fuel filter location PONTIAC FIERO 1988 Service Repair Manual

[x] Cancel search | Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 20 of 1825

F CARLINE

ITEM 10

TransmissionRransaxle Service

The manual transmission or transaxle fluid does not

require changing. (Corvette only.) Change fluid in over-

drive unit every 30,000 miles (50 000 km).

For automatic transmissions or transaxles, change

both the fluid and filter every 15,000 miles (25 000 km) if

the car is mainly driven under one or more of these

conditions:

@ In heavy city traffic where the outside temperature

regularly reaches 90°F (32°C) or higher.

@ In hilly or mountainous terrain.

@ Frequent trailer pulling.

@ Uses such as found in taxi, police car or delivery

service.

If you do not use your car under any of these condi-

tions, change both the fluid and filter every 100,000 miles

(160 000 km). See you Owner's Manual for further

details.

ITEM 11

Spark Plug Service*

Replace spark plugs with type listed in your Owner's

Manual.

ITEM 12

Spark Plug Wire Inspection*

Clean wires and inspect for burns, cracks or other dam-

age. Check the wire boot fit at distributor and at spark plugs.

Replace wires as needed.

ITEM 13

Positive Crankcase Ventilation (PCV) Valve

Inspection*

Inspect valve for proper function. Replace valve if

necessary as well as any worn, plugged or collapsed

hoses.

ITEM 14

EGR System Service*

Conduct EGR System Service as referenced in the

EGR System Chart shown in the appropriate 6E Section.

Also, refer to your GM maintenance schedule booklet for

specific applications.

ITEM 15

Air Cleaner and PCV Filter Replacement*

On 1.6 and 2.0 liter engines, replace every 50,000

miles (80 000 km). On all other engines, replace every

30,000 miles (50 000 km). Replace more often under

dusty conditions. Ask your dealer for the proper replace-

ment interval for your driving conditions.

MAINTENANCE AND LUBRICATION 08-3

ITEM 16

Engine Timing Check*

Adjust timing to underhood label specifications. If

no specifications are shown, no adjustment is needed.

ITEM 17

Fuel Tank, Cap and Lines Inspection*

Inspect fuel tank, cap and lines (including fuel rails

and injection assembly, if so equipped) for damage or

leaks. Inspect fuel cap gasket for an even filler neck

imprint or any damage. Replace parts as needed.

ITEM 18

Thermostatically Controlled Air Cleaner

Inspection*

If your car is equipped, inspect all hoses and ducts

for proper hookup. Make sure valve works properly.

OWNER INSPECTIONS AND SERVICES

Listed below are inspections and services which

should be made by either you or a qualified technician at

the intervals shown to help ensure proper safety, emission

performance and dependability of your car. Take any

problems promptly to your dealer or another qualified

technician for service advice. Whenever repairs are neces-

sary, have them completed at once. For your safety and

that of others, any safety-related parts that could have

been damaged in an accident should be inspected and all

needed repairs should be done before operating your car.

Be sure to use the proper fluids and lubricants as shown in

Figure OB-2.

WHILE OPERATING YOUR VEHICLE

Automatic transmissionltransaxle shift indi-

cator operation - Make sure the indicator points to the

gear chosen.

Horn operation - Blow the horn occasionally to

make sure it works. Check all button locations.

I

Brake system operation -- Be alert to abnormal

sounds, increased brake pedal travel or repeated pulling to

one side when braking. Also, if a brake warning light

comes on or flashes, or the anti-lock warning light (if

equipped) comes on or remains on, something may be

wrong with part of the brake system. Have it inspected and

repaired at once.

Exhaust system operation - Be alert to any

changes in the sound of the system or any smell of fumes.

These are signs the system may be leaking or overheating.

.

Have it inspected and repaired at once. Also see "Engine

Exhaust Gas Caution (Carbon Monoxide)" and "Catalytic

Converter" in your Owner's Manual.

*An Emission Control Service

Page 434 of 1825

ENGINE FUEL 6C.3

a Fuel feed and return pipes are secured to the

underbody with clamps and screw assemblies.

The pipes should be inspected occasionally for

leaks, kinks or dents.

e Follow the same routing as the original pipe.

e Pipes must be properly secured to the frame to

prevent chafing. A minimum of 6 mm

(1/4")

clearance must be maintained around a pipe to

prevent contact and chafing.

MPFl Fuel Pipes

Due to the fact that fuel pipes are under high

pressure, these systems require special consideration for service.

Many feed and return pipes use screw couplings

with

"0" Rings. Any time these fittings are loosened

to service or replace components, ensure that:

a A backup wrench is used while loosening and

tightening the fitting.

e Check all "0" rings at fitting locations (if

applicable) for cuts or any damage and replace

any that appear worn or damaged.

e Use correct torque when tightening fittings.

