trunk PONTIAC FIERO 1988 Service Repair Manual

[x] Cancel search | Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 21 of 1825

OB-4 MAINTENANCE AND LUBRICATION

Tire and wheel operation - Be alert to a vibra-

tion of the steering wheel or seat at normal highway

speeds. This may mean a wheel balance is needed. Also, a

pull right or left on a straight, level road may show the

need for

a tire pressure adjustment or wheel alignment.

Steering system operation - Be alert to

changes in steering action. An inspection is needed when

the steering wheel is harder to turn or has too much free

play or if unusual sounds are noted when turning or

parking.

Headlight aim operation - Take note of light

pattern occasionally. If beam aim doesn't look right,

headlights should be adjusted.

AT EACH FUEL FILL

Engine oil level check - Check engine oil level

and add if necessary. See your Owner's

Manual for further

details.

NOTICE: A large loss in this system may indicate a

problem. Have it inspected and repaired at once.

Engine coolant level and condition - Check

engine coolant level in coolant reservoir tank and add if

necessary. Replace if dirty or rusty. See your Owner's

Manual for further details.

NOTICE: A large loss in this system may indicate a

problem. Have it inspected and repaired at once.

Windshield washer fluid level check -- Check

washer fluid level in container and add if necessary.

Hood latch operation - When opening hood on

cars equipped with hoods that open from the front, note

the operation of secondary latch. It should keep hood from

opening all the way when primary latch is released. Make

sure that hood closes firmly.

AT LEAST MONTI-ILY

Tire and wheel inspection and pressure

check--

Check tires for abnormal wear or damage. Also,

check for damaged wheels. Keep pressures as shown on

Tire Placard on the driver's door (include spare unless it is

a stowaway). Pressure should b\: checked when tires are

"cold". See "Tires" in Owner's Manual for further

infomation.

Light operation check - Check operation of

license plate light, side-marker lights, headlights includ-

ing high beams, parking lights, taillights, brake lights.

turn signals, backup lights, instrument panel and interior

lights and hazard warning flashers.

Fluid leak check - After the car has been parked

for a while, inspect the surface beneath the car for water,

oil, fuel or other fluids. Water dripping from the air

conditioning system after use is normal. If you notice fuel

leaks or fumes, the cause should be found and corrected at

once.

AT LEAST TWICE A YEAR (FOR EXAMPLE,

EVERY SPRING AND FALL)

Power steering pump fluid level check --

Check power steering pump fluid level in accordance with

Owner's Manual instructions and keep at proper level.

NOTICE: A large loss in this system may indicate a

problem. Have it inspected and repaired at once.

Brake master cylinder reservoir fluid level

check ---- Check fluid and keep at proper level. Note: It is

normal for the brake fluid level to go down slightly as the

brake pads wear

- so be sure to keep reservoir filled.

NOTICE: A large loss in this system may indicate a

problem. Have

it inspected and repaired at once.

Clutch system service --- manual transmis-

sionltransaxle --- For cars equipped with hydraulic

clutch system, check the reservoir fluid level and add fluid

as required. All others, check clutch pedal free travel and

adjust as necessary. See your Owner's Manual for further

details.

~

NOTICE: A large loss in this system may indicate a

problem. Have it inspected and repaired at once.

Weatherstrip Lubrication - Clean surface and

then apply a thin film of silicone grease with a clean cloth.

EACH TIME OIL IS CHANGED

Automatic and manual transmissionltrans-

axle fluid level check - Check transmission/transaxle

fluid level and add as required. (Corvette only) if equipped

with manual transmission

- check fluid in the overdrive

unit and add as required.

NOTICE: A large loss in this system may indicate a

problem. Have

it inspected and repaired at once.

Brake systems inspection - For convenience,

the following should be done when wheels are removed

for rotation: Inspect lines and hoses for proper hookup,

binding, leaks, cracks, chafing, etc. Inspect disc brake

pads for wear and rotors for surface condition. Also in-

spect drum brake linings for wear and cracks. Inspect

other brake parts, including drums, wheel cylinders, park-

ing brake, etc. at the same time. Check parking brake

adjustment.

INSPECT BRAKES MORE OFTEN IF DRIVING

HABITS OR CONDITIONS RESULT IN FREQUENT

BRAKING.

Steering, suspension and front drive axle

boot and seal inspection

- Inspect front and rear

suspension and steering system for damaged, loose or

missing parts, signs of wear or lack of lubrication. Inspect

power steering lines and hoses for proper hookup, bind-

ing, leaks, cracks, chafing, etc. (On cars equipped with

manual steering gear, check for seal leakage.) On

front-

wheel-drive cars, clean then inspect drive axle boot seals

for damage, tears or leakage. Replace seals if necessary.

Exhaust system inspection - Inspect complete

system. Inspect body near the exhaust system. Look for

broken, damaged, missing or out-of-position parts as well

as open seams, holes, loose connections or other condi-

tions which could cause a heat buildup in the tloor pan or

could let exhaust fumes seep into the trunk or passenger

compartment.

