Stop the vehicle and check that the snow

chains are correctly tightened.

It is strongly recommended that you

practise fitting the snow chains on a level

and dry surface before setting off.

Avoid driving with snow chains on roads that have been cleared of snow to avoid

damaging the vehicle's tyres and the road

surface. If the vehicle is fitted with alloy

wheels, check that no part of the chain or its

fixings is in contact with the wheel rim.

Rechargeable hybrid vehicles

The use of snow chains is only

authorised on the front wheels.

The driving mode selector must be on the

4WD position (depending on version).

Energy economy mode

This system manages the duration of use of

certain functions, in order to conserve a sufficient

level of charge in the battery with the ignition off.

After switching off the engine and for a maximum

cumulative period of around 30 minutes, you can

continue to use functions such as the audio and

telematics system, dipped beam headlamps or

courtesy lamps.

Selecting the mode

A confirmation message is displayed when

energy economy mode is entered, and the active

functions are placed on standby.

If a telephone call is in progress at the

time, it will be maintained for around 10

minutes via the audio system’s hands-free

system.

Exiting the mode

These functions are automatically reactivated the

next time the vehicle is used.

To restore the use of these functions

immediately, start the engine and let it run:

– For less than 10 minutes, to use the

equipment for approximately 5 minutes.

– For more than 10 minutes, to use the

equipment for approximately 30 minutes.

Let the engine run for the specified duration to

ensure that the battery charge is sufficient.

Page 180 of 292

178

Practical information

used in town, over short distances. It may be

necessary to have the condition of the brakes

checked, even between vehicle services.

Unless there is a leak in the circuit, a drop in the

brake fluid level indicates that the brake pads

are worn.

After washing the vehicle, moisture, or in wintry conditions, ice can form on the

brake discs and pads: braking efficiency may

be reduced. Gently dab the brakes to dry and

defrost them.

Brake disc wear

For information on checking brake disc

wear, contact a PEUGEOT dealer or a

qualified workshop.

Wheels and tyres

The inflation pressure of all tyres, including the spare wheel, must be

checked on "cold” tyres.

The pressures indicated on the tyre pressure

label are valid for "cold" tyres. If you have driven

for more than 10 minutes or more than 6 miles

(10 kilometres) at over 31 mph (50

km/h), add

0.3 bar (30 kPa) to the values indicated on the

label.

Under-inflation increases energy

consumption. Non-compliant tyre

pressures cause tyres to wear prematurely

and have an adverse effect on the vehicle's

road holding - risk of accident!

Driving with worn or damaged tyres reduces the

braking and road holding performance of the

vehicle. Regularly check the condition of the

tyres (tread and sidewalls) and rims as well as

the presence of the valve caps.

When the wear indicators no longer appear set

back from the tread, the depth of the grooves is

less than 1.6 mm; replace the tyres as soon as

possible.

Using different size wheels and tyres from those

specified can affect the lifetime of tyres, wheel

rotation, ground clearance, the speedometer

reading and have an adverse effect on road

holding.

Fitting different tyres on the front and rear axles

can cause the ESC to mistime.

Always mark the direction of rotation on the tyres

that will be stored when fitting winter or summer

tyres. Store them in a cool, dry place and away

from direct exposure to the sun's rays.

Winter or 4-seasons tyres can be

identified by this symbol on their

sidewalls.

Shock absorbers

It is not easy for drivers to detect when

shock absorbers are worn. Nevertheless,

the shock absorbers have a major impact on

road holding and braking performance. For your safety and driving comfort, it is

important to have them regularly checked by a

PEUGEOT dealer or a qualified workshop.

Timing and accessory kits

The timing and accessory kits are used

from the time the engine is started until it

is switched off. It is normal for them to wear over

time.

A

faulty timing or accessory kit can damage

the engine, rendering it unusable. Observe the

recommended replacement frequency, stated in

distance travelled or time elapsed, whichever is

reached first.

AdBlue® (BlueHDi)

To respect the environment and ensure compliance with the Euro 6 standard, without

adversely affecting the performance or fuel

consumption of its Diesel engines, PEUGEOT

has taken the decision to equip its vehicles with

a system that combines SCR (Selective Catalytic

Reduction) with a Diesel Particle Filter (DPF) for

the treatment of exhaust gases.

SCR system

Using a liquid called AdBlue® that contains

urea, a catalytic converter turns up to 85% of

the nitrogen oxides (NOx) into nitrogen and

water, which are harmless to health and the

environment.

