tires PONTIAC BONNEVILLE 2003 Owner's Manual

[x] Cancel search | Manufacturer: PONTIAC, Model Year: 2003, Model line: BONNEVILLE, Model: PONTIAC BONNEVILLE 2003Pages: 418, PDF Size: 20.24 MB

Page 256 of 418

Will you have to make any holes in the body of

your vehicle when you install a trailer hitch?

If

you do, then be sure to seal the holes later when

you remove the hitch.

If you don’t seal them, deadly

carbon monoxide (CO) from your exhaust can get

into your vehicle. See

Engine Exhaust on

page 2-36. Dirt and water can also enter the

vehicle.

Safety Chains

You should always attach chains between your vehicle

and your trailer. Cross the safety chains under the

tongue of the trailer

so that the tongue will not drop to

the road

if it becomes separated from the hitch.

Instructions about safety chains may be provided by the

hitch manufacturer or by the trailer manufacturer.

Follow the manufacturer’s recommendation for attaching

safety chains and do not attach them to the bumper.

Always leave just enough slack

so you can turn

with your rig. And, never allow safety chains to drag on

the ground.

Trailer Brakes

Does your trailer have its own brakes? Be sure to read

and follow the instructions for the trailer brakes

so

you’ll be able to install, adjust and maintain them

properly. Because you have

anti-lock brakes, do not try to tap

into your vehicles brake system.

If you do, both

brake systems won’t work well, or at all.

Trailer Wiring Harness

All of the electrical circuits required for your trailer

lighting system can be accessed at the driver’s side rear

lamp connector. This connector is located under the

carpet on the rear corner of your trunk compartment.

Driving with a Trailer

Towing a trailer requires a certain amount of experience.

Before setting out for the open road, you’ll want to get

to know your rig. Acquaint yourself with the feel of

handling and braking with the added weight of the trailer.

And always keep in mind that the vehicle you are

driving is now a good deal longer and not nearly as

responsive as your vehicle is by itself.

Before you start, check the trailer hitch and platform

(and attachments), safety chains, electrical connector,

lamps, tires and mirror aajustment.

ii tne rraiier nas

electric brakes, start your vehicle and trailer moving and

then apply the trailer brake controller by hand to be

sure the brakes are working. This lets you check your

electrical connection at the same time.

Oiiriiig your trip, check occasicfially tc be sure that the

load is secure, and that the lamps and any trailer

brakes are still working.

4-39

Page 261 of 418

Section 5 Service and Appearance Care

Windshield Wiper Blade Replacement ............. 5-61

Tires .............................................................. 5.62

Inflation

.. Tire Pressure ................................ 5.62

Check Tire Pressure System

.......................... 5.64

Tire Inspection and Rotation

........................... 5.65

When It

Is Time for New Tires ....................... 5-67

Buying New Tires

........................................ 5-67

Uniform Tire Quality Grading

.......................... 5.68

Wheel Replacement

...................................... 5.69

Tire Chains

.................................................. 5-71

Accessory Inflator

......................................... 5.72

If a Tire Goes Flat ........................................ 5.72

Changing a Flat Tire

..................................... 5.73

Compact Spare Tire

..................................... 5-81

Appearance Care ............................................ 5.82

Wheel

Alignment and Tire Balance

.................. 5-69

Cleaning the Inside of Your Vehicle

................. 5-82

Care of Safety Belts

...................................... 5-85

Weatherstrips ............................................... 5.85

Cleaning the Outside of Your Vehicle .............. 5-85

Sheet Metal Damage

..................................... 5.87

Finish Damage

............................................. 5.87

Underbody Maintenance

................... ...... 5.87

Chemical Paint Spotting

................................. 5.88

Vehicle Identification ..................................... 5-90

Vehicle Identification Number (VIN)

...... ., ...... 5-90

Service Parts Identification Label

........ ...... 5-90

Electrical System ............................... ...... 5-91

Add-on Electrical Equipment

................ , ...... 5-91

Headlamp Wiring

.......................................... 5-91

Windshield Wiper Fuses

................................ 5-91

Power Windows and Other Power Options

....... 5-91

Fuses and Circuit Breakers

............................ 5-92

Removing the Rear Seat Cushion

................... 5-95

Capacities and Specifications ........................ 5-100

Normal Maintenance Replacement Parts ......... 5-101

GM Vehicle Care/Appearance Materials .......... 5.88

5-2

Page 303 of 418

Notice: Continuing to drive with worn-out brake

pads could result in costly brake repair.