Page 117 of 1825

2C-10 CHASSIS SHEET METAL

ROCKER PANEL AIR DEFLECTOR

Remove or Disconnect

1. Five top screws (#I).

2. Hoist car.

3. Seven bolts holding rocker panel rubber

air

deflector

(#2) and remove.

4. Seven screws holding rocker deflector to bottom

of rocker panel

(#3).

5. Two screws holding rear rocker deflector to rear

wheel opening

(#4).

6. Five

push type fasteners at the lower rear of the

wheel well splash shield, lift shield to gain

access to the two forward nuts.

7. Two nuts (#5) from rocker deflector front to

fender.

8. Rocker deflector.

9. Nine screws holding rocker panel deflector

support.

10. Support.

Install or Connect

To install, reverse removal procedure.

REAR BUMPER FASCIA EXTENSION

Remove or Disconnect

1. Hoist car,

2. Drill out

eight fascia extension to fascia rivets

(#I) (four each side). Four

bolts from fascia extension to lower quar-

ter panel

(#2).

Five (each side) push clips from fascia to sup-

port

(443).

Four screws from rear fascia extension to fender

(#4).

Lower car.

Right side trunk trim and spare tire.

Rear trim panel.

Left trim panel.

Right and left side fascia and fascia extension

nuts (six each side)

(#5).

Right and left tail lamp wing nuts and remove

housing.

Seven fascia push nuts and disconnect electrical

connector for license plate

(#6).

Rear bumper fascia from car.

Twelve (six each side) fascia extension to fascia

retaining nuts and remove fascia extension

(#7).

Install or Connect

To install, reverse removal procedure.

Page 986 of 1825

EXHAUST SYSTEM 6F-1

SEC"B0N 6F

EXHAUST SYSTEM

CAUTION: Exhaust system components should avoid overheating and possible damage to the

have enough clearance from the underbody to passenger compartment carpets.

................................. General Description 6F- 1 Hanger ............................................................ 6F- I

..................... ....................... Exhaust Pipe .. 6F- I Clamp ............................................................ 6F- I

Muffler .......................................................... 6F- 1 Catalytic Converter ......................................... 6F- 1

.......................... Resonator ........................... .. 6F- 1

GENERAL DESGRIP"F0N

When inspecting or replacing exhaust system

components, make sure there is adequate clearance

from all points on the underbody to avoid possible

overheating of the floor pan and possible damage to the

passenger compartment insulation and trim materials.

Check complete exhaust system and nearby body

areas and trunk lid for broken, damaged, missing or

mispositioned parts, open seams, holes, loose

connections or other deterioration which could permit

exhaust fumes to seep into the trunk or passenger

compartment. Dust or water in the trunk may be an

indication of a problem in one of these areas. Any

defects should be corrected immediately. To help

insure continued integrity, the exhaust system pipe

qever a

rearward of the muffler must be replaced whe.-

new muffler is installed.

EXHAUST PlPE

The exhaust manifold to crossover pipe

connections are of the ball type, thus eliminating the

need for gaskets.

MUFFLER

The mufflers are a tri-flow design. Some muffler

installations have a slot in the inlet and/or outlet pipe

which indexes to a key (tab) welded on the exhaust

and/or tail pipe to help maintain alignment.

RESONATOR

A resonator is used on some series exhaust

systems. It allows the use of mufflers with less back

pressure and provides for optimum tuning

characteristics of the exhaust system. The

installation of exhaust system supports is

very important as improperly installed supports can

cause annoying vibrations which are difficult to

diagnose.