If pipes are replaced always use original

equipment parts, or parts that meet GM

specifications.

Fuel and Vapor Hoses

NOTICE: Fuel and vapor hoses are specially

manufactured. If replacement becomes necessary,

it is important to use only replacement hoses

meeting GM Specification 6163-M. These hoses

are identified with the words "Fluoroelastomer"

on them. Hoses not so marked could cause early

failure, or fail to meet emission standards.

e Do not use rubber hose within 4" of any part of

the exhaust system, or within

10" of the catalytic

converter.

FUEL PUMP

The electric fuel pump is in the fuel tank. The

tank has an outlet for a vapor return system. Any vapor

which forms is returned to the fuel tank along with hot

fuel through a separate line. This greatly reduces any

possibility of vapor lock by keeping cool fuel from the

tank constantly circulating through the fuel pump.

FUEL PUMP RELAY

To control fuel pump operation, a fuel pump

relay is used.

When the ignition switch is turned to "RUN"

position, the fuel pump relay activates the electric fuel

pump for

1.5 to 2.0 seconds to prime the injector(s). If

the ECM does not receive reference pulses from the

distributor after this time, the ECM signals the relay

to turn off the fuel pump. The relay will once again

activate the fuel pump when the

ECM receives

distributor reference pulses.

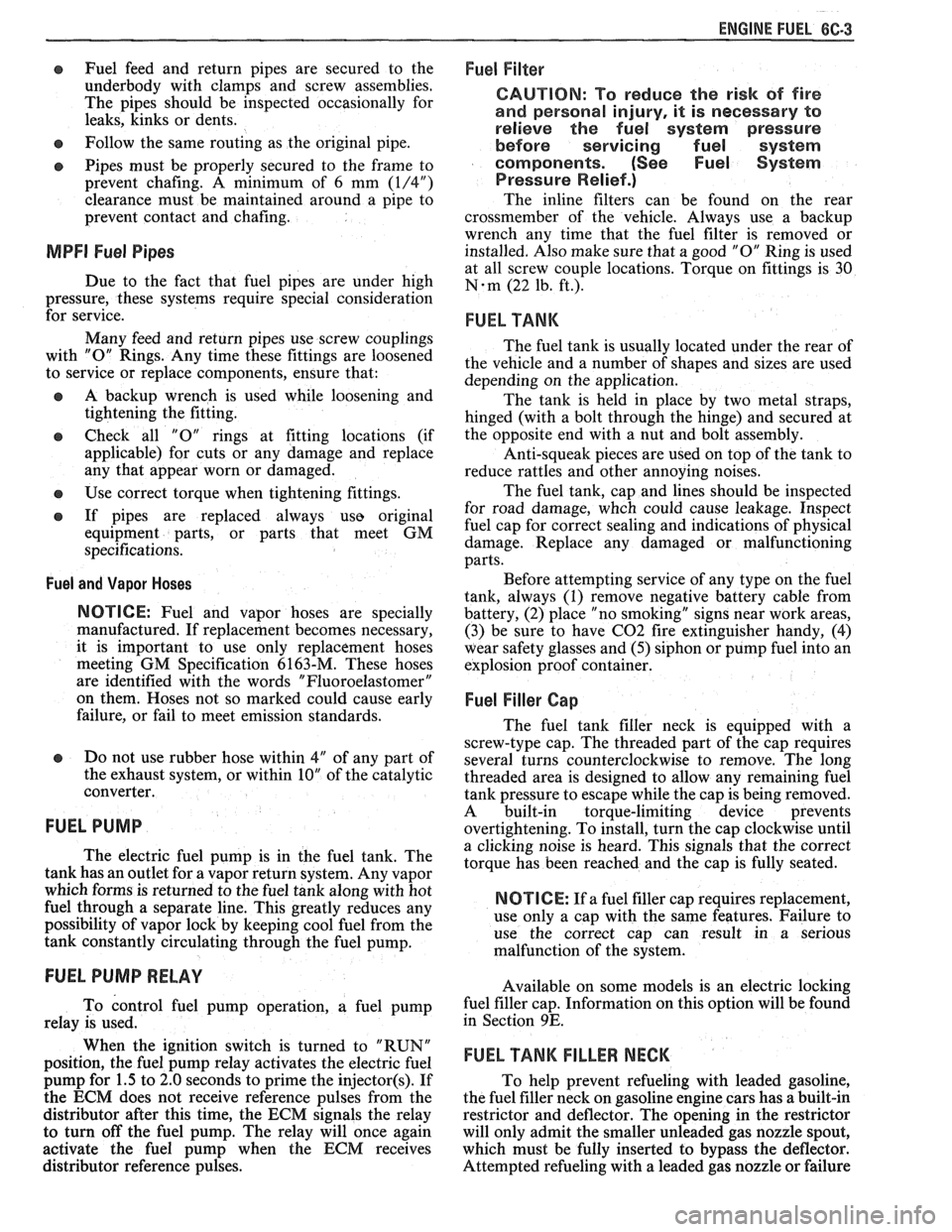

Fuel Filter

CAUTION: To reduce the risk of fire

and personal injury, it is necessary

to

relieve the fuel system pressure

before servicing fuel system

components. (See Fuel System

Pressure Relief.)

The inline filters can be found on the rear

crossmember of the vehicle. Always use a backup

wrench any time that the fuel filter is removed or

installed. Also make sure that a good

"0" Ring is used

at all screw couple locations. Torque on fittings is

30

N-m (22 lb. ft.).

FUEL TANK

The fuel tank is usually located under the rear of