Some driving conditions or climates may cause a brake

squeal when the brakes are first applied or lightly

applied. This does not mean something

is wrong with

your brakes.

Properly torqued wheel nuts are necessary to help

prevent brake pulsation. When tires are rotated, inspect

brake pads for wear and evenly tighten wheel nuts in

the proper sequence to GM torque specifications.

Brake linings should always be replaced as complete

axle sets.

See

Brake System Inspection on page 6-23.

Brake Pedal Travel

See your dealer if the brake pedal does not return to

normal height, or

if there is a rapid increase in

pedal travel. This could be a sign of brake trouble.

Brake Adjustment

Every time you apply the brakes, with or without the

vehicle moving, your brakes adjust for wear.

Replacing Brake System Parts

The braking system on a vehicle is complex. Its many

parts have to be of top quality and work well together

if

the vehicle is to have really good braking. Your

vehicle was designed and tested with top-quality GM

brake parts. When you replace parts of your braking

system

- for example, when your brake linings

wear down and you need new ones put in

- be sure

you get new approved GM replacement parts.

If

you don’t, your brakes may no longer work properly. For

example,

if someone puts in brake linings that are

wrong for your vehicle, the balance between your front

and rear brakes can change

- for the worse. The

braking performance you’ve come to expect can change

in many other ways

if someone puts in the wrong

replacement brake parts.

Battery

Your new vehicle comes with a maintenance free

ACDelco@ battery. When it’s time for a new battery, get

one that has the replacement number shown on the

original battery’s label. We recommend an ACDelco

battery.

Warning: Battery posts, terminals and related

accessories contain lead and lead compounds,

chemicals known to the State of California to cause

cancer and reproductive harm. Wash hands after

handling.

