motor Peugeot Boxer 2016 User Guide

[x] Cancel search | Manufacturer: PEUGEOT, Model Year: 2016, Model line: Boxer, Model: Peugeot Boxer 2016Pages: 292, PDF Size: 10.07 MB

Page 266 of 292

264

boxer_en_Chap11_Particularites_ed01-2015

SErVIc I n G

r eservoir

Check and top up the fluid level regularly. Replace the fluid

annually. Replace the fluid if it contains water.

Check the condition of the hydraulic hose and the sealing of the

hydraulic system regularly.

Pump and motor

Requires no servicing, the ball bearings are lubricated for life and

the plain bearings by the pumped fluid.

Lubrication

the tipper body and ram pivots do not have grease nipples.

Lubricate regularly the hinges and retainers for the tipper body sides

as well as the catches for the rear tipper body side.

Sub-chassis and tipper body

For maximum life, we recommend that you clean your tipper body

by washing it down regularly with hose.

touch-in the paint chips quickly to avoid the spread of rust.

After 8 months of use, check the tightening torque of the

fixings of the underbody to the chassis (following the

recommendations of the body converter).

cleaning the valve slider

● Remove the plug 244A taking care to recover the ball.

●

Using a wide screwdriver

, remove the bore / piston bolt

assembly.

●

Check that the piston slides smoothly and remove any

impurities. Pass a magnet over if there is any swarf present.

●

Refit the assembly and ensure that the piston slides smoothly

.

Retain the ball with some grease on the plug for reassembly.

●

Bleed the hydraulic system.

Bleed the electro-hydraulic unit

● Remove the hexagonal plug 257.

●

Slacken by a half turn the bolt

587 located inside, using a

hexagonal 6 mm spanner.

●

Operate the electro-hydraulic unit for a few moments by

pressing the raise button.

●

The tipper body does not rise, or very slowly

. When fluid flows

from the orifice, the system is bled.

●

Retighten bolt

587 and refit the plug 257, check that the tipper

body lowers correctly.

tipper body

Page 269 of 292

267

boxer_en_Chap11_Particularites_ed01-2015

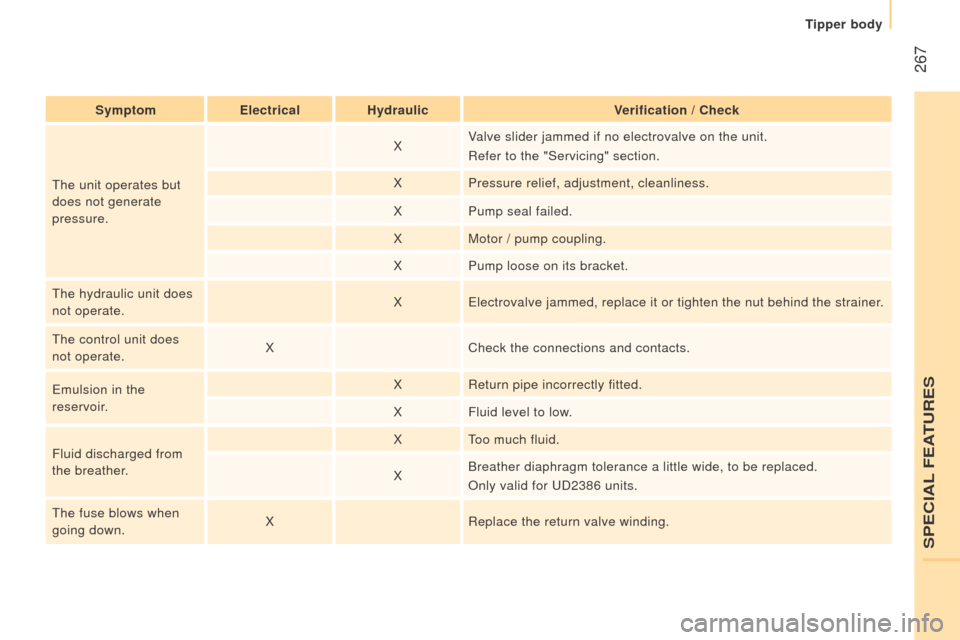

SymptomElectricalHydraulic Verification / c heck

t

he unit operates but

does not generate

pressure. X

Valve slider jammed if no electrovalve on the unit.

Refer to the "Servicing" section.

X Pressure relief, adjustment, cleanliness.

X Pump seal failed.

X Motor / pump coupling.