the vehicle and a number of shapes and sizes are used

depending on the application.

The tank is held in place by two metal straps,

hinged (with a bolt through the hinge) and secured at

the opposite end with a nut and bolt assembly.

Anti-squeak pieces are used on top of the tank to

reduce rattles and other annoying noises.

The fuel tank, cap and lines should be inspected

for road damage, whch could cause leakage. Inspect

fuel cap for correct sealing and indications of physical

damage. Replace any damaged or malfunctioning

parts.

Before attempting service of any type on the fuel

tank, always

(1) remove negative battery cable from

battery, (2) place "no smoking" signs near work areas,

(3) be sure to have C02 fire extinguisher handy, (4)

wear safety glasses and

(5) siphon or pump fuel into an

explosion proof container.

Fuel Filler Gap

The fuel tank filler neck is equipped with a

screw-type cap. The threaded part of the cap requires

several turns counterclockwise to remove. The long

threaded area is designed to allow any remaining fuel

tank pressure to escape while the cap is being removed.

A built-in torque-limiting device prevents

overtightening. To install, turn the cap clockwise until

a clicking noise is heard. This signals that the correct

torque has been reached and the cap is fully seated.

N OTI G E: If a fuel filler cap requires replacement,

use only a cap with the same features. Failure to

use the correct cap can result in a serious

malfunction of the system.

Available on some models is an electric locking

fuel filler cap. Information on this option will be found

in Section

9E.

FUEL TANK FILLER NECK

To help prevent refueling with leaded gasoline,

the fuel filler neck on gasoline engine cars has a built-in

restrictor and deflector. The opening in the restrictor

will only admit the smaller unleaded gas nozzle spout,

which must be fully inserted to bypass the deflector.