Page 182 of 292

180

Practical information

for a few hours to allow the top-up to be carried

out.

Never pour the AdBlue® into the Diesel

fuel tank.

If any AdBlue® is splashed, or if there are

any spillages on the bodywork, rinse

immediately with cold water or wipe with a

damp cloth.

If the fluid has crystallised, clean it off using a

sponge and hot water.

Important: in the event of a top-up after

an AdBlue breakdown, you must wait

about 5

minutes before switching on the

ignition, without opening the driver's door,

unlocking the vehicle or bringing the

electronic key into the passenger

compartment.

Switch on the ignition, then wait for 10

seconds before starting the engine.

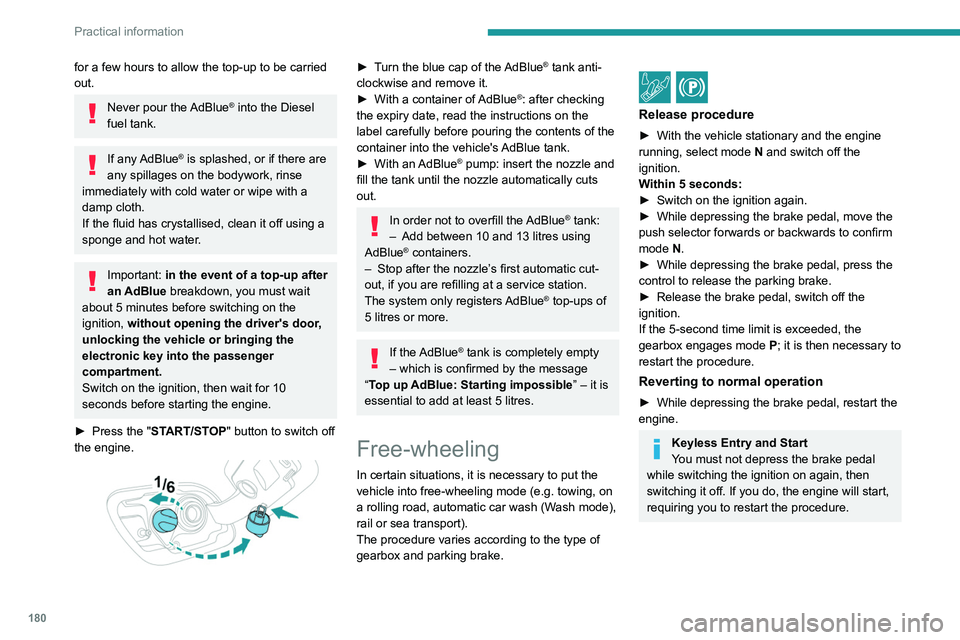

►

Press the "

START/STOP" button to switch off

the engine.

► Turn the blue cap of the AdBlue® tank anti-

clockwise and remove it.

►

With a container of

AdBlue

®: after checking

the expiry date, read the instructions on the

label carefully before pouring the contents of the

container into the vehicle's AdBlue tank.

►

With an

AdBlue® pump: insert the nozzle and

fill the tank until the nozzle automatically cuts

out.

In order not to overfill the AdBlue® tank:

–

Add between 10 and 13 litres using

AdBlue® containers.

–

Stop after the nozzle’ s first automatic cut-

out, if you are refilling at a service station.

The system only registers AdBlue

® top-ups of

5

litres or more.

If the AdBlue® tank is completely empty

– which is confirmed by the message

“Top up

AdBlue: Starting impossible ” – it is

essential to add at least 5 litres.

Free-wheeling

In certain situations, it is necessary to put the

vehicle into free-wheeling mode (e.g. towing, on

a rolling road, automatic car wash (Wash mode),

rail or sea transport).

The procedure varies according to the type of

gearbox and parking brake.

/

Release procedure

► With the vehicle stationary and the engine

running, select mode N and switch off the

ignition.

Within 5

seconds:

►

Switch on the ignition again.

►

While depressing the brake pedal, move the

push selector forwards or backwards to confirm

mode

N.

►

While depressing the brake pedal, press the

control to release the parking brake.

►

Release the brake pedal, switch off the

ignition.

If the 5-second time limit is exceeded, the

gearbox engages mode P

; it is then necessary to

restart the procedure.

Reverting to normal operation

► While depressing the brake pedal, restart the

engine.

Keyless Entry and Start

You must not depress the brake pedal

while switching the ignition on again, then

switching it off. If you do, the engine will start,

requiring you to restart the procedure.