X Pump loose on its bracket.

t

he hydraulic unit does

not operate. X

e

lectrovalve jammed, replace it or tighten the nut behind the strainer.

t

he control unit does

not operate. X

Check the connections and contacts.

e

mulsion in the

reservoir. X

Return pipe incorrectly fitted.

X Fluid level to low.

Fluid discharged from

the breather. X

too much fluid.

X Breather diaphragm tolerance a little wide, to be replaced.

Only valid for

u D2386 units.

t

he fuse blows when

going down. X

Replace the return valve winding.

SPeCIAL FeAtuReS

tipper body

Page 283 of 292

5

3

EASE OF USE

and

COMFORT

Steering mounted controls

boxer-post-it_en_Chap03_Ergo-et-confort_ed01-2015

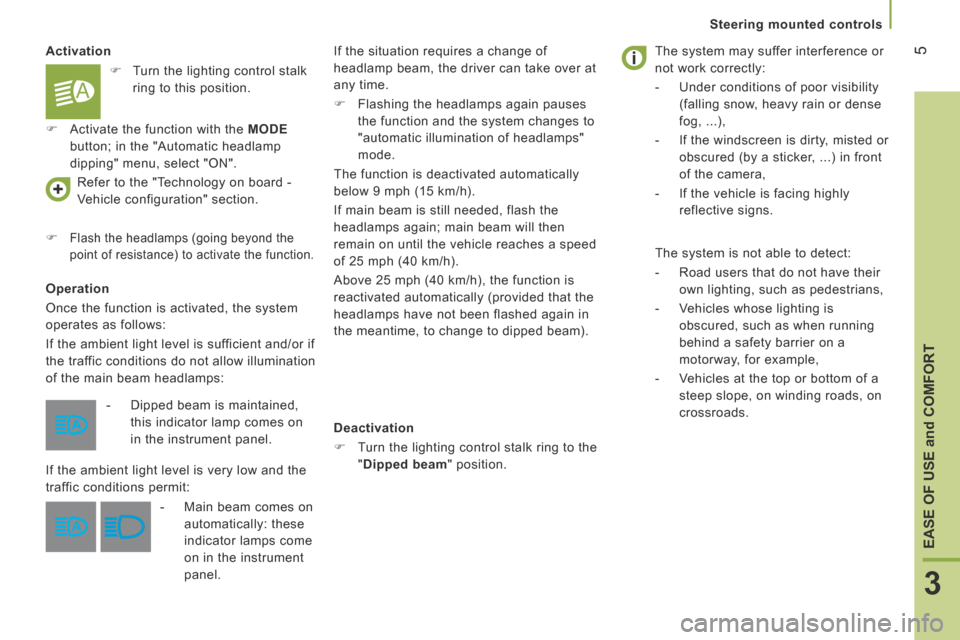

Activation

Operation

Once the function is activated, the system

operates as follows:

If the ambient light level is sufficient and/or if

the traffic conditions do not allow illumination

of the main beam headlamps:

Refer to the "Technology on board -

Vehicle configuration" section.

Flash the headlamps (going beyond the

point of resistance) to activate the function.

If the situation requires a change of

headlamp beam, the driver can take over at

any time.

Flashing the headlamps again pauses

the function and the system changes to

"automatic illumination of headlamps"

mode.

The function is deactivated automatically

below 9 mph (15 km/h).

If main beam is still needed, flash the

headlamps again; main beam will then

remain on until the vehicle reaches a speed

of 25 mph (40 km/h).

Above 25 mph (40 km/h), the function is

reactivated automatically (provided that the

headlamps have not been flashed again in

the meantime, to change to dipped beam).

Deactivation

Turn the lighting control stalk ring to the

" Dipped beam " position.

The system may suffer interference or

not work correctly:

- Under conditions of poor visibility

(falling snow, heavy rain or dense

fog, ...),

- If the windscreen is dirty, misted or

obscured (by a sticker, ...) in front

of the camera,

- If the vehicle is facing highly

reflective signs.

The system is not able to detect:

- Road users that do not have their

own lighting, such as pedestrians,

- Vehicles whose lighting is

obscured, such as when running

behind a safety barrier on a

motorway, for example,

- Vehicles at the top or bottom of a

steep slope, on winding roads, on

crossroads. - Dipped beam is maintained,

this indicator lamp comes on

in the instrument panel.

If the ambient light level is very low and the

traffic conditions permit:

- Main beam comes on

automatically: these

indicator lamps come

on in the instrument

panel.

Turn the lighting control stalk

ring to this position.

Activate the function with the MODE

button; in the "Automatic headlamp

dipping" menu, select "ON".