Attempted refueling with a leaded gas nozzle or failure

Page 438 of 1825

ENGINE FUEL 6C-7

Fig. 3 Fuel Filter Location

1. FUEL 1 2. BRACKET I

I

3. "0" RING

Fig. 4 Fuel Filter

PULSATOR

LOSE0 CELL FOAM SOUND

ISOLATOR SLEEVE

FUELLEVEL SENDER ROLLER

VANE FUEL PUMP

RUBBER SOUND INSULATOR

FILTER STRAINER FUEL GAGE SENDING UNIT WITH FUEL PUMP

Fig. 5 Fuel Pump

Page 584 of 1825

DRIVEABILITY AND EMISSIONS - 5.OL (VIN El CEZ-C2-9

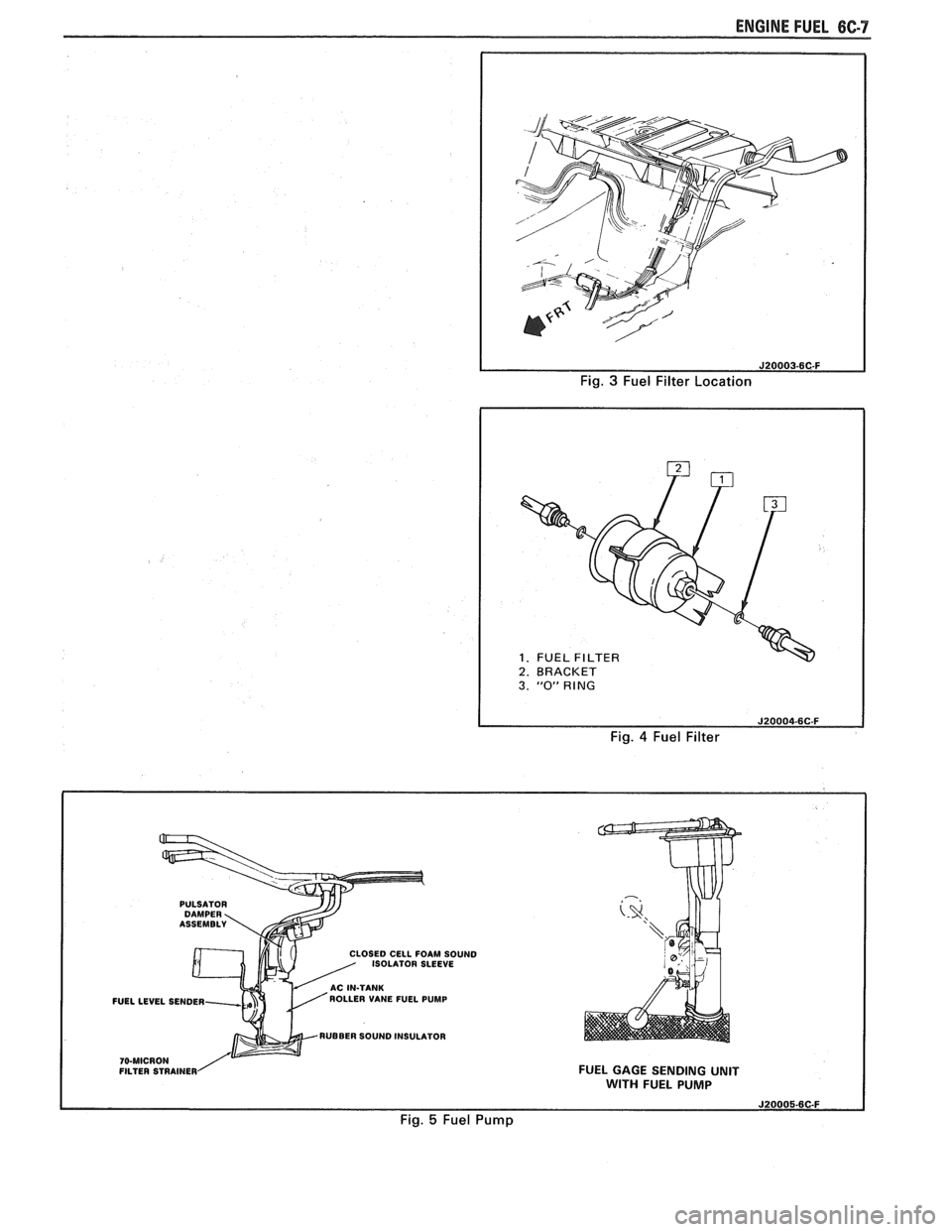

u PART IDENTIFICATION NUMBER

VENDOR IDENTlFlCATl

Figure C2-12 - Fuel Injector Part Number Location

Remove or Disconnect

lectrical connectors to fuel injectors. (Squeeze

plastic tabs and pull straight

up.)

2. Fuel meter

cover assembly following above

procedure.

3. With fuel meter cover gasket in place to prevent

damage to casting, use a screwdriver and fulcrum

to carefully lift out each injector (Figure

C2-11).

4. Lower (small) o-rings from nozzle of injectors and

discard.

5. Fuel meter cover gasket and discard.

6. Upper (large o-rings and steel backup washers

from top of each fuel injector cavity and discard.

Inspect

@ Fuel injector filter for evidence of dirt and

contamination.

If present, check for presence of

dirt in fuel lines and fuel tank.

Important

Be sure to replace the injector with an identical

part. Injectors from other models can fit in Model

220 TBI, but are calibrated for different flow rates.

(See Figure

C2-12 for part number location.)