Advice on care and maintenance

General recommendations

Observe the following recommendations to avoid

damaging the vehicle.

Exterior

Never use a high-pressure jet wash in

the engine compartment - risk of

damaging the electrical components!

Do not wash the vehicle in bright sunshine or

extremely cold conditions.

When washing the vehicle in an

automatic roller-brush car wash, be sure

to lock the doors and, depending on version,

move the electronic key away and deactivate

the "hands-free" function (Hands-Free

Tailgate Access).

When using a pressure washer, keep the jet

nozzle at a minimum distance of 30 cm from

the vehicle (particularly when cleaning areas

containing chipped paint, sensors or seals).

Promptly clean up any stains containing

chemicals liable to damage the vehicle's

paintwork (including tree resin, bird

droppings, insect secretions, pollen and tar).

Depending on the environment, clean the

vehicle frequently to remove salty deposits

(in coastal areas), soot (in industrial areas)

Page 186 of 292

184

In the event of a breakdown

The jack must only be used to change a wheel with a damaged or punctured tyre.

Do not use any jack other than the one

supplied with the vehicle.

If the vehicle does not have its original jack,

contact a PEUGEOT dealer or a qualified

workshop to obtain the one that was intended

by the manufacturer.

The jack meets European standards, as

defined in the Machinery Directive 2006/42/

CE.

The jack does not require any maintenance.

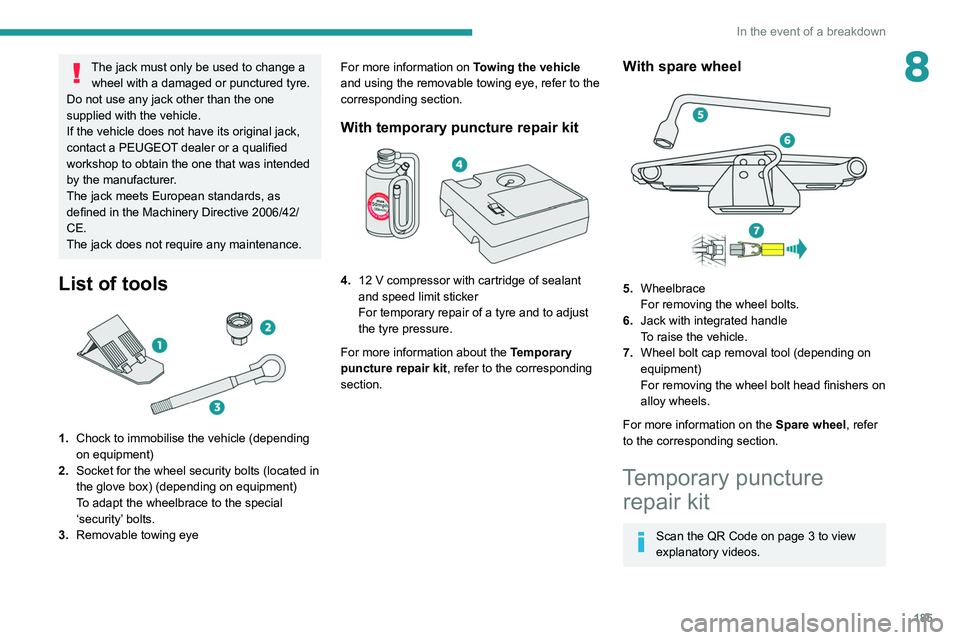

List of tools

1. Chock to immobilise the vehicle (depending

on equipment)

2. Socket for the wheel security bolts (located in

the glove box) (depending on equipment)

To adapt the wheelbrace to the special

‘security’ bolts.

3. Removable towing eye

Non-BlueHDi engines

► Open the bonnet and then, if necessary ,

unclip the cover to access the priming pump.

►

Loosen the degassing bolt.

► Operate the priming pump until fuel

appears in the transparent tube.

►

Retighten the degassing bolt.

►

Operate the starter motor until the engine

starts (if the engine does not start at the first

attempt, wait around 15

seconds before trying

again).

►

If the engine does not start after a few

attempts, operate the priming pump again, then

the starter motor

.

►

Put the cover back in place and clip it in, then

close the bonnet.