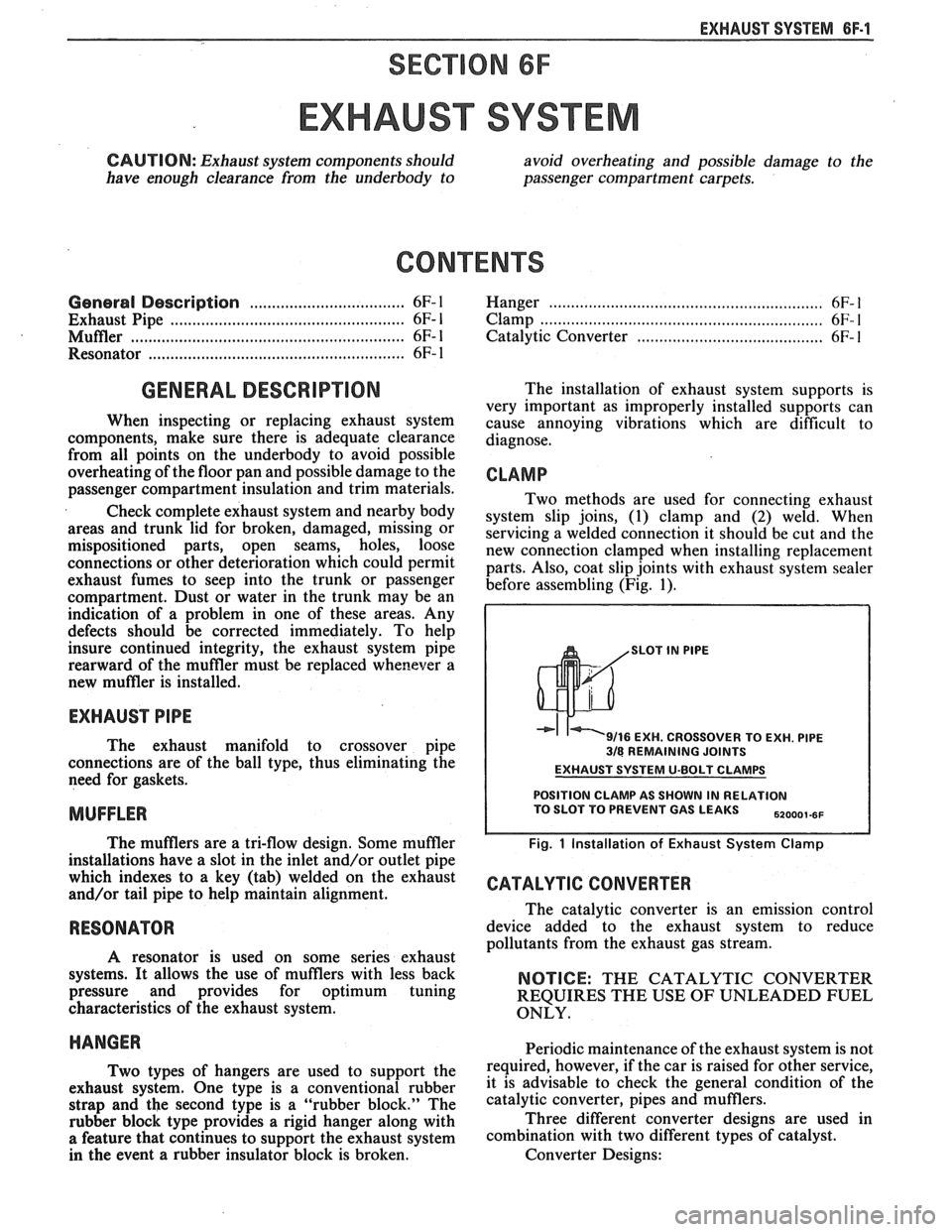

CLAMP

Two methods are used for connecting exhaust

system slip joins, (1) clamp and

(2) weld. When

servicing a welded connection it should be cut and the

new connection clamped when installing replacement

parts. Also, coat slip joints with exhaust system sealer

before assembling (Fig. 1).

SLOT IN PlPE

9/16 EXH. CROSSOVER TO EXH. PlPE 318 REMAINING JOINTS

EXHAUST SYSTEM U-BOLT CLAMPS

POSITION CLAMP AS SHOWN IN RELATION TO SLOT TO PREVENT GAS LEAKS ,,ooo,.,,

Fig. 1 Installation of Exhaust System Clamp

CATALYTIC CONVERTER

The catalytic converter is an emission control

device added to the exhaust system to reduce

pollutants from the exhaust gas stream.

NOTICE: THE CATALYTIC CONVERTER

REQUIRES THE USE OF UNLEADED FUEL

ONLY.

HANGER Periodic maintenance of the exhaust system is not

T~~ types of hangers are used to support the required, however, if the car is raised for other service,

exhaust system. one type is a conventional rubber it is advisable to check the general condition of the

strap and the second type is a "rubber block." The catalytic converter, pipes and mufflers.

rubber block type provides a rigid hanger along with Three

different converter designs are used in

a feature that continues to support the exhaust system combination with two different types of catalyst.

in the event a rubber insulator block is broken. Converter Designs:

Page 1434 of 1825

DRIVER INFORMATION CENTER (DIC)