5-44

Page 311 of 418

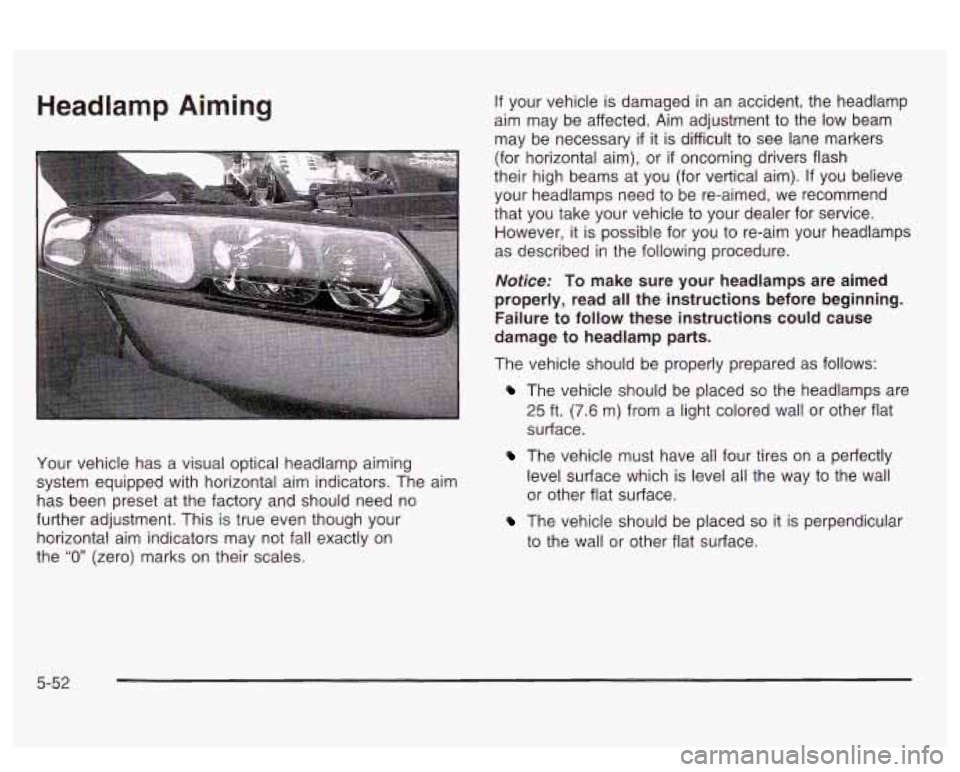

Headlamp Aiming

Your vehicle has a visual optical headlamp aiming

system equipped with horizontal aim indicators. The aim

has been preset at the factory and should need no

further adjustment. This is true even though your

horizontal aim indicators may not fall exactly on

the

“0” (zero) marks on their scales.

If your vehicle is damaged in an accident, the headlamp

aim may be affected. Aim adjustment to the

low beam

may be necessary

if it is difficult to see lane markers

(for horizontal aim), or

if oncoming drivers flash

their high beams at you (for vertical aim).

If you believe

your headlamps need to be re-aimed, we recommend

that you take your vehicle to your dealer for service.

However, it is possible for you to re-aim your headlamps

as described in the following procedure.

Notice: To make sure your headlamps are aimed

properly, read all the instructions before beginning.

Failure

to follow these instructions could cause

damage to headlamp parts.

The vehicle should be properly prepared as follows:

The vehicle should be placed so the headlamps are

25 ft. (7.6 m) from a light colored wall or other flat

surface.

The vehicle must have all four tires on a perfectly

level surface which is level all the way to the wall

or other flat surface.

The vehicle should be placed so it is perpendicular

to the wall or other flat surface.

5-52

Page 312 of 418

0 The vehicle should not have any snow, ice or mud

attached to it.

* The vehicle should be fully assembled and all other

work stopped while headlamp aiming is being done.

0 The vehicle should be normally loaded with a

full tank of fuel and one person or

160 Ibs. (75 kg)

on the driver’s seat.

Tires should be properly inflated.