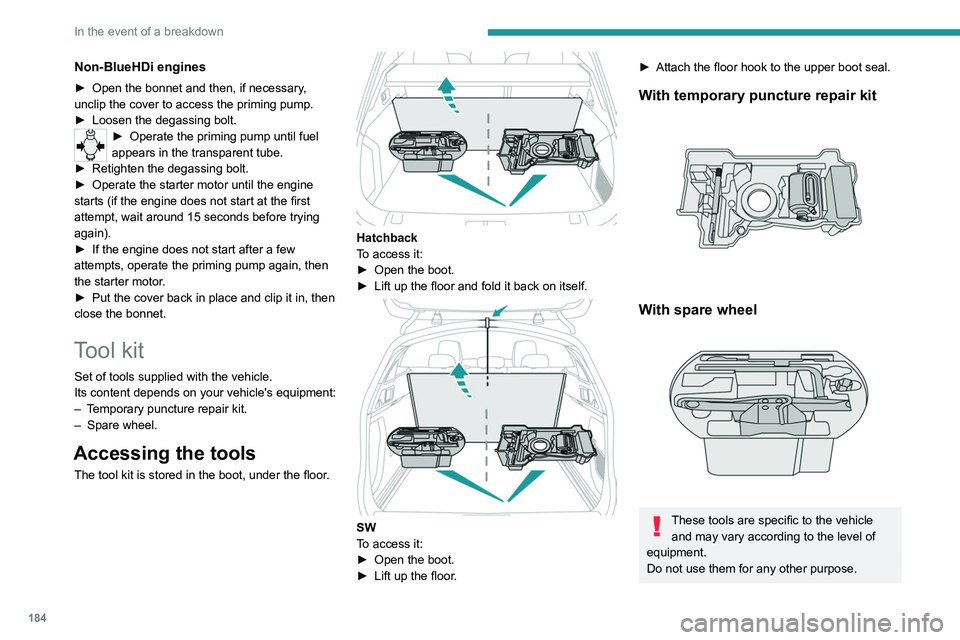

Tool kit

Set of tools supplied with the vehicle.

Its content depends on your vehicle's equipment:

–

T

emporary puncture repair kit.

–

Spare wheel.

Accessing the tools

The tool kit is stored in the boot, under the floor.

Hatchback

To access it:

►

Open the boot.

►

Lift up the floor and fold it back on itself.

SW

To access it:

►

Open the boot.

►

Lift up the floor

.

► Attach the floor hook to the upper boot seal.

With temporary puncture repair kit

With spare wheel

These tools are specific to the vehicle and may vary according to the level of

equipment.

Do not use them for any other purpose.

Page 187 of 292

185

In the event of a breakdown

8The jack must only be used to change a wheel with a damaged or punctured tyre.

Do not use any jack other than the one

supplied with the vehicle.

If the vehicle does not have its original jack,

contact a PEUGEOT dealer or a qualified

workshop to obtain the one that was intended

by the manufacturer.

The jack meets European standards, as

defined in the Machinery Directive 2006/42/

CE.

The jack does not require any maintenance.

List of tools

1. Chock to immobilise the vehicle (depending

on equipment)

2. Socket for the wheel security bolts (located in

the glove box) (depending on equipment)

To adapt the wheelbrace to the special

‘security’ bolts.

3. Removable towing eye For more information on

Towing the vehicle

and using the removable towing eye, refer to the

corresponding section.

With temporary puncture repair kit

4. 12 V compressor with cartridge of sealant

and speed limit sticker

For temporary repair of a tyre and to adjust

the tyre pressure.

For more information about the Temporary

puncture repair kit, refer to the corresponding

section.

With spare wheel

5. Wheelbrace

For removing the wheel bolts.

6. Jack with integrated handle

To raise the vehicle.

7. Wheel bolt cap removal tool (depending on

equipment)

For removing the wheel bolt head finishers on

alloy wheels.

For more information on the Spare wheel, refer

to the corresponding section.

Temporary puncture repair kit

Scan the QR Code on page 3 to view

explanatory videos.