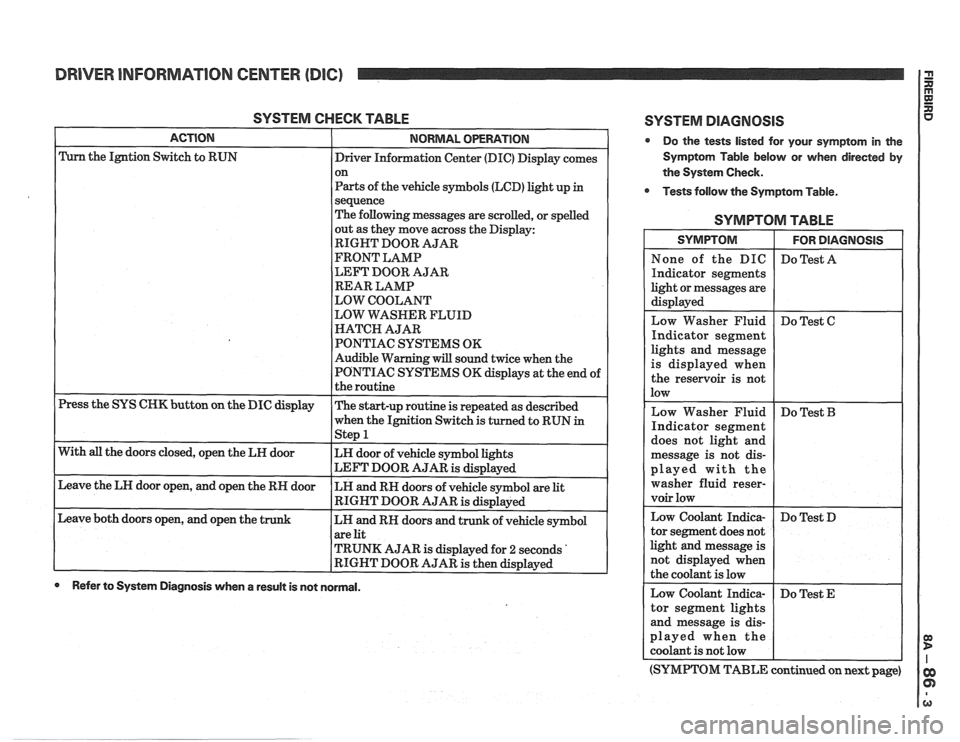

SYSTEM CHECK TABLE

ACTION NORMAL OPERATION

Press the SYS CHK button on the DIC display

With

all the doors closed, open the LH door

Leave the LH door open, and open the RH door

Leave both doors open, and open the

t

Driver Information Center (DIC) Display comes

on

Parts of the vehicle symbols (LCD) light up

in

sequence

The following messages are scrolled, or spelled

out as they move across the Display:

RIGHT DOOR AJAR

FRONT LAMP

LEFT DOOR AJAR

REAR LAMP

LOW COOLANT

LOW WASHER FLUID

HATCH AJAR

PONTIAC SYSTEMS OK

Audible Warning will sound twice when the

PONTIAC SYSTEMS OK displays at the end of

the routine

The start-up routine is repeated as described

when the Ignition Switch is turned to RUN

in - Step 1

LH door of vehicle symbol lights

LEFT DOOR AJAR

is displayed

LH and RH doors of vehicle symbol are

lit

RIGHT DOOR AJAR is displayed

LH and RH doors and trunk of vehicle symbol

are lit

TRUNK AJAR is displayed for

2 seconds '

RIGHT DOOR AJAR is then displayed

0 Refer to System Diagnosis when a result is not normal.

SYSTEM DlAGNOSlS

Do the tests listed for your symptom in the

Symptom Table below or when directed by

the System Check.

Tests follow the Symptom Table.

SYMPTOM TABLE

ights and message

s displayed when

he reservoir is not

ed with the

er fluid

reser-

(SYMPTOM TABLE continued on next page)

Page 1436 of 1825

DRIVER INFORMATION CENTER (DIC)

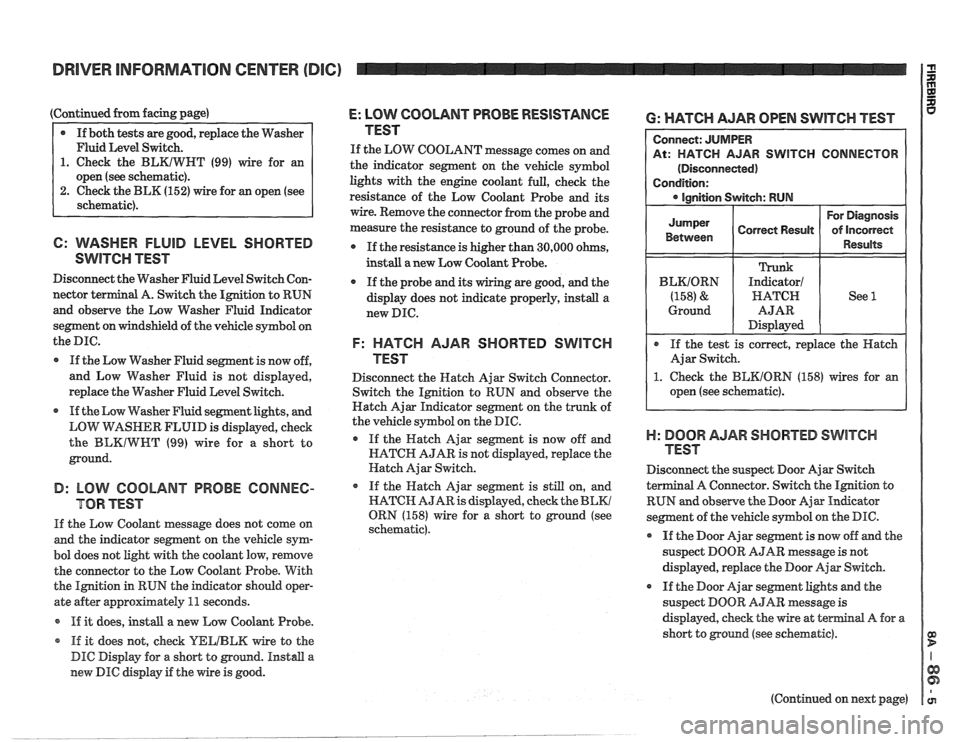

(Continued from facing page)

@ If both tests are good, replace the Washer

Fluid Level Switch.

1. Check the BLKIWHT (99) wire for an

open (see schematic).