Headlamp aiming is done with the vehicle low beam

lamps. The high beam lamps will be correctly aimed

if

the low beam lamps are aimed properly. The

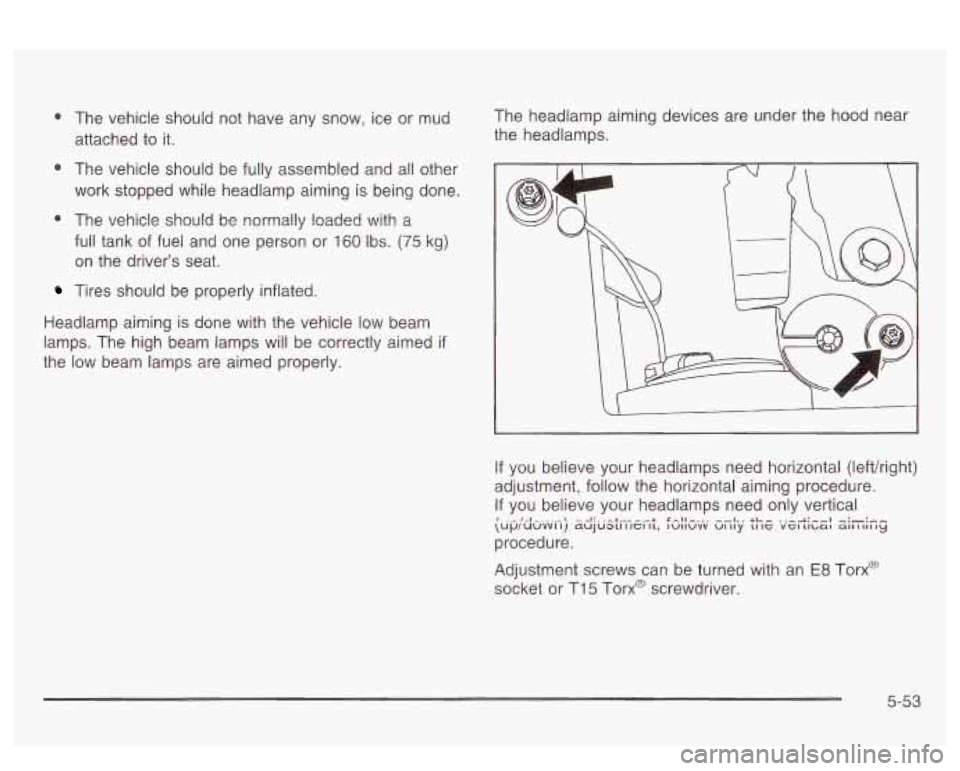

headlamp aiming devices are under the hood near

the headlamps.

If you believe your headlamps need horizontal (lefthight)

adjustment, follow the horizontal aiming procedure.

If you believe your headlamps need only vertical

procedure.

\Up/UUvvl I) ~UJU~CI I IGI 11, IUIIUVV UI IIY LI IC VGI Llbat all I 111 IY I 1-1 --l:..-L---L x-II ^.., --I., +I..^ .,-&:--I -:-:--

Adjustment screws can be turned with an E8 Torx@

socket or

Ti 5 Torx@ screwdriver.

5-53

Page 321 of 418

Tires

Your new vehicle comes with high-quality tires made by

a leading tire manufacturer.

If you ever have questions

about your tire warranty and where to obtain service,

see your

P tiac Warranty booklet for details.

Poorly maintained and improperly used

Overloading your tires can cause

tires are dangerous.

overheating as a result of too much

friction. You could have an air-out and a

serious accident. See ”Loading Your

Vehicle”

in the Index.

Underinflated tires pose the same danger

as overloaded tires. The resulting accident

could cause serious injury. Check all tires

frequently to maintain the recommended

pressure. Tire pressure should be checked

when your tires are cold.

CAUTION: (Continued)

Overinflated tires are more likely be

cut, punctured or broken by a sudden impact

- such as when you hit a pothole.

Keep tires at the recommended pressure.

If your tread is badly worn, or if your tires

have been damaged, replace them. See

”Inflation

- Tire Pressure” in this section

for inflation pressure adjustment for higher

speed driving.

Worn, old tires can cause accidents.

Inflation -- Tire Pressure

The Tire-Loading Information label, which is on the rear

edge of the driver’s door, shows the correct inflation

pressures for your tires when they’re cold.

“Cold” means

your vehicle has been sitting for at least three hours

or driven no more than

1 mile (1.6 km).

If you’ll be driving at high speeds (e.g., speeds

of

100 mph (160 km/h) or higher), where it is legal,

set the cold inflation pressure to the maximum

inflation pressure shown on the tire sidewall, or

to

35 psi (244 kPa), whichever is lower.

5-62

Page 322 of 418

See the example below. When you end this high-speed

driving, return to the cold inflation pressure shown on

the Tire-Loading Information label.

Example:

You’ll find maximum load and inflation pressure molded

on the tire’s sidewall, in small letters near the rim

flange. It will read something like this: Maximum load

690

kg (1521 Ibs) @ 300 kPa (44 psi) Max. Press.

For this example, you would set the inflation pressure

for high-speed driving at

35 psi (244 kPa).

Notice: Don’t let anyone tell you that underinflation

or overinflation

is all right. It’s not. If your tires

don’t have enough air (underinflation), you can get

the following:

Too much flexing

Too much heat

Tire overloading

Bad wear

Bad handling

Bad fuel economy

If your tires have too much air (overinflation), you

can get the following:

Unusual wear

Bad handling

Rough ride

Needless damage from road hazards

When to Check

Check your tires once a month or more.