Page 188 of 292

186

In the event of a breakdown

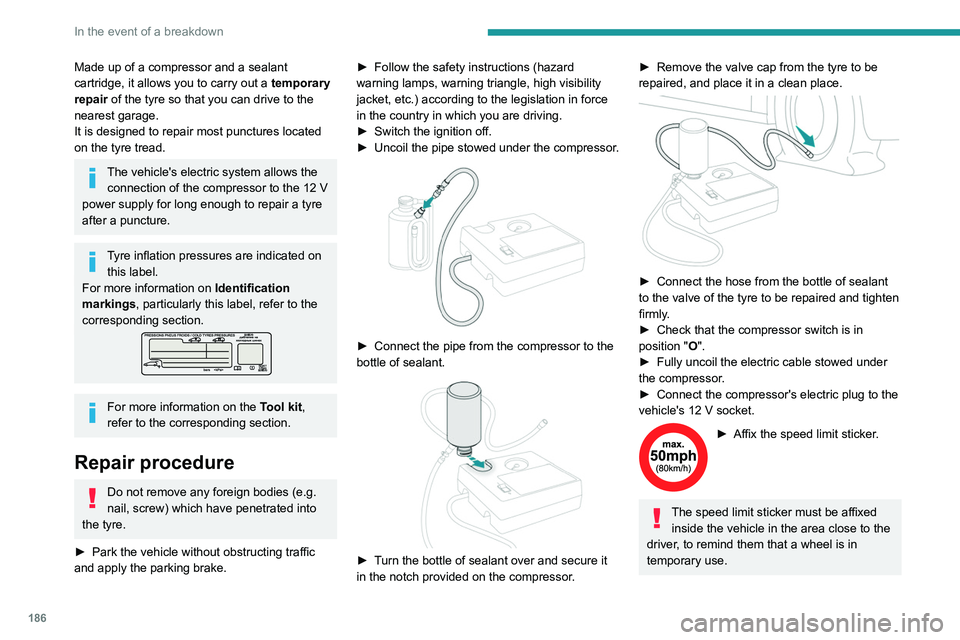

Made up of a compressor and a sealant

cartridge, it allows you to carry out a temporary

repair of the tyre so that you can drive to the

nearest garage.

It is designed to repair most punctures located

on the tyre tread.

The vehicle's electric system allows the connection of the compressor to the 12 V

power supply for long enough to repair a tyre

after a puncture.

Tyre inflation pressures are indicated on this label.

For more information on Identification

markings, particularly this label, refer to the

corresponding section.

For more information on the Tool kit,

refer to the corresponding section.

Repair procedure

Do not remove any foreign bodies (e.g.

nail, screw) which have penetrated into

the tyre.

►

Park the vehicle without obstructing traffic

and apply the parking brake. ►

Follow the safety instructions (hazard

warning lamps, warning triangle, high visibility

jacket, etc.) according to the legislation in force

in the country in which you are driving.

►

Switch the ignition off.

►

Uncoil

the pipe stowed under the compressor.

► Connect the pipe from the compressor to the

bottle of sealant.

► Turn the bottle of sealant over and secure it

in the notch provided on the compressor.

► Remove the valve cap from the tyre to be

repaired, and place it in a clean place.

► Connect the hose from the bottle of sealant

to the valve of the tyre to be repaired and tighten

firmly

.

►

Check that the compressor switch is in

position

"O".

►

Fully uncoil the electric cable stowed under

the compressor

.

►

Connect the compressor's electric plug to the

vehicle's 12

V socket.

► Affix the speed limit sticker .

The speed limit sticker must be affixed

inside the vehicle in the area close to the

driver, to remind them that a wheel is in

temporary use.

Page 190 of 292

188

In the event of a breakdown

Should the pressure of one or more tyres

be adjusted, it is necessary to reinitialise

the under-inflation detection system.

For more information on Tyre under-inflation

detection, refer to the corresponding section.