2. Check the BLK (152) wire for an open (see

schematic).

6: WASHER FLUID LEVEL SHORTED

SwlTen TEST

Disconnect the Washer Fluid Level Switch Con-

nector

terminal A. Switch the Ignition to RUN

and observe the Low Washer Fluid Indicator

segment on windshield of the vehicle symbol on

the

me.

If the Low Washer Fluid segment is now off,

and Low Washer Fluid is not displayed,

replace the Washer Fluid Level Switch.

If the Low Washer Fluid segment lights, and

LOW

VirASHER FLUID is displayed, check

the

BLKIWWT (99) wire for a short to

ground.

B: LOW COOLANT PROBE CONNEC-

TOR TEST

If the Low Coolant message does not come on

and the indicator segment on the vehicle sym-

bol does not light with the coolant low, remove

the connector to the Low Coolant Probe. With

the Ignition in RUN the indicator

should oper-

ate after approximately

11 seconds.

If it does,

install a new Low Coolant Probe.

* If it does not, check YELIBLM wire to the

DIC Display for a short to ground. Install a

new DIC display if the wire is good.

E: LOW COOLANT PROBE RESISTANCE

TEST

If the LOW COOLANT message comes on and

the indicator segment on the vehicle symbol

lights with the engine coolant full, check the

resistance of the Low Coolant Probe and its

wire. Remove the connector from the probe and

measure the resistance to ground of the probe.

If the resistance is higher than 30,000 ohms,

instdl a new Low Coolant Probe.

If the probe

and its wiring are good, and the

display does not indicate properly, install a

new DIC.

F: HATCH AJAR SHORTED SWITCH

TEST

Disconnect the Hatch Ajar Switch Connector.

Switch the Ignition to RUN and observe the

Hatch Ajar Indicator segment on the trunk of

the vehicle symbol on the DIC.

If the Hatch Ajar segment is now off and

HATCH AJAR is not displayed, replace the

Hatch Ajar Switch.

o If the Hatch Ajar segment is still on, and

HATCH AJAR is displayed, check the

BLKl

ORN (158) wire for a short to ground (see

schematic).

6: WATCH AJAR OPEN SWITCH TEST

R SWITCH CONNECTOR

1. Check the BEKIORN (158) wires for an

open (see schematic).

)-I: BOOR AJAR SHORTED SWITCH

TEST

Disconnect the suspect Door Ajar Switch

a1 A Connector. Switch the Ignition to

RUN and observe the Door Ajar

Indieator

segment of the vehicle symbol on the DIC.

@ If the Door Ajar segment is now off and the

suspect DOOR AJAR message is not

displayed, replace the Door Ajar Switch.

If the Door Ajar segment lights and the

suspect DOOR

AJAR message is

displayed, check the wire at

terminal A for a

short to ground (see schematic).

(Continued on next page)

Page 1437 of 1825

DRIVER INFORMATION CENTER (DIC) I $

(Continued from previous page)

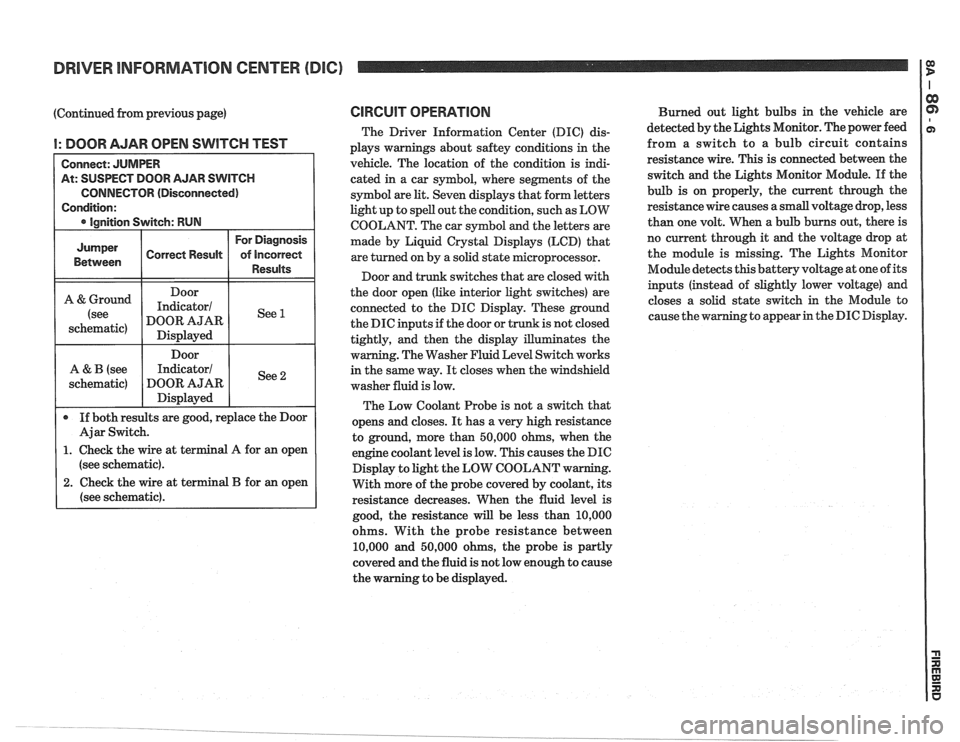

I: DOOR AJAR OPEN SWITCH TEST

At: SUSPECT DOOR AJAR SWITCH

CONNECTOR (Disconnected)

(see schematic).