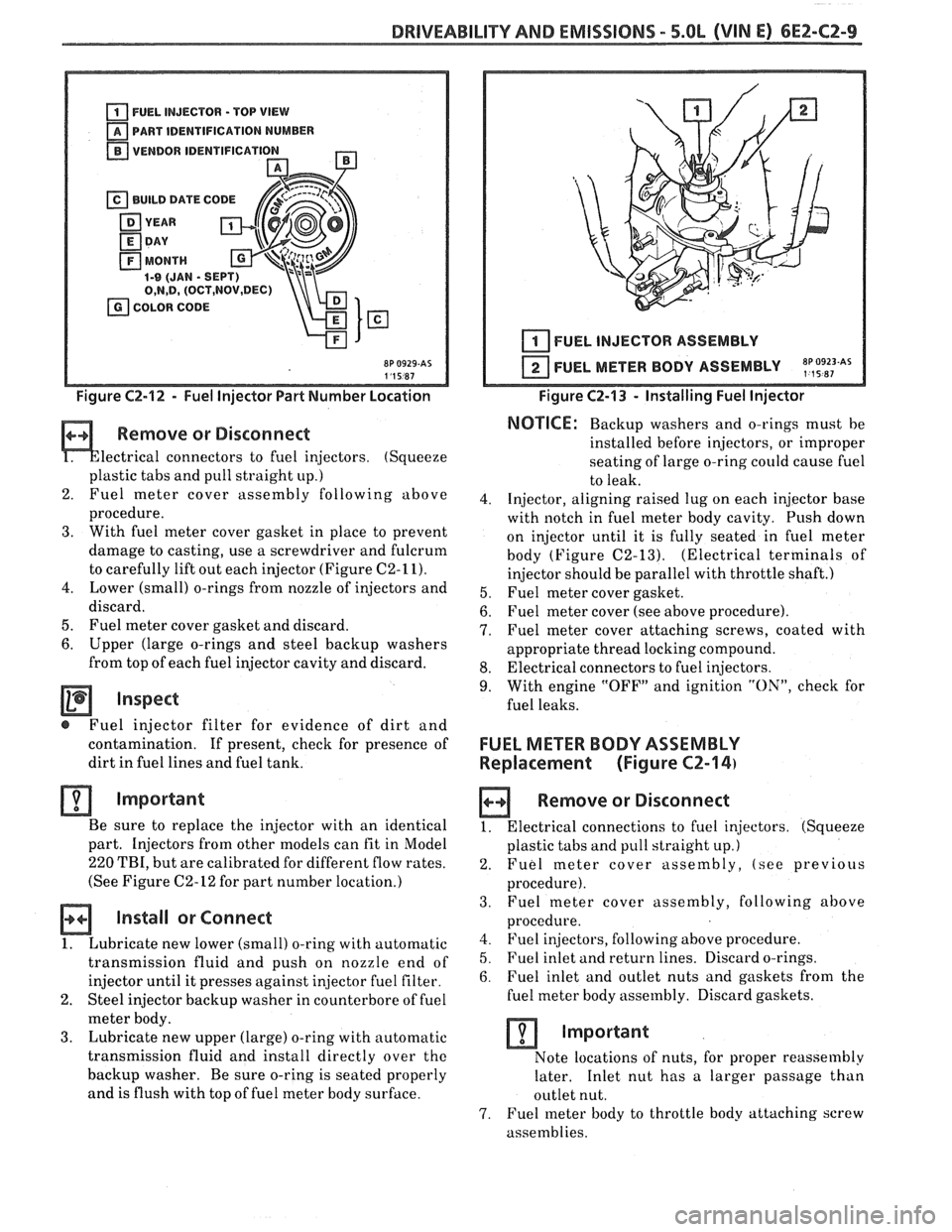

Install or Connect

1. Lubricate new lower (small) o-ring with automatic

transmission fluid and push on nozzle end of

injector until it presses against

in,jector fuel filter.

2. Steel injector backup washer in counterbore of fuel

meter body.

3. Lubricate new upper (large) o-ring with automatic

transmission fluid and install directly over

the

backup washer. Be sure o-ring is seated properly

and is flush with top of fuel meter body surface.

I I 1 I FUEL INJECTOR ASSEMBLY

FUEL METER BODY ASSEMBLY

~p,~9~~~As

Figure C2-13 - Installing Fuel Injector

NOTICE: Backup washers and o-rings must be

installed before injectors, or improper

seating of large o-ring

could cause fuel

to leak.

4. Injector, aligning raised lug on each injector base

with notch in fuel meter body cavity. Push down

on injector until it is fully seated in fuel meter

body (Figure

C2-13). (Electrical terminals of

injector should be parallel with throttle shaft.)

5. Fuel meter cover gasket.

6. Fuel meter cover (see above procedure).

7. Fuel meter cover attaching screws, coated with

appropriate thread locking compound.

8. Electrical connectors to fuel injectors.

9. With engine "OFF" and ignition "ON", check for

fuel leaks.

FUEL METER BODY ASSEMBLY

Replacement (Figure

CZ-14)

a Remove or Disconnect

1. Electrical connections to fuel injectors. (Squeeze

plastic tabs and pull straight up.)

2. Fuel meter cover assembly, (see previous

procedure).

3. Fuel

meter cover assembly, following above

procedure.

4. Fuel injectors, following above procedure.

5. Fuel inlet and return lines. Discard o-rings.

6. Fuel inlet and outlet nuts and gaskets from the

fuel meter body assembly. Discard gaskets.

Important

Note locations of nuts, for proper reassembly

later. Inlet nut has a larger passage than

outlet nut.

7. Fuel meter body to throttle body attaching screw

assemblies.