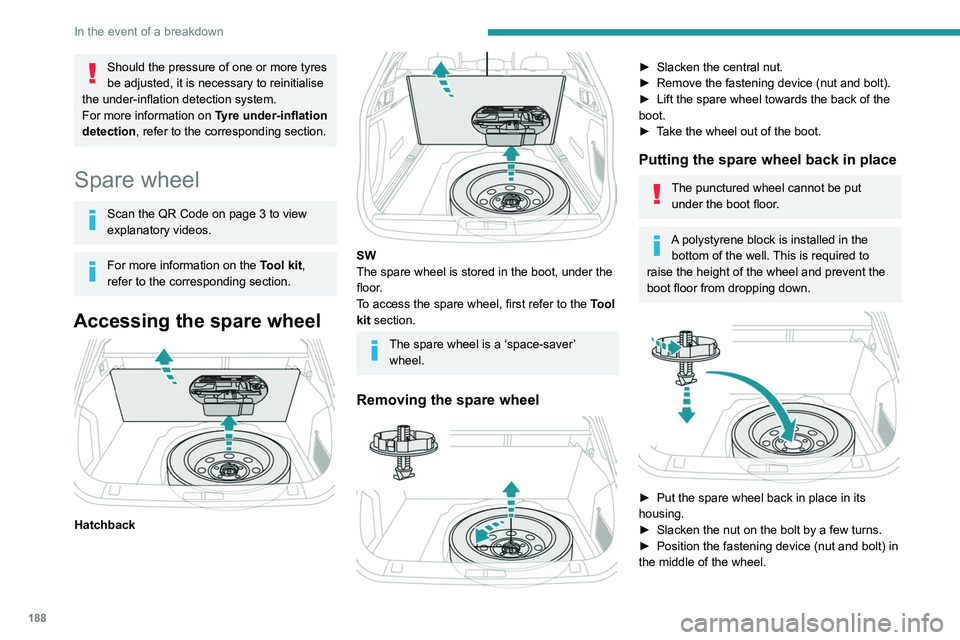

Spare wheel

Scan the QR Code on page 3 to view

explanatory videos.

For more information on the Tool kit,

refer to the corresponding section.

Accessing the spare wheel

Hatchback

SW

The spare wheel is stored in the boot, under the

floor.

To access the spare wheel, first refer to the

Tool

kit

section.

The spare wheel is a ‘space-saver’ wheel.

Removing the spare wheel

► Slacken the central nut.

► Remove the fastening device (nut and bolt).

►

Lift the spare wheel towards the back of the

boot.

►

T

ake the wheel out of the boot.

Putting the spare wheel back in place

The punctured wheel cannot be put under the boot floor.

A polystyrene block is installed in the bottom of the well. This is required to

raise the height of the wheel and prevent the

boot floor from dropping down.

► Put the spare wheel back in place in its

housing.

►

Slacken the nut on the bolt by a few turns.

►

Position the fastening device (nut and bolt) in

the middle of the wheel.

Page 191 of 292

189

In the event of a breakdown

8

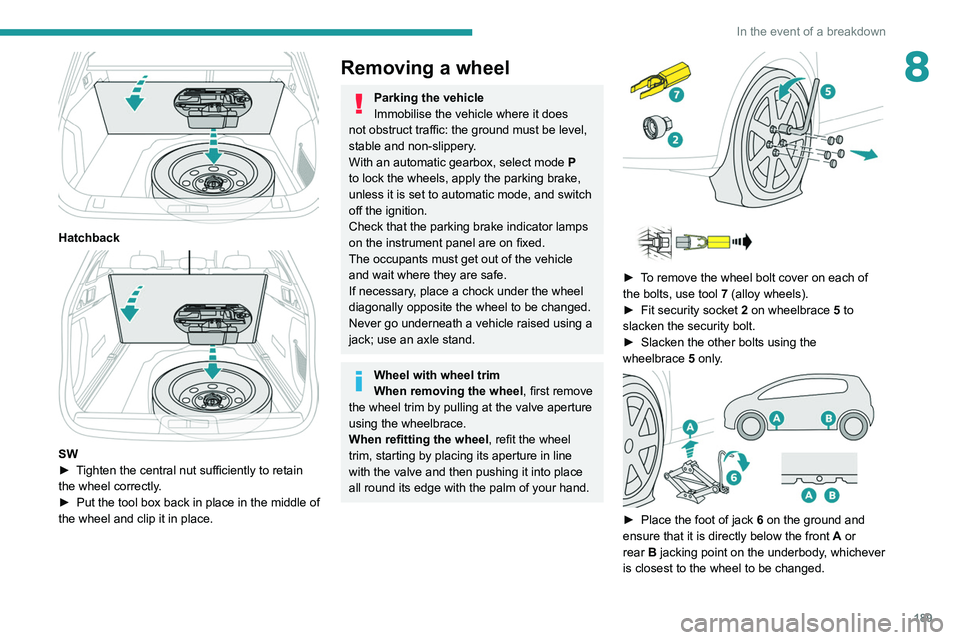

Hatchback

SW

► T ighten the central nut sufficiently to retain

the wheel correctly.

►

Put the tool box back in place in the middle of

the wheel and clip it in place.

Removing a wheel

Parking the vehicle

Immobilise the vehicle where it does

not obstruct traffic: the ground must be level,

stable and non-slippery.

With an automatic gearbox, select mode

P

to lock the wheels, apply the parking brake,

unless it is set to automatic mode, and switch

off the ignition.

Check that the parking brake indicator lamps

on the instrument panel are on fixed.

The occupants must get out of the vehicle

and wait where they are safe.