2. Check the wire at terminal B for an open

(see schematic).

CIRCUIT OPERATION

The Driver Information Center (DIC) dis-

plays warnings about

saftey conditions in the

vehicle. The location of the condition is indi-

cated in a car symbol, where segments of the

symbol are

lit. Seven displays that form letters

light up to spell out the condition, such as LOW

COOLANT. The car symbol and the letters are

made by Liquid

Crystal Displays (LCD) that

are turned on by a solid state microprocessor.

Door and trunk switches that are closed with

the door open (like interior light switches) are

connected to the DIC Display. These ground

the DIC inputs if the door or trunk is not closed

tightly, and then the display illuminates the

warning. The Washer Fluid Level Switch works

in the same way.

It closes when the windshield

washer fluid is low.

The Low Coolant Probe is not a switch that

opens and closes.

It has a very high resistance

to ground, more than 50,000 ohms, when the

engine coolant level is low. This causes the DIC

Display to light the LOW COOLANT w

With more of the probe covered by coolant, its

resistance decreases. When the fluid level is

good, the resistance

will be less than 10,000

ohms. With the probe resistance between

10,000 and 50,000 ohms, the probe is partly

covered and the fluid is not low enough to cause

the warning to be displayed. Burned

out light bulbs in the vehicle are

detected by the Lights Monitor. The power feed

from a switch to a bulb circuit contains

resistance wire. This is connected between the

switch and the Lights Monitor Module.

If the

bulb is on properly, the current through the

resistance wire causes a small voltage drop, less

than one volt. When a bulb burns out, there is

no current through it

and the voltage drop at

the module is missing. The Lights Monitor

Module detects this battery voltage at one of its

inputs (instead of slightly lower voltage) and

closes a solid state switch in the Module to

g to appear in the DIC Display.