Page 649 of 1825

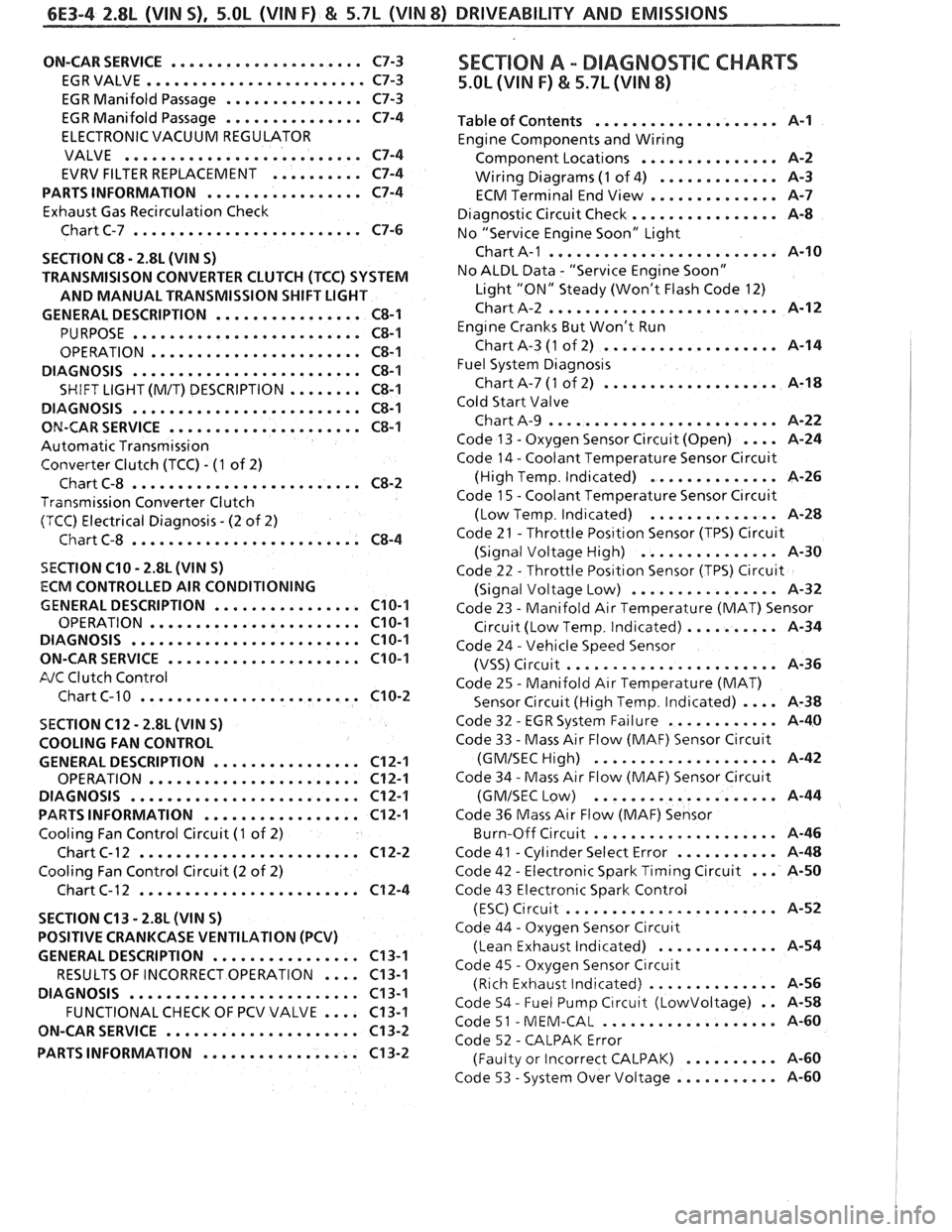

6E3-4 2.8L (VIN S) . 5.OL (VIN F) & 5.7L (VIN 8) DRIVEABILITY AND EMISSIONS

ON-CAR SERVICE ..................... C7-3

EGRVALVE

........................ C7-3

EGR Manifold Passage

............... C7-3

EGR Manifold Passage

............... C7-4

ELECTRONIC VACUUM REGULATOR

VALVE

.......................... C7-4

EVRV FILTER REPLACEMENT

.......... C7-4

PARTS INFORMATION

................. C7-4

Exhaust Gas Recirculation Check

Chart C-7

......................... C7-6

SECTION

C8 . 2.8L (VIN S)