Don’t forget your compact spare tire. It should be at

60 psi (420 kPa).

How to Check

Use a good quality pocket-type gage to check tire

pressure. You can’t tell

if your tires are properly inflated

simply by looking at them. Radial tires may look

properly inflated even when they’re underinflated.

Be sure to put the valve caps back

on the valve stems.

They help prevent leaks by keenin9 out dirt and

moisture.

5-63

Page 323 of 418

Check Tire Pressure System

The check tire pressure system can alert you to a large

change in the pressure of one tire. The system won’t

alert you before you drive that a tire is low or flat.

You must begin driving before the system will work

properly.

The CHECK TIRE PRESSURE message will appear on

the Driver Information Center (DIC) or the system

monitor TIRE PRESS light will come on

if pressure

difference (low pressure) is detected in one tire.

The check tire pressure system may not alert you

if:

more than one tire is low,

the vehicle is moving faster than 65 mph (105 km/h),

the system is not yet calibrated,

the compact spare tire is installed,

the tire treadwear is uneven,

tire chains are being used, or

the vehicle is being driven on a rough or

frozen road. If

the anti-lock brake system warning light comes on,

the check tire pressure system may not be working

properly. See your dealer for service. Also, see

Anti-Lock Brake System Warning Light on page 3-43.

The check tire pressure system detects differences

in tire rotation speeds that are caused by changes in tire

pressure. The system can alert you about a low

tire

- but it doesn’t replace normal tire maintenance.

See

Tires on page 5-62.

When the CHECK TIRE PRESSURE message appears

on the Driver Information Center (DIC) or the systems

monitor TIRE PRESS light comes on, you should

stop as soon as you can and check all your tires for

damage. If a tire is flat, see

If a Tire Goes Flat on

page

5-72. Also check the tire pressure in all four tires

as soon as you can. See

Inflation -- Tire Pressure

on page

5-62.

Any time you adjust a tire’s pressure or have one or more

tires repaired or replaced, you’ll need to reset (calibrate)

the check tire pressure system. You’ll also need to reset

the system whenever you rotate the tires, buy new tires

and install or remove the compact spare.

Don’t reset the check tire pressure system without first

correcting the cause of the problem and checking

and adjusting the pressure in all four tires.

If you reset

the system when the tire pressures are incorrect,

the check tire pressure system will not work properly

and may not alert you when a tire is low

or high.

5-64

Page 324 of 418

To reset (calibrate) the system with a Driver Information

Center (DIC):

1.

2.

3.

4.

5.

Turn the ignition switch to ON.

Using the MODE and SELECT buttons, change the The system Completes

the calibration process during

DIC to display TIRE PRESSURE. driving. Calibration time

can take

45 to 90 minutes, ..,

Press and hold the RESET button for about five

seconds.

The display should change to read TIRE

PRESSURE RESET. If TIRE PRESSURE RESET

does not appear on the display after about five

seconds, see your dealer for service.

When you release the button after seeing the TIRE

PRESSURE RESET message, the display will

change to read TIRE PRESSURE NORMAL.

1.

2.

4. Release the TIRE PRESS RESET button and the

system should reset. The TIRE PRESS light will

go out.

To reset (calibrate) the system with a systems monitor:

n 3.

Turn the ignition switch to ON.

Press and hold the TIRE PRESS RESET button for

about five seconds.

should begin to flash.

If the TIRE PRESS light

does not begin to flash after about five seconds, see

your dealer for service.

TIL- TI~T nnr-nn I:-.LL -- LL- -..-.I.--- I I le I 1nc r ncaa II~I 11 VI I 11 IC ayatcl I 13 I I IUI IILUI

depending on your driving habits. After the system has

been calibrated, the system will alert the driver that

a tire is low, up to a maximum speed of

65 mph

(1 05 km/h).