Page 1766 of 1825

ROOF - F STYLE 8H-7

SECTION A-A VIEW A

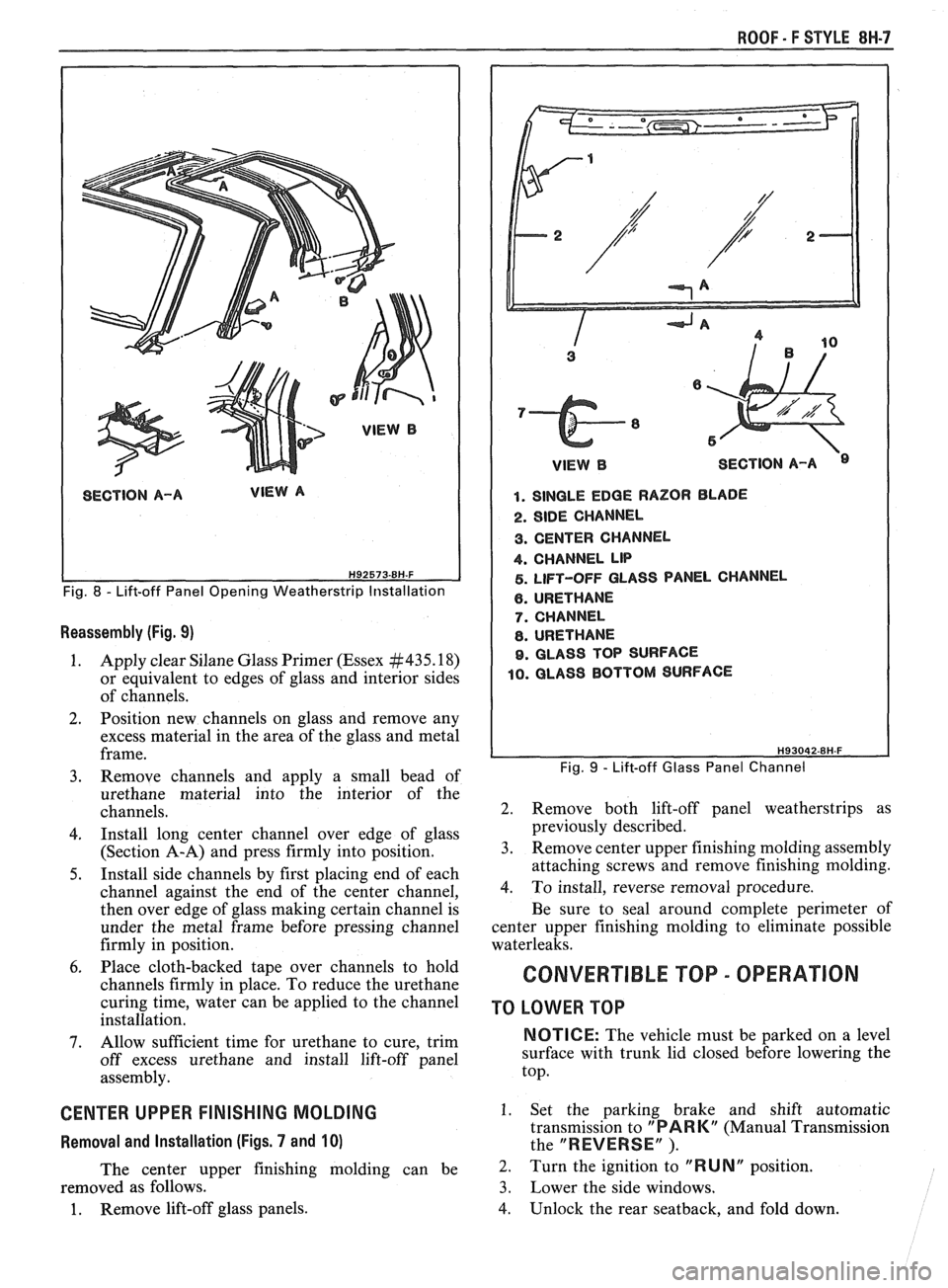

Fig. 8 - Lift-off Panel Opening Weatherstrip Installation

Reassembly (Fig. 9)

1. Apply clear Silane Glass Primer (Essex #435.18)

or equivalent to edges of glass and interior sides

of channels.

2. Position new channels on glass and remove any

excess material in the area of the glass and metal

frame.

3. Remove channels and apply a small bead of

urethane material into the interior of the

channels.

4. Install long center channel over edge of glass

(Section A-A) and press firmly into position.

5. Install side channels by first placing end of each

channel against the end of the center channel,

then over edge of glass making certain channel is

under the metal frame before pressing channel

firmly in position.

6. Place cloth-backed tape over channels to hold

channels firmly in place. To reduce the urethane

curing time, water can be applied to the channel

installation.

7. Allow sufficient time for urethane to cure, trim

off excess urethane and install lift-off panel

assembly.