If necessary, place a chock under the wheel

diagonally opposite the wheel to be changed.

Never go underneath a vehicle raised using a

jack; use an axle stand.

Wheel with wheel trim

When removing the wheel , first remove

the wheel trim by pulling at the valve aperture

using the wheelbrace.

When refitting the wheel , refit the wheel

trim, starting by placing its aperture in line

with the valve and then pushing it into place

all round its edge with the palm of your hand.

► To remove the wheel bolt cover on each of

the bolts, use tool 7 (alloy wheels).

►

Fit security socket

2 on wheelbrace

5

to

slacken the security bolt.

►

Slacken the other bolts using the

wheelbrace

5

only.

► Place the foot of jack 6 on the ground and

ensure that it is directly below the front A or

rear

B jacking point on the underbody, whichever

is closest to the wheel to be changed.

Page 192 of 292

190

In the event of a breakdown

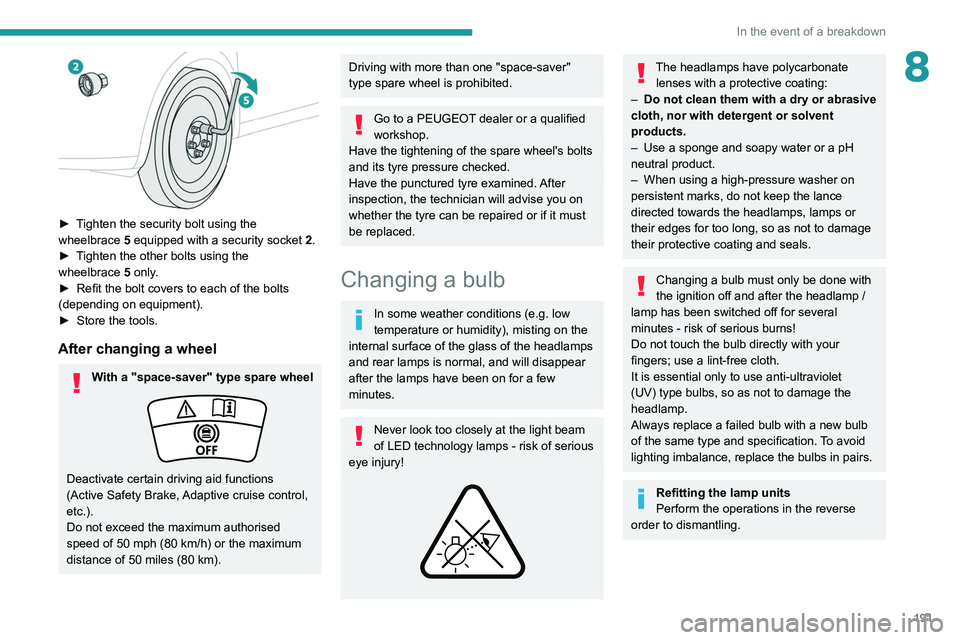

► Tighten the security bolt using the

wheelbrace 5 equipped with a security socket 2.

► Tighten the other bolts using the

wheelbrace 5 only.

► Refit the bolt covers to each of the bolts

(depending on equipment).

► Store the tools.

After changing a wheel

With a "space-saver" type spare wheel

Deactivate certain driving aid functions

(Active Safety Brake, Adaptive cruise control,

etc.).

Do not exceed the maximum authorised

speed of 50 mph (80 km/h) or the maximum

distance of 50 miles (80 km).