TRANSMISISON CONVERTER CLUTCH (TCC) SYSTEM

AND MANUAL TRANSMISSION SHIFT LIGHT

GENERAL DESCRIPTION

................ C8-1

PURPOSE ......................... C8-1

OPERATION ....................... C8-1

DIAGNOSIS

......................... C8-1

SHIFT LIGHT (M/T) DESCRIPTION ........ C8-1

DIAGNOSIS

......................... C8-1

ON-CAR SERVICE ..................... C8-1

Automatic Transmission

Converter Clutch (TCC)

. (1 of 2)

Chart C-8

......................... C8-2

Transmission Converter Clutch

(TCC) Electrical Diagnosis

. (2 of 2)

Chart C-8

......................... C8-4

SECTION C10 . 2.8L (WIN S)

ECM CONTROLLED AIR CONDITIONING

GENERAL DESCRIPTION

................ C10-1

OPERATION ....................... C10-1

DIAGNOSIS ......................... C10-1

ON-CARSERVICE ..................... C10-1

FJC Clutch Control

Chart C-

1 0 ........................ C10-2

SECTION C12 . 2.8L (VlN S)

COOLING FAN CONTROL

GENERAL DESCRIPTION

................ C12-1

OPERATION ....................... C12-1

DIAGNOSIS

......................... C12-1

PARTS INFORMATION ................. C12-1

Cooling Fan Control Circuit (1 of 2)

Chart

C- 12 ........................ C12-2

Cooling Fan Control Circuit (2 of 2)

Chart C-12

........................ C12-4

SECTION C13

. 2.8L (WIN S)

POSITIVE CRANKCASE VENTILATION (PCV)

GENERAL DESCRIPTION

................ C13-1

RESULTS OF INCORRECT OPERATION

.... C13-1

DIAGNOSIS

......................... C13-1

FUNCTIONALCHECK OF PCV VALVE .... C13-1

ON-CAR SERVICE

..................... C13-2

PARTS INFORMATION

................. C13-2

SEC"T0N A . DIAGNOSTIC CHARTS

5.OL (VIN F) & 5.7L (VIN 8)

.................... Table of Contents A-1

Engine Components and Wiring

............... Component Locations A-2

Wiring Diagrams

(1 of 4) ............. A-3

ECM Terminal End View

.............. A-7

Diagnostic Circuit Check

................ A-8

No "Service Engine Soon" Light

......................... Chart A-1 A-10

No ALDL Data

. "Service Engine Soon"

Light "ON" Steady (Won't Flash Code 12)

Chart A-2

......................... A-12

Eng~ne Cranks But Won't Run

Chart A-3

(1 of 2) ................... A-14

Fuel System

Diagnos~s

Chart A-7 (1 of 2) ................... A-18

Cold Start Valve

Chart A-9

......................... A-22

Code 13

. Oxygen Sensor Circuit (Open) .... A-24

Code 14

. Coolant Temperature Sensor Circuit

(High Temp

. Indicated) .............. A-26

Code

1 5 . Coolant Temperature Sensor C~rcuit

. .............. (Low Temp Ind~cated) A-28

Code 21

. Throttle Pos~tlon Sensor (TPS) Circuit

(Signal Voltage High)

............... A-30

Code 22

. Throttle Pos~t~on Sensor (TPS) Circuit

................ (Signal Voltage Low) A-32

Code 23

. Manifold Air Temperature (MAT) Sensor

C~rcuit (Low Temp . Indicated) .......... A-34

Code 24

. Vehicle Speed Sensor

....................... (VSS) Circuit A-36

Code 25

. Manifold Air Temperature (MAT)

Sensor Circuit (High Temp

. Indicated) .... A-38

. ............ Code 32 EGR System Failure A-40

Code 33

. Mass Air Flow (MAF) Sensor Circuit

.................... (GMISECHlgh) A-42

Code 34

. Mass Air Flow (MAF) Sensor Circu~t

.................... (GMISEC Low) A-44

Code 36 Mass Air Flow

(MAF) Sensor

.. ..... ........... Burn-Off Circuit , , A-46

. ........... Code 41 Cyl~nder Select Error A-48

... . Code 42 Electronic Spark Timing Circuit A-50

Code 43 Electronic Spark Control

(ESC)

C~rcuit ....................... A-52

Code 44

. Oxygen Sensor Circu~t

(Lean Exhaust lnd~cated) ............. A-54

Code 45

. Oxygen Sensor Circuit

(Rich Exhaust Indicated)