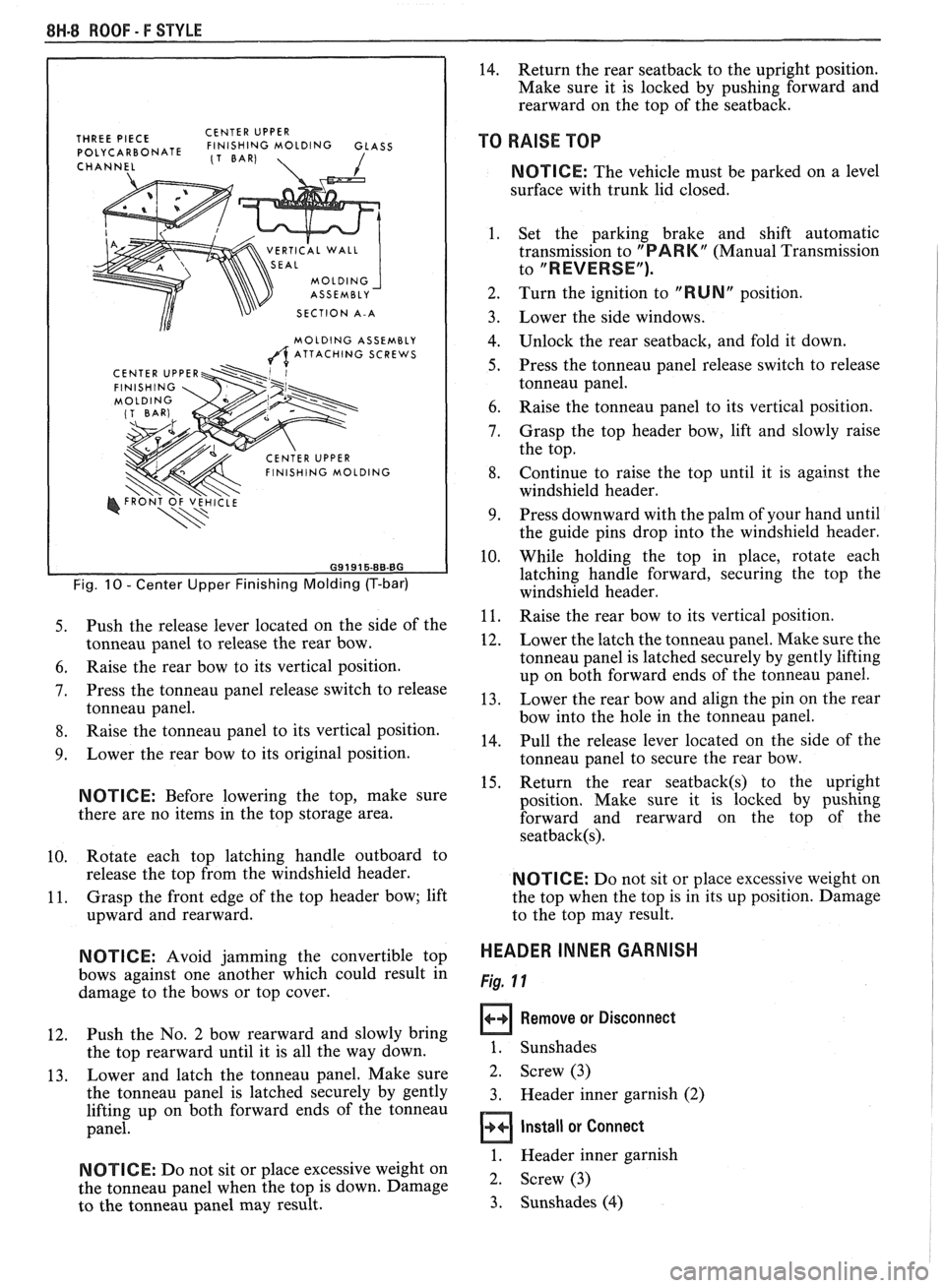

CENTER UPPER FINISHING MOLDING

Removal and Installation (Figs. 7 and 10)

The center upper finishing molding can be

removed as follows.

1. Remove lift-off glass panels.

1 VlEWB SECTION A-A

1. SINGLE EDGE RAZOR BLADE

2. SIDE CHANNEL

3. CENTER CHANNEL

4. CHANNEL LIP

5. LIFT-OFF GLASS PANEL CHANNEL

6. URETHANE

7. CHANNEL

8. URETHANE

9. GLASS TOP SURFACE

10. GLASS BOTTOM SURFACE

Fig. 9 - Lift-off Glass Panel Channel

2. Remove both lift-off panel weatherstrips as

previously described.

3. Remove center upper finishing molding assembly

attaching screws and remove finishing molding.

4. To install, reverse removal procedure.

Be sure to seal around complete perimeter of

center upper finishing molding to eliminate possible

waterleaks.

CONVERTIBLE TOP - OPERATION

TO LOWER TOP

NOTICE: The vehicle must be parked on a level

surface with trunk lid closed before lowering the

top.

1. Set the parking brake and shift automatic

transmission to

"PARK" (Manual Transmission

the

"REVERSE" ).

2. Turn the ignition to "RUNN position.

3. Lower the side windows.

4. Unlock the rear seatback, and fold down.

Page 1767 of 1825

8H.8 ROOF - F STYLE

THREE PIECE CENTER

UPPER POLYCARBONATE FINISHING MOLDING GLASS (1 BAR)

CHANNEL 1

VERTICAL WALL

SECTION A-A

MOLDING ASSEMBLY

A ATTACHING SCREWS

Fig. 10 - Center Upper Finishing Molding (T-bar)

5. Push the release lever located on the side of the

tonneau panel to release the rear bow.

6. Raise the rear bow to its vertical position.

7. Press the tonneau panel release switch to release

tonneau panel.

8. Raise the tonneau panel to its vertical position.

9. Lower the rear bow to its original position.

NOTICE: Before lowering the top, make sure

there are no items in the top storage area.

10. Rotate

each top latching handle outboard to

release the top from the windshield header.

11. Grasp

the front edge of the top header bow; lift

upward and rearward.

N OTI C E: Avoid jamming the convertible top

bows against one another which could result in

damage to the bows or top cover.

12. Push the

No. 2 bow rearward and slowly bring

the top rearward until it is all the way down.

13. Lower

and latch the tonneau panel. Make sure

the tonneau panel is latched securely by gently

lifting up on both forward ends of the tonneau

panel.

NOTICE: Do not sit or place excessive weight on

the tonneau panel when the top is down. Damage

to the tonneau panel may result.

14. Return the rear seatback to the upright position.

Make sure it is locked by pushing forward and

rearward on the top of the seatback.

TO RAISE TOP

NOTICE: The vehicle must be parked on a level

surface with trunk lid closed.

1. Set the parking brake and shift automatic

transmission to

"PARK" (Manual Transmission

to

"REVERSE").

2. Turn the ignition to "RUN" position.

Lower the side windows.

Unlock the rear seatback, and fold it down.

Press the tonneau panel release switch to release

tonneau panel.

Raise the tonneau panel to its vertical position.

Grasp the top header bow, lift and slowly raise

the top.

Continue to raise the top until it is against the

windshield header.

Press downward with the palm of your hand until

the guide pins drop into the windshield header.

While holding the top in place, rotate each

latching handle forward, securing the top the

windshield header.

Raise the rear bow to its vertical position.

Lower the latch the tonneau panel. Make sure the

tonneau panel is latched securely by gently lifting

up on both forward ends of the tonneau panel.

Lower the rear bow and align the pin on the rear

bow into the hole in the tonneau panel.

Pull the release lever located on the side of the

tonneau panel to secure the rear bow.

Return the rear

seatback(s) to the upright

position. Make sure it is locked by pushing

forward and rearward on the top of the

seatback(s).

NOTICE: Do not sit or place excessive weight on

the top when the top is in its up position. Damage

to the top may result.

HEADER INNER GARNISH

Fig. 11

Remove or Disconnect

1. Sunshades

2. Screw (3)

3. Header inner garnish (2)

Install or Connect

1. Header inner garnish

2. Screw (3)

3. Sunshades

(4)