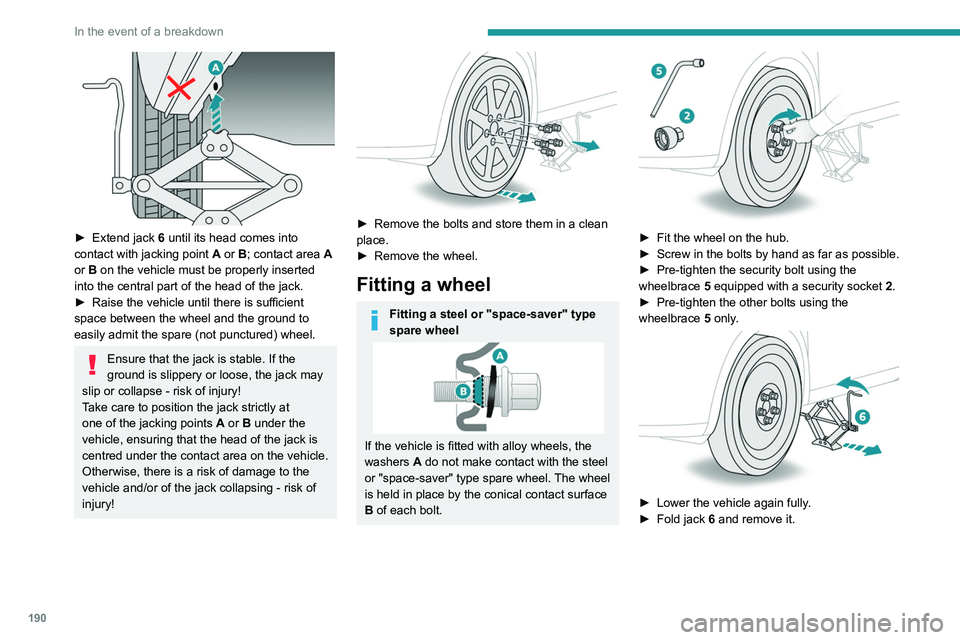

► Extend jack 6 until its head comes into

contact with jacking point A or B; contact area A

or B on the vehicle must be properly inserted

into the central part of the head of the jack.

►

Raise the vehicle until there is sufficient

space between the wheel and the ground to

easily admit the spare (not punctured) wheel.

Ensure that the jack is stable. If the

ground is slippery or loose, the jack may

slip or collapse - risk of injury!

Take care to position the jack strictly at

one of the jacking points

A

or B under the

vehicle, ensuring that the head of the jack is

centred under the contact area on the vehicle.

Otherwise, there is a risk of damage to the

vehicle and/or of the jack collapsing - risk of

injury!

► Remove the bolts and store them in a clean

place.

►

Remove the wheel.

Fitting a wheel

Fitting a steel or "space-saver" type

spare wheel

If the vehicle is fitted with alloy wheels, the

washers A do not make contact with the steel

or "space-saver" type spare wheel. The wheel

is held in place by the conical contact surface

B of each bolt.

► Fit the wheel on the hub.

► Screw in the bolts by hand as far as possible.

►

Pre-tighten the security bolt using the

wheelbrace

5

equipped with a security socket

2

.

►

Pre-tighten the other bolts using the

wheelbrace

5

only.

► Lower the vehicle again fully .

► Fold jack 6 and remove it.

Page 193 of 292

191

In the event of a breakdown

8

► Tighten the security bolt using the

wheelbrace 5 equipped with a security socket 2 .

►

T

ighten the other bolts using the

wheelbrace

5

only.

►

Refit the bolt covers to each of the bolts

(depending on equipment).

►

Store the tools.

After changing a wheel

With a "space-saver" type spare wheel

Deactivate certain driving aid functions

(Active Safety Brake, Adaptive cruise control,

etc.).

Do not exceed the maximum authorised

speed of 50 mph (80 km/h) or the maximum

distance of 50 miles (80 km).

Driving with more than one "space-saver"

type spare wheel is prohibited.

Go to a PEUGEOT dealer or a qualified

workshop.

Have the tightening of the spare wheel's bolts

and its tyre pressure checked.

Have the punctured tyre examined. After

inspection, the technician will advise you on

whether the tyre can be repaired or if it must

be replaced.

Changing a bulb

In some weather conditions (e.g. low

temperature or humidity), misting on the

internal surface of the glass of the headlamps

and rear lamps is normal, and will disappear

after the lamps have been on for a few

minutes.

Never look too closely at the light beam

of LED technology lamps - risk of serious

eye injury!

The headlamps have polycarbonate lenses with a protective coating:

–

Do not clean them with a dry or abrasive

cloth, nor with detergent or solvent

products.

–

Use a sponge and soapy water or a pH

neutral product.

–

When using a high-pressure washer on

persistent marks, do not keep the lance

directed towards the headlamps, lamps or

their edges for too long, so as not to damage

their protective coating and seals.

Changing a bulb must only be done with

the ignition off and after the headlamp /

lamp has been switched off for several

minutes - risk of serious burns!

Do not touch the bulb directly with your

fingers; use a lint-free cloth.

It is essential only to use anti-ultraviolet

(UV) type bulbs, so as not to damage the

headlamp.

Always replace a failed bulb with a new bulb

of the same type and specification. To avoid

lighting imbalance, replace the bulbs in pairs.

Refitting the lamp units

Perform the operations in the reverse

order to dismantling.