Tire Inspection and Rotation

Tires should be rotated every 6,000 to 8,000 miles

(10 000 to 13 000 km).

Any time you notice unusual wear rotate your tires as

soon as possible and check wheel alignment. Also

check for damaged tires or wheels. See

When It Is Time

for New Tires on page 5-67 and Wheel Replacement

on page 5-69 for more information.

Tne purpose

oi reguiar rorarion is io acnieve more

uniform wear for all tires on the vehicle. The first rotation

is the most important. See “Part A: Scheduled

Maintenance Services,” in Section

6, for scheduled

rotation intervals.

5-65

Page 325 of 418

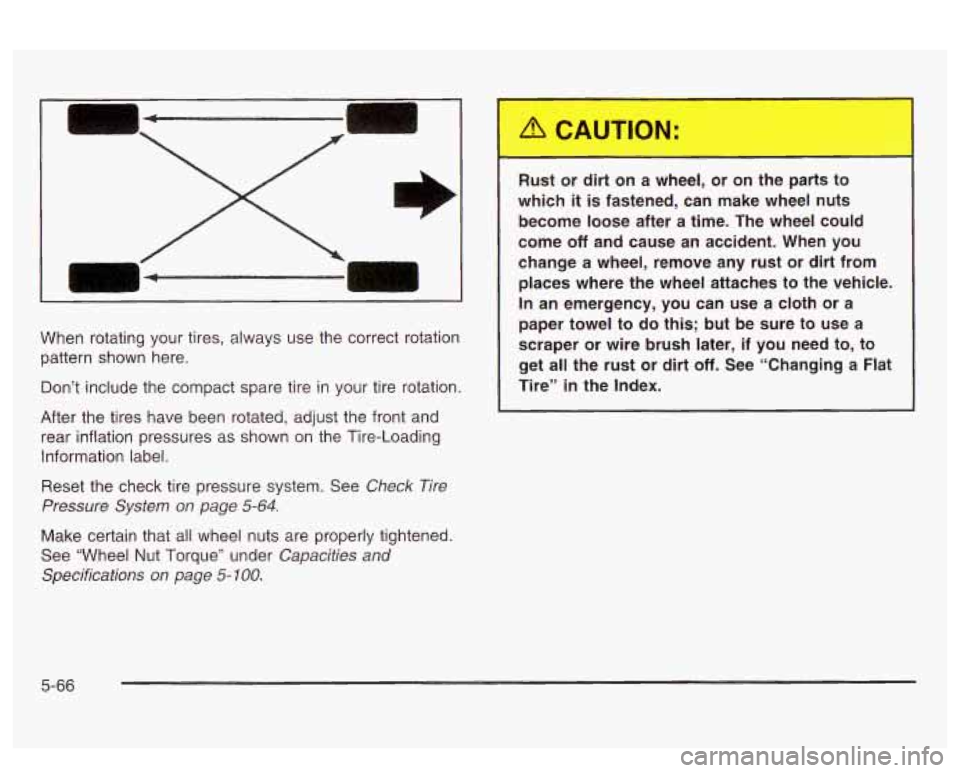

When rotating your tires, always use the correct rotation

pattern shown here.

Don’t include the compact spare tire in your tire rotation.

After the tires have been rotated, adjust the front and

rear inflation pressures as shown on the Tire-Loading

Information label.

Reset the check tire pressure system. See

Check Tire

Pressure System on page

5-64.

Make certain that all wheel nuts are properly tightened.

See “Wheel Nut Torque” under

Capacities and

Specifications on page

5- 100.

Rust or dirt on a wheel, or on the parts to

which

it is fastened, can make wheel nuts

become loose after a time. The wheel could

come

off and cause an accident. When you

change a wheel, remove any rust or dirt from

places where the wheel attaches to

the vehicle.

In an emergency, you can use a cloth or a

paper towel to do this; but be sure to use a

scraper or wire brush later, if you need

to, to

get all the rust or dirt

off. See “Changing a Flat

Tire”

in the Index.

5-66