.............. A-56

Code 54

. Fuel Pump C~rcuit (Lowvoltage) . . 14-58

. ................... Code 51 MEM-CAL A-60

Code 52

. CALPAK Error

.......... (Faulty or Incorrect CALPAK) A-60

. ........... Code 53 System Over Voltage A-60

Page 984 of 1825

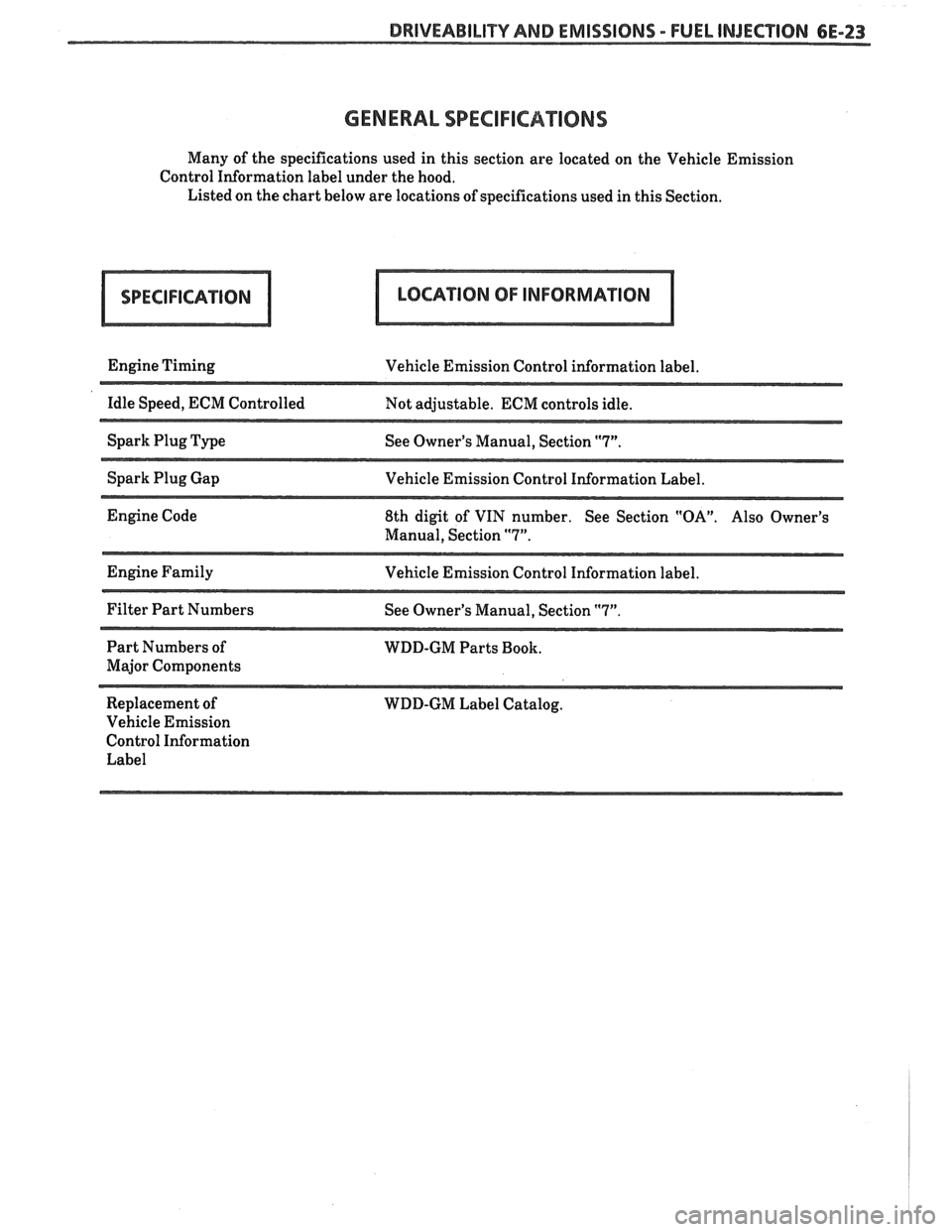

DRIVEABILITY AND EMISSIONS - FUEL INJECTION 6E-23

GENERAL SPECIFICA"I0NS

Many of the specifications used in this section are located on the Vehicle Emission

Control Information label under the hood.

Listed on the chart below are locations of specifications used in this Section.

Engine Timing

Vehicle Emission Control information label.

--

Idle Speed, ECM Controlled

Not adjustable. ECM controls idle.

Spark Plug Type

See Owner's Manual, Section

"7".

Spark Plug Gap

Vehicle Emission Control Information Label.

Engine Code

8th digit of VIN number. See Section

"OA". Also Owner's

Manual, Section

"7".

Engine Family

Vehicle Emission Control Information label.

Filter Part Numbers

See Owner's Manual, Section

"7".

Part Numbers of

WDD-GM Parts Book.

Major Components

Replacement of WDD-GM Label Catalog.

Vehicle Emission

Control